Professional Documents

Culture Documents

Control Valve Sizing Gti

Control Valve Sizing Gti

Uploaded by

Snehashis Bose0 ratings0% found this document useful (0 votes)

2 views4 pagesOriginal Title

Control valve sizing gti

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

2 views4 pagesControl Valve Sizing Gti

Control Valve Sizing Gti

Uploaded by

Snehashis BoseCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

Control valve sizing is discussed in depth in Section 6.

15, and therefore only a few general recommendations are made

here. One should first determine both the minimum and maximum C v (Kv in Europe) requirements for the valve, considering

not only normal but also start-up and emergency conditions.

The selected valve should perform adequately over a range of 0.8 Cv min to 1.2 Cvmax . If this results in a rangeability requirement that exceeds the capabilities

on one valve, use two or more valves. Control valves should not be operated outside their rangeability. Driskell (see Bibliography) properly points to the fact

that all “fat” settles in the control valve. In constant speed

pumping systems, each design engineer will add their own

safety margin in calculating pressure drops through pipes and

exchangers, and finally in selecting the pump.

Therefore, the control valve will end up with all these

safety margins as added pressure drops, resulting in a muchoversized

valve. A highly oversized valve will operate in a

nearly closed state, which is an unstable and undesirable

operating condition. In variable-speed pumping systems, this

problem does not exist, because there the pump speed is

adjusted to meet the load, and therefore the effect of accumulated

safety margins is eliminated.

You might also like

- Rtaa Svd01a en - 01012004Document10 pagesRtaa Svd01a en - 01012004alcomech100% (3)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Control Valve Sizing and Selection: STEP #1: Define The SystemDocument5 pagesControl Valve Sizing and Selection: STEP #1: Define The Systemprassna_kamat15730% (1)

- Siemens Valve SizingDocument32 pagesSiemens Valve SizingSteven Wei100% (2)

- Masoneilan Control Valve SizingDocument13 pagesMasoneilan Control Valve SizingZakariya100% (1)

- 4L60E Converter Valves:: Operation, Test Procedures and The Effects of WearDocument5 pages4L60E Converter Valves:: Operation, Test Procedures and The Effects of WeartranstechozNo ratings yet

- Vibration ChatteringDocument14 pagesVibration ChatteringAnonymous l2sT4aENo ratings yet

- MasoneilanDocument32 pagesMasoneilanFelix AlorNo ratings yet

- Valve Sizing and SelectionDocument6 pagesValve Sizing and SelectionZeBocaoNo ratings yet

- Control Valve - Surge Relief Valve Selection GuideDocument20 pagesControl Valve - Surge Relief Valve Selection GuideSriya PetikiriarachchigeNo ratings yet

- Valve Sizing Sample CalculationDocument6 pagesValve Sizing Sample Calculationanne_sibius100% (1)

- Control Valve SizingDocument6 pagesControl Valve SizingAlfonsus W.M.No ratings yet

- TT US Circuit-SaverDocument7 pagesTT US Circuit-SaverLeonardo FigueroaNo ratings yet

- Large Size Quarter Turn Control Valves Can Improve Safety in PipelinesDocument19 pagesLarge Size Quarter Turn Control Valves Can Improve Safety in PipelinesgpuzoneNo ratings yet

- Insdustrial Hydraulics Manual: Volume ControlsDocument19 pagesInsdustrial Hydraulics Manual: Volume ControlsM Ahmed LatifNo ratings yet

- Antisurge Valve Response Time Optimistaiton PDFDocument5 pagesAntisurge Valve Response Time Optimistaiton PDFsanjeevchhabraNo ratings yet

- Valve Authority: Definition and RelevanceDocument5 pagesValve Authority: Definition and RelevancekktayNo ratings yet

- Assign Control Valve Pressure Drops: Sample ProblemDocument4 pagesAssign Control Valve Pressure Drops: Sample Problemaugur886@hotmail.comNo ratings yet

- Specifying Surge Relief Valves in Liquid PipelinesDocument6 pagesSpecifying Surge Relief Valves in Liquid Pipelinesmatteo2009No ratings yet

- Control Valve Question and Answer - 2Document13 pagesControl Valve Question and Answer - 2TATA STEELNo ratings yet

- Estrangulador SwacoDocument129 pagesEstrangulador SwacoKamilo Forero100% (5)

- Dimensions Specifications: 125 Booster Pump ControlDocument6 pagesDimensions Specifications: 125 Booster Pump ControlDheeraj ThakurNo ratings yet

- Guidelines On The Maintenance of Pressure Relief Valves On Board Gas CarriersDocument17 pagesGuidelines On The Maintenance of Pressure Relief Valves On Board Gas Carriers123habib123fikriNo ratings yet

- Tips For Specifying Pneumatic ValvesDocument11 pagesTips For Specifying Pneumatic ValvesLuis OrduzNo ratings yet

- Surge Relief Valve Definition Function Types Sizing SelectionDocument6 pagesSurge Relief Valve Definition Function Types Sizing Selectionkamala 123100% (1)

- Control Valve SizingDocument7 pagesControl Valve SizingJojolasNo ratings yet

- Control Valve Characteristics PDFDocument20 pagesControl Valve Characteristics PDFPrem SagarNo ratings yet

- Control Valve Common Interview QuestionsDocument10 pagesControl Valve Common Interview QuestionsMustafa MehdiNo ratings yet

- Masoneilan Control Valve Sizing HandbookDocument35 pagesMasoneilan Control Valve Sizing Handbooknajamsyed6754100% (1)

- Compressor Control, Load Sharing and Anti-SurgeDocument6 pagesCompressor Control, Load Sharing and Anti-SurgeJason Thomas100% (1)

- Surge Detection and Surge Control Systems For Centrifugal Compressors - Part 2Document3 pagesSurge Detection and Surge Control Systems For Centrifugal Compressors - Part 2Dewanjee AshrafNo ratings yet

- Valve Sizing and Selection: FREE ResourcesDocument6 pagesValve Sizing and Selection: FREE ResourcesSARATH KRISHNAKUMARNo ratings yet

- Valve Sizing and SelectionDocument7 pagesValve Sizing and SelectionmanuNo ratings yet

- Control Valve Sizing-Engineering DataDocument21 pagesControl Valve Sizing-Engineering Datapalindapc100% (1)

- Troubleshooting FCC Circulation ProblemsDocument6 pagesTroubleshooting FCC Circulation ProblemsLefter RinaldoNo ratings yet

- Relief Valves and Relief SystemsDocument10 pagesRelief Valves and Relief Systemsmatteo2009No ratings yet

- Linde Synchron Control BrochureDocument24 pagesLinde Synchron Control BrochurethierrylindoNo ratings yet

- Super Choke BasicsDocument10 pagesSuper Choke BasicsTg TarroNo ratings yet

- STC Oil Control Valve (Mechanical) - 4Document2 pagesSTC Oil Control Valve (Mechanical) - 4Parveen KashyapNo ratings yet

- Purpora Engineering PV TESTER MANUALDocument18 pagesPurpora Engineering PV TESTER MANUALPeterNo ratings yet

- Super Choke BasicsDocument10 pagesSuper Choke Basicsel_guariquenoNo ratings yet

- Valve Sizing and SelectionDocument7 pagesValve Sizing and SelectionCHEMNED0607No ratings yet

- Shuttle Valve PDFDocument6 pagesShuttle Valve PDFDEBASISH SARKARNo ratings yet

- So, You Think You Know Shuttle Valves?Document6 pagesSo, You Think You Know Shuttle Valves?AkileshNo ratings yet

- SPM Full Bore Emergency Unloading Valve Manual PDFDocument9 pagesSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoNo ratings yet

- Understanding Double Seated Shut Off Valves: Tech Tip 12Document4 pagesUnderstanding Double Seated Shut Off Valves: Tech Tip 12AlphaNo ratings yet

- 5.CHAPTER 13 - Flow Controls and Flow DividersDocument12 pages5.CHAPTER 13 - Flow Controls and Flow DividersVinod YbNo ratings yet

- C3W Distributor Valve Test DataDocument10 pagesC3W Distributor Valve Test DataChandra Mohan Rawat0% (1)

- Controlling Anti-Surge Valves in Low Flow Load Balancing OperationDocument7 pagesControlling Anti-Surge Valves in Low Flow Load Balancing Operationmasimaha1379100% (1)

- Pressure Relief ValvesDocument6 pagesPressure Relief ValvesShashank Sudhakar PathakNo ratings yet

- Control Valve Technical Specification For Severe Service - CCIDocument5 pagesControl Valve Technical Specification For Severe Service - CCIVikas SinghNo ratings yet

- Practical Tips For RT-flex-1Document8 pagesPractical Tips For RT-flex-1George DomusciuNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- 301222 - Pipeline Evacuation CompressorDocument9 pages301222 - Pipeline Evacuation CompressorSnehashis BoseNo ratings yet

- SSRN-id4136535Document68 pagesSSRN-id4136535Snehashis BoseNo ratings yet

- Soluttion Ch-2Document22 pagesSoluttion Ch-2Snehashis BoseNo ratings yet

- Loan Activities and Their ConditionsDocument4 pagesLoan Activities and Their ConditionsSnehashis BoseNo ratings yet

- 281222 - Presentation on Pipeline evacuationDocument36 pages281222 - Presentation on Pipeline evacuationSnehashis BoseNo ratings yet

- Pen PortraitDocument4 pagesPen PortraitSnehashis BoseNo ratings yet

- Solution Ch1Document9 pagesSolution Ch1Snehashis BoseNo ratings yet

- (p1) Ili Presentation 1Document40 pages(p1) Ili Presentation 1Snehashis BoseNo ratings yet

- Ch-2 ForceDocument52 pagesCh-2 ForceSnehashis BoseNo ratings yet

- Control Valve Selection and SizingDocument16 pagesControl Valve Selection and SizingSnehashis BoseNo ratings yet

- Reaffirmed 2003Document93 pagesReaffirmed 2003Snehashis BoseNo ratings yet

- Ch-7 TriangleDocument48 pagesCh-7 TriangleSnehashis BoseNo ratings yet

- Soluttion Ch-1Document22 pagesSoluttion Ch-1Snehashis BoseNo ratings yet

- Solution Ch3Document14 pagesSolution Ch3Snehashis BoseNo ratings yet

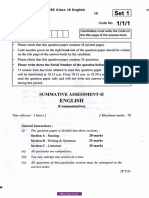

- CBSE Class 10 English Communicative Previous Year Question Paper 2015 Set 1 1 1Document11 pagesCBSE Class 10 English Communicative Previous Year Question Paper 2015 Set 1 1 1Snehashis BoseNo ratings yet

- CBSE Class 10 English Communicative Previous Year Question Paper 2020 Set 1 4 1Document7 pagesCBSE Class 10 English Communicative Previous Year Question Paper 2020 Set 1 4 1Snehashis BoseNo ratings yet

- LNG Project - Concept To Commissioning July 2017Document26 pagesLNG Project - Concept To Commissioning July 2017Snehashis BoseNo ratings yet

- CBSE Class 10 English Communicative Previous Year Question Paper 2019 Set 1 3 1Document7 pagesCBSE Class 10 English Communicative Previous Year Question Paper 2019 Set 1 3 1Snehashis BoseNo ratings yet

- CBSE Class 10 English Communicative Previous Year Question Paper 2019 Set 1 4 1Document7 pagesCBSE Class 10 English Communicative Previous Year Question Paper 2019 Set 1 4 1Snehashis BoseNo ratings yet

- CBSE Class 10 English Communicative Previous Year Question Paper 2016 Set 1 1Document8 pagesCBSE Class 10 English Communicative Previous Year Question Paper 2016 Set 1 1Snehashis BoseNo ratings yet

- Brain TeaserDocument2 pagesBrain TeaserSnehashis BoseNo ratings yet

- Concepts of Instrumentation Module: Self Operated RegulatorsDocument48 pagesConcepts of Instrumentation Module: Self Operated RegulatorsSnehashis BoseNo ratings yet

- Mod MuxDocument116 pagesMod MuxSnehashis BoseNo ratings yet

- Fundamentals of Flow Computers: Fig. 1. Electronic Gas Measurement (EGM) As Defined in API 21.1Document11 pagesFundamentals of Flow Computers: Fig. 1. Electronic Gas Measurement (EGM) As Defined in API 21.1Snehashis BoseNo ratings yet

- Faq rs232 LoopbackDocument4 pagesFaq rs232 LoopbackSnehashis BoseNo ratings yet

- LNG - GAIL & IndiaDocument21 pagesLNG - GAIL & IndiaSnehashis BoseNo ratings yet

- Olin ModbDocument10 pagesOlin ModbSnehashis BoseNo ratings yet

- Concepts of Instrumentation Module: Control ValvesDocument140 pagesConcepts of Instrumentation Module: Control ValvesSnehashis BoseNo ratings yet

- Con Uc TivityDocument2 pagesCon Uc TivitySnehashis BoseNo ratings yet

- Concepts of Instrumentation Module: ValvesDocument23 pagesConcepts of Instrumentation Module: ValvesSnehashis BoseNo ratings yet