Professional Documents

Culture Documents

Meseg Gear Pump

Meseg Gear Pump

Uploaded by

imranCopyright:

Available Formats

You might also like

- Continental TorquesDocument13 pagesContinental Torquesfredtanner100% (2)

- Sperry Drill MotorsDocument4 pagesSperry Drill Motorsjoseahilarrazam100% (1)

- RENK MAAG Turbo Gearboxes 0413-1Document24 pagesRENK MAAG Turbo Gearboxes 0413-1RCMNo ratings yet

- CatalogDocument100 pagesCatalogFrancis Lebel100% (1)

- KMT Aqua Dyne Bare Shaft Series 250 - REV 03 10 - L2 PDFDocument2 pagesKMT Aqua Dyne Bare Shaft Series 250 - REV 03 10 - L2 PDFMark1025No ratings yet

- Aquaplus Tech Info 2005 Rev 1 - EnglishDocument23 pagesAquaplus Tech Info 2005 Rev 1 - EnglishJvlValenzuelaNo ratings yet

- Swap LS Engines into Chevelles & GM A-Bodies: 1964-1972From EverandSwap LS Engines into Chevelles & GM A-Bodies: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (3)

- LS Gen IV Engines 2005 - Present: How to Build Max PerformanceFrom EverandLS Gen IV Engines 2005 - Present: How to Build Max PerformanceRating: 5 out of 5 stars5/5 (2)

- Role of AI in RetailDocument46 pagesRole of AI in RetailpavanNo ratings yet

- API 676 Pump Rotary DatasheetDocument6 pagesAPI 676 Pump Rotary DatasheetvuongNo ratings yet

- API 676 Datasheet PDFDocument6 pagesAPI 676 Datasheet PDFPierre Norris0% (1)

- KMT Aqua-Dyne Bare Shaft Series 250 - REV 03-10 - LDocument2 pagesKMT Aqua-Dyne Bare Shaft Series 250 - REV 03-10 - LAgung SyNo ratings yet

- Coupling PDFDocument7 pagesCoupling PDFAnkur GaurNo ratings yet

- Molub-Alloy Gear Oils PI Engl PDFDocument2 pagesMolub-Alloy Gear Oils PI Engl PDFPieter van der WaltNo ratings yet

- 1.3 Sanitary Pumps CfsDocument4 pages1.3 Sanitary Pumps CfsJitendra KadamNo ratings yet

- SEEMSAN - MSL Series Gear PumpDocument4 pagesSEEMSAN - MSL Series Gear PumpMayur ThorveNo ratings yet

- MAAGGear WPU Coal MillsDocument8 pagesMAAGGear WPU Coal MillsMuhammadNo ratings yet

- Catalogo SEWDocument76 pagesCatalogo SEWLuca MemoliNo ratings yet

- Moog Pumps RKP Catalog enDocument75 pagesMoog Pumps RKP Catalog enSantiago Bonilla RiveraNo ratings yet

- Reliable Pump (NEW)Document56 pagesReliable Pump (NEW)himanshu makwanaNo ratings yet

- Helical Gearbox InstallationDocument8 pagesHelical Gearbox InstallationKUNALJAYNo ratings yet

- GyroDrill Mud Motor Handbook 2013Document103 pagesGyroDrill Mud Motor Handbook 2013Don Braithwaite100% (1)

- Petrol Cold Water Commercial &ndustrial Operation and Maintenance PDFDocument16 pagesPetrol Cold Water Commercial &ndustrial Operation and Maintenance PDFhrmlynNo ratings yet

- KMT Aqua Dyne Bare Shaft Series 500 - REV 03 10 - L2Document2 pagesKMT Aqua Dyne Bare Shaft Series 500 - REV 03 10 - L2Jeff RyersonNo ratings yet

- VX 135 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowerDocument2 pagesVX 135 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowercm_chemical81No ratings yet

- Atlanta Servo Drive System 060812Document85 pagesAtlanta Servo Drive System 060812Anonymous JGugvoz1No ratings yet

- Ks Si 0010 en WebDocument0 pagesKs Si 0010 en WebMoaed KanbarNo ratings yet

- Catalog SBDocument40 pagesCatalog SBNicho WijayaNo ratings yet

- Pentax 50hz MSHDDocument5 pagesPentax 50hz MSHDRenzo TrNo ratings yet

- 07 Frameless Motors & GearmotorsDocument46 pages07 Frameless Motors & GearmotorsHassan IrshadNo ratings yet

- Maag LGD Lateral Gear Drive For Horizontal MillsDocument8 pagesMaag LGD Lateral Gear Drive For Horizontal MillsMuhammadNo ratings yet

- Psa Nitrogen GeneratorDocument7 pagesPsa Nitrogen GeneratorFarjallahNo ratings yet

- Maag LGD Lateral Gear Drive For Horizontal MillsDocument8 pagesMaag LGD Lateral Gear Drive For Horizontal Mills1977julNo ratings yet

- ESPDocument4 pagesESPGerardo BautistaNo ratings yet

- OTW MaterijalDocument29 pagesOTW Materijalb_0102_7891No ratings yet

- Rapid Mixer GranulatorDocument2 pagesRapid Mixer Granulatorjaypharma111No ratings yet

- Houttuin 216 10Document6 pagesHouttuin 216 10royert80No ratings yet

- MAN Alpha FP PropellerDocument2 pagesMAN Alpha FP PropellerSea Man MktNo ratings yet

- Rapid Mixer Granulators RMGDocument4 pagesRapid Mixer Granulators RMGShahadat HossainNo ratings yet

- Piston Pumps Paste-Thickened Tailings PB-PPPT-0215 LowresDocument10 pagesPiston Pumps Paste-Thickened Tailings PB-PPPT-0215 LowresMartin Lara100% (1)

- Gamma Meccanica Technical InformationDocument8 pagesGamma Meccanica Technical InformationHafiani HichamNo ratings yet

- Denison Calzoni Type MRD Mrde MRV MrveDocument48 pagesDenison Calzoni Type MRD Mrde MRV MrveSilvio RomanNo ratings yet

- 31fae81aeef24f52fcbfede5f8db735aDocument10 pages31fae81aeef24f52fcbfede5f8db735aFeni KartikaNo ratings yet

- Different Types of Mechanical SealDocument20 pagesDifferent Types of Mechanical SealGlobe Star Engineers Pvt Ltd63% (8)

- Brochure BEGEMANN BS Pumps-Low ResolutionDocument6 pagesBrochure BEGEMANN BS Pumps-Low ResolutionunknownsaylorNo ratings yet

- Brochure BEGEMANN PA Pumps-Low ResolutionDocument6 pagesBrochure BEGEMANN PA Pumps-Low ResolutionIsaac RubioNo ratings yet

- Catalo Gear PumpDocument4 pagesCatalo Gear Pumptrantuan74No ratings yet

- R999002168 2023 03 EN SMS 11 05 2023 GyDocument22 pagesR999002168 2023 03 EN SMS 11 05 2023 GyMartino RossiNo ratings yet

- Centrifugal Slurry Pump RangeDocument16 pagesCentrifugal Slurry Pump Rangecitramuara100% (4)

- Motor M42SP 5Document6 pagesMotor M42SP 5Anonymous 13bD6J7No ratings yet

- GL-5 High Performance Extreme Pressure Hypoid Gear Oil IntroDocument1 pageGL-5 High Performance Extreme Pressure Hypoid Gear Oil IntroMUKUL SHARMANo ratings yet

- Mobil SHC™ Gear SeriesDocument4 pagesMobil SHC™ Gear SeriesJeefNo ratings yet

- Servo Mesh Oil GradesDocument1 pageServo Mesh Oil Gradessrinu rao bandaruNo ratings yet

- Pump SCE B 2Document8 pagesPump SCE B 2Zankar R ParikhNo ratings yet

- Roller Bearing Supported Mills FINAL LRDocument8 pagesRoller Bearing Supported Mills FINAL LRHiresomannavar MahanteshNo ratings yet

- Catalogue - BoretsDocument218 pagesCatalogue - BoretsCarlosCarrilloNo ratings yet

- Maag WPU Two-Stage Gear Unit Up To 1500 KWDocument8 pagesMaag WPU Two-Stage Gear Unit Up To 1500 KWTrọng HoàngNo ratings yet

- Maag WPU Two-Stage Gear Unit Up To 1500 KWDocument8 pagesMaag WPU Two-Stage Gear Unit Up To 1500 KWAmit SinghNo ratings yet

- Maag CPU Central Gear Unit: For Horizontal MillsDocument8 pagesMaag CPU Central Gear Unit: For Horizontal MillsCloves KelherNo ratings yet

- KyAnh A320F Structure GeneralDocument101 pagesKyAnh A320F Structure Generalnqarmy100% (1)

- Technology and Livelihood Education: Quarter 1 - Module 4: Food ProcessingDocument22 pagesTechnology and Livelihood Education: Quarter 1 - Module 4: Food ProcessingLIEZEL SERONDO75% (4)

- BS 957-2008Document11 pagesBS 957-2008diegoNo ratings yet

- Tropical Homes, Inc. vs. National Housing Authority - 1Document4 pagesTropical Homes, Inc. vs. National Housing Authority - 1PNP MayoyaoNo ratings yet

- Group Activity Questions Buss. MathDocument1 pageGroup Activity Questions Buss. MathIreneRoseMotas100% (1)

- Company Name Address1 Address2 Area City Pincode Contact Number Designation Mobile URL Email ID Remarks Contact PersonDocument18 pagesCompany Name Address1 Address2 Area City Pincode Contact Number Designation Mobile URL Email ID Remarks Contact Personmurugesh18100% (1)

- Tentree'sDocument6 pagesTentree's陈皎月No ratings yet

- Safety Data Sheet: Shell Tellus Oil 68Document9 pagesSafety Data Sheet: Shell Tellus Oil 68andi permanaNo ratings yet

- Sta ExaDocument12 pagesSta ExaNiño Jose A. Flores (Onin)No ratings yet

- Long Michael Resume NewDocument4 pagesLong Michael Resume Newapi-384226140No ratings yet

- Comparison Chart: (Conduction, Convection, Radiation)Document5 pagesComparison Chart: (Conduction, Convection, Radiation)RandyNo ratings yet

- AMT49413 DatasheetDocument21 pagesAMT49413 DatasheetShubham PanchbhaiNo ratings yet

- Cost & EstimationDocument70 pagesCost & EstimationPalash DongreNo ratings yet

- Limits, Fits and TolerancesDocument17 pagesLimits, Fits and TolerancesSarswati SuryawanshiNo ratings yet

- Refiners Rhapsody 49 TheobatDocument80 pagesRefiners Rhapsody 49 TheobatIyere GiftNo ratings yet

- Stuart Goldsmith - Do You Have Enough AlreadyDocument8 pagesStuart Goldsmith - Do You Have Enough AlreadyJesuisquelquundebienNo ratings yet

- Housing and Meal Plans at Fiu: BusinessDocument2 pagesHousing and Meal Plans at Fiu: BusinessJose CamposNo ratings yet

- SDLC ModelDocument11 pagesSDLC Modeladititech724No ratings yet

- Q2 MODULE 5 - AssessmentDocument3 pagesQ2 MODULE 5 - Assessmentleo markNo ratings yet

- CGP9023M Virtual and Augmented Reality For Games A01 Brief 2324Document5 pagesCGP9023M Virtual and Augmented Reality For Games A01 Brief 2324waleedkabbaderNo ratings yet

- CPF Form 4BDocument2 pagesCPF Form 4BBala SelvakumarNo ratings yet

- Thesis Final QuestionnaireDocument2 pagesThesis Final QuestionnaireJarby Vann CapitoNo ratings yet

- The VerdictDocument4 pagesThe Verdicthttps://twitter.com/wagelabourNo ratings yet

- Universal Mechanical Tester: Innovation With IntegrityDocument4 pagesUniversal Mechanical Tester: Innovation With IntegrityDlair Ramadan0% (1)

- IEC StandardsDocument2 pagesIEC StandardsHammad Ali Zaman100% (1)

- Basic Computer Hardware Quiz Questions and AnswerDocument10 pagesBasic Computer Hardware Quiz Questions and Answerkipassevone-1601100% (1)

- Step by Step GuideDocument5 pagesStep by Step GuideSourav SahaNo ratings yet

- ISE II Sample Paper 4 (With Answers)Document13 pagesISE II Sample Paper 4 (With Answers)Marta Navarro LópezNo ratings yet

- CBH-22-304 Plain Washer Din 434 M12, 16 SelfDocument2 pagesCBH-22-304 Plain Washer Din 434 M12, 16 SelfqualityNo ratings yet

Meseg Gear Pump

Meseg Gear Pump

Uploaded by

imranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Meseg Gear Pump

Meseg Gear Pump

Uploaded by

imranCopyright:

Available Formats

AN 1SO-9001-2008 CERTIFIED CO

SERIES-MESEG

Microtech Engineering offer precision engineered range of rotary gear pumps,

which are characterized by enduring performance and efficiency in functioning. We

provide optimum quality of Rotary Gear pump which uses the meshing of gears to

pump fluid by displacing it through. Our range of Rotary Gear pump is manufactured

with premium grade raw material. The Rotary Gear pump is non-pulsing, self-

priming, and can run dry for short periods. Our Rotary Gear pump is used in various

industries for transferring oils and viscous liquids. Rotary Gear pump are

applicable for all kind of thin liquids, oils, solvents, fuel, viscous chemicals and

food application. Rotary Gear pump excel at efficiently pumping thick liquids such

as asphalt, chocolate, and adhesives. the pump has a wide temperature range as

well, handling liquids up to 750°F / 400°C. This is due to the single point of end

clearance.

This Pumps works as a Positive Displacement Rotary Gear pump. These have

modified profile teeth, which can yield accurate capacity within the force range.

Rotary Gear pump are designed in double helical heringesbone gear, which offers

constant volume without any pulsation. These Rotary Gear pump are simple in

design and robust and sturdy in construction. Only tested materials are used to

give long life to Rotary Gear pump. They are built in various sizes and versions to

suit every possible industrial application

CONSTRUCTION OF ROTARY GEAR PUMP :

Rotary Gear Pump Body - Graded CI Casting / SS 304/ SS 316

Rotary Gear Pump Gear - Alloy Steel/Single Helical/ SS 304/ SS 316

/

Rotary Gear Pump Shaft - Alloy Steel/Hardened ans Ground/ SS 304/ SS 316

Rotary Gear Pump Bush - Self Lubricated Sinntered Bronze Bushes

Rotary Gear Pump Sealing - Oil Seal size 1/4" to 3" BSP

Rotary Gear Pump Range - 5 to 500 LPM

Due to content research & development data is subject to change

AN 1SO-9001-2008 CERTIFIED CO

Application SERIES-MESEG

ADVANTAGES OF ROTARY GEAR PUMP :

Only two moving parts, Only one stuffing box, Non-pulsating discharge, Excellent for high-

viscosity liquids, Constant and even discharge regardless of pressure conditions, Operates well in

either direction, Can be made to operate with one direction of flow with either rotation, Direction

of rotion clockwise or anticlockwise looking from shaft end, Gear made of high quality steel,

Simple attachment with a flange, Turning direction to the right or left 1440 or 2880 r.p.m., etc.

FEATURES OF ROTARY GEAR PUMP:

High efficiency, Low noise, Compact design, Easy maintenance, Reliability, Modified profile single

helical gears, Hardened and ground shafts, Self lubricated sintered bronze bush bearing, etc.

APPLICATION OF ROTARY GEAR PUMP :

Food industries, Oil, Steel, Refining, Paints, Dairy, Sugar, Chemical ,Petrochemical and

pharmaceutical, lube oils, Castor oils, Grease , wax, Diesel Oils, Fuel Oils, Transformer oils, sodium

silicate, caustic soda, resins, enamels, adhesives, fatty acids, paints and varnish, pulp , Atomizing

of fuel oil at high pressure for burners and boilers, juices, Syrups, Alcohol, Kerosene, Lubrication

of gear boxes, cranes, Machine tools, Mineral Oils, Fish and Animal Oils, Vegetable Oils, Tar,

Asphalts, Sugar Syrups, Molasses, Varnishes and viscous chemicals, etc.

Due to content research & development data is subject to change

AN 1SO-9001-2008 CERTIFIED CO

MESEG

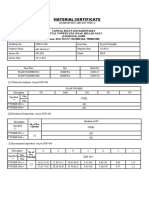

MESEG- PERFORMANCE CHART

MODEL SUC DEL CAPICITY PRESSURE IN KG.CM2 NET WEIGHT IN KG

LPM M3/HR 1 2 3 4 5 6 7 8 9 10

MOTOR REQUIRED IN SPEED 1400RPM

MESEG-10 10 10 10 0.6 0.25 0.25 0.25 0.25 0.5 0.5 0.5 0.5 0.75 0.75 2.4

MESEG-15 15 15 20 1.2 0.5 0.5 0.5 0.5 0.75 0.75 0.75 0.75 1 1 2.8

MESEG-20 20 20 30 1.8 0.5 0.5 0.75 0.75 0.75 1 1 1 1.5 1.5 5

MESEG-25 25 25 50 3 0.5 0.75 0.75 1 1 1.5 1.5 1.5 2 2 6

MESEG-40 40 40 110 6.6 1.5 2 3 3 3 5 5 5 5 5 11

MESEG-50 50 50 225 13.5 3 3 5 5 5 5 7.5 7.5 7.5 12.5 18.5

MESEG-65 65 65 350 21 5 7.5 7.5 10 10 10 12.5 12.5 15 15 29

MESEG-80 80 80 500 30 7.5 10 10 12.5 12.5 15 15 17.5 20 20 45

Due to content research & development data is subject to change

You might also like

- Continental TorquesDocument13 pagesContinental Torquesfredtanner100% (2)

- Sperry Drill MotorsDocument4 pagesSperry Drill Motorsjoseahilarrazam100% (1)

- RENK MAAG Turbo Gearboxes 0413-1Document24 pagesRENK MAAG Turbo Gearboxes 0413-1RCMNo ratings yet

- CatalogDocument100 pagesCatalogFrancis Lebel100% (1)

- KMT Aqua Dyne Bare Shaft Series 250 - REV 03 10 - L2 PDFDocument2 pagesKMT Aqua Dyne Bare Shaft Series 250 - REV 03 10 - L2 PDFMark1025No ratings yet

- Aquaplus Tech Info 2005 Rev 1 - EnglishDocument23 pagesAquaplus Tech Info 2005 Rev 1 - EnglishJvlValenzuelaNo ratings yet

- Swap LS Engines into Chevelles & GM A-Bodies: 1964-1972From EverandSwap LS Engines into Chevelles & GM A-Bodies: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (3)

- LS Gen IV Engines 2005 - Present: How to Build Max PerformanceFrom EverandLS Gen IV Engines 2005 - Present: How to Build Max PerformanceRating: 5 out of 5 stars5/5 (2)

- Role of AI in RetailDocument46 pagesRole of AI in RetailpavanNo ratings yet

- API 676 Pump Rotary DatasheetDocument6 pagesAPI 676 Pump Rotary DatasheetvuongNo ratings yet

- API 676 Datasheet PDFDocument6 pagesAPI 676 Datasheet PDFPierre Norris0% (1)

- KMT Aqua-Dyne Bare Shaft Series 250 - REV 03-10 - LDocument2 pagesKMT Aqua-Dyne Bare Shaft Series 250 - REV 03-10 - LAgung SyNo ratings yet

- Coupling PDFDocument7 pagesCoupling PDFAnkur GaurNo ratings yet

- Molub-Alloy Gear Oils PI Engl PDFDocument2 pagesMolub-Alloy Gear Oils PI Engl PDFPieter van der WaltNo ratings yet

- 1.3 Sanitary Pumps CfsDocument4 pages1.3 Sanitary Pumps CfsJitendra KadamNo ratings yet

- SEEMSAN - MSL Series Gear PumpDocument4 pagesSEEMSAN - MSL Series Gear PumpMayur ThorveNo ratings yet

- MAAGGear WPU Coal MillsDocument8 pagesMAAGGear WPU Coal MillsMuhammadNo ratings yet

- Catalogo SEWDocument76 pagesCatalogo SEWLuca MemoliNo ratings yet

- Moog Pumps RKP Catalog enDocument75 pagesMoog Pumps RKP Catalog enSantiago Bonilla RiveraNo ratings yet

- Reliable Pump (NEW)Document56 pagesReliable Pump (NEW)himanshu makwanaNo ratings yet

- Helical Gearbox InstallationDocument8 pagesHelical Gearbox InstallationKUNALJAYNo ratings yet

- GyroDrill Mud Motor Handbook 2013Document103 pagesGyroDrill Mud Motor Handbook 2013Don Braithwaite100% (1)

- Petrol Cold Water Commercial &ndustrial Operation and Maintenance PDFDocument16 pagesPetrol Cold Water Commercial &ndustrial Operation and Maintenance PDFhrmlynNo ratings yet

- KMT Aqua Dyne Bare Shaft Series 500 - REV 03 10 - L2Document2 pagesKMT Aqua Dyne Bare Shaft Series 500 - REV 03 10 - L2Jeff RyersonNo ratings yet

- VX 135 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowerDocument2 pagesVX 135 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowercm_chemical81No ratings yet

- Atlanta Servo Drive System 060812Document85 pagesAtlanta Servo Drive System 060812Anonymous JGugvoz1No ratings yet

- Ks Si 0010 en WebDocument0 pagesKs Si 0010 en WebMoaed KanbarNo ratings yet

- Catalog SBDocument40 pagesCatalog SBNicho WijayaNo ratings yet

- Pentax 50hz MSHDDocument5 pagesPentax 50hz MSHDRenzo TrNo ratings yet

- 07 Frameless Motors & GearmotorsDocument46 pages07 Frameless Motors & GearmotorsHassan IrshadNo ratings yet

- Maag LGD Lateral Gear Drive For Horizontal MillsDocument8 pagesMaag LGD Lateral Gear Drive For Horizontal MillsMuhammadNo ratings yet

- Psa Nitrogen GeneratorDocument7 pagesPsa Nitrogen GeneratorFarjallahNo ratings yet

- Maag LGD Lateral Gear Drive For Horizontal MillsDocument8 pagesMaag LGD Lateral Gear Drive For Horizontal Mills1977julNo ratings yet

- ESPDocument4 pagesESPGerardo BautistaNo ratings yet

- OTW MaterijalDocument29 pagesOTW Materijalb_0102_7891No ratings yet

- Rapid Mixer GranulatorDocument2 pagesRapid Mixer Granulatorjaypharma111No ratings yet

- Houttuin 216 10Document6 pagesHouttuin 216 10royert80No ratings yet

- MAN Alpha FP PropellerDocument2 pagesMAN Alpha FP PropellerSea Man MktNo ratings yet

- Rapid Mixer Granulators RMGDocument4 pagesRapid Mixer Granulators RMGShahadat HossainNo ratings yet

- Piston Pumps Paste-Thickened Tailings PB-PPPT-0215 LowresDocument10 pagesPiston Pumps Paste-Thickened Tailings PB-PPPT-0215 LowresMartin Lara100% (1)

- Gamma Meccanica Technical InformationDocument8 pagesGamma Meccanica Technical InformationHafiani HichamNo ratings yet

- Denison Calzoni Type MRD Mrde MRV MrveDocument48 pagesDenison Calzoni Type MRD Mrde MRV MrveSilvio RomanNo ratings yet

- 31fae81aeef24f52fcbfede5f8db735aDocument10 pages31fae81aeef24f52fcbfede5f8db735aFeni KartikaNo ratings yet

- Different Types of Mechanical SealDocument20 pagesDifferent Types of Mechanical SealGlobe Star Engineers Pvt Ltd63% (8)

- Brochure BEGEMANN BS Pumps-Low ResolutionDocument6 pagesBrochure BEGEMANN BS Pumps-Low ResolutionunknownsaylorNo ratings yet

- Brochure BEGEMANN PA Pumps-Low ResolutionDocument6 pagesBrochure BEGEMANN PA Pumps-Low ResolutionIsaac RubioNo ratings yet

- Catalo Gear PumpDocument4 pagesCatalo Gear Pumptrantuan74No ratings yet

- R999002168 2023 03 EN SMS 11 05 2023 GyDocument22 pagesR999002168 2023 03 EN SMS 11 05 2023 GyMartino RossiNo ratings yet

- Centrifugal Slurry Pump RangeDocument16 pagesCentrifugal Slurry Pump Rangecitramuara100% (4)

- Motor M42SP 5Document6 pagesMotor M42SP 5Anonymous 13bD6J7No ratings yet

- GL-5 High Performance Extreme Pressure Hypoid Gear Oil IntroDocument1 pageGL-5 High Performance Extreme Pressure Hypoid Gear Oil IntroMUKUL SHARMANo ratings yet

- Mobil SHC™ Gear SeriesDocument4 pagesMobil SHC™ Gear SeriesJeefNo ratings yet

- Servo Mesh Oil GradesDocument1 pageServo Mesh Oil Gradessrinu rao bandaruNo ratings yet

- Pump SCE B 2Document8 pagesPump SCE B 2Zankar R ParikhNo ratings yet

- Roller Bearing Supported Mills FINAL LRDocument8 pagesRoller Bearing Supported Mills FINAL LRHiresomannavar MahanteshNo ratings yet

- Catalogue - BoretsDocument218 pagesCatalogue - BoretsCarlosCarrilloNo ratings yet

- Maag WPU Two-Stage Gear Unit Up To 1500 KWDocument8 pagesMaag WPU Two-Stage Gear Unit Up To 1500 KWTrọng HoàngNo ratings yet

- Maag WPU Two-Stage Gear Unit Up To 1500 KWDocument8 pagesMaag WPU Two-Stage Gear Unit Up To 1500 KWAmit SinghNo ratings yet

- Maag CPU Central Gear Unit: For Horizontal MillsDocument8 pagesMaag CPU Central Gear Unit: For Horizontal MillsCloves KelherNo ratings yet

- KyAnh A320F Structure GeneralDocument101 pagesKyAnh A320F Structure Generalnqarmy100% (1)

- Technology and Livelihood Education: Quarter 1 - Module 4: Food ProcessingDocument22 pagesTechnology and Livelihood Education: Quarter 1 - Module 4: Food ProcessingLIEZEL SERONDO75% (4)

- BS 957-2008Document11 pagesBS 957-2008diegoNo ratings yet

- Tropical Homes, Inc. vs. National Housing Authority - 1Document4 pagesTropical Homes, Inc. vs. National Housing Authority - 1PNP MayoyaoNo ratings yet

- Group Activity Questions Buss. MathDocument1 pageGroup Activity Questions Buss. MathIreneRoseMotas100% (1)

- Company Name Address1 Address2 Area City Pincode Contact Number Designation Mobile URL Email ID Remarks Contact PersonDocument18 pagesCompany Name Address1 Address2 Area City Pincode Contact Number Designation Mobile URL Email ID Remarks Contact Personmurugesh18100% (1)

- Tentree'sDocument6 pagesTentree's陈皎月No ratings yet

- Safety Data Sheet: Shell Tellus Oil 68Document9 pagesSafety Data Sheet: Shell Tellus Oil 68andi permanaNo ratings yet

- Sta ExaDocument12 pagesSta ExaNiño Jose A. Flores (Onin)No ratings yet

- Long Michael Resume NewDocument4 pagesLong Michael Resume Newapi-384226140No ratings yet

- Comparison Chart: (Conduction, Convection, Radiation)Document5 pagesComparison Chart: (Conduction, Convection, Radiation)RandyNo ratings yet

- AMT49413 DatasheetDocument21 pagesAMT49413 DatasheetShubham PanchbhaiNo ratings yet

- Cost & EstimationDocument70 pagesCost & EstimationPalash DongreNo ratings yet

- Limits, Fits and TolerancesDocument17 pagesLimits, Fits and TolerancesSarswati SuryawanshiNo ratings yet

- Refiners Rhapsody 49 TheobatDocument80 pagesRefiners Rhapsody 49 TheobatIyere GiftNo ratings yet

- Stuart Goldsmith - Do You Have Enough AlreadyDocument8 pagesStuart Goldsmith - Do You Have Enough AlreadyJesuisquelquundebienNo ratings yet

- Housing and Meal Plans at Fiu: BusinessDocument2 pagesHousing and Meal Plans at Fiu: BusinessJose CamposNo ratings yet

- SDLC ModelDocument11 pagesSDLC Modeladititech724No ratings yet

- Q2 MODULE 5 - AssessmentDocument3 pagesQ2 MODULE 5 - Assessmentleo markNo ratings yet

- CGP9023M Virtual and Augmented Reality For Games A01 Brief 2324Document5 pagesCGP9023M Virtual and Augmented Reality For Games A01 Brief 2324waleedkabbaderNo ratings yet

- CPF Form 4BDocument2 pagesCPF Form 4BBala SelvakumarNo ratings yet

- Thesis Final QuestionnaireDocument2 pagesThesis Final QuestionnaireJarby Vann CapitoNo ratings yet

- The VerdictDocument4 pagesThe Verdicthttps://twitter.com/wagelabourNo ratings yet

- Universal Mechanical Tester: Innovation With IntegrityDocument4 pagesUniversal Mechanical Tester: Innovation With IntegrityDlair Ramadan0% (1)

- IEC StandardsDocument2 pagesIEC StandardsHammad Ali Zaman100% (1)

- Basic Computer Hardware Quiz Questions and AnswerDocument10 pagesBasic Computer Hardware Quiz Questions and Answerkipassevone-1601100% (1)

- Step by Step GuideDocument5 pagesStep by Step GuideSourav SahaNo ratings yet

- ISE II Sample Paper 4 (With Answers)Document13 pagesISE II Sample Paper 4 (With Answers)Marta Navarro LópezNo ratings yet

- CBH-22-304 Plain Washer Din 434 M12, 16 SelfDocument2 pagesCBH-22-304 Plain Washer Din 434 M12, 16 SelfqualityNo ratings yet