Professional Documents

Culture Documents

KE3-DST-MEQ-0908-3509 Rev 0 Floating Oil Colletion System

KE3-DST-MEQ-0908-3509 Rev 0 Floating Oil Colletion System

Uploaded by

SUBAS CHANDRA BEHERACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KE3-DST-MEQ-0908-3509 Rev 0 Floating Oil Colletion System

KE3-DST-MEQ-0908-3509 Rev 0 Floating Oil Colletion System

Uploaded by

SUBAS CHANDRA BEHERACopyright:

Available Formats

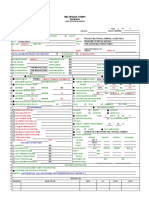

EPCC :

1 OWNE PMC PHASE III UPSTREAM DOC. NO. : KE3-DST-MEQ-0908-3509

PROJECT SURFACE FACILITIES

REV.

2 PROJECT PAGE 2 OF 4

DATA SHEET FOR FLOATING OIL COLLECTION SYSTEM Engg. Sub-Contractor :

3 REV. 0

TAG NO. M-6602 / P-6602

4 PROJECT: KEYI FPF SERVICE: Skim Oil

5 MANUFACTURER: SIZE / MODEL: QUANTITY: 1

6 PUMP TYPE PISTON PLUNGER METERING DIAPHRAGM DIRECT ACTING STEAM / GAS

7 ROTARY GEAR SCREW OTHER Sliding Shoe

8 DRIVERS NO. MOTORS 1 ITEM NO. NO. TURBINES ITEM NO.

9 OTHERS NO. ITEM NO.

10

11 SITE CONDITIONS MANUFACTURERS DATA

12 ALT (m) 520 ATM PRESS (kPa) 96.8 RATED BHP (kW) RPM

13 RELATIVE HUMIDITY MIN (%) 14 MAX (%) 68 HHP (kW) RPM

14 OUTDOOR TEMP. MIN (OC) 13 MAX (OC) 50 EFFICIENCY (%) MECH. VOLUMETRIC

15 INDOOR TEMP. MIN (OC) MAX (OC) ACCELERATION HEAD (kPa)

16 AREA CLASSIFICATION NPSH REQUIRED (at grade)

17 UNCLASSIFIED

18 CLASS 1 ZONE 2 GROUP IIA/IIB, T3 LIQUID STEAM

19 LOCATION DESIGN PRESS kPag

O

20 INDOOR OUTDOOR DESIGN TEMP C

21 HEATED UNHEATED HYDRO TEST kPag

22 COVERED TROPICAL CYLINDER TYPE

23 DUST

24 CORROSIVE GASES MAX FRAME BHP (kW) @ RPM

25 OTHER STEAM / GAS CONSUMPTION (kg / hr)

26 COOLING WATER (m 3 / hr)

27 OPERATING CONDITIONS JACKET STEAM (kg / hr)

28 LIQUID Recovered Crude Oil FLAMMABLE RELIEF VALVE SETTING (kPag)

29 CORR / EROSION BY TOXIC SUCTION LINE SIZE

30 PUMPING TEMP (OC) RATED 40 MIN 10 MAX 65 DIAMETER (mm) LENGTH (m)

O

31 VISCOSITY (cP) RATED 412.5 @ 40 C API MATERIAL CLASS

O

32 126.5 @ 50 C

33 SPECIFIC GRAVITY ACCESSORIES (ALSO REFER TO SHT. 3)

O

34 RATED 0.850 MAX 0.900 @ 40 C BASE PLATE (pump & driver)

35 VAPOR PRESS (kPa) SOLE PLATE

O

36 RATED 10 MAX 20 @ 20 C INLET PULSATION DAMPERS % MAX AMPL.

37 NPSH AVAILABLE (at grade) 3.5 m (exclude acc hd) OUTLET PULSATION DAMPERS % MAX AMPL.

38 JACKET FOR HEATING COOLING

39 MINIMUM NORMAL RATED GEAR UNIT

40 FLOW m3 / hr 2.5 RATING (kW) S.F.

41 SUCTION PRESS kPa(a) 100 MFG MODEL

42 DISCHARGE PRESS kPa(a) 600 INTEGRAL SEPARATE V-BELT

43 DIFFERENTIAL PRESS kPa 500 GUARD

44 LIQUID COMPRESSIBILITY VARIABLE SPEED DRIVE UNIT

45 MFG MODEL

46 NOZZLES SIZE RATING FACING POSITION SPEED RANGE (rpm) TO (rpm)

47 SUCTION By Vendor 150# RF By Vendor RATED POWER (kW)

48 DISCHARGE By Vendor 150# RF By Vendor RELIEF VALVE

49 STEAM IN INTEGRAL SEPARATE

50 STEAM OUT SIZE (mm) SET POINT (kPag)

51 COUPLING

52 TESTS AND INSPECTION TYPE Flexible

53 REQ'D WITNESS MFR MODEL

54 HYDROSTATIC STEAM CYLINDER LAGGING

55 RUNNING WEIGHT (kg)

56 PERFORMANCE PUMP DRIVER

57 NPSH BASE PLATE TOTAL

58 LINEARITY ACCURACY DIMENSIONS L x W x H (m)

59 REPEATABILITY FLOATING SKIMMER & FLEXIBLE HOSE

60 SHOP INSPECTION APPLICABLE SPECIFICATIONS

61 DISMANTLE & INSPECT API 674 API 675 API 676

62 OTHER Manuf. Std.

63

64

66

67

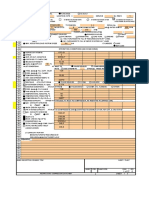

EPCC :

1 OWNE PMC DOC. NO. : KE3-DST-MEQ-0908-3509

PHASE III UPSTREAM SURFACE

PROJECT

FACILITIES PROJECT

REV.

2 PAGE 3 OF 4

DATA SHEET FOR FLOATING OIL COLLECTION SYSTEM Engg. Sub-Contractor :

3 REV. 0

TAG NO. M-6602 / P-6602

4 CONSTRUCTION

5 RECIPROCATING ROTARY CONTROLLED VOLUME

6 BORE (mm) STROKE (mm) PUMP TYPE BORE (mm) STROKE (mm)

7 ROD LOAD GEAR SPUR HELICAL NO. FEEDS

8 ACTUAL (kg) SCREW LOBE VANE

9 ALLOWED (kg) PROGRESSIVE CAVITY DIAPHRAGM DIA NO.

10 STALL (kPa) RAM (kPa) VALVE, TYPE NO.

11 SIMPLEX DUPLEX ROTOR MOUNT NO. VALVES PER FEED

12 MULTIPLEX CLOSE CLEARANCE OVERHUNG BTWN BEARINGS BACK PRESS VALVE BY

13 SINGLE DOUBLE ACTING TIMING GEARS

14 NO. TYPE YES NO CAPACITY CONTROL (Not Required)

15 REMOVABLE LINER INTERNAL EXTERNAL MANUAL

16 VALVE TYPE DISPLACEMENT (mm 3 / rev) REMOTE

17 DISC WING EXTERNAL BYPASS

18 DOUBLE PORTED BALL SPEED VARIATION

19 SUCTION DISCHARGE STROKE ADJUSTMENT

20 VELOCITY m/s PNEUMATIC

21 NUMBER VALVES ELECTRONIC

22 AREA (ea.) mm 2 CONTROL SIGNAL RANGE:

23 SCREWED PRESSURE FIT TO kPag

24 HORIZONTAL VERTICAL TO mA

25 TAILRODS

26 MATERIALS (BY VENDOR) Note 2

27 LIQUID STEAM CASING BODY CASING BODY

28 CYLINDER LINER CONTOUR PLATE

29 LINER STATOR HYDRAULIC DIAPH

30 HEAD ROTOR PROCESS DIAPH

31 PISTON / PLGR END PLATE PLUNGER

32 PISTON RINGS VANES VALVES

33 PISTON ROD TIMING GEARS VALVE SEATS

34 VALVES BEARING HOUSING VALVE GUIDE

35 SEATS SHAFT VALVE BODY

36 SPRINGS SHAFT SLEEVE VALVE GASKET

37 SHAFT GLAND FRAME

38 CRANKSHAFT BASE PLATE HEAD

39 GLAND LANTERN RING

40 LANTERN RING HOSE

41 BASE PLATE SKIMMER

42

43 PACKING AND MECHANICAL SEAL

44 PACKING MAT'L NO. OF RINGS SIZE OF RINGS (LIQ / STM)

45 SEAL MFG MODEL

46 SEAL CODE FLUSH PLAN QUENCH GLAND

47 SELF FLUSHED EXTERNAL FLUSHED FLUSH FLUID

48 MECH. LUBRICATOR DRIVEN BY

49 FLUID END MOTOR GAS END SHAFT

50 BEARINGS DRIVER

51 RADIAL BEARING TYPE Motor MAKE

52 TYPE MAT'L MODEL ENCLOSURE IP55

53 NO. INT / EXT POWER (kW) VOLT / PH / HZ 400V / 3PH / 50HZ

54 THRUST BEARING SPEED (rpm) SPACE HEATER

55 TYPE MAT'L

56

57 REMARKS VENDOR TO COMPLETE DATA SHEET

58 1. Vendor shall supply the complete Floating Oil Collection System, including the skim oil head, motor, set of flexible hoses(50m length), adaptors, trolly and boom etc,

59 as a stand-alone and indendent system to skim oil from the retention pond and discharge to the specified location.

60 2. Process liquid contact parts shall be in SS316.

61 3. Electrical equipment shall be suitable for Haz. Area Class 1, Zone 2, Group IIA/IIB, Temp. T3.

62

63

64

65

66

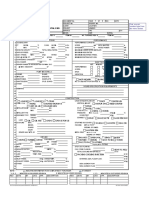

EPCC :

1 OWNE PMC DOC. NO. : KE3-DST-MEQ-0908-3509

PHASE III UPSTREAM SURFACE

PROJECT

FACILITIES PROJECT

REV.

2 PAGE 4 OF 4

DATA SHEET FOR FLOATING OIL COLLECTION SYSTEM Engg. Sub-Contractor :

3 REV. 0

TAG NO. M-6602 / P-6602

4 SCOPE OF SUPPLY / SERVICES By Pump vendor

5 1) Pump including lnternal safety relief valve Yes No

6 2) Motor with motor holding down bolts Yes No

7 3) Coupling with coupling guard Yes No

8 4) Belt with belt guard Yes No

9 5) Gear box Yes No

10 6) Common baseplate Yes No

11 7) Holding down bolts Yes No

12 8) Mating flanges with bolts, nuts & gaskets, for non ANSI type and rating Yes No

13 9) Drip tray with piping. Yes No

14 10) Mechanical seal Yes No

15 11) Flushing plan piping & Instruments with accessories as per API plan. Yes No

16 12) Cooling / Quenching plan piping & Instruments as per API plan. Yes No

17 13) Minimum flow bypass orifice. Yes No

18 14) Minimum continuous flow control valve. Yes No

19 15) Vibration probes. Yes No

20 16) Bearing temp. RTDs/ temp.switch as required by specification Yes No

21 17) Motor winding temp.RTDs / temp.switch Yes No

22 18) Monitors for 15, 16,17 Yes No

23 19) Local Control Panel Yes No

24 20) Commissioning & startup spares / special tools ( Separate quote to be furnished) Yes No

25 21) Spares for 2 years normal operation ( List to be furnished) Yes No

26 22) Painting Vendor standard Clients specification Yes No

27 23) Inspection & shop testing Yes No

28 24) Supervision of erection & commissioning Yes No

29 25) Performance testing at shop with contract driver Yes No

30 26) Documentation as per PE specification. Yes No

31 27) Performance testing at field Yes No

32 28) Torsional vibration analysis and report Yes No

33 29) Motor Space Heater (for 37kw and above) Yes No

34 30) Internal earth terminal (inside cable terminal box) - for motors between 4kw and 30kw, both inclusive Yes No

35 31) Earthing lugs Yes No

36 32) Skim oil head Yes No

37 33) Flexible hoses with adaptors (Length 50m) Yes No

38 34) Trolley Yes No

39 35) Discharge hose with quick release couplings Yes No

40 36) Floating oil collection boom (To be supplied as a warehouse equipment) Yes No

41 37) Motor hand switch for start/stop function Yes No

42

43

44

45

46

47

48

49 REMARKS (Cont……)

50 4. Vendor to fill balance information and furnish completed Data Sheet.

51 5. Skim Oil Head is a light weight weir or gravity skimmer, it requires no separate power

52 to operate, but uses the hydraulic pull of a pump or vacuum to create the skim.

53 6. The retention pond size: 10mX10mX2m

54

55

56

57

58

59

60

61

62

63

You might also like

- Yamaha V-Star 650 Shop ManualDocument360 pagesYamaha V-Star 650 Shop ManualRıdvan Kurtuldu100% (3)

- 2005 Volvo V70R XC70 XC90 Car Wiring DiagramDocument151 pages2005 Volvo V70R XC70 XC90 Car Wiring DiagramMats Frånberg71% (7)

- Student Industrial Work ExperienceDocument42 pagesStudent Industrial Work ExperienceAmir O. Osho80% (5)

- Caterpillar Cat 302.5C Mini Hydraulic Excavator (Prefix GBB) Service Repair Manual (GBB00001 and Up)Document20 pagesCaterpillar Cat 302.5C Mini Hydraulic Excavator (Prefix GBB) Service Repair Manual (GBB00001 and Up)kfmuseddk100% (1)

- Isuzu 6Sd1Tc: 306 Horsepower Industrial DieselDocument1 pageIsuzu 6Sd1Tc: 306 Horsepower Industrial DieselBryan Baring50% (2)

- API 675 Pump DatasheetDocument2 pagesAPI 675 Pump DatasheetArun CPNo ratings yet

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Document3 pagesData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisNo ratings yet

- API 610 10th Edition (Iso 13709) Pump DatasheetDocument3 pagesAPI 610 10th Edition (Iso 13709) Pump DatasheetMuhammad Azka50% (4)

- Process Data Sheet For Fired HeaterDocument8 pagesProcess Data Sheet For Fired HeaterBangkiyak LanangNo ratings yet

- LNG Booster Pump DatasheetDocument7 pagesLNG Booster Pump DatasheetsswahyudiNo ratings yet

- 40 Tons Railway Turntable CaculationDocument2 pages40 Tons Railway Turntable CaculationAbdulRehmanChaudaryNo ratings yet

- Data Sheet Multiphase Pump BornermanDocument5 pagesData Sheet Multiphase Pump BornermanUmar Ijaz KhanNo ratings yet

- Data Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary UnitsDocument10 pagesData Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary Unitsrajindo1No ratings yet

- 22-DS-R-002 Rev 0 API 616 Turbine Data SheetDocument13 pages22-DS-R-002 Rev 0 API 616 Turbine Data SheetChike NwachukwuNo ratings yet

- Centrifugal Compressor Specification Sheet: Operating ConditionsDocument6 pagesCentrifugal Compressor Specification Sheet: Operating ConditionsIsmail SayyedNo ratings yet

- Sulphuric Acid Dosing Pump Motor ManualDocument28 pagesSulphuric Acid Dosing Pump Motor ManualmohammedsfNo ratings yet

- Data Sheet No. Ds-P-5983 Rev. 1: Centrifugal Pump Data Sheet U.S. Customary UnitsDocument10 pagesData Sheet No. Ds-P-5983 Rev. 1: Centrifugal Pump Data Sheet U.S. Customary Unitsrajindo1No ratings yet

- Mechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraDocument5 pagesMechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraAhmad RifaiNo ratings yet

- DatasheetDocument71 pagesDatasheetRhadityo Shakti BudimanNo ratings yet

- Brown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet Si UnitsDocument4 pagesBrown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet Si UnitsLipika GayenNo ratings yet

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur DieselDocument7 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur DieselBilel MahjoubNo ratings yet

- Página: 1 De: 5Document6 pagesPágina: 1 De: 5Rathawit SingpanjanateeNo ratings yet

- Api 674 Pump Data SheetDocument5 pagesApi 674 Pump Data Sheetroronoa_zorro11No ratings yet

- Atlas Copco India LTD.: Gas Process ApplicationDocument4 pagesAtlas Copco India LTD.: Gas Process ApplicationAmit SurtiNo ratings yet

- Specification Datasheet For Instrument Air Compressor PackageDocument5 pagesSpecification Datasheet For Instrument Air Compressor PackageBarata RendengNo ratings yet

- Brown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsDocument15 pagesBrown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsLipika GayenNo ratings yet

- Data Sheet No. Ds-P-5107 Rev. 2: 6590-10 6590-10D1-J310-03 J-RE-PUMP-610-P 2 12-Jul-00 1 6 KMG / BeyDocument8 pagesData Sheet No. Ds-P-5107 Rev. 2: 6590-10 6590-10D1-J310-03 J-RE-PUMP-610-P 2 12-Jul-00 1 6 KMG / Beyrajindo1No ratings yet

- Greater Nile Petroleum Company Limited OGP Technical Services SDN BHDDocument2 pagesGreater Nile Petroleum Company Limited OGP Technical Services SDN BHDwado11No ratings yet

- Information To Be Completed by Purchaser by Manufacturer With Proposal by Manuacturer After Order by Manufacturer or Purchaser As ApplicableDocument5 pagesInformation To Be Completed by Purchaser by Manufacturer With Proposal by Manuacturer After Order by Manufacturer or Purchaser As ApplicableHisham ElsayedNo ratings yet

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueDocument6 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueBilel MahjoubNo ratings yet

- CWC Mec DTS P001abcdDocument8 pagesCWC Mec DTS P001abcdAlonso1593No ratings yet

- KE3-DST-ELC-0908-6037 - 0 - Electrical Motor - PKM6921-K-1ABDocument3 pagesKE3-DST-ELC-0908-6037 - 0 - Electrical Motor - PKM6921-K-1ABSUBAS CHANDRA BEHERANo ratings yet

- Fire Monitors DatasheetsDocument1 pageFire Monitors DatasheetsmoodydoodyNo ratings yet

- Operating Conditions Liquid: Client: ServiceDocument1 pageOperating Conditions Liquid: Client: ServiceAde IskandarNo ratings yet

- Mechanical Data Sheet For Fuel Gas FiltersDocument4 pagesMechanical Data Sheet For Fuel Gas FilterssudjonoNo ratings yet

- Api 610 Datasheet PDF FreeDocument7 pagesApi 610 Datasheet PDF FreeRisyda PutriNo ratings yet

- Centrifugal Pump Process Data Sheet (API 610 10th. Ed.) : In-Tank Vertical, Submerged MotorDocument2 pagesCentrifugal Pump Process Data Sheet (API 610 10th. Ed.) : In-Tank Vertical, Submerged MotorJuan José Grajeda AguayoNo ratings yet

- 02 190 0012 MK 062Document9 pages02 190 0012 MK 062phuchau nguyenNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Data Sheet Pompa HydrantDocument3 pagesData Sheet Pompa HydrantAnonymous 6S9tcbhNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Positive Displacement PumpDocument2 pagesPositive Displacement Pumpanon_884425478No ratings yet

- Centrifugal Pump - Horizontal End Suction - Asme B73.1Document3 pagesCentrifugal Pump - Horizontal End Suction - Asme B73.1wado11No ratings yet

- Hoja de Datos de BombaDocument5 pagesHoja de Datos de Bombaluis zambranoNo ratings yet

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- 14960-000-ME-DAS-003 Data Sheet For Sump PumpsDocument8 pages14960-000-ME-DAS-003 Data Sheet For Sump PumpsAshish TIwariNo ratings yet

- Hoja API Vs4 001Document9 pagesHoja API Vs4 001brujula24No ratings yet

- Tank DatasheetDocument5 pagesTank DatasheetGandhi AlamsyahNo ratings yet

- Reciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneralDocument10 pagesReciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneraltxagusNo ratings yet

- KE3-DST-ELC-0908-6036 - ELE Motor Upto 250 KWDocument3 pagesKE3-DST-ELC-0908-6036 - ELE Motor Upto 250 KWSUBAS CHANDRA BEHERANo ratings yet

- 001.17056.000028-AK007-01 Cartridge FilterDocument5 pages001.17056.000028-AK007-01 Cartridge FilterQuy RomNo ratings yet

- Engro Daharki - Pakistan Small Capacity Ammonia Pump-Preliminary Data Sheet 0Document6 pagesEngro Daharki - Pakistan Small Capacity Ammonia Pump-Preliminary Data Sheet 0Arslan NisarNo ratings yet

- Packaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorDocument6 pagesPackaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorNuzul FurqonyNo ratings yet

- R-Pump Cal Sheet1Document12 pagesR-Pump Cal Sheet1santosh kumarNo ratings yet

- 5691 CPP Me DS 0001 0 PDFDocument17 pages5691 CPP Me DS 0001 0 PDFĐiệnBiênNhâmNo ratings yet

- 1-MVCP00116-885PSVr2 20210524100343 852 XDocument4 pages1-MVCP00116-885PSVr2 20210524100343 852 XŁukasz BolewskiNo ratings yet

- Compaq Prover - Rev - ABDocument1 pageCompaq Prover - Rev - ABPsa Metering RU II DumaiNo ratings yet

- Client: Data Sheet Fire Dampers: GeneralDocument1 pageClient: Data Sheet Fire Dampers: GeneralAlif FirdausNo ratings yet

- 9572 TBA Progressive Cavity Pump - Rev.0Document4 pages9572 TBA Progressive Cavity Pump - Rev.0budy wening setyo wibowoNo ratings yet

- 417 2016052-Di041-509 - 1Document1 page417 2016052-Di041-509 - 1lamisma09No ratings yet

- Pump Datasheet API 675 FORMATDocument2 pagesPump Datasheet API 675 FORMATbaladharan05No ratings yet

- KE3-DST-ELC-0908-6040 - DST-Electric - Motor-LV (19-11-09)Document3 pagesKE3-DST-ELC-0908-6040 - DST-Electric - Motor-LV (19-11-09)SUBAS CHANDRA BEHERANo ratings yet

- (API 674-2nd) Reciprocating PumpDocument6 pages(API 674-2nd) Reciprocating PumpadistiNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesFrom EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerNo ratings yet

- Zorya-Mashproekt 24.08.10Document79 pagesZorya-Mashproekt 24.08.10SUBAS CHANDRA BEHERANo ratings yet

- Format No.:-1MYN691001-011 / 01: D S D SDocument1 pageFormat No.:-1MYN691001-011 / 01: D S D SSUBAS CHANDRA BEHERANo ratings yet

- 2313-4040-001 Rev NaDocument16 pages2313-4040-001 Rev NaSUBAS CHANDRA BEHERANo ratings yet

- 2314-4005-001 Rev NaDocument4 pages2314-4005-001 Rev NaSUBAS CHANDRA BEHERANo ratings yet

- 2314-4010-001 Rev NaDocument11 pages2314-4010-001 Rev NaSUBAS CHANDRA BEHERANo ratings yet

- 2313-4010-001 Rev NaDocument7 pages2313-4010-001 Rev NaSUBAS CHANDRA BEHERANo ratings yet

- 2090-4006-001 Rev NaDocument1 page2090-4006-001 Rev NaSUBAS CHANDRA BEHERANo ratings yet

- KE3-DST-ELC-0908-6033 - 11KV MotorDocument4 pagesKE3-DST-ELC-0908-6033 - 11KV MotorSUBAS CHANDRA BEHERANo ratings yet

- 2313-4005-001 Rev NaDocument6 pages2313-4005-001 Rev NaSUBAS CHANDRA BEHERANo ratings yet

- Electrical - Manhour Estimation - Rev 0 FOR ADIPDocument1 pageElectrical - Manhour Estimation - Rev 0 FOR ADIPSUBAS CHANDRA BEHERANo ratings yet

- KE3-DST-ELC-0908-6036 - ELE Motor Upto 250 KWDocument3 pagesKE3-DST-ELC-0908-6036 - ELE Motor Upto 250 KWSUBAS CHANDRA BEHERANo ratings yet

- 2090-4017-001 Rev NaDocument3 pages2090-4017-001 Rev NaSUBAS CHANDRA BEHERANo ratings yet

- Electrical Manhours-GASCO FIRE WATER PUMPDocument1 pageElectrical Manhours-GASCO FIRE WATER PUMPSUBAS CHANDRA BEHERANo ratings yet

- MTO For SubstationDocument16 pagesMTO For SubstationSUBAS CHANDRA BEHERANo ratings yet

- KE3-CAL-ELC-0908-6075 - 0-Distr-Tranf Sizing CalDocument3 pagesKE3-CAL-ELC-0908-6075 - 0-Distr-Tranf Sizing CalSUBAS CHANDRA BEHERANo ratings yet

- 2) Generator Site Rating Size For P1100E1Document2 pages2) Generator Site Rating Size For P1100E1SUBAS CHANDRA BEHERANo ratings yet

- 6897 enDocument72 pages6897 enLuisSilvaNo ratings yet

- Acd GupdDocument2 pagesAcd GupdJeremy JerezNo ratings yet

- RTS2370A Eng 01 765189Document2 pagesRTS2370A Eng 01 765189Ivone LongarettiNo ratings yet

- 02wged PDFDocument284 pages02wged PDFAlex Box0% (1)

- 4H.2209 - Illustrated Spare Parts Manual - KFP4R-UF07 - FM-UL PDFDocument91 pages4H.2209 - Illustrated Spare Parts Manual - KFP4R-UF07 - FM-UL PDFPankaj JainNo ratings yet

- Fuel Average CalculatorDocument1,088 pagesFuel Average CalculatorskainthNo ratings yet

- Rolling Contact BearingsDocument37 pagesRolling Contact BearingsErik BaltssNo ratings yet

- Dirtbike - Streetbike - Atv-Utv - Watercraft - Snowmobile - 50CcDocument24 pagesDirtbike - Streetbike - Atv-Utv - Watercraft - Snowmobile - 50CcAlex CatoNo ratings yet

- Catalouge For Cenlub ProductDocument34 pagesCatalouge For Cenlub ProductUdaya Manju50% (2)

- Sundez Ground Source Heat Pump Installation&Instruction ManualDocument34 pagesSundez Ground Source Heat Pump Installation&Instruction ManualDragoslav KresacNo ratings yet

- 3512 Land Electric - LEHW0066-00 P2Document4 pages3512 Land Electric - LEHW0066-00 P2AustinNo ratings yet

- 26K inDocument3 pages26K inossoskiNo ratings yet

- Manual Do Trator de Esteira Zomlion - ZD220-3Document51 pagesManual Do Trator de Esteira Zomlion - ZD220-3Jaciane AraujoNo ratings yet

- Illustrated Parts List: RTLO-18918A-AS3 November 2012Document47 pagesIllustrated Parts List: RTLO-18918A-AS3 November 2012AnGel Amaya100% (1)

- 2020-03a - Kiln Shut Down PDFDocument1 page2020-03a - Kiln Shut Down PDFhiddenhidden16No ratings yet

- Lantis 818Document45 pagesLantis 818Amiet ChatterpalNo ratings yet

- Binder Del AlumnoDocument268 pagesBinder Del AlumnoCesar QuintanillaNo ratings yet

- Mercedes 190eDocument290 pagesMercedes 190eJames100% (4)

- Wind Turbine Design For Wind PowerDocument7 pagesWind Turbine Design For Wind Powermuhammad husnainNo ratings yet

- Engineering Thermodynamics - Problems and Solutions, Chapter-9Document20 pagesEngineering Thermodynamics - Problems and Solutions, Chapter-9ZelNo ratings yet

- Parts Catalogue: KARIZMA ZMR (May, 2014)Document93 pagesParts Catalogue: KARIZMA ZMR (May, 2014)Athiq NehmanNo ratings yet

- Stock Kmi Per 14 September 2022Document30 pagesStock Kmi Per 14 September 2022xspeed shopNo ratings yet

- Click On Item# To Order Repair Manual in The ONLINE Store: Return To PPT Catalog PageDocument1 pageClick On Item# To Order Repair Manual in The ONLINE Store: Return To PPT Catalog PageMylène RacineNo ratings yet

- Midsized With Big Features.: Horizontal Directional Drilling SystemDocument2 pagesMidsized With Big Features.: Horizontal Directional Drilling SystemJose RodriguezNo ratings yet