Professional Documents

Culture Documents

House Plan Jasmine 1

House Plan Jasmine 1

Uploaded by

simeon james villacrusisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

House Plan Jasmine 1

House Plan Jasmine 1

Uploaded by

simeon james villacrusisCopyright:

Available Formats

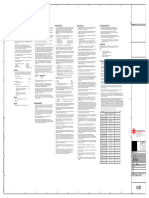

GENERAL NOTES FORM WORKS STRUCTURAL STEEL:

1. GENERAL NOTES AND TYPICAL STRUCTURAL DETAILS SHALL APPLY TO ALL DRAWINGS UNLESS OTHERWISE SHOWN

1. FORMS SHALL BE PROVIDED FOR ALL CONCRETE INDICATED UNLESS SPECIFIED OTHERWISE. FORMS SHALL 1. ALL STRUCTURAL STEEL WORKS SHALL BE IN ACCORDANCE WITH AISC SPECIFICATION FOR DESIGN, FABRICATION, & ERECTION OF

OR NOTED.

BE SET TRUE TO LINE AND GRADE AND MAINTAINED SO AS TO ENSURE COMPETENT WORK WITHIN THE STRUCTURAL STEEL FOR BUILDING.

2. THE CONTRACTOR SHALL EXAMINE THE DRAWINGS AND SHALL NOTIFY THE ENGINEER/ARCHITECT OF ANY

ALLOWABLE TOLERANCES SPECIFIED AND SHALL BE MORTAR TIGHT.

DISCREPANCIES HE MAY FIND BEFORE PROCEEDING WITH THE WORK, OR DURING CONSTRUCTION. 2. ALL STRUCTURAL STEEL SHAPES & PLATES SHALL CONFORM TO ASTM-A36.

2. FORMS AND THEIR SUPPORTS SHALL BE DESIGNED SO AS NOT TO DAMAGE PREVIOUSLY PLACED

3. IT SHALL BE THE CONTRACTOR'S RESPONSIBILITY TO PROVIDE ADEQUATE SHORING AND BRACING FOR THE

STRUCTURE.

STRUCTURE FOR ALL LOADS THAT MAY BE IMPOSED DURING CONSTRUCTIO 3. ALL SPLICES AND CONNECTIONS SHALL BE DESIGNED FOR AT LEAST 125% OF CAPACITY OF THE MEMBERS BEING JOINED OR A

3. NO CONSTRUCTION LOAD SHALL BE SUPPORTED ON, NOR ANY SHORING REMOVED FROM ANY PART OF

MINIMUM STRESS OF 8 KIPS.

STRUCTURE UNDER CONSTRUCTION EXCEPT WHEN THAT PORTION OF THE STRUCTURE IN COMBINATION

WITH THE REMAINING FORMING AND SHORING SYSTEM HAS SUFFICIENT STRENGTH TO SUPPORT SAFELY ITS 4. ALL STRUCTURAL WELDING SHALL CONFORM TO E70 xx.

WEIGHT AND ADDITIONAL IMPOSED LOAD.

4. FORMS SHALL BE REMOVED IN SUCH MANNER AS NOT TO IMPAIR SAFETY AND SERVICEABILITY OF THE 5. ALL STRUCTURAL ANCHORAGE BOLTS SHALL CONFORM TO A325, UNLESS OTHERWISE NOTED.

STRUCTURE.

6. THE CONTRACTOR SHALL SUBMIT SHOP/FABRICATION DRAWINGS OF ALL STRUCTURAL STEEL FRAMING TO INCLUDE MATERIAL

FOUNDATION NOTES: CONSTRUCTION JOINT SCHEDULE, ERECTION SCHEMES, DETAIL OF CONNECTION & SPLICES FOR REVIEW AND APPROVAL OF THE ENGINEER PRIOR TO ERECTION.

1. SAFE BEARING CAPACITY (SBC) USED IN THE DESIGN = 96 KPA

2. THE STRUCTURAL ENGINEER-OF-RECORD, UPON NOTIFICATION, SHALL CONDUCT A THOROUGH INSPECTION OF THE

1. ALL SURFACES OF CONSTRUCTION JOINTS SHALL BE ROUGHENED TO 6mm. AMPLITUDE 7. ALL STRUCTURAL STEEL SURFACE SHALL BE APPLIED WITH A SHOP COAT OF ZINC CHROMATE PRIMER AFTER FABRICATION AND

FOUNDATION WORKS AFTER EXCAVATION FOR FOOTINGS ARE COMPLETED. NO REINFORCING STEEL OR FORMWORKS

2. ALL CONSTRUCTION JOINTS SHALL BE CLEANED TO REMOVE DUST, CHIPS, OR OTHER FOREIGN MATTERS PRIOR TO ERECTION AND SECOND OF THE SAME PAINT AFTER WELDING AND/OR ERECTION.

SHALL BE PLACED PRIOR TO INSPECTION. CONCRETE POURING OF THE FOUNDATION SYSTEM SHALL NOT BE ALLOWED

PRIOR TO PLACING OF ADJACENT CONCRETE.

WITHOUT FIRST OBTAINING WRITTEN APPROVAL FROM THE STRUCTURAL ENGINEER-ON-RECORD.

3. THE CONTRACTOR SHALL SUBMIT THE PROPOSED LOCATIONS OF CONSTRUCTION JOINTS TO THE ENGINEER 8. THE CONTRACTOR SHALL VERIFY ACTUAL DIMENSIONS AS SHOWN IN DRAWINGS AT JOB SITE PRIOR TO PREPARATION OF SHOP

FOR APPROVAL BY THE STRUCTURAL ENGINEER BEFORE STARTING CONSTRUCTION. DRAWINGS.

CONCRETE NOTES

9. ALL WELDS NOT SPECIFIED SHALL BE CONTINUOUS FILLET WELDS, USING NOT LESS THAN THE MINIMUM SIZE BASE ON THINNER

RECOMMENDED END HOOKS, ALL GRADES PART JOINED PER AISC / AWS.

ALL WORK SHALL BE DONE IN ACCORDANCE WITH THE MINIMUM REQUIREMENTS OF THE NATIONAL STRUCTURAL CODE OF

10. MINIMUM TWO BOLT CONNECTIONS SHALL BE MADE BY USE OF M12 BOLT UNLESS SHOWN OTHERWISE ON THE DWGS.

THE PHILIPPINES (NSCP) VOL.1 OR THE AMERICAN CONCRETE INSTITUTE BUILDING CODE FOR REINFORCED CONCRETE ACI

318 EXCEPT AS MODIFIED HEREIN. 180 DEGREE HOOK 90 DEGREE HOOK

FINISHED BEND 11. ALL GUSSET PLATES AND STIFFENERS SHALL BE 6mm THICKNESS UNLESS NOTED OTHERWISE ON THE DRAWING.

BAR SIZE

DIAMETER, D (MM) A OR G J A OR G

SCHEDULE OF STRUCTURAL CONCRETE AT 28 DAYS COMPRESSIVE STRENGTH (MM) (MM) (MM) 12. DOUBLE ANGLE OR CHANNEL MEMBERS SHALL HAVE STITCH BOLTS & RING FILLS OR WELDED FILLERS NOT MORE THAN 600mm

ON CENTERS EXCEPT FOR DIAGONAL X-BRACING AND HANGING SUPPORTS OF WHICH STITCHING MAY BE SPACED NOT MORE THAN

60 130 80 115 900mm ON CENTERS UNLESS NOTED OTHERWISE ON THE DRAWING.

LOCATION STRUCTURAL 28-DAY COMPRESSIVE STRENGTH MAX. SLUMP

ELEMENTS MPa (psi) mm (in) 80 155 105 155

FOUNDATION FOOTING/SOG 20.7 (3000) 100 (4") 100 180 130 255

2F SUS. SLAB/CORBELS 20.7 (3000) 100 (4") 120 205 155 305

ALL LEVELS WALLS 20.7 (3000) 100 (4") 155 280 205 410

SLAB ON GRADE EXPANSION AND CONSTRUCTION JOINT

247 285 300 485

SCHEDULE OF CONCRETE AGGREGATES 275 435 340 560

307 485 375 610

ITEMS MAXIMUM AGGREGATE SIZE

FOOTINGS 25 mm (1")

SLABS, BEAMS, COLUMNS, OTHERS. 19 mm (3/4")

CURBS AND MASS, CONCRETE/SLAB ON GRADE 25 mm (1")

1. LOCATION OF ALL CONSTRUCTION OR COLD JOINTS MUST NOT BE WITHIN THE SUPPORT AREA. FOR CASE

UNAVOIDABLE, PROPOSED LOCATION MUST BE APPROVED FIRST BY THE ENGINEER/ARCHITECT.

3. PIPES OR DUCTS EXCEEDING ONE THIRD THE SLAB OR WALL THICKNESS SHALL NOT BE PLACED IN STRUCTURAL

CONCRETE UNLESS SPECIFICALLY DETAILED. PIPES MAY PASS THROUGH STRUCTURAL CONCRETE IN SLEEVES BUT

SHALL NOT BE EMBEDDED THEREIN. CONCRETE SLAB NOTES

3 REINFORCING BARS, ANCHOR BOLTS, AND OTHER INSERTS SHALL BE SECURED IN PLACE BEFORE POURING

CONCRETE. BAR PLACEMENT AND SUPPORTS SHALL BE IN ACCORDANCE WITH THE RECOMMENDED ACI PRACTICE.

SUSPENDED SLAB CONSTRUCTION JOINT AND CHANGE SOFFIT DETAIL

4. ALL INSERTS, ANCHOR BOLTS, ETC. TO BE EMBEDDED IN THE CONCRETE SHALL BE HOT DIP GALVANIZED UNLESS NOTES:

NOTED OTHERWISE. 1. ALL REINFORCEMENT SHALL BE 20MM CLEAR MINIMUM FROM TOP AND BOTTOM SLAB.

5. IN GENERAL, THE LATEST EDITION OF THE MANUAL OF STANDARD PRACTICE FOR DETAILING CONCRETE 2. UNLESS OTHERWISE DETAILED IN CONDITIONING SLAB HAVING SAME REINFORCEMENT RUNNING IN ONE

DIRECTION, REINFORCING SHALL BE BENT, EXTENDED OR CUT AS FOLLOWS.

STRUCTURES, ACI 315, SHALL BE ADHERED TO, UNLESS SHOWN OTHERWISE.

6. USE OF ADMIXTURES IS PERMITTED TO PRODUCE PROPER SLUMP AND WORKABILITY BUT SUBJECT TO THE

ENGINEER'S APPROVAL. ADDITION OF WATER TO CONCRETE AT JOB SITE IS NOT ALLOWED.

7. PREPARE AND SUBMIT CONCRETE MIX DESIGN INCLUDING AGGREGATES GRADATION, WATER AND CEMENT

CONTENTS, AND CYLINDER STRENGTH TEST RESULT FOR REVIEW.

SCHEDULE OF REINFORCING STEEL AND REINFORCING BARS

DIAMETER OF BARS ASTM GRADE

33

A615 / A615M (DEFORMED) 40

A615 / A615M (DEFORMED) 60 EXTERIOR SPAN INTERIOR SPAN INTERIOR SPAN

1. BARS SHALL BE CLEAN OF RUST, GREASE OR OTHER MATERIALS LIKELY TO IMPAIR BOND. ALL REINFORCING BAR 4. TEMPERATURE BARS FOR SLAB SHALL BE GENERALLY PLACED NEAR THE TENSION FACE AND SHALL NOT BE

BEND SHALL BE MADE COLD.

5.

LESS THAN 0.0018 BT. DOOR AND WINDOW OPENING DETAILS

2. IN GENERAL, BAR SPLICES SHALL BE MADE AT POINTS OF MINIMUM STRESS. SPLICES SHALL BE SECURELY WIRED

TOGETHER STAGGER SPLICES AT LEAST 600mm. WHENEVER POSSIBLE IN BEAMS AND SLABS. SPLICE TOP BARS AT CENTER OF SLAB. CONSTRUCTION JOINT FOR SLAB SHALL NOT BE MORE THAN 3.0M APART.

MID SPAN AND BOTTOM BARS NEAR SUPPORT. SPLICE OF REINFORCEMENT SHALL BE MADE ONLY AS REQUIRED OR

PERMITTED ON DESIGN DRAWINGS OR AS ALLOWED BY THE ACI CODE OR AS AUTHORIZED BY THE ENGINEERS.

3. BARS NOTED AS CONTINUOUS SHALL HAVE A MINIMUM SPLICE LENGTH OF 48 BAR DIAMETER BUT NOT LESS THAN STIRRUPS AND TIE HOOKS, ALL GRADES

300mm. UNLESS OTHERWISE NOTED.

4. REINFORCEMENTS SHALL BE SPLICED ONLY AS INDICATED ON THE DRAWINGS.

5. MINIMUM CONCRETE COVER FOR REINFORCING BARS SHALL BE:

GENERAL USE SEISMIC USE

BAR SIZE D (mm)

ITEMS COVER

A OR G A OR G H APPROX. A OR G H APPROX.

CONCRETE CAST AGAINST EARTH 75mm

40 105mm 105mm 55mm 130mm 90mm

EXPOSED TO EXTERIOR OR WEATHER 50mm

55 115mm 115mm 80mm 170mm 145mm

FORMED SURFACE BELOW GRADE 50mm

65 155mm 140mm 100mm 205mm 140mm

SLAB ON GRADE 48mm

145 305mm 200mm 145mm 275mm 170mm

STRUCTURAL SLABS TOP & BOTTOM (INTERIOR) 20mm

155 410mm 265mm 145mm 365mm 230mm

GENERAL USE SEISMIC LOAD

7. WELDING OF REINFORCING STEEL IS NOT PERMITTED UNLESS OTHERWISE SHOWN ON THE DRAWING.

8. SHOP DRAWINGS : THE CONTRACTOR SHALL SUBMIT SHOP DRAWINGS FOR REINFORCING STEEL PREPARED

IN ACCORDANCE WITH ACI 315. INDICATE BENDING DIAGRAM, ASSEMBLY DIAGRAM, SPLICING AND LAPS OF

6d

RODS AND SHAPES DIMENSIONS AND DETAILS FOR REINFORCING BARS.

b

9. ANCHOR BOLTS, DOWELS AND OTHER EMBEDDED ITEMS ARE TO BE SECURELY TIED IN PLACE BEFORE

CONCRETE IS POURED.

1 GENERAL NOTES

S-00 SCALE: NTS

AVIDA ESTATES NUVALI S-00

JASMINE (STD-NORM)

1 9

You might also like

- Structural Drawings g+2 1Document34 pagesStructural Drawings g+2 1Syed Arman AlamNo ratings yet

- Bihar Museum, PatnaDocument15 pagesBihar Museum, PatnaAarushi Barnwal50% (2)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Design Criteria: GeneralDocument1 pageDesign Criteria: GeneralRolly Marc G. SoteloNo ratings yet

- For Construction Drawing - FCD: General Structural Notes & SpecificationsDocument1 pageFor Construction Drawing - FCD: General Structural Notes & SpecificationsJossell De AlaNo ratings yet

- STRUCTURALDocument12 pagesSTRUCTURALKevin NamayaNo ratings yet

- ST-01 To ST-12Document12 pagesST-01 To ST-12Regina LagaticNo ratings yet

- Awetu - Jimma - Shopes and Public Restroom - STDocument13 pagesAwetu - Jimma - Shopes and Public Restroom - STAhmed KedirNo ratings yet

- E. Formworks: (Structural)Document1 pageE. Formworks: (Structural)Nonoy Justiniane-Giray JrNo ratings yet

- Steel Design Project PublishDocument48 pagesSteel Design Project PublishCzelsi Carlos NavarroNo ratings yet

- Metro Proj - 12 MTR Span-1Document3 pagesMetro Proj - 12 MTR Span-1kukadiya127_48673372No ratings yet

- Compilation 2010-t-2Document1 pageCompilation 2010-t-2api-271252079No ratings yet

- Pipe CulvertDocument12 pagesPipe CulvertSajjad Khan100% (1)

- Att-06 Drawing MarkupsDocument13 pagesAtt-06 Drawing MarkupsabdullahNo ratings yet

- TWAS-Tender Addendum - StructuralDocument116 pagesTWAS-Tender Addendum - StructuralnvnagarajuNo ratings yet

- سوبرDocument7 pagesسوبرmahmoudbargouthi4No ratings yet

- Plan For CID No. 21ID0029-2Document10 pagesPlan For CID No. 21ID0029-2Lara FloresNo ratings yet

- Revisions:: PE Project: 230647Document1 pageRevisions:: PE Project: 230647Karthik NNo ratings yet

- Mcpherson Design GROUP P.CDocument26 pagesMcpherson Design GROUP P.CdeviationzNo ratings yet

- Quiruben M. Mera Engr. Landrito R. Pilao: S-1 Highline Builders CompanyDocument1 pageQuiruben M. Mera Engr. Landrito R. Pilao: S-1 Highline Builders CompanyHighline BuildersNo ratings yet

- STRUCDocument5 pagesSTRUCEdward D. SarcoNo ratings yet

- S1Document1 pageS1joemarferrerjoemz1234No ratings yet

- General Notes: Submittal For ApprovalDocument6 pagesGeneral Notes: Submittal For ApprovalMyo AungNo ratings yet

- SampleDocument3 pagesSampleerniE抖音 AI Mobile Phone Based MovieNo ratings yet

- Buildings UKDocument3 pagesBuildings UKerniE抖音 AI Mobile Phone Based MovieNo ratings yet

- Ground Water Tank Structural DrawingDocument8 pagesGround Water Tank Structural DrawingMonish Lakhey ShresthaNo ratings yet

- D Eugp1 TPT G 000 Gen FWG 001 R01Document1 pageD Eugp1 TPT G 000 Gen FWG 001 R01debapriyoNo ratings yet

- Irc 2018 With SC Modifications - Load Table: General Structural NotesDocument6 pagesIrc 2018 With SC Modifications - Load Table: General Structural Notespriya giriNo ratings yet

- General Specifications: I. Clearing and EarthworksDocument4 pagesGeneral Specifications: I. Clearing and EarthworksFroilan AngbengcoNo ratings yet

- STR - 1Document1 pageSTR - 1shankar9841469226No ratings yet

- A1.0 General NotesDocument1 pageA1.0 General NotesNguyen DuongNo ratings yet

- E. Reinforcement A. General B. Foundation: NotesDocument12 pagesE. Reinforcement A. General B. Foundation: NotesIsrael AdegboyegaNo ratings yet

- Schedule OpeningsDocument1 pageSchedule OpeningsArun S DasNo ratings yet

- GCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 1Document1 pageGCU Consultants (Johor) SDN BHD: General Notes and Miscellaneous Detail 1TOM YEENo ratings yet

- STR 1Document1 pageSTR 1Christian BenitezNo ratings yet

- Bound Brook 300 - Structural PackageDocument25 pagesBound Brook 300 - Structural PackageGuillermo Romero HuertasNo ratings yet

- J0673-S001 - General NotesDocument1 pageJ0673-S001 - General NotesEmon RayNo ratings yet

- Fabrication: Structural and Miscellaneous Steel: (REF: TECH. SPEC. 143256-ES-C-1008, 1011 & 1012) Materials: PaintingDocument1 pageFabrication: Structural and Miscellaneous Steel: (REF: TECH. SPEC. 143256-ES-C-1008, 1011 & 1012) Materials: PaintingRoberto Andrés Fernández DomínguezNo ratings yet

- CW - 03 General Notes (Sheet 01 of 02)Document1 pageCW - 03 General Notes (Sheet 01 of 02)Hurriyat AliNo ratings yet

- General Concrete Slab Concrete Hollow Block Structural SteelDocument1 pageGeneral Concrete Slab Concrete Hollow Block Structural Steelparkrocky0No ratings yet

- Surat Metro General Arrangment DrawingsDocument5 pagesSurat Metro General Arrangment Drawingsdebapriyo50% (2)

- Polytechnic University of The Philippines Santa Maria BulacanDocument1 pagePolytechnic University of The Philippines Santa Maria BulacanCharleneMendozaEspirituNo ratings yet

- General Construction Notes:: Two Story Residential Building Jerg Sunogan S-1Document6 pagesGeneral Construction Notes:: Two Story Residential Building Jerg Sunogan S-1clemennikki29No ratings yet

- 2 Structural DrawingsDocument7 pages2 Structural DrawingsRA LapitanNo ratings yet

- J0647-S001 - General NotesDocument1 pageJ0647-S001 - General NotesEmon Ray100% (1)

- J1273-S001-General NotesDocument1 pageJ1273-S001-General Notesroy jackNo ratings yet

- 2021-12-1 - 1605 QA Review SetDocument12 pages2021-12-1 - 1605 QA Review SetDung AnhNo ratings yet

- AISC Shapes 1947Document31 pagesAISC Shapes 1947salaverriaNo ratings yet

- Typical Truss Detail Construction Notes S-5: Not To Scale Not To Scale Sheet Content: M G Tambalque Design & ConstructionDocument1 pageTypical Truss Detail Construction Notes S-5: Not To Scale Not To Scale Sheet Content: M G Tambalque Design & ConstructionCedrixe MadridNo ratings yet

- NoteDocument1 pageNotePom tancoNo ratings yet

- J1078-S001-General NotesDocument1 pageJ1078-S001-General Notesroy jackNo ratings yet

- D8834-Ga-Tk101 10-Sheet Tank Ga's (Signed)Document7 pagesD8834-Ga-Tk101 10-Sheet Tank Ga's (Signed)Santheep KumarNo ratings yet

- J0535-S001 - General Notes PDFDocument1 pageJ0535-S001 - General Notes PDFSaiful IslamNo ratings yet

- Schedule of Drawings:: Drawing Drawing Title NODocument4 pagesSchedule of Drawings:: Drawing Drawing Title NOma.shaheNo ratings yet

- S 001Document1 pageS 001Rashed SiddiqiNo ratings yet

- Structural Notes: Virginia Department of TransportationDocument26 pagesStructural Notes: Virginia Department of TransportationRal GLNo ratings yet

- General Note SampleDocument13 pagesGeneral Note SampleShyam AwalNo ratings yet

- General NotesDocument1 pageGeneral NotesWee RenNo ratings yet

- Design of 33 SQM HousingDocument1 pageDesign of 33 SQM HousingDJNo ratings yet

- S0-04 - General NotesDocument1 pageS0-04 - General NotesJason toraldeNo ratings yet

- Proposed 2 Storey Warehouse Structure Steel Design Project:: Group MemberDocument13 pagesProposed 2 Storey Warehouse Structure Steel Design Project:: Group MemberDominic Robiso DatuinNo ratings yet

- Beam-Column Calculation For RetrofittingDocument7 pagesBeam-Column Calculation For Retrofittingsimeon james villacrusisNo ratings yet

- Cubao CFRP Estimate v2Document12 pagesCubao CFRP Estimate v2simeon james villacrusisNo ratings yet

- Dar - Feb.8,2023Document16 pagesDar - Feb.8,2023simeon james villacrusisNo ratings yet

- SCCI. MOB (ADMIN) - Feb.20,2023Document13 pagesSCCI. MOB (ADMIN) - Feb.20,2023simeon james villacrusisNo ratings yet

- 0001 Mdi For 3RD FLR Z1-B 1Document1 page0001 Mdi For 3RD FLR Z1-B 1simeon james villacrusisNo ratings yet

- SCCI. MOB (ADMIN) - Feb.13,2023-EditedDocument13 pagesSCCI. MOB (ADMIN) - Feb.13,2023-Editedsimeon james villacrusisNo ratings yet

- Utility Change OrderDocument6 pagesUtility Change Ordersimeon james villacrusisNo ratings yet

- Precast 9th FLDocument1 pagePrecast 9th FLsimeon james villacrusisNo ratings yet

- (Z1-B 6TH FLR) BDocument1 page(Z1-B 6TH FLR) Bsimeon james villacrusisNo ratings yet

- Up 001Document39 pagesUp 001simeon james villacrusisNo ratings yet

- Material Delivery Inspection: Type of WorkDocument1 pageMaterial Delivery Inspection: Type of Worksimeon james villacrusisNo ratings yet

- Material Delivery Inspection: Type of WorkDocument1 pageMaterial Delivery Inspection: Type of Worksimeon james villacrusisNo ratings yet

- Two Way Slab DesignDocument1 pageTwo Way Slab Designsimeon james villacrusisNo ratings yet

- 032322.solaric Proposal 133kWP - Phil Bright Corp.Document2 pages032322.solaric Proposal 133kWP - Phil Bright Corp.simeon james villacrusisNo ratings yet

- CHT2-CC-22 - Warehouse 2 Precast FabricationDocument32 pagesCHT2-CC-22 - Warehouse 2 Precast Fabricationsimeon james villacrusisNo ratings yet

- Big Ass Fan QuotationDocument2 pagesBig Ass Fan Quotationsimeon james villacrusisNo ratings yet

- 6Document1 page6simeon james villacrusisNo ratings yet

- 1.0 Greenheat Corp - Cost Roposal (03162022)Document4 pages1.0 Greenheat Corp - Cost Roposal (03162022)simeon james villacrusisNo ratings yet

- Engineering Studies Report - Yr12 2018Document12 pagesEngineering Studies Report - Yr12 2018Three Went DownNo ratings yet

- Fy Tos Space FramesDocument11 pagesFy Tos Space FramesKomal GuptaNo ratings yet

- Campus Map GMUDocument1 pageCampus Map GMUcloudman81No ratings yet

- Dosti Greater Thane Kalher Project Bhiwandi Phase 1 2 BHKDocument17 pagesDosti Greater Thane Kalher Project Bhiwandi Phase 1 2 BHKtbcsonaliNo ratings yet

- Denah RafterDocument1 pageDenah RafterYusuf KhoirNo ratings yet

- SHD ACT PMC DDR 009 R0 Design Development ReportDocument8 pagesSHD ACT PMC DDR 009 R0 Design Development ReportHamayet RaselNo ratings yet

- BW - P17a - RMM - IFC - FPS - RF - R00 - Shoring Pile ReinforcementDocument1 pageBW - P17a - RMM - IFC - FPS - RF - R00 - Shoring Pile ReinforcementAleksandar MilutinovicNo ratings yet

- Adp Fsa Heater InstallDocument20 pagesAdp Fsa Heater Installgroomerz6612No ratings yet

- 00 General Permit SetDocument9 pages00 General Permit SetFrancesco Cristofano1No ratings yet

- Proposed Expansion of Crumb Tower: Mondelez International-Sricity-Nellore-ApDocument2 pagesProposed Expansion of Crumb Tower: Mondelez International-Sricity-Nellore-ApMvv SatyanarayanaNo ratings yet

- PRELIMDocument11 pagesPRELIMJonabel OsioNo ratings yet

- Ukqa 2032Document9 pagesUkqa 2032Mohamad IkhwanNo ratings yet

- Corbin Russwin ED5200S Series M107 Option TemplateDocument1 pageCorbin Russwin ED5200S Series M107 Option TemplateAlan VillalpandoNo ratings yet

- ArchitectureDesign 2015-05Document126 pagesArchitectureDesign 2015-05cazacenco_alexandru100% (3)

- Case Study - ChecklistDocument4 pagesCase Study - Checklistsafiulla syedNo ratings yet

- Experimental and Theoretical Studies On GFRG Panels Have Been Carried Out at IIT MadrasDocument21 pagesExperimental and Theoretical Studies On GFRG Panels Have Been Carried Out at IIT MadrasTeZa GoudNo ratings yet

- Material Approximate Cost EstimateDocument1 pageMaterial Approximate Cost EstimateKurt Laurhon CabahugNo ratings yet

- Measurement of Concrete - Formwork in Ground BeamsDocument1 pageMeasurement of Concrete - Formwork in Ground BeamsTham CherryNo ratings yet

- 3000 (Est .) SF T 300 (Est.) 460: Only Bathroom Fittings and Fixtures To Be Supplied by ClientDocument5 pages3000 (Est .) SF T 300 (Est.) 460: Only Bathroom Fittings and Fixtures To Be Supplied by ClientPadmaja DasNo ratings yet

- Egger Stammhaus: We Always Knew More Was Possible. Now We Have The ProofDocument20 pagesEgger Stammhaus: We Always Knew More Was Possible. Now We Have The Proofyuri roseroNo ratings yet

- Module 8A - Metal ReinforcementDocument9 pagesModule 8A - Metal ReinforcementGabriel RamosNo ratings yet

- Apartment - Final Case - 40Document1 pageApartment - Final Case - 40alexanderNo ratings yet

- Construction of Patenga Container Terminal Wharf Jetty Owner: 34 Engineer Construction Brigade Constractor: CRBC Eel ConsortiumDocument2 pagesConstruction of Patenga Container Terminal Wharf Jetty Owner: 34 Engineer Construction Brigade Constractor: CRBC Eel ConsortiumEngr. MahmudNo ratings yet

- Pre Romanesque ArtDocument30 pagesPre Romanesque ArtAlberto AyucobNo ratings yet

- Identify and Interpret Drawing and PlansdocDocument55 pagesIdentify and Interpret Drawing and PlansdocAnonymous kEIhEuRNo ratings yet

- Embassy Grove Ready To Move Residential Project in BangaloreDocument26 pagesEmbassy Grove Ready To Move Residential Project in BangaloreElan The MarkNo ratings yet

- National Building Code and Guidelines For Residential BuildingsDocument11 pagesNational Building Code and Guidelines For Residential BuildingsRamavath BharathNo ratings yet

- Real Estate Weekly - Jan. 14, 2010Document28 pagesReal Estate Weekly - Jan. 14, 2010Real Estate Weekly100% (1)

- DomesDocument12 pagesDomesVidhi ParekhNo ratings yet