Professional Documents

Culture Documents

UltraGas+ (125-1150) + Technical+ INM-en+ 2017

UltraGas+ (125-1150) + Technical+ INM-en+ 2017

Uploaded by

Raluca OlaruOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UltraGas+ (125-1150) + Technical+ INM-en+ 2017

UltraGas+ (125-1150) + Technical+ INM-en+ 2017

Uploaded by

Raluca OlaruCopyright:

Available Formats

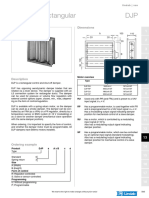

Hoval UltraGas® (125-1150)

Floor-standing gas condensing boiler

■■Description

Hoval UltraGas® (125-1150)

Floor-standing gas condensing boiler

• Floor-standing gas condensing boiler, com-

bustion chamber made of stainless steel

• Maximal flue gas condensation through tube

heat exchanger aluFer® stainless steel,

flue gas side: aluminium Model range

water side: stainless steel UltraGas® Output range

• Thermal insulation with mineral wool mat at 40/30 °C

• Water pressure sensor: type kW

-- Fulfils the function of a minimum and

maximum pressure limiter (125) 28-123

-- Replacement for the water shortage (150) 28-150

• Water pressure sensor (minimal and maxi- (200) 44-200

mal limiter integrated) (250) 49-250

• Flue gas temperature sensor with flue gas (300) 57-300

limiter function (350) 58-350

• Pre-mix burner (400) 97-400

-- with fan and venturi (450) 97-450

-- modulating operation (500) 97-500

-- automatic ignition (575) 136-575

-- ionisation guard (650) 136-650

-- gas pressure monitor (720) 142-720

• Gas boiler fully cased with steel plates, (850) 166-850

red powder-coated (1000) 224-1000 Permissions boilers

• Heating connections incl. counter flanges, (1150) 233-1150

screws and seals backwards for: UltraGas® (125-1150)

H (720) 142-720

-- flow CE product ID No.: CE-0085AQ0620

H (1000) 224-1000

-- return - high temperature

-- return - low temperature

• UltraGas® (400-1150):

with integrated gas pipe compensator Options for TopTronic® E controller Optional

• TopTronic® E controller installed • Can be expanded by max. 1 module expan- • Transport in individual pieces and welding

• Possibility of connecting an external gas sion: on site (delivery time approx. 6 weeks)

solenoid valve with error output -- module expansion heating circuit or • For liquefied gas

-- module expansion heat accounting or -- propane up to 1000 kW

-- module expansion universal • With or without neutralisation

TopTronic® E controller • Can be networked with a total of up to • Direct combustion air connection

16 controller modules: • Free-standing calorifier see Calorifiers.

Control panel -- heating circuit/hot water module • High-pressure version UltraGas® H

• Colour touchscreen 4.3 inch -- solar module (720,1000) with operating pressure 8 bar

• Heat generator blocking switch for interrupt- -- buffer module (delivery time approx. 8 weeks)

ing operation -- measuring module

• Fault signalling lamp Delivery

Number of modules that can be additionally • Boiler, casing and insulation separately

TopTronic® E control module installed in the heat generator: packed and delivered

• Simple, intuitive operating concept UltraGas® (125-300)

• Display of the most important operating -- 1 module expansion and 1 controller module or On-site

statuses -- 2 controller modules • Mounting of insulation,

• Configurable start screen casing and control panel

• Operating mode selection UltraGas® (350-500) • Mounting of boiler feet

• Configurable day and week programmes -- 1 module expansion and 2 controller modules

• Operation of all connected Hoval CAN bus or

modules -- 1 controller module and 2 module expansions or

• Commissioning wizard -- 3 controller modules

• Service and maintenance function

• Fault message management UltraGas® (575-1150)

• Analysis function -- 4 controller modules or module expansions

• Weather display (with online option)

• Adaptation of the heating strategy based on Note

the weather forecast (with online option) Max. 1 module expansion can be connected to

the basic module heat generator (TTE-WEZ)!

TopTronic® E basic module heat generator

(TTE-WEZ)

• Control functions integrated for The supplementary plug set must be

-- 1 heating/cooling circuit with mixer ordered in order to use expanded controller

-- 1 heating/cooling circuit without mixer functions.

-- 1 hot water loading circuit

-- bivalent and cascade management

• Outdoor sensor Further information about the TopTronic® E

• Immersion sensor (calorifier sensor) see “Controls”

• Contact sensor (flow temperature sensor)

• Rast-5 basic plug set

Subject to modifications, 1.4.2017 201

Hoval UltraGas® (125-1150)

■■Part No.

Floor-standing gas condensing boiler Part No.

Hoval UltraGas®

Floor-standing gas condensing boiler with built-

in Hoval TopTronic® E control

Control functions integrated for

-- 1 heating circuit with mixer

-- 1 heating circuit without mixer

-- 1 hot water loading circuit

-- bivalent and cascade management

• Can be optionally expanded by max.

1 module expansion:

-- module expansion heating circuit or

-- module expansion heat accounting or

-- module expansion universal

• Can be optionally networked with a

total of up to 16 controller modules

(incl. solar module)

Boiler made of steel with TopTronic® E control,

combustion chamber made of stainless steel.

Secondary heating surfaces made of aluFer®

stainless steel composite pipe. Premix burner

with blower. Modulating burner.

Delivery

Boiler, casing and thermal insulation separately

packed

Floor-standing gas condensing boiler with

TopTronic® E

Output range

UltraGas® 40/30 °C Working pressure

type kW 1 bar

(125) 28-125 5 7011 992

(150) 28-150 5 7011 993

(200) 44-200 5 7011 994

(250) 49-250 5 7011 995

(300) 57-300 5 7011 996

(350) 58-350 6 7011 997

(400) 97-400 6 7011 998

(450) 97-450 6 7011 999

(500) 97-500 6 7012 000

(575) 136-575 6 7012 001

(650) 136-650 6 7012 002

(720) 142-720 6 7012 003

(850) 166-850 6 7012 004

(1000) 224-1000 6 7012 005

(1150) 233-1150 6 7015 789

1

kW = modulation range

UltraGas® PGS

(execution for installation on site)

Delivery time approx. 6 weeks

Output range

UltraGas® at 40/30 °C Working pressure

type kW bar

(200) PGS 44-200 5 7012 006

(250) PGS 49-250 5 7012 007

(300) PGS 57-300 5 7012 008

(350) PGS 58-350 6 7012 009

(400) PGS 97-400 6 7012 010

(450) PGS 97-450 6 7012 011

(500) PGS 97-500 6 7012 012

(575) PGS 136-575 6 7012 013

(650) PGS 136-650 6 7016 225

(720) PGS 142-720 6 7016 226

202 Subject to modifications, 1.4.2017

Hoval UltraGas® (125-1150)

■■Part No.

Floor-standing gas condensing boiler Part No.

Hoval UltraGas®

(delivery in separate parts)

Floor-standing gas condensing boiler with built-in

Hoval TopTronic® E control for delivery in sepa-

rate parts. Assembled on-site by the installer.

UltraGas® Output Operating

type at 40/30 °C pressure

kW 1 bar

(125) 28-125 5 7013 629

(150) 28-150 5 7013 630

(200) 44-200 5 7013 631

(250) 49-250 5 7013 632

(300) 57-300 5 7013 633

(350) 58-350 6 7013 634

(400) 97-400 6 7013 635

(450) 97-450 6 7013 636

(500) 97-500 6 7013 637

(575) 136-575 6 7013 638

(650) 136-650 6 7013 639

(720) 142-720 6 7013 640

(850) 166-850 6 7013 641

(1000) 224-1000 6 7013 642

(1150) 233-1150 6 7015 790

1

kW = modulation range

Floor-standing gas condensing boiler

Hoval UltraGas®

(high-pressure design)

Delivery time approx. 8 weeks

Floor-standing gas condensing boiler in high-

pressure design (operating pressure 8 bar)

UltraGas® Output Operating

type at 40/30 °C pressure

kW 1 bar

H (720) 142-720 8 7013 657

H (1000) 224-1000 8 7013 669

1

kW = modulation range

Modification set for propane 6015 473

for UltraGas® (400-500)

UltraGas® (800D-1000D)

Output range see technical data.

Modification set for propane 6015 474

for UltraGas® (575-720), H (720)

UltraGas® (1150D-1440D)

Output range see technical data.

No conversion kit is required for boiler

types UltraGas® (125-350) and (850-1000).

Conversion must be performed in ac-

cordance with the instructions included

with the delivery.

Subject to modifications, 1.4.2017 203

Hoval UltraGas® (125-1150)

■■Part No.

Accessories Part No.

Gas filter

with measurement nozzle before and behind

the filter inset (diameter: 9 mm)

Pore width of the filter inset < 50 µm

Max. pressure difference 10 mbar

Max. inlet pressure 100 mbar

Type Connection

70612/6B Rp ¾″ 2007 995

70602/6B Rp 1″ 2007 996

70604/6B Rp 1¼″ 2054 495

70603/6B Rp 1½″ 2007 997

70631/6B Rp 2″ 2007 998

Valve testing system

for UltraGas® (125-1150),

UltraGas® (250D-2300D)

Automatic, compact testing system for testing

the leakage of the gas valve before each burn-

er start with ready-to-connect wiring. Suitable

for all gas qualities for which the UltraGas® is

permitted.

UltraGas® (125-350) 6039 964

UltraGas® (400-720) 6039 965

UltraGas® (850,1150) 6039 966

204 Subject to modifications, 1.4.2017

Hoval UltraGas® (125-1150)

■■Part No.

TopTronic® E module expansions Part No.

for TopTronic® E basic module heat generator

TopTronic® E module expansion heating 6034 576

circuit TTE-FE HK

Expansion to the inputs and outputs of the

basic module heat generator or the heating

circuit/domestic hot water module for imple-

menting the following functions:

-- 1 heating circuit without mixer or

-- 1 heating circuit with mixer

incl. fitting accessories

1x contact sensor ALF/2P/4/T L = 4.0 m

+ OR

ODER

Can be installed in:

Boiler control, wall housing, control panel

Note

The supplementary plug set may have to be

ordered to implement functions differing from

the standard!

TopTronic® E module expansion heating 6037 062

circuit incl. energy balancing TTE-FE HK-

EBZ

Expansion to the inputs and outputs of the

basic module heat generator or the heating

circuit/domestic hot water module for imple-

menting the following functions:

-- 1 heating/cooling circuit w/o mixer or

-- 1 heating/cooling circuit with mixer

in each case incl. energy balancing

incl. fitting accessories

3x contact sensor ALF/2P/4/T L = 4.0 m

Can be installed in:

Boiler control, wall housing, control panel

Note

Suitable flow rate sensors (pulse sensors)

must be provided on site.

TopTronic® E module expansion Universal 6034 575

TTE-FE UNI

Expansion to the inputs and outputs of a

controller module (basic module heat genera-

tor, heating circuit/domestic hot water module,

solar module, buffer module) for implementing

various functions

incl. fitting accessories

Can be installed in:

Boiler control, wall housing, control panel

Further information

see “Controls” - “Hoval TopTronic® E module

expansions” chapter

Note

Refer to the Hoval System Technology

to find which functions and hydraulic arrange-

ments can be implemented.

Subject to modifications, 1.4.2017 205

Hoval UltraGas® (125-1150)

■■Part No.

Accessories for TopTronic® E Part No.

Supplementary plug set

for basic module heat generator (TTE-WEZ) 6034 499

for controller modules and module expansion TTE-FE 6034 503

HK

TopTronic® E controller modules

TTE-HK/WW TopTronic® E heating circuit/ 6034 571

hot water module

TTE-SOL TopTronic® E solar module 6037 058

TTE-PS TopTronic® E buffer module 6037 057

TTE-MWA TopTronic® E measuring module 6034 574

TopTronic® E room control modules

TTE-RBM TopTronic® E room control modules

easy white 6037 071

comfort white 6037 069

comfort black 6037 070

Enhanced language package TopTronic® E 6039 253

one SD card required per control module

Consisting of the following languages:

HU, CS, SK, RO, PL, TR, ES, HR, SR, PT,

NL, DA, JA

TopTronic® E remote connection

TTE-GW TopTronic® E online LAN 6037 079

TTE-GW TopTronic® E online WLAN 6037 078

SMS remote control unit 6018 867

System component SMS remote 6022 797

control unit

TopTronic® E interface modules

GLT module 0-10 V 6034 578

Gateway module Modbus TCP/ 6034 579

RS485

Gateway module KNX 6034 581

TopTronic® E wall casing

WG-190 Wall casing small 6035 563

WG-360 Wall casing medium 6035 564

WG-360 BM Wall casing medium with 6035 565

control module cut-out

WG-510 Wall casing large 6035 566

WG-510 BM Wall casing large with 6038 533

control module cut-out

TopTronic® E sensors

AF/2P/K Outdoor sensor 2055 889

TF/2P/5/6T Immersion sensor, L = 5.0 m 2055 888

ALF/2P/4/T Contact sensor, L = 4.0 m 2056 775

TF/1.1P/2.5S/6T Collector sensor, L = 2.5 m 2056 776

System housing

System housing 182 mm 6038 551

System housing 254 mm 6038 552

Bivalent switch 2061 826

Further information

see “Controls”

206 Subject to modifications, 1.4.2017

Hoval UltraGas® (125-1150)

■■Part No.

Part No.

Flow temperature switch

for under floor heating (1 guard per heating

circuit) 15-95 °C, differential gap 6 K, capillary

tube max. 700 mm, setting (visible from the

outside) inside the housing cover.

Clamp-on thermostat RAK-TW1000.S 242 902

Thermostat with strap, without cable and plug

Set clamp-on thermostat RAK-TW1000.S 6033 745

Thermostat with strap, with cable (4 m) and

plug

Immersion thermostat RAK-TW1000.S SB 150 6010 082

Thermostat with pocket ½″ - depth of immer-

sion 150 mm, brass nickel-plated

Safety set

Complete with safety valve (3 bar),

Pressure gauge and autom. aspirator with

shut-off valve. Connection inner thread

For UltraGas® (125-200) 6018 709

DN 25 - Rp 1″ to 200 kW

For UltraGas® (250-350) 6018 710

DN32 - Rp 1¼″ to 350 kW

Automatic quick release air vent ½″ 2002 582

with cut-off valve

Accessory for sludge separator

Assembly tube for flow and return

for assembly on flow resp. high and low tem-

perature return of the Hoval UltraGas® boiler.

With screws and nuts for connection of

- an additional safety temperature limiter and

a maximum pressure limiter on the flow

and

- an expansion tank on the return

Assembly tube flow Suitable for

Dimension UltraGas® Connection

DN 65 (125-300) flow 6032 993

DN 65 (125-300) return 6023 108

DN 100 (350-500) flow 6023 109

DN 100 (350-500) return 6023 110

DN 125 (575-1150) flow 6023 111

DN 125 (575-1150) return 6023 112

Assembly tube return

Further information see “Dimensions”

Fuse set 6025 358

Compatible with armature pipe for

meeting safety requirements

of EN 12828 > 300 kW (single boiler)

and SWKI 93-1 > 70 kW.

Consisting of:

- adjustable maximum pressure limiter

incl. ball valve

- safety temperature limiter

(RAK-ST.131)

Subject to modifications, 1.4.2017 207

Hoval UltraGas® (125-1150)

■■Part No.

Accessories Part No.

Connection for direct combustion air inlet

Cannot be combined with motorised

air intake suction flap

UltraGas® (125,150) 6018 903

UltraGas® (200-300) 6018 904

UltraGas® (350) 6018 905

UltraGas® (400-500) 6018 906

UltraGas® (575-720) 6012 476

UltraGas® (850,1150) 6019 728

Recommendation:

If the air inlet at the facade is near a noise sen-

sitive place (window of bedroom, terrace etc.),

we recommend to use a sound absorber at the

direct combustion air inlet.

Connection for direct combustion air inlet

Can only be used in combination with a mo-

torised air intake suction flap (must be ordered

separately). Can also be used for cascading

boiler systems with a common flue gas line.

Complete with cabling.

UltraGas® (125,150) 6025 113

UltraGas® (200-300) 6025 114

UltraGas® (350) 6025 115

UltraGas® (400-500) 6025 104

UltraGas® (575-720) 6025 063

UltraGas® (850,1150) 6025 094

Motorised air intake suction flap DN 110 6015 196

for UltraGas® (125-350)

For cascading boiler systems with a

common flue gas line.

Complete with cabling

Motorised air intake suction flap DN 180 6015 197

for UltraGas® (400-1150)

For cascading boiler systems with a

common flue gas line.

Complete with cabling

Hydraulic shut-off gate PN 16

to be installed directly on flow and/or return.

As option when no flow/return set has been

ordered. Complete with cabling.

UltraGas® (125-300) DN 65 6002 660

UltraGas® (350-500) DN 100 6042 055

also suitable for high-pressure version

UltraGas® (575-1150) DN 125 6037 866

also suitable for high-pressure version

Gas pipe compensator 1″ 6034 556

for UltraGas® (125,150) and

UltraGas® (250D,300D)

for compensating for connection

tolerances in the gas pipe

Gas pipe compensator 1½″ 6034 557

for UltraGas® (200-350) and

UltraGas® (400D-700D)

for compensating for connection

tolerances in the gas pipe

208 Subject to modifications, 1.4.2017

Hoval UltraGas® (125-1150)

■■Part No.

Condensate drainage Part No.

to UltraGas® (125-1150)

Placed under the boiler

Condensate box KB 22 6033 767

for UltraGas® (125-1150), (250D-2300D),

UltraOil® (65-300), (320D-600D)

For condensate drainage into higher

situated drain pipe with delivery pump.

Max. delivery height 3.5 m, from

1200 kW two delivery pumps necessary.

Delivery rate 120 l/h

incl. liquid level switch, silicone hose

9/13 mm, 4 m long, electrical cable

1.5 m with plug

Use one box per boiler.

Neutralisation box KB 23 6001 917

for UltraGas® (125-1150), (250D-2300D),

UltraOil® (65-300), (320D-600D)

Condensate drainage into lower situated

drain pipe without condensate

delivery pump

with neutralisation

12 kg neutralisation granulate

Placed under the boiler

Use one box per boiler.

Neutralisation box KB 24 6033 764

for UltraGas® (125-1150), (250D-2300D),

UltraOil® (65-300), (320D-600D)

for transporting condensation water into

a higher lying drainage duct,

max. delivery height 3.5 m, from

1200 kW two delivery pumps necessary.

Delivery rate 120 l/h

incl. liquid level switch, silicone hose

9/13 mm, 4 m long, electrical cable

1.5 m with plug

12 kg granulate

Use one box per boiler.

Condensate pump 6034 771

for transporting condensation water

into a higher drainage duct.

Including connection line,

completely wired,

cable and plug for connection

to the boiler controller

max. transport height: 4.3 m

Delivery rate up to 294 l/h

combinable with neutralisation box

can be mounted in boiler socket

Neutralisation granulate 2028 906

for neutralisation box

Refill set volume 3 kg

Life time of one filling:

approx. 2-4 years; depending on amount

of condensate

Subject to modifications, 1.4.2017 209

Hoval UltraGas® (125-1150)

■■Part No.

Service Part No.

Commissioning

Commissioning by works service or Hoval

trained authorised serviceman/company is

condition for warranty.

For commissioning and other services

please contact your Hoval sales office.

210 Subject to modifications, 1.4.2017

Hoval UltraGas® (125-1150)

■■Technical data

Type (125) (150) (200) (250) (300)

• Nominal output 80/60 °C with natural gas 1 kW 25-114 25-139 39-185 44-231 51-278

• Nominal output 40/30 °C with natural gas 1 kW 28-125 28-150 44-200 49-250 57-300

• Nominal output 80/60 °C with propane 2 kW 31-113 35-138 63-185 78-230 80-278

• Nominal output 40/30 °C with propane 2 kW 34-125 39-150 70-200 87-250 91-300

• Nominal load with natural gas 1 kW 26-116 26-141 40-188 45-235 52-283

• Nominal load with propane 2 kW 32-116 36-141 65-190 80-235 84-283

• Working pressure heating maximum/minimum bar 5.0/1.0 5.0/1.0 5.0/1.0 5.0/1.0 5.0/1.0

• Test pressure bar 7.5 7.5 7.5 7.5 7.5

• Working temperature maximum °C 90 90 90 90 90

• Boiler water content l 206 194 359 341 318

• Minimum water flow l/h 0 0 0 0 0

• Boiler weight (without water content, incl. casing) kg 434 458 641 674 726

• Boiler efficiency at full load at 80/60 °C %

97.9/88.2 97.8/88.1 97.9/88.2 97.9/88.2 98.0/88.3

(related to net calorific value NCV / gross calorific value GCV)

• Boiler efficiency at partial load 30% (according to EN 303)

% 108.1/97.4 108.0/97.3 108.1/97.4 108.1/97.4 108.0/97.3

(related to net calorific value NCV / gross calorific value GCV)

• Standard efficiency (according to DIN 4702 part 8) 40/30 °C % 109.6/98.7 109.6/98.7 109.7/98.8 109.7/98.8 109.7/98.8

(related to net calorific value NCV / gross calorific value GCV) 75/60 °C % 107.1/96.5 107.1/96.5 107.2/96.6 107.2/96.6 107.2/96.6

• Heat loss rate at 70 °C Watt 480 480 530 530 530

• Standard emission rate Nitrogen oxides mg/kWh 26 29 39 38 38

• Content of CO2 in the flue gas maximum/minimum output % 9.0/8.8 9.0/8.8 9.0/8.8 9.0/8.8 9.0/8.8

• Dimensions see table of dimensions

• Connections Flow/return DN DN 65/PN 6DN 65/PN 6DN 65/PN 6DN 65/PN 6 DN 65/PN 6

Gas inches Rp 1″ Rp 1″ Rp 1½″ Rp 1½″ Rp 1½″

Flue gas Ø inside mm 155 155 252 252 252

• Gas flow pressure minimum/maximum

Natural gas E/LL mbar 17.4-80 17.4-80 17.4-80 17.4-80 17.4-80

Propane mbar 37-57 37-57 37-57 37-57 37-57

• Gas connection value at 0 °C/1013 mbar:

Natural gas E (Wo = 15.0 kWh/m3) NCV = 9.97 h/m3 m3/h 11.6 14.1 18.8 23.5 28.3

Natural gas LL (Wo = 12.4 kWh/m3) NCV = 8.57 h/m3 m3/h 13.5 16.5 21.9 27.4 33.0

Propane 3 (NCV = 25.9 kWh/m3) m3/h 4.5 5.4 7.3 9.1 10.9

• Operation voltage V/Hz 230/50 230/50 230/50 230/50 230/50

• Control voltage V/Hz 24/50 24/50 24/50 24/50 24/50

• Minimum/maximum electrical power consumption Watt 44/168 44/247 44/143 44/224 46/345

• Stand-by Watt 12 12 12 12 12

• IP rating (integral protection) IP 20 20 20 20 20

• Sound power level

- Heating noise (EN 15036 part 1) (room air dependent) dB(A) 69 72 65 68 72

- Exhaust noise is radiated from the mouth (DIN 45635 part 47) dB(A) 65 67 61 64 66

• Sound pressure level heating noise (depending on install. conditions) 3 dB(A) 59 62 55 58 62

• Condensate quantity (natural gas) at 40/30 °C l/h 10.9 13.3 17.7 22.1 26.6

• pH value of the condensate approx. 4.2 approx. 4.2 approx. 4.2 approx. 4.2 approx. 4.2

• Flue gas system: requirements, values

Temperature class T120 T120 T120 T120 T120

Type of connection B23P, C53, C63

Volume flow rate combustion air Nm3/h 143 175 233 291 350

Flue gas mass flow kg/h 192 234 312 390 470

Flue gas temperature at nominal output and operation 80/60 °C °C 69 71 69 70 71

Flue gas temperature at nominal output and operation 40/30 °C °C 48 49 48 49 49

Volume flow rate combustion air Nm3/h 143 175 233 291 350

Feed pressure total at the combustion air/flue gas line 4 Pa 100 120 120 130 130

Maximum draught/depression at flue gas outlet Pa -50 -50 -50 -50 -50

1

Data related to NCV. The boiler series is tested for EE/H-settings. With a factory setting of the Wobbe coefficient of 15.0 kWh/m3 operation at a

Wobbe coefficient of 12.0 up to 15.7 kWh/m3 is possible without new settings.

2

Data related to NCV.

3

See also notes at “Engineering”.

4

Details for multi-boiler plants (cascade) with common flue gas line: see Hoval UltraGas® (250D-2000D).

• Boiler flow resistance see diagrams.

Subject to modifications, 1.4.2017 211

Hoval UltraGas® (125-1150)

■■Technical data

Type (350) (400) (450) (500) (575) (650)

• Nominal output 80/60 °C with natural gas 1 kW 51-324 87-371 87-417 87-463 122-533 122-603

• Nominal output 40/30 °C with natural gas 1 kW 58-350 97-400 97-450 97-500 136-575 136-650

• Nominal output 80/60 °C with propane 2 kW 95-320 139-370 139-410 139-455 169-524 169-592

• Nominal output 40/30 °C with propane 2 kW 109-350 154-400 154-450 154-500 185-575 185-650

• Nominal load with natural gas 1 kW 53-330 89-377 89-424 89-471 125-542 125-613

• Nominal load with propane 2 kW 100-330 144-377 144-424 144-471 175-542 175-613

• Working pressure heating maximum/minimum bar 6.0/1.0 6.0/1.0 6.0/1.0 6.0/1.0 6.0/1.0 6.0/1.0

• Test pressure bar 9.0 9.0 9.0 9.0 9.0 9.0

• Working temperature maximum °C 90 90 90 90 90 90

• Boiler water content l 428 411 387 375 549 529

• Minimum water flow l/h 0 0 0 0 0 0

• Boiler weight (without water content, incl. casing) kg 881 922 972 991 1277 1303

• Boiler efficiency at full load at 80/60 °C % 98.2/88.5 98.3/88.6 98.3/88.6 98.3/88.6 98.3/88.6 98.3/88.6

(related to net calorific value NCV/gross calorific value GCV)

• Boiler efficiency at partial load 30% (according to EN 303) % 108.0/97.3 108.1/97.4 108.0/97.3 108.0/97.3 108.1/97.4 108.0/97.3

(related to net calorific value NCV/gross calorific value GCV)

• Standard efficiency (accord. to DIN 4702 part 8) 40/30 °C % 109.8/98.9 109.8/98.9 109.8/98.9 109.8/98.9 109.9/99.0 109.9/99.0

(related to net cal. value NCV/gross cal. value GCV) 75/60 °C % 107.3/96.7 107.3/96.7 107.3/96.7 107.3/96.7 107.4/96.8 107.4/96.8

• Heat loss rate at 70 °C Watt 750 750 750 750 1000 1000

• Standard emission rate Nitrogen oxides mg/kWh 41 43 42 41 48 48

• Content of CO2 in the flue gas maximum/minimum output % 9.0/8.8 9.0/8.8 9,0/8.8 9.0/8.8 9.0/8.8 9.0/8.8

• Dimensions see table of dimensions

• Connections Flow/return DN DN 100/PN 6 DN 100/PN 6 DN 100/PN 6 DN 100/PN 6 DN 125/PN 6 DN 125/PN 6

Gas inches Rp 1½″ Rp 2″ Rp 2″ Rp 2″ Rp 2″ Rp 2″

Flue gas Ø inside mm 302 302 302 302 302 302

• Gas flow pressure minimum/maximum

Natural gas E/LL mbar 17.4-80 17.4-80 17.4-80 17.4-80 17.4-80 17.4-80

Propane mbar 37-57 37-57 37-57 37-57 37-57 37-57

• Gas connection value at 0 °C/1013 mbar:

Natural gas E (Wo = 15.0 kWh/m3) NCV = 9.97 h/m3 m3/h 32.6 37.7 42.4 47.1 54.2 61.3

Natural gas LL (Wo = 12.4 kWh/m3) NCV = 8.57 h/m3 m3/h 38.0 44 49.5 55.0 63.2 71.5

Propane 3 (NCV = 25.9 kWh/m3) m3/h 12.6 14.6 16.4 18.2 20.9 23.7

• Operation voltage V/Hz 230/50 230/50 230/50 230/50 230/50 230/50

• Control voltage V/Hz 24/50 24/50 24/50 24/50 24/50 24/50

• Minimum/maximum electrical power consumption Watt 49/330 60/445 60/582 60/745 62/720 62/1030

• Stand-by Watt 12 12 12 12 12 12

• IP rating (integral protection) IP 20 20 20 20 20 20

• Sound power level

- Heating noise (EN 15036 part 1) (room air dependent) dB(A) 74 71 73 75 72 75

- Exhaust noise is radiated from the mouth (DIN 45635 part 47) dB(A) 71 72 73 74 69 72

• Sound pressure level heating noise dB(A) 64 61 63 65 62 65

(depending on installation conditions) 3

• Condensate quantity (natural gas) at 40/30 °C l/h 30.6 35.4 39.9 44.3 50.9 57.6

• pH value of the condensate approx. 4.2 approx. 4.2 approx. 4.2 approx. 4.2 approx. 4.2 approx. 4.2

• Flue gas system: requirements, values

Temperature class T120 T120 T120 T120 T120 T120

Type of connection B23P, C53, C63

Volume flow rate combustion air Nm3/h 404 467 525 583 671 759

Flue gas mass flow kg/h 541 626 704 782 900 1018

Flue gas temperat. at nominal output and operation 80/60 °C °C 69 71 71 72 71 72

Flue gas temperat. at nominal output and operation 40/30 °C °C 46 48 47 49 47 49

Volume flow rate combustion air Nm3/h 404 467 525 583 671 759

Feed pressure total at the combustion air/flue gas line 4 Pa 130 130 130 130 130 130

Maximum draught/depression at flue gas outlet Pa -50 -50 -50 -50 -50 -50

1

Data related to NCV. The boiler series is tested for EE/H-settings. With a factory setting of the Wobbe coefficient

of 15.0 kWh/m3 operation at a Wobbe coefficient of 12.0 up to 15.7 kWh/m3 is possible without new settings.

2

Data related to NCV.

3

See also notes at “Engineering”.

4

Details for multi-boiler plants (cascade) with common flue gas line: see Hoval UltraGas® (250D-2000D).

• Boiler flow resistance see diagrams.

212 Subject to modifications, 1.4.2017

Hoval UltraGas® (125-1150)

■■Technical data

Type (720) (850) (1000) (1150) H (720) H (1000)

• Nominal output 80/60 °C with natural gas 1 kW 127-665 148-788 199-927 208-1060 127-665 199-927

• Nominal output 40/30 °C with natural gas 1 kW 142-720 166-850 224-1000 233-1150 142-720 224-1000

• Nominal output 80/60 °C with propane 2 kW 169-655 235-789 269-927 - 169-655 269-927

• Nominal output 40/30 °C with propane 2 kW 185-720 257-851 293-1000 - 185-720 293-1000

• Nominal load with natural gas 1 kW 130-677 152-802 205-943 214-1080 130-677 205-943

• Nominal load with propane 2 kW 175-677 238-803 272-943 - 175-677 272-943

• Working pressure heating maximum/minimum bar 6.0/1.0 6.0/1.0 6.0/1.0 6.0/1.0 8.0/1.0 8.0/1.0

• Test pressure bar 9.0 9.0 9.0 9.0 12.0 12.0

• Working temperature maximum °C 90 90 90 90 90 90

• Boiler water content l 478 860 793 737 478 793

• Minimum water flow l/h 0 0 0 0 0 0

• Boiler weight (without water content. incl. casing) kg 1396 1850 1965 2023 1424 1962

• Boiler efficiency at full load at 80/60 °C % 98.3/88.6 98.3/88.6 98.3/88.6 98.3/88.6 98.3/88.6 98.3/88.6

(related to net calorific value NCV/gross calorific value GCV)

• Boiler efficiency at partial load 30% (according to EN 303) % 108.0/97.3 108.1/97.4 108.1/97.4 108.1/97.4 107.7/97.0 108.1/97.4

(related to net calorific value NCV/gross calorific value GCV)

• Standard efficiency (according to DIN 4702 part 8) 40/30 °C % 109.9/99.0 109.9/99.0 109.9/99.0 109.9/99.0 109.9/99.0 109.9/99.0

(related to net calorific value NCV/gross calorific value GCV) 75/60 °C % 107.4/96.8 107.4/96.8 107.4/96.8 107.4/96.8 107.4/96.8 107.4/96.8

• Heat loss rate at 70 °C Watt 1000 1200 1200 1200 1000 1200

• Standard emission rate Nitrogen oxides mg/kWh 48 35 35 38 48 35

• Content of CO2 in the flue gas maximum/minimum output % 9.0/8.8 9.0/8.8 9.0/8.8 9.0/8.8 9.0/8.8 9.0/8.8

• Dimensions see table of dimensions

DN 125/ DN 125/ DN 125/ DN 125 DN125/ DN 125

• Connections Flow/return DN

PN 6 PN 6 PN 6 PN6 PN16 PN6

Gas inches Rp 2″ Rp 2″ Rp 2″ Rp 2″ Rp 2″ Rp 2″

Flue gas Ø inside mm 302 402 402 402 302 402

• Gas flow pressure minimum/maximum

Natural gas E/LL mbar 17.4-80 17.4-60 17.4-60 17.4-60 17.4-80 17.4-60

Propane mbar 37-57 37-57 37-57 - 37-57 37-57

• Gas connection value at 0 °C/1013 mbar:

Natural gas E (Wo = 15.0 kWh/m3) NCV = 9.97 h/m3 m3/h 67.7 80.2 94.3 108.2 67.7 94.3

Natural gas LL (Wo = 12.4 kWh/m3) NCV = 8.57 h/m3 m3/h 79.0 93.6 110.0 126.2 79.0 110.0

Propane 3 (NCV = 25.9 kWh/m3) m3/h 26.1 31.0 36.4 - 26.1 36.4

1x230/50 1x230/50 1x230/50

• Operation voltage V/Hz 230/50 230/50 230/50

3x400/50 3x400/50 3x400/50

• Control voltage V/Hz 24/50 24/50 24/50 24/50 24/50 24/50

• Minimum/maximum electrical power consumption Watt 62/1150 51/1010 103/2420 103/2730 62/1150 103/2420

• Stand-by Watt 9 9 9 9 9 9

• IP rating (integral protection) IP 20 20 20 20 20 20

• Sound power level

- Heating noise (EN 15036 part 1) (room air dependent) dB(A) 77 77 82 - 77 82

- Exhaust noise is radiated from the mouth (DIN 45635 part 47) dB(A) 74 70 74 - 74 74

• Sound pressure level heating noise dB(A) 67 67 72 - 67 72

(depending on installation conditions) 3

• Condensate quantity (natural gas ) at 40/30 °C l/h 63.6 75.4 88.9 102.2 63.6 88.9

• pH value of the condensate approx. 4.2 approx. 4.2 approx. 4.2 approx. 4.2 approx. 4.2 approx. 4.2

• Flue gas system: requirements. values

Temperature class T120 T120 T120 T120 T120 T120

Type of connection B23P, C53, C63

Volume flow rate combustion air Nm3/h 838 992 1167 1342 838 1167

Flue gas mass flow kg/h 1124 1331 1565 1800 838 1167

Flue gas temperature at nominal output and operation 80/60 °C °C 71 69 69 71 1124 1565

Flue gas temperature at nominal output and operation 40/30 °C °C 46 49 49 50 71 69

Feed pressure total at the combustion air/flue gas line 4 Pa 130 130 130 130 130 130

Maximum draught/depression at flue gas outlet Pa -50 -50 -50 -50 -50 -50

1

Data related to NCV. The boiler series is tested for EE/H-settings. With a factory setting of the Wobbe coefficient

of 15.0 kWh/m3 operation at a Wobbe coefficient of 12.0 up to 15.7 kWh/m3 is possible without new settings.

2

Data related to NCV.

3

See also notes at “Engineering”.

4

Details v

• Boiler flow resistance see diagrams.

Subject to modifications, 1.4.2017 213

Hoval UltraGas® (125-1150)

■■Technical data

Flow resistance on the heating water side

Hoval UltraGas® (125, 150) Hoval UltraGas® (200-300)

25 60

mbar [mbar]

mbar [mbar]

20 50

40

15

Druckverlust

Druckverlust

30

10

20

5 10

0 0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 0 5 10 15 20 25 30

Volumenstrom

m3/h [m3/h] m3/h

Volumenstrom [m3/h]

Hoval UltraGas® (350-500) Hoval UltraGas® (575-720), UltraGas® H (720)

30 25

mbar [mbar]

mbar [mbar]

25 20

20 15

Druckverlust

Druckverlust

15 10

10 5

5 0

0 0 5 10 15 20 25 30 35 40 45 50 55 60 65

0 5 10 15 20 25 30 35 40 45 Volumenstrom

m3/h [m3/h]

m /h 3

Volumenstrom [m3/h]

Hoval UltraGas® (850-1150), UltraGas® H (1000)

60 m3/h = Throughput flow rate

mbar = Flow resistance

50

40

mbar

30

20

10

0

0 10 20 30 40 50 60 70 80 90 100

m3/h

214 Subject to modifications, 1.4.2017

Hoval UltraGas® (125-1150)

■■Dimensions

UltraGas® (125-1150)

(Dimensions in mm)

Note:

Minimal space see separate page

8 Flue gas connector left or right

9 Control panel

10 Condensate drain with

screw including syphon for plastic tube

11 Air inlet connector (option)

1 Flow heating 12 Boiler foot adjustable up to 80 mm

2 Low temperature return 13 Safety valve connection flow (option)

3 Gas connection 14 Safety valve connection return (option)

4 Safety flow 15 Expansion Rp 1″

5 High temperature return 16 Pressure limiter Rp ¾″

6 Electrical connection left or right 17 Safety temperature control Rp ½″

7 Draining (behind the front casing) 18 Cleaning opening left or right

Type A B C D D1 D2 E F G H I J K L M N O Q R

(125,150) 1823 633 1336 981 854 324 820 1565 1378 701 677 143 491 287 199 199 200 242 1633

(200-300) 1923 743 1684 1247 1204 321 930 1667 1428 718 710 155 498 287 280 200 186 368 1696

(350) 2070 923 1775 1268 1294 326 1110 1800 1438 808 630 160 528 284 345 205 205 345 1720

(400-500) 2070 923 1775 1268 1294 326 1110 1800 1438 808 630 160 528 284 345 205 205 -12 1829

(575-720) 2086 1103 1928 1438 1480 316 1290 1800 1442 834 608 202 554 284 367 367 110 86 1847

(850-1150) 2139 1363 2243 1703 1790 313 1550 1854 1494 858 636 204 578 294 417 417 218 198 1888

H (720) 2086 1103 1928 1438 1480 316 1290 1800 1442 834 608 202 554 284 367 367 110 86 1847

H (1000) 2139 1363 2243 1703 1790 313 1550 1854 1494 858 636 204 578 294 417 417 218 198 1888

Type S T U V W X Y Z 1,2,5 3 4 8 10 11

(125,150) 351 90 1632 107 207 473 195 138 DN 65/PN 6/4 holes Rp 1″ R 1½″ Ø 155/159 DN 25 Ø 122/125

(200-300) 371 100 1702 108 207 472 217 183 DN 65/PN 6/4 holes Rp 1½″ R 1½″ Ø 252/256 DN 25 Ø 197/200

(350) 435 100 1730 100 204 484 267 210 DN 100/PN 6/4 holes Rp 1½″ R 1½″ Ø 302/306 DN 25 Ø 197/200

(400-500) 447 100 1812 176 204 484 267 210 DN 100/PN 6/4 holes Rp 2″ R 1½″ Ø 302/306 DN 25 Ø 247/250

(575-720) 513 100 1818 176 204 530 357 218 DN 125/PN 6/8 holes Rp 2″ R 2″ Ø 302/306 DN 40 Ø 247/250

(850-1150) 624 100 1880 176 214 554 455 243 DN 125/PN 6/8 holes Rp 2″ R 2″ Ø 402/406 DN 40 Ø 247/250

H (720) 513 100 1818 176 204 530 357 218 DN 125/PN16/8 holes Rp 2″ R 2″ Ø302/306 DN 40 Ø247/250

H (1000) 624 100 1880 176 214 554 455 243 DN 125/PN16/8 holes Rp 2″ R 2″ Ø402/406 DN 40 Ø247/250

Subject to modifications, 1.4.2017 215

Hoval UltraGas® (125-1150)

■■Dimensions

Opening dimension UltraGas®

Boiler without casing and insulation

(Dimensions in mm)

UltraGas® Measurements for installation as individual parts

type A B C D E F G H I J K

(125,150) 1520 680 1072 980 1295 1380 1191 1040 140 680 236

(200-300) 1585 790 1422 1330 1355 1445 1260 1390 140 950 316

(350) 1610 970 1530 1420 1380 1450 1272 1480 160 970 377

(400-500) 1810 970 1530 1420 1380 1650 1272 1480 160 970 377

(575-720) 1810 1150 1720 1605 1400 1635 1316 1690 175 1150 408

(850-1150) 1885 1410 2027 1916 1483 1686 1375 2000 199 1410 458

H (720) 1810 1150 1720 1605 1400 1635 1316 1690 175 1150 408

H (1000) 1885 1410 2027 1916 1483 1686 1375 2000 199 1410 458

Weights for insertion in separate parts UltraGas®

(all measures in kg)

UltraGas® Weights for insertion in separate parts

type 1 base 2 heat exchanger 3 burner

(125,150) 47 250 38

(200) 73 395 54

(250) 73 430 54

(300) 73 475 54

(350) 113 550 70

(400) 113 585 70

(450) 113 630 70

(500) 113 650 70

(575) 143 900 94

(650) 143 935 94

(720) 143 1030 94

(850) 184 1320 138

(1000) 228 1430 138

(1150) 228 1488 138

H (720) 143 1130 94

H (1000) 228 1650 138

Required min. width of door and corridor to bring in the boiler

The following informations are minimal dimensions

B Boiler width

B L Max. length of boiler

K= xL T Door width

T K Corridor width

K

B Calculation example for the necessary corridor width

L T= xL Door width T = 1000

K

B 970

< 150 UltraGas® (400-500) K = x 1531 = corridor width ≥ 1486

1000

216 Subject to modifications, 1.4.2017

Hoval UltraGas® (125-1150)

■■Dimensions

Space requirements UltraGas® (125-1150)

(Dimensions in mm)

For swinging out the burner

this area must remain free

(see dimension table)

If the gas line is routed horizontally to

the left, the minimum distance D must be

observed.

UltraGas®

type A A minimal B C D H H minimal

(125,150) 180 1

802

820 1237 200 1823 1711 3

(200-300) 360 1 160 2 930 1584 200 1923 1811 3

(350-500) 200 1 100 2 1110 1679 200 2070 1958 3

(575-720) 200 1 100 2 1290 1843 0 2086 1984 3

(850-1150) 420 1 230 2 1550 2154 0 2139 2037 3

1

If room height is too small: reduction of dimension possible. See A minimal.

2

Attention! With A minimal the burner can not be swung out completely anymore! This makes cleaning more difficult!

3

Feet can be shortened, no base cladding possible. For details, see next page.

* The cleaning aperture must be easily accessible. As a result, a minimum distance of 500 mm

must be maintained on the cleaning opening side.

Subject to modifications, 1.4.2017 217

Hoval UltraGas® (125-1150)

■■Dimensions

UltraGas® with shortened boiler feet UltraGas®

(Dimensions in mm) type A

(125,150) 1723-1783

(200-300) 1823-1883

(350-500) 1970-2030

(575-720), H(720) 1986-2046

(850-1150), H(1000) 2039-2099

Cut off 120 mm

UltraGas® with masonry base and adjustable feet UltraGas®

type A

(125,150) 1711-1771

(200-300) 1811-1871

(350-500) 1958-2018

(575-720), H(720) 1984-2044

(850-1150), H(1000) 2037-2097

1 Neutralisation box

2 Condensate pump

3 Masonry base

4 Feet adjustable up to 20-80 mm

UltraGas® with masonry base without adjustable feet UltraGas®

type A

(125,150) 1721

(200-300) 1821

(350-500) 1968

(575-720), H(720) 1994

(850-1150), H(1000) 2047

Base plates and feeds

will not be refunded!

218 Subject to modifications, 1.4.2017

Hoval UltraGas® (125-1150)

■■Dimensions

Neutralisation unit for Hoval UltraGas® (125-1150)

(Dimensions in mm)

Neutralisation box type KB 23

Application

– Condensate drainage into lower situated drain pipe.

– With condensate neutralisation.

– Placed under or adjacent to the boiler

Execution

– Plastic condensate collector box with neutralisation unit

– 12 kg neutralisation granulate

– When installing under to boiler:

Fit boiler connection line to neutralisation box.

On site

– In case of installation adjacent to the boiler, fit connection pipes

between the boiler (siphon) and the neutralisation box.

– Drain pipe from the neutralisation box

1 Condensate inlet from the boiler

2 Outlet R ¾″

3 Condensate box with 12 kg granulate

Neutralisation box with pump

type KB 24

Application

– Condensate drainage into a higher situated drain pipe

– With condensate pump, delivery height 3.5 mm

– With condensate neutralisation, 12 kg granulate

– Placed under or adjacent to boiler

Execution

– Collector box with delivery pump and neutralisation unit

– 12 kg neutralisation granulate

– Pump delivery height max. 3.5 m (2 dm³/min)

– Silicone hose Ø 9/13 mm, length 4 m

– Electric cable length 1.5 m with plug for connection to the boiler

control panel if the installation is located under the boiler

– Plastic connection pipe Ø 25, boiler (siphon) to neutralisation

box if the installation is located under the boiler.

On site

– Drain pipe if the silicone hose is too short.

In the case of installation adjacent to boiler:

– Connection pipe between the boiler (siphon)

and the neutralisation box

– Electrical connection between the delivery pump and the

electrical control panel if the supply cable is too short.

Condensate box with pump

type KB 22

Application

– Condensate drainage into a higher situated drain pipe

– With condensate pump, delivery height 3.5 mm

– Placed under or adjacent to boiler 1 Condensate inlet from the boiler

2 Outlet from pump, silicon hose Ø 9/13 mm, length 4 m

Execution 3 Condensate box with 12 kg granulate (KB 24)

Type characteristics as KB 24, but without neutralisation granulate 4 Condensate pump

Subject to modifications, 1.4.2017 219

Hoval UltraGas® (125-1150)

■■Engineering

Standards and guidelines • Parts of the boiler/the calorifier which have Combustion air

The following standards and guidelines must contact with water are made of ferrous mate- The supply of combustion air must be guaran-

be complied with: rials and stainless steel. teed. There must be no possibility to close the

• On account of the danger of stress cracking air supply opening. For direct combustion air to

• Hoval technical information and installation corrosion in the parts made of stainless steel boiler (LAS system) mount the connection for

instructions the chloride, nitrate and sulfate contents of direct combustion air inlet.

• hydraulic and technical control regulations the heating water must not exceed 50 mg/l

of Hoval in total. The minimum free cross-section for the com-

• local building law • The pH value of the heating water should lie bustion air can be assumed simplified as fol-

• fire protection regulations between 8.3 and 9.5 after 6 to 12 weeks of lows: Considering nominal output!

• DVGW regulations heating operation.

• DIN EN 12828 • Room air-dependent operation:

Safety-relevant requirements Filling and replacement water: Minimum free cross-section of the opening

• DIN EN 12831 Heaters • For a plant using Hoval boilers untreated into the open: 150 cm² or twice 75 cm² and

Rules for the calculation of the heat require- domestic water is generally best suited as additionally 2 cm² necessary for each kW of

ments of buildings filling and replacement water. However, the output over 50 kW for vent into the open.

• VDI 2035 Protection against damage by cor- quality of the untreated domestic water must • Room air-independent operation with sepa-

rosion and boiler scale formation in heating at least fulfil the standard set in VDI 2035 or rate combustion air pipe to the boiler:

and service water installations be desalinated and/or be treated with inhibi 0.8 cm2 per 1 kW of output. The pressure

• VDE 0100 tors. The stipulations of EN 14868 must be drop in the combustion air pipe must be con-

• local fire brigade regulations observed. sidered for the calculation of the flue gas

• according to local regulations • In order to maintain a high level of boiler system.

efficiency and to avoid overheating of the

heating surfaces the values given in the

Water quality table should not be exceeded (dependent on Gas connection

Heating water: boiler performance ratings - for multi-boiler Commissioning

• The European Standard EN 14868 and the plants rating of smallest boiler applies - and • Start-up is to be carried out only by a spe-

Directive VDI 2035 must be observed. on the water content of the plant). cialist of Hoval and the gas supplier.

• Hoval boilers and calorifiers are designed • The total amount of filling and replacement • Burner setting values according to the instal-

for heating plants without significant oxygen water which is used throughout the total ser lation instructions.

intake (plant type I according to EN 14868). vice life of the boiler must not exceed three

• Plants with times the water capacity of the plant. Manual gas shut-off tap and gas filter

-- continuous oxygen intake (e.g. under- • If frost protection agent is being used, Immediately in front of the boiler a manual gas

floor heating systems without diffusion please contact the Hoval company to ask for shut-off device (tap) must be installed accord-

proof plastic piping) or the separate engineering sheet. ing to relevant regulations.

-- intermittent oxygen intake (e.g. where

frequent refilling is necessary)

must be equipped with separate circuits. Frost protection agent In the UltraGas® (400-1150) types, an ex-

• Treated heating water must be tested at • see separate engineering sheet ternal gas filter must be installed in the gas

least once yearly, according to the inhibitor “Use of frost protection agent”. supply line.

manufacturer’s instructions, more frequent Make sure that the gas line from the external

testing may be necessary. gas filter to the gas connection of the boiler

• A refilling is not necessary if the quality Heating room is cleaned.

of the heating water in existing installa- • Gas boilers cannot be positioned in rooms

tions (e.g. exchange of boiler) conforms to in which halogen compounds can occur and For the UltraGas® (125-350) types, it is nec-

VDI 2035. The Directive VDI 2035 applies into which combustion air can enter (e.g. essary to comply with the local regulations

equally to the replacement water. laundrettes, hairdressers). concerning the need for a gas filter.

• New and if applicable existing installations • Halogen compounds can be caused by

must be adequately cleaned and flushed cleaning and degreasing solutions, dissol-

before being recharged! The boiler may only vents, glue and bleaching lyes. Pay attention Type of gas

be filled after the heating system has been to the Procal leaflet, corrosion through • The boiler is only to be operated with the

flushed. Halogen compounds. type of gas stated on the rating plate.

• A gas pressure controller to reduce the boi

ler inlet pressure must be installed on site for

propane.

Table 1: Maximum filling quantity without/with demineralisation based on VDI 2035

Total hardness of the filling water up to... Gas pressure natural gas

Necessary flow pressure at the boiler inlet:

[mol/m ]

3 1

<0.1 0.5 1 1.5 2 2.5 3 >3.0

For UltraGas® (125-720)

f°H <1 5 10 15 20 25 30 >30 • min. 17.4 mbar, max. 80 mbar

d°H <0.56 2.8 5.6 8.4 11.2 14.0 16.8 >16.8 For UltraGas® (850-1150)

e°H <0.71 3.6 7.1 10.7 14.2 17.8 21.3 >21.3 • min. 17.4 mbar, max. 60 mbar

~mg/l <10 50.0 100.0 150.0 200.0 250.0 300.0 >300

Gas pressure propane

Conductance 2 <20 100.0 200.0 300.0 400.0 500.0 600.0 >600

Necessary flow pressure at the boiler inlet:

boiler size of the For UltraGas® (125-1000)

maximum filling quantity without demineralisation

individual boiler • min. 37 mbar, max. 57 mbar

50 to 200 kW NO DEMAND 50 l/kW 20 l/kW 20 l/kW

200 to 600 kW 50 l/kW 50 l/kW 20 l/kW always demineralise

over 600 kW Space requirements

See “Dimensions” for information

1

Total of alkaline earths

2

If the conductance in µS/cm exceeds the tabular value an analysis of the water is necessary.

220 Subject to modifications, 1.4.2017

Hoval UltraGas® (125-1150)

■■Engineering

Pump after-run time Noise level

The circulating pump must continue to run • The acoustic power level value is dependent

for at least 2 minutes each time the burner on the local and spacial circumstances.

is switched off (the pump after-run time is • The acoustic pressure level is dependent

included in the boiler control with the on the installation conditions and can for

TopTronic® E controller). instance be 5 to 10 dB(A) lower than the

acoustic power level at a distance of 1 m.

• DIN 4108 must be observed when installing

Heating boiler in the attic in domestic living areas

If the gas boiler is positioned on the top floor,

the installation of a low water protection, which Recommendation:

automatically turns the gas burner off in case If the air inlet at the facade is near a noise sen-

of water shortage, is recommended. sitive place (window of bedroom, terrace etc.),

we recommend to use a sound absorber at the

direct combustion air inlet.

Condensate drain

• The condensate from the flue gas system

can be discharged through the boiler. A con

Flue gas system

• Gas boilers must be connected to a flue gas

densate trap is not needed anymore with the

system (chimney or flue gas lines).

flue gas system.

• Flue gas lines must be gas tight and leak

• The condensate drainage without neutralisa-

tight against condensate and over pressure.

tion is allowed, if you are using for the drain

• The flue gas lines must be secured against

only plastic tubes or stoneware (possibly

unwanted loosening of the plug connections.

obtain special exemption from the relevant

• The flue gas system must be connected with

authority).

an angle, so that the resulting condensate

• A siphon must be installed at the condensa

of the flue gas system can flow back to the

te outlet on the gas boiler (included in the

boiler and can be neutralised there before

boiler scope of delivery).

discharging into the canalisation.

• The condensate must be openly lead into

• Gas boilers with condensation heat utilisa-

the canalisation (funnel).

tion are to be connected to a flue gas line

min. Temperature class T120.

• A flue gas temperature limiter is built in in

Expansion tank the boiler.

• An adequately dimensioned expansion tank

must be provided.

• The expansion tank has to be installed in

principle at the boiler return, or at the safety

flow.

• At the safety flow a safety valve and an au

tomatic exhauster must be installed.

Allocation of gas filters for UltraGas®

UltraGas® Gas throughput Gas filter type Dimension Pressure drop

gas filter

(with clean filter)

Type m3/h mbar

(125) 11.6 70602/6B Rp 1″ 0.2

(150) 14.1 70603/6B Rp 1½″ 0.1

(200) 18.8 70603/6B Rp 1½″ 0.2

(250) 23.5 70603/6B Rp 1½″ 0.2

(300) 28.3 70603/6B Rp 1½″ 0.3

(350) 32.6 70603/6B Rp 1½″ 0.4

(400)1 37.7 70631/6B Rp 2″ 0.3

(450)1 42.4 70631/6B Rp 2″ 0.3

(500)1 47.1 70631/6B Rp 2″ 0.4

(575)1 54.2 70631/6B Rp 2″ 0.5

(650)1 61.3 70631/6B Rp 2″ 0.6

(720)1 67.7 70631/6B Rp 2″ 0.7

H (720)1 67.7 70631/6B Rp 2″ 0.7

(850)1 80.2 70631/6B Rp 2″ 1.0

(1000)1 94.3 70631/6B Rp 2″ 1.4

H (1000)1 94.3 70631/6B Rp 2″ 1.4

(1150) 1 108.2 70631/6B Rp 2″ 1.8

1

On the UltraGas® (400-1150) installation of a gas filter in front of the gas burner is mandatory!

It is essential to set the dimensions of the gas line!

Subject to modifications, 1.4.2017 221

Hoval UltraGas® (125-1150)

■■Engineering

Dimensions flue gas systems Connecting pipes

Horizontal connecting pipes must be installed

Basic rules: with an inclination of at least 50 mm per metre

• Height over sea level max. 1000 m. of their length installed in the direction of the

boiler to allow free return flow of condensation

water towards the boiler. The whole flue gas

• The first 2 m of the flue gas line must be

system must be installed so that condensate

configured with the same dimension as the

can never collect at any point.

flue gas connector, after which the size of

• Combustion air:

the flue gas system can be selected ac-

In the case of room air-independent operation

cording to the table below.

(accessories optional) the air pipe should be

of the same dimension as the flue gas line.

If the flue gas line diameter is greater than

the combustion air connection an individual

calculation must be effected.

Flue gas line

Boiler (smooth walled) Number of bow 90° (flue gas + air supply)

type Flue gas dim. mm Dimension Total pipe length in m (flue gas + air supply)

UltraGas® internal DN 1 2 3 4 5*

(125) 155 130 24 23 22 21

(150) 155 15 14 13 12

(125) 155 150 44 44 44 44

(150) 155 44 44 44 44

(200) 252 24 24 23 22

(250) 252 12 12 11 11

(125) 155 175 50 50 50 50

(150) 155 50 50 50 50

(200) 252 50 50 50 50

(250) 252 46 45 45 44

(200) 252 200 50 50 50 50

(250) 252 50 50 50 50

(300) 252 50 50 50 50

(350) 302 42 41 40 39

(250) 252 250 50 50 50 50

(300) 252 50 50 50 50

(350) 302 50 50 50 50

(400) 302 50 50 50 50

(450) 302 50 50 50 50

(500) 302 50 50 50 50

(350) 302 300 50 50 50 50

(400) 302 50 50 50 50

(450) 302 50 50 50 50

(500) 302 50 50 50 50

(575) 302 50 50 50 50

(650) 302 50 50 50 50

(720) 302 50 50 50 50

(850) 402 350 50 50 50 50

(850) 402 400 50 50 50 50

(1000) 402 400 50 50 50 50

(1150) 402 400 50 50 50 50

Notice: The data contained in the table “Dimensions flue gas systems” represent guide values.

An exact calculation for the flue gas duct must be made on-site.

* With 5 bends or more the feed pressure total at the combustion air/flue gas line is to be reduced by 30% for the calculation.

With total pipe lengths exceeding 50 m, a separate calculation is necessary.

222 Subject to modifications, 1.4.2017

Hoval UltraGas® (125-1150)

■■Examples

UltraGas® (125-1150)

Gas boiler with

-- 1 direct circuit

Hydraulic schematic BDEE005

2 3 4 5 6 7 8

AF

RBM

TTE-GW

TTE-WEZ

B1

T T

DKP

P

T P

STB Pmax

UltraGas

HT

NT

: 12.03.2015 Verbindungshinweise / Achtung ! Für die Installation muss das anlagenbezogene Schema verwendet werden!

Notice / Nota / Remarque: Attention! This is just a schematic. For installation please use the detail-plan!

...

n: 4.1 Attenzione! Per la messa in opera, utilizzare le schema dettagliato!

Notice:

BDEE005.dwg

-- The example schematics merely show

Attention! Pour la réalisation pratique de l'installation, il faut utiliser le schéma détaillé!

2 3 and do not contain all

the basic principle 4 5 6 7 8

information required for installation. The

installation must be done according to

local conditions, dimensioning and regula-

tions.

-- With underfloor heating a flow tempera- TTE-WEZ TopTronic® E basic module heat generator (installed)

ture monitor must be built in. B1 Flow temperature guard (if required)

-- Shut-off devices to the safety valve (pres- AF Outdoor sensor

surised expansion tank, safety valve, etc.) DKP Pump for heating circuit without mixer

are to safe against unintended closing!

-- Mount bags to prevent single pipe gravity Option

RBM TopTronic® E room control module

circulation!

TTE-GW TopTronic® E Gateway

Subject to modifications, 1.4.2017 223

Hoval UltraGas® (125-1150)

■■Examples

UltraGas® (125-1150)

Gas boiler with

-- calorifier

-- 1 direct circuit and 1-... mixer circuit(s)

Hydraulic schematic BDEE030

2 3 4 5 6 7 8

AF

RBM

TTE-GW

TTE-WEZ

TTE-FE

HK

VF1 B1.1 VF2 B1.2

T T T T T T

DKP MK1 MK2

P

T

YK1 YK2

T P

STB Pmax

UltraGas

HT SF

NT

SLP

m: 09.03.2015 Verbindungshinweise / Achtung ! Für TTE-WEZ TopTronic

die Installation muss E basic module

das anlagenbezogene

®

heat verwendet

Schema generatorwerden!

(installed)

: ...

Notice / Nota / Remarque: VF1 Flow temperature sensoruse

Attention! This is just a schematic. For installation please 1 the detail-plan!

B1.1 Flow temperature guard (if required)

on: 4.1 Attenzione! PerMK1la messa in opera, utilizzare le schema dettagliato!

Pump mixer circuit 1

Notice:

BDEE030.dwg

-- The example schematics merely show

Attention! PourYK1

la réalisation pratique

Actuator demixer

l'installation,

1 il faut utiliser le schéma détaillé!

2 the basic principle and3 do not contain all 4 5 AF 6

Outdoor sensor 7 8

information required for installation. The SF Calorifier sensor

DKP Pump for heating circuit without mixer

installation must be done according to

SLP Calorifier charging pump

local conditions, dimensioning and regula-

tions. Option

-- With underfloor heating a flow tempera- RBM TopTronic® E room control module

ture monitor must be built in. TTE-GW TopTronic® E Gateway

-- Shut-off devices to the safety valve (pres-

surised expansion tank, safety valve, etc.) TTE-FE HK TopTronic® E module expansion heating circuit

are to safe against unintended closing! VF2 Flow temperature sensor 2

-- Mount bags to prevent single pipe gravity B1.2 Flow temperature guard (if required)

MK2 Pump mixer circuit 2

circulation!

YK2 Actuator mixer 2

224 Subject to modifications, 1.4.2017

Hoval UltraGas® (125-1150)

■■Examples

UltraGas® (125-1150)

Gas boiler with

-- calorifier

-- 1 direct circuit and 1-... mixer circuit(s)

(HT/LT separation)

2

Hydraulic 3

schematic BDEE050 4 5 6 7 8

AF

RBM

TTE-GW

TTE-WEZ

TTE-FE

HK

VF1 VF2 B1.2

T T T T T T

DKP MK1 MK2

P

T

YK1 YK2

T P

STB Pmax

UltraGas

HT SF

NT

SLP

Datum: 10.07.2015 Verbindungshinweise / Achtung ! Für die Installation muss das anlagenbezogene Schema verwendet werden!

Notice / Nota / Remarque: Attention! This is just a schematic. For ®installation please use thegenerator

detail-plan!(installed)

Name: ... TTE-WEZ TopTronic E basic module heat

Version: 4.1 Attenzione! VF1

Per la messa inFlowopera,temperature

utilizzare le schema

sensordettagliato!

1

Notice:

Datei: BDEE050.dwg MK1

Attention! Pour la réalisationPump mixer

pratique circuit 1 il faut utiliser le schéma détaillé!

de l'installation,

2-- The example schematics

3 merely show 4 5 YK1 Actuator

6 mixer 1 7 8

the basic principle and do not contain all AF Outdoor sensor

information required for installation. The SF Calorifier sensor

DKP Pump for heating circuit without mixer

installation must be done according to

SLP Calorifier charging pump

local conditions, dimensioning and regula-

tions. Option

-- With underfloor heating a flow tempera- RBM TopTronic® E room control module

ture monitor must be built in. TTE-GW TopTronic® E Gateway

-- Shut-off devices to the safety valve (pres-

surised expansion tank, safety valve, etc.) TTE-FE HK TopTronic® E module expansion heating circuit

are to safe against unintended closing! VF2 Flow temperature sensor 2

-- Mount bags to prevent single pipe gravity B1.2 Flow temperature guard (if required)

MK2 Pump mixer circuit 2

circulation!

YK2 Actuator mixer 2

Subject to modifications, 1.4.2017 225

You might also like

- 02 - Cabin Slim Ac Ug 2 D - 21 enDocument13 pages02 - Cabin Slim Ac Ug 2 D - 21 enkdc termice100% (1)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Belaria® Comfort ICM (8,13) CatalogDocument35 pagesBelaria® Comfort ICM (8,13) CatalogMisterTeoNo ratings yet

- .: 139 One GE, Frame 5, MS 5001 N, Zero Hour Overhauled - Gas Turbine Package 24,25 MWDocument10 pages.: 139 One GE, Frame 5, MS 5001 N, Zero Hour Overhauled - Gas Turbine Package 24,25 MWAkram GeadNo ratings yet

- Brochure Gas Turbine SGT-400 For Power Generation PDFDocument4 pagesBrochure Gas Turbine SGT-400 For Power Generation PDFfrdnNo ratings yet

- SGT 400Document4 pagesSGT 400pramodtryNo ratings yet

- Revised Heat Gain Rates From Typical Commercial Cooking Appliances From RPDocument36 pagesRevised Heat Gain Rates From Typical Commercial Cooking Appliances From RPReza KhajeNo ratings yet

- UltraGas - HovalDocument22 pagesUltraGas - HovalAlex DorcaNo ratings yet

- Hoval+Thermalia+ Technical+ INM-en+ 2017 PDFDocument94 pagesHoval+Thermalia+ Technical+ INM-en+ 2017 PDFTunadcoNo ratings yet

- Hoval Biolyt: Pellet BoilerDocument18 pagesHoval Biolyt: Pellet BoilerDaniel SarbuNo ratings yet

- TopGas® Classic (12-30) CatalogDocument21 pagesTopGas® Classic (12-30) CatalogVilmos GyeroNo ratings yet

- Max 3 (420-2700) Catalog PDFDocument20 pagesMax 3 (420-2700) Catalog PDFBenga Adrian100% (1)

- Belaria+twin+ Technical+ INM-en+ 2017 PDFDocument38 pagesBelaria+twin+ Technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQNo ratings yet

- Max-3 - Carte Tehnica PDFDocument17 pagesMax-3 - Carte Tehnica PDFAnonymous 4MLEo9TVQNo ratings yet

- Air Cooled Chillers & Heat Pumps: Winpower He-ADocument7 pagesAir Cooled Chillers & Heat Pumps: Winpower He-AMontassar BouslamaNo ratings yet

- Belaria® Dual AR (60) CatalogDocument17 pagesBelaria® Dual AR (60) CatalogMisterTeoNo ratings yet

- AC HitachiDocument6 pagesAC HitachiANKQNo ratings yet

- Brochure Uniflair Chiller TRADocument5 pagesBrochure Uniflair Chiller TRAMasab AnisNo ratings yet

- Brochure Uniflair Chiller TRADocument5 pagesBrochure Uniflair Chiller TRAPablo gilNo ratings yet

- Steel Shell Boiler: Responsibility For Energy and EnvironmentDocument12 pagesSteel Shell Boiler: Responsibility For Energy and Environmentrahimi mohamadNo ratings yet

- Brochure Uniflair Chiller TRA - 60HzDocument7 pagesBrochure Uniflair Chiller TRA - 60HzMasab AnisNo ratings yet

- Brochure Uniflair Chiller TRA - 60HzDocument7 pagesBrochure Uniflair Chiller TRA - 60HzPablo gilNo ratings yet

- Binder1 PDFDocument316 pagesBinder1 PDFAR-Jay ARNo ratings yet

- 05 Heat Pump 06 ExA EnglDocument98 pages05 Heat Pump 06 ExA EnglbaczonifNo ratings yet

- 13 - Winpower Se Tcaey 4360 8860 - Thaey 4360 6670Document7 pages13 - Winpower Se Tcaey 4360 8860 - Thaey 4360 6670David Baillon OpazoNo ratings yet

- New Power Source Module N.america2Document4 pagesNew Power Source Module N.america2Safiq UddinNo ratings yet

- A6V101025025 - Boiler Sequence Controller RMK770 - enDocument22 pagesA6V101025025 - Boiler Sequence Controller RMK770 - enΠαναγιώτης ΤσάπαςNo ratings yet

- Carrier Paquetes de 75-150 TonDocument2 pagesCarrier Paquetes de 75-150 Tonhvac.mayoreoNo ratings yet

- Chiller Selection Building A+j Cooling Only Rev 2Document7 pagesChiller Selection Building A+j Cooling Only Rev 2Anton WelgemoedNo ratings yet

- Fulton Vantage Technical DataDocument6 pagesFulton Vantage Technical DatajrodNo ratings yet

- Air Cooled Chillers & Heat Pumps: Fullpower SeDocument5 pagesAir Cooled Chillers & Heat Pumps: Fullpower SeAnarNo ratings yet

- Turbine Cat SolarDocument2 pagesTurbine Cat SolarAbid Lakhani100% (1)

- Centaur 40: Gas Turbine Generator SetDocument2 pagesCentaur 40: Gas Turbine Generator Setaemis2010No ratings yet

- Air Cooled Water Chillers and Heat Pumps With R410A Featuring Hermetic Scroll CompressorsDocument2 pagesAir Cooled Water Chillers and Heat Pumps With R410A Featuring Hermetic Scroll CompressorscarlosloucaoNo ratings yet

- H060 Laboratory Cooling Plant With Ice Store: P.A. Hilton LTDDocument4 pagesH060 Laboratory Cooling Plant With Ice Store: P.A. Hilton LTDManoj KhatriNo ratings yet

- Technical Brochures AW HT 0031 0071 enDocument50 pagesTechnical Brochures AW HT 0031 0071 endouslasNo ratings yet

- Solar Turbines Taurus 65 Data SheetDocument2 pagesSolar Turbines Taurus 65 Data SheetLuis SanguinettiNo ratings yet

- Vi PriceList1 2-19-15Document124 pagesVi PriceList1 2-19-15overlord5555No ratings yet

- Honeywell - Aquatrol AQ2000 Series BrochureDocument12 pagesHoneywell - Aquatrol AQ2000 Series BrochureRubens KunNo ratings yet

- Viesmann: Vitotronic 300-KDocument14 pagesViesmann: Vitotronic 300-KPatrick NgwangNo ratings yet

- 30RB - RQ - Carrier - ManualzzDocument19 pages30RB - RQ - Carrier - ManualzzmelodyNo ratings yet

- Catalogue Standard Air Handling Units Blauair PDFDocument24 pagesCatalogue Standard Air Handling Units Blauair PDFIonut CatalinNo ratings yet

- Catalogue Standard Air Handling Units BlauairDocument24 pagesCatalogue Standard Air Handling Units BlauairIonut CatalinNo ratings yet

- Quinta Pro Range Suggested Schematics PDFDocument32 pagesQuinta Pro Range Suggested Schematics PDFAnonymous CRQ100No ratings yet

- BT19G012GB-00 Technical Bulletin 1680093460100Document32 pagesBT19G012GB-00 Technical Bulletin 1680093460100Ira BilokonNo ratings yet

- Ecolean4 Sgu-0111-EDocument6 pagesEcolean4 Sgu-0111-EAmNo ratings yet

- Imo Rotary Pump HandbookDocument2 pagesImo Rotary Pump HandbookOreolNo ratings yet

- Lennox MS8H Mini Split Heat Pump SpecsDocument16 pagesLennox MS8H Mini Split Heat Pump SpecsMeselao Meselao MeselaoNo ratings yet

- High-Temperature Monobloc Air-to-Water Heat Pumps With Integrated Hydronic ModuleDocument16 pagesHigh-Temperature Monobloc Air-to-Water Heat Pumps With Integrated Hydronic Modulekathy_es16No ratings yet

- t6590 Manual Honeywell PDFDocument7 pagest6590 Manual Honeywell PDFCosmin GheorghiesNo ratings yet

- TAEevo Tech Flyer - pndTbkkBS1mQTLpvd6P8 PDFDocument2 pagesTAEevo Tech Flyer - pndTbkkBS1mQTLpvd6P8 PDFAdi DahlanNo ratings yet

- Carte Tehnica Centrala Termica Immergas Eolo Star 23Document12 pagesCarte Tehnica Centrala Termica Immergas Eolo Star 23Adrian BasteaNo ratings yet

- Dedicated Outdoor Air Systems: Models RV and RVEDocument12 pagesDedicated Outdoor Air Systems: Models RV and RVEAndres Aguilar-MatamorosNo ratings yet

- HOVAL Scheda Tecnica Caldaia Ultragas 35 650Document54 pagesHOVAL Scheda Tecnica Caldaia Ultragas 35 650PgNo ratings yet

- Rhoss Chiller Z-Power SEDocument6 pagesRhoss Chiller Z-Power SErobasiNo ratings yet

- Taurus 65 DSDocument2 pagesTaurus 65 DSChesterNo ratings yet

- Steam TurbineDocument27 pagesSteam Turbinecram1960100% (3)

- Tcaey-Thaey 2110-4340Document4 pagesTcaey-Thaey 2110-4340dbaillonNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- CombiVal WPE, WPER, WPEF (300)Document6 pagesCombiVal WPE, WPER, WPEF (300)Raluca OlaruNo ratings yet

- Lindab Airductsystems - Presiune Admisa - 2Document1 pageLindab Airductsystems - Presiune Admisa - 2Raluca OlaruNo ratings yet

- Calpeta Debit Rectangulara DJPDocument3 pagesCalpeta Debit Rectangulara DJPRaluca OlaruNo ratings yet

- Clapete VAV LINDAB - Model VRUDocument5 pagesClapete VAV LINDAB - Model VRURaluca OlaruNo ratings yet

- Meistream Plus: Class C Bulkmeter For Cold Potable Water DN 40... 150 PN 16Document4 pagesMeistream Plus: Class C Bulkmeter For Cold Potable Water DN 40... 150 PN 16Raluca OlaruNo ratings yet

- Ai Access Doors 1006 - enDocument8 pagesAi Access Doors 1006 - enRaluca OlaruNo ratings yet

- Sem-Safe Water Mist: Total Weight: XX KGDocument1 pageSem-Safe Water Mist: Total Weight: XX KGRaluca OlaruNo ratings yet

- Sem-Safe Water Mist: NotesDocument1 pageSem-Safe Water Mist: NotesRaluca OlaruNo ratings yet

- Sem-Safe Water Mist: Last Revision By: Reference No.: MaterialDocument1 pageSem-Safe Water Mist: Last Revision By: Reference No.: MaterialRaluca OlaruNo ratings yet

- France Air - Plafon Filtrant BVX3Document2 pagesFrance Air - Plafon Filtrant BVX3Raluca OlaruNo ratings yet

- Grundfosliterature 3929715 PDFDocument352 pagesGrundfosliterature 3929715 PDFRaluca OlaruNo ratings yet

- Ibtm5660 2223-04Document84 pagesIbtm5660 2223-04Yuki ChanNo ratings yet

- PBRS Energy Prescriptive Pathway v1 0Document8 pagesPBRS Energy Prescriptive Pathway v1 0jamalNo ratings yet

- As 1361-1995 Electric Heat-Exchange Water Heaters - For Domestic ApplicationsDocument7 pagesAs 1361-1995 Electric Heat-Exchange Water Heaters - For Domestic ApplicationsSAI Global - APACNo ratings yet

- Catalogue Produits OnanDocument6 pagesCatalogue Produits OnanJohn LarsonNo ratings yet

- IMPRESSA F50 Classic: Instructions For UseDocument42 pagesIMPRESSA F50 Classic: Instructions For UseDarko BurićNo ratings yet

- Compression Mould.Document26 pagesCompression Mould.Aadi AdarshNo ratings yet

- Instant Water Heater - JOVEN Home AppliancesDocument7 pagesInstant Water Heater - JOVEN Home AppliancesthaiNo ratings yet

- References IndustrialboilerserviceDocument16 pagesReferences IndustrialboilerserviceagusaryasNo ratings yet

- Product Catalogue: World Class Quality Products Proudly Made in ZambiaDocument18 pagesProduct Catalogue: World Class Quality Products Proudly Made in ZambiaBhosle ImpexNo ratings yet

- Plaquette 081020Document28 pagesPlaquette 081020amiyare.taybNo ratings yet

- Flue & Chimney SystemsDocument16 pagesFlue & Chimney SystemsAirtherm Flues LimitedNo ratings yet

- Solar Water Heating SystemDocument41 pagesSolar Water Heating SystemAtmesh PoudyalNo ratings yet

- CH #2 NumericalsDocument3 pagesCH #2 NumericalsMs Noor ul AinNo ratings yet

- Air/water Heat Pump F2040: UHB EN 1826-5 231845 User ManualDocument28 pagesAir/water Heat Pump F2040: UHB EN 1826-5 231845 User ManualIacome DanNo ratings yet

- How To Build A Homemade Hot Water HeaterDocument7 pagesHow To Build A Homemade Hot Water HeaterSaliu MalikNo ratings yet

- Compact P CTS 700 Product DataDocument48 pagesCompact P CTS 700 Product DataDylan DooleyNo ratings yet

- Ashrae Pocket Guide I P PDFDocument36 pagesAshrae Pocket Guide I P PDFMUKESH DAYMANo ratings yet

- 15-9032 FT Opro Central Domestic BD 180915Document2 pages15-9032 FT Opro Central Domestic BD 180915Sameeh KaddouraNo ratings yet

- Manual de Instalação, Operação e Controle - Bomba de CalorDocument12 pagesManual de Instalação, Operação e Controle - Bomba de CalorBruno PorcelNo ratings yet

- The Definition of PlumbingDocument9 pagesThe Definition of PlumbingWidimongar JarqueNo ratings yet

- Diy Solar Water HeaterDocument96 pagesDiy Solar Water HeaterTemujin Ras Al GhulNo ratings yet

- Сервисная инструкция WH-SDC (UD) 09-12-14-16 F3 (9) E8Document196 pagesСервисная инструкция WH-SDC (UD) 09-12-14-16 F3 (9) E8sergeyNo ratings yet

- Ecotec: Instructions For Installation and ServicingDocument52 pagesEcotec: Instructions For Installation and ServicingweeniboiNo ratings yet

- Klemetson 1985 Aquacultural-EngineeringDocument18 pagesKlemetson 1985 Aquacultural-EngineeringJorge RodriguezNo ratings yet

- ML7430E/ML7435E: Electric Linear Actuators For Modulating ControlDocument4 pagesML7430E/ML7435E: Electric Linear Actuators For Modulating ControlMarco ReNo ratings yet

- FGSSDocument4 pagesFGSSYoon SDNo ratings yet

- Buderus - SM - GB012 - 102011 - EN ManualDocument35 pagesBuderus - SM - GB012 - 102011 - EN Manualmadimadi11No ratings yet

- Oil Refinery Plant - 50TPDDocument36 pagesOil Refinery Plant - 50TPDsfagroindustriiesNo ratings yet

- AHAC BookletDocument36 pagesAHAC BookletsantiagovbNo ratings yet