Professional Documents

Culture Documents

25 - A - 497 INT69 YL Diagnose

25 - A - 497 INT69 YL Diagnose

Uploaded by

IDEA RefrisolICEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

25 - A - 497 INT69 YL Diagnose

25 - A - 497 INT69 YL Diagnose

Uploaded by

IDEA RefrisolICECopyright:

Available Formats

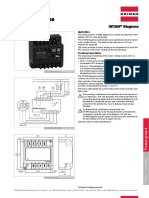

INT69 YL® Diagnose

INT69 YL® Diagnose

Application

The compressor protection INT69 YL Diagnose is a further development of

the reliable KRIWAN motor protectors. Additional inputs for phase

monitoring, oil temperature, oil flow, oil level and oil filter soiling as well as

supplementary flexible-response protective functions help to improve the

availability and extend the service life of a refrigeration system.

The INT69 YL Diagnose automatically saves operational and error data in a

non-volatile memory. This data can be retrieved and analysed for diagnosis.

The full scope of the diagnosis is achieved by using a KRIWAN-specific AMS

sensor.

This motor protector is mainly employed on compressors of which, in

addition to the motor's direction of rotation, the oil management is also

essential for the function.

Functional description

The temperature monitoring of the motor winding is done with two

evaluation processes:

• Static: Switch-off is immediate if the nominal response temperature of

the built-in AMS or PTC sensors is reached.

• Dynamic: If the temperature increases unusually quickly, the motor is

switched off immediately even if the temperature is still far below the

nominal response temperature. This prevents excess temperatures from

occurring.

INT69 YL Diagnose The oil temperature is evaluated statically.

If no oil temperature sensor is installed, a 100 ohm resistor has to be

installed at the input.

A short circuit at an AMS or PTC input also leads to a switch-off. A short

L1

L2 cycling leads to a reset delay.

L3 If the contact of the oil level sensor (e.g. INT276) is open for more than 3s,

N the motor protector will lock switch off.

PE If the contact of the oil filter sensor is open for more than 10s while the motor

is running, the motor protector will lock switch off.

The start-up time of 10s begins when the motor starts. If after this start-up

Q1 F1 F2

time has elapsed, the contact of the oil flow sensor for 3s is open while the

motor is running, the motor protector switches off. The motor protector also

switches off if the contact of the oil flow sensor is open on expiry of the start-

up time.

L N L1 L2 L3 Following cooling off and/or error rectification and subsequent restart delay,

DP

the compressor may be restarted. Restart after a lock-out is only possible

INT69 YL Diagnose Q1

after a reset.

X X 1 2 3 4 5 6 7 8 9 10 11 14 12 If an oil level, oil flow or oil filter sensor is not needed, a jumper needs to be

connected at the respective input.

The phase monitoring of the motor voltage is active 1s after the start of the

Button

motor. The correct phase sequence is monitored for 5s; the phase

M asymmetry is monitored for the total motor running time. If a wrong phase

Oil temperature

Oil level

Oil filter

Oil flow

3 AC

sequence is detected or there is a phase failure, the motor protector will lock

switch off.

Motor PTC After motor stop, the phase monitoring and the operating recognition is

deactivated for approx. 10s, to prevent unintended locking due to brief

Product group A

Wiring diagram reverse running of the compressor.

For operation in the specified manner, the supply voltage has to be on

permanently on the INT69 YL Diagnose.

The built-in LED signals the current status of the motor protector (see flash

code).

The mounting, maintenance and operation are to be carried out by an

5.85 64.8 Ø3.84 15.9 electrician. The valid European and national standards for connecting

electrical equipment and cooling installations have to be observed.

Connected sensors and connection lines that extend from the terminal

box have to feature at least a basic insulation.

The electric circuit in which the sensor is located does not feature any

safe electrical isolation from electric circuits with dangerous voltages,

but is only separated by a basic insulation.

See back side for further specifications

Edition: 710.00375.2

72.1

81.5

4.7

76.5 35

Dimensions in mm

Technical changes reserved

KRIWAN Industrie-Elektronik GmbH · Allmand 11 · D-74670 Forchtenberg · phone (+49) 7947 822 0 · fax (+49) 7947 1288 · e-mail: info@kriwan.com · home: www.kriwan.com

INT69 YL® Diagnose

INT69 YL® Diagnose

Flash code Technical specifications

The KRIWAN flash code allows for a quick and easy status display and Supply voltage AC/DC 50/60Hz 24-240V

troubleshooting. (UL: 24-230V) ±10% 3VA

The flash code consists of a cyclical red and orange flash sequence. The Permitted ambient temperature -30...+70°C

current status can be determined from the number of pulsing flashes. Temperature measuring circuits

- Type 1-2 AMS sensors in series

alternative 1-9 PTC sensors acc. to

DIN 44081, DIN 44082 in series

1.5s 0.8s 1.5s

- R25,total <1.8kΩ

- Rtrip, static 4.5kΩ ±20%

pause 1 red pause 2 orange pause 1 - Rreset 2.75kΩ ±20%

(1-5 pulses) (1-5 pulses) - Max. length connection line 30m

Short circuit monitoring system PTC Typically <30Ω

Flash code

Input oil flow, oil level and oil filter

soiling

- Designed for Potential-free normally open contact

Overview flash code (typ. 3.3V, 1mA)

Green lit Compressor operational - Max. length connection line 30m

Motor voltage 3 AC 20-100Hz 80-690V ±10%

Green flashing Compressor running

Phase monitoring

Red/Orange flashing Error, compressor is switched off; for description - Phase sequence Active about 1s after motor start for

see table below about 5s

- Phase asymmetry Active about 1s after the motor start

until the motor stop

1st flashing 2nd flashing Description - Inactive After motor stop for approx. 10s

sequence sequence Switching frequency overstepping 3 switch-offs in 60s or 10 switch-offs

(LED red) (LED orange) in 1h

1 1 Motor temperature: Operation with frequency Suitable

Static switch-off, converters

Permissible winding temperature Reset delay

exceeded

- Motor temperature static 5min ±1min

2 Motor temperature: - Motor temperature dynamic

Dynamic switch-off, 1./24h 10min ±2min

Temperature rise in the motor 2./24h 60min ±12min

winding unusually fast 3./24h Locked

3 Motor temperature: - Oil temperature Undelayed

Reset delay after static switch-off

- Switching frequency overstepping

4 Motor temperature: 3./60s 5min ±1min

Sensor input detected open circuit 10./1h 30min ±6min

or short circuit - Incorrect phase sequence Locked

5 Motor temperature: - Phase asymmetry

Reset delay after dynamic switch- 1. - 3./20min 5min ±1min

off 4./20min Locked

2 1 Motor voltage: 1.-9./24h 5min ±1min

Incorrect phase sequence 10./24h Locked

2 Motor voltage: - Oil flow

Phase failure/asymmetry 1.-2./24h 5min ±1min

3./24h Locked

Product group A

4 Motor voltage:

Reset delay after "Motor voltage" - Oil filter Locked

error - Oil level Locked

3 5 General: Resetting the lock or the reset delay Main reset >5s or reset by keyboard

Reset delay after "General" error only possible if there is no error

current

4 2 Oil: level too low

External button

3 Oil: - Designed for Potential-free normally open contact

Reset delay after "Oil" error (typ. 3.3V, 1mA)

5 1 Permissible oil temperature - Max. length connection line 1m

exceeded

Relay

3 Oil temperature sensor input - Contact AC 240V 2.5A C300

detected open circuit or short at least AC/DC 24V 20mA

circuit

- Mechanical service life Approx. 1 million switching cycles

4 Oil flow too low

Interface Diagnose port (DP)

Edition: 710.00375.2

5 Oil filter soiled Protection class acc. to EN 60529 IP00

Order data Connection type 6.3mm flat plugs (L1-L3, L and N),

push-in spring terminals,

INT69 YL Diagnose 25 A 497 0.25-0.75mm2

Accessories and application see www.kriwan.com Housing material PA glass-fibre-reinforced

information Mounting Screw mounted

Dimensions Refer to dimensions in mm

Weight Approx. 150g

Check base EN 61000-6-2, EN 61000-6-3

EN 61010-1

Overvoltage category II

Pollution level 2

Approval UL File No. E75899 cURus

Technical changes reserved

KRIWAN Industrie-Elektronik GmbH · Allmand 11 · D-74670 Forchtenberg · phone (+49) 7947 822 0 · fax (+49) 7947 1288 · e-mail: info@kriwan.com · home: www.kriwan.com

You might also like

- Arfken Solutions 6th EditionDocument5 pagesArfken Solutions 6th EditionParul25% (4)

- Exhaust Temp. Scanner Service Manual - 2001Document24 pagesExhaust Temp. Scanner Service Manual - 2001Alfredo80% (5)

- SP1 ManualDocument13 pagesSP1 ManualAnonymous RCPxaonfvNo ratings yet

- D8T and D9T Track-Type Tractors Event Code ListDocument5 pagesD8T and D9T Track-Type Tractors Event Code ListEVCYNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Erbe ICC 200 - Service GuidelineDocument3 pagesErbe ICC 200 - Service Guidelineibss_mcmNo ratings yet

- 3600 Elta Software User GuideDocument0 pages3600 Elta Software User Guidelara610731No ratings yet

- A626S21 INT69-DMY Diagnose 71000445 0-EbookDocument2 pagesA626S21 INT69-DMY Diagnose 71000445 0-EbookSergeyNo ratings yet

- Int 69-2Document1 pageInt 69-2Ricardo Del CarpioNo ratings yet

- Kriwan Overload Module - InT369-DiagnoseDocument2 pagesKriwan Overload Module - InT369-DiagnoseDaniel PertuzNo ratings yet

- A263 - INT69 TM2 - Diagnose - 71000448 - 0Document2 pagesA263 - INT69 TM2 - Diagnose - 71000448 - 0bnx5dkq786No ratings yet

- A620 Int69sc2 71000393 3Document2 pagesA620 Int69sc2 71000393 3bnx5dkq786No ratings yet

- KRIWANDocument2 pagesKRIWANlaureenmartin690No ratings yet

- INT69 SC2 DiagnoseDocument2 pagesINT69 SC2 DiagnoseROGELIONo ratings yet

- Kriwan INT280-60 - DiagnoseDocument4 pagesKriwan INT280-60 - DiagnosehamzaNo ratings yet

- A620s80 81 Int69kf2 PDFDocument1 pageA620s80 81 Int69kf2 PDFMIGUEL ÁNGEL TOMÉNo ratings yet

- INT69 Control ModuleDocument1 pageINT69 Control ModuleTiborNo ratings yet

- INT69 Control ModuleDocument1 pageINT69 Control ModuleTiborNo ratings yet

- A253S80 INT69TM2 Diagnose 71000428 0-EbookDocument1 pageA253S80 INT69TM2 Diagnose 71000428 0-EbookMarco Tulio Da SilvaNo ratings yet

- Sitrans CV Ap01 Us 2016Document10 pagesSitrans CV Ap01 Us 2016muggle1357No ratings yet

- Motorne ZastiteDocument1 pageMotorne ZastiteMilan DenicNo ratings yet

- Lmof 123Document10 pagesLmof 123Idham JaelaniNo ratings yet

- 95-8790 - (X-Series-Flame-Detectors-with-Pulse-Output)Document16 pages95-8790 - (X-Series-Flame-Detectors-with-Pulse-Output)pabloperezmtz1No ratings yet

- 4 Stage ThermostatDocument16 pages4 Stage ThermostatKrishnan GovindarajNo ratings yet

- INT69 Motor Protector: ® ApplicationDocument2 pagesINT69 Motor Protector: ® ApplicationmrcndoruNo ratings yet

- CTC Series: Compact Temperature CalibratorDocument14 pagesCTC Series: Compact Temperature CalibratorJonathan AntillonNo ratings yet

- GO Switch, Seal Fail Relay PDFDocument2 pagesGO Switch, Seal Fail Relay PDFtotovasiNo ratings yet

- Irdh265 4Document4 pagesIrdh265 4Deepak JainNo ratings yet

- PTCDocument3 pagesPTCarranguezjr5991No ratings yet

- 4Tm Series Compressor Control: Motor Protector For Refrigeration CompressorsDocument3 pages4Tm Series Compressor Control: Motor Protector For Refrigeration CompressorsAbdelmadjid BatirNo ratings yet

- Gas Engines Application and Installation Guide: Ignition Systems Starting Systems Engine Protection SystemsDocument34 pagesGas Engines Application and Installation Guide: Ignition Systems Starting Systems Engine Protection SystemsMauro DiazNo ratings yet

- Fire Safety in Cable Tunnels, Risers and FlatsDocument2 pagesFire Safety in Cable Tunnels, Risers and Flatsrogercp2981No ratings yet

- KMOTurbo AntiSurgeDocument4 pagesKMOTurbo AntiSurgeazhan77No ratings yet

- FTA550EDocument11 pagesFTA550EBaraa' KahlawiNo ratings yet

- Cummins Diesel Engine Fault Code GuideDocument20 pagesCummins Diesel Engine Fault Code GuideSy Demba100% (1)

- Selectable Volt Free: InstructionmanualDocument12 pagesSelectable Volt Free: InstructionmanualPerDormire MagacinNo ratings yet

- 16e09 101 Installation Operation Instructions en Us 4209196 PDFDocument16 pages16e09 101 Installation Operation Instructions en Us 4209196 PDFDaniel MontesNo ratings yet

- Centro-Matic: Model 85535 Controller Series "C"©Document6 pagesCentro-Matic: Model 85535 Controller Series "C"©SIDI ahmedou yahyaNo ratings yet

- AZM300 ManualDocument12 pagesAZM300 ManualBalatenteraislamHelperNo ratings yet

- 3Document10 pages3Вячеслав ГлушакNo ratings yet

- Electronic Sensor and SystemDocument30 pagesElectronic Sensor and SystemDammiam Gatica100% (2)

- Anti Surge Control PDFDocument4 pagesAnti Surge Control PDFWong DaNo ratings yet

- Electronic Lubrication Control Unit Model 85307, Single Line SystemDocument24 pagesElectronic Lubrication Control Unit Model 85307, Single Line SystemVictor Edy Facundo DelzoNo ratings yet

- Automatic / Manual Start Unit For Gen-Sets: Provides Flexible Start and Control Functions For Diesel GeneratorsDocument2 pagesAutomatic / Manual Start Unit For Gen-Sets: Provides Flexible Start and Control Functions For Diesel GeneratorsSiding BarroNo ratings yet

- S87ABCDJKDocument20 pagesS87ABCDJKalex riveraNo ratings yet

- Brochure Vibrocontrol 1100 enDocument4 pagesBrochure Vibrocontrol 1100 enRizki SanjayaNo ratings yet

- 16 E09 Thermostat ENDocument8 pages16 E09 Thermostat ENEli WilsonNo ratings yet

- Injection Pure Jet - ENGDocument38 pagesInjection Pure Jet - ENGSašo-Pregl Klaudija-MartinecNo ratings yet

- Jofra CalDocument8 pagesJofra CalFR PERANo ratings yet

- LOA2 LOA3 Oil Burner Controls2 PDFDocument10 pagesLOA2 LOA3 Oil Burner Controls2 PDFAdamNo ratings yet

- Ion QuestDocument8 pagesIon QuestsetyajiNo ratings yet

- BccontDocument78 pagesBccontIonut GrozaNo ratings yet

- Electric Actuation - Bernard ControlsDocument4 pagesElectric Actuation - Bernard ControlsGoutham KSNo ratings yet

- Fenwal 35 63J103 017 Submittal SheetDocument5 pagesFenwal 35 63J103 017 Submittal Sheetjim perdigonNo ratings yet

- CTC Jofra DatasheetDocument12 pagesCTC Jofra DatasheetRosalinda Giron PrincipeNo ratings yet

- 68-0135 Pilot ModuleDocument24 pages68-0135 Pilot ModuleJosh C JoshuaNo ratings yet

- Ourproducts 4tm Series DatasheetDocument5 pagesOurproducts 4tm Series Datasheetalejo gNo ratings yet

- Goodman TSTATG1152-2 Owner's Manual enDocument23 pagesGoodman TSTATG1152-2 Owner's Manual enkrievkalnsgNo ratings yet

- EN Datasheet CoreTec4 1ZBG000197 - Hitachi - Energy - CoreTec 4 - SpecsDocument6 pagesEN Datasheet CoreTec4 1ZBG000197 - Hitachi - Energy - CoreTec 4 - SpecsPedro CruzNo ratings yet

- Cble Protector WireDocument8 pagesCble Protector WireduvanNo ratings yet

- Controlador Llama Siemens Lmo...Document13 pagesControlador Llama Siemens Lmo...Ronald Yucra CadenaNo ratings yet

- MSR127 Minotaur Monitoring Safety Relays: Installation InstructionsDocument4 pagesMSR127 Minotaur Monitoring Safety Relays: Installation InstructionsMike DuránNo ratings yet

- Moisture States in AggregateDocument2 pagesMoisture States in AggregateJANET GTNo ratings yet

- Manual Silver Crest SFB 10.1 A1 10-In-1 Remote ControlDocument111 pagesManual Silver Crest SFB 10.1 A1 10-In-1 Remote ControlDragos DragoshNo ratings yet

- DAC V3 Readme - BDocument61 pagesDAC V3 Readme - Bpetesqueeler7052No ratings yet

- BITUMEN ProjectDocument26 pagesBITUMEN ProjectAbood Buriahi100% (2)

- Appendix H Planet Gear Bearing Analysis ReportDocument13 pagesAppendix H Planet Gear Bearing Analysis ReportCarloK98No ratings yet

- Electric Fuel PumpDocument5 pagesElectric Fuel PumprfffffNo ratings yet

- Point of Sale PoSDocument21 pagesPoint of Sale PoSBenhur LeoNo ratings yet

- Insertion Ultrasonic Flow MeterDocument3 pagesInsertion Ultrasonic Flow Meterbsanidhya10No ratings yet

- Man BWDocument24 pagesMan BWDhanie KhruxzNo ratings yet

- 6 4 4Document3 pages6 4 4Rodolfo PonceNo ratings yet

- Totem InstructionsDocument2 pagesTotem InstructionsTheDoctorFeelGoodNo ratings yet

- TST N 002 02.21 001 (01) Product Cleanliness Power ElectronicsDocument5 pagesTST N 002 02.21 001 (01) Product Cleanliness Power ElectronicsBeppe GasparettiNo ratings yet

- Mini RsioDocument13 pagesMini RsioAnonymous 7kJDSaNo ratings yet

- 1.4 B Tija Centromedulara PFN LungDocument18 pages1.4 B Tija Centromedulara PFN LungGhica CostinNo ratings yet

- IC Contractor Progress Payment Template 8531 V1Document6 pagesIC Contractor Progress Payment Template 8531 V1elbaraniNo ratings yet

- AX2 Data SheetDocument15 pagesAX2 Data Sheetguxiang0831No ratings yet

- Critique of Nashville's Transit Improvement Plan Malcolm Getz PHD January 2018Document19 pagesCritique of Nashville's Transit Improvement Plan Malcolm Getz PHD January 2018Andy MartinNo ratings yet

- Belzona 4341Document2 pagesBelzona 4341Bobby SatheesanNo ratings yet

- DT300-Series-manual Timer 04Document2 pagesDT300-Series-manual Timer 04eeindustrialNo ratings yet

- 03 - F30H Complete VehicleDocument106 pages03 - F30H Complete VehiclePepo MenéndezNo ratings yet

- Ce162p Module 2 Lecture 3 Strap FootingDocument11 pagesCe162p Module 2 Lecture 3 Strap FootingPROSPEROUS LUCKILYNo ratings yet

- Release Note For Local Loading Tool (LLT) 4.5.3: Reference: ICO-OPE-00119 V04Document9 pagesRelease Note For Local Loading Tool (LLT) 4.5.3: Reference: ICO-OPE-00119 V04AleksandarNo ratings yet

- Unit 1Document9 pagesUnit 1sunnynnusNo ratings yet

- Rishi Agarwal CVDocument2 pagesRishi Agarwal CVSourav PandaNo ratings yet

- Edc Question BankDocument6 pagesEdc Question BankManoj KumarNo ratings yet

- Segui 6e ISM Ch08Document105 pagesSegui 6e ISM Ch08miraj patelNo ratings yet

- MCC JOT Basic ProfilesDocument11 pagesMCC JOT Basic ProfilesSaurabh VermaNo ratings yet