Professional Documents

Culture Documents

Innio Ets t3 Us en 2023 Screen Ijb-123003-En-us

Innio Ets t3 Us en 2023 Screen Ijb-123003-En-us

Uploaded by

eyaeyoutaCopyright:

Available Formats

You might also like

- Unimog U 1550 L / U 1550 L/37: Technical DataDocument2 pagesUnimog U 1550 L / U 1550 L/37: Technical Dataquzwzwvfxuyoiovwnc100% (1)

- Datasheet 390B4-GCH Rev 130422mjDocument7 pagesDatasheet 390B4-GCH Rev 130422mjKeshka KoteraNo ratings yet

- Engine Sheet Type 3 e 2015Document2 pagesEngine Sheet Type 3 e 2015Esteban Vasquez GiraldoNo ratings yet

- Innio BR t3 Update A4 en 2021 Update NovDocument2 pagesInnio BR t3 Update A4 en 2021 Update NovRogelio PerozoNo ratings yet

- Jms Type 3 Fs SP 2016Document2 pagesJms Type 3 Fs SP 2016Jorge SGNo ratings yet

- GE Jenbacher Type 3 New RatingsDocument2 pagesGE Jenbacher Type 3 New RatingsSunil WadekarNo ratings yet

- GE - Engine Type Sheet - Type 3 - EN - 2015 - RZDocument2 pagesGE - Engine Type Sheet - Type 3 - EN - 2015 - RZr.eddie.cookeNo ratings yet

- Ytg 202110Document2 pagesYtg 202110Mhamad AlloucheNo ratings yet

- Wacker Neuson LTN6Document2 pagesWacker Neuson LTN6Jessica Tatiana Muñoz Ortiz67% (3)

- A) 1, 2 Engine B) 3 Engine: ST ND RDDocument2 pagesA) 1, 2 Engine B) 3 Engine: ST ND RDPing ApiwatNo ratings yet

- DIESEL ENGINES 12V/16V 2000 M92: MarineDocument2 pagesDIESEL ENGINES 12V/16V 2000 M92: MarineAlexlo LopezNo ratings yet

- Flender Load GearsDocument2 pagesFlender Load GearsAli EsentürkNo ratings yet

- Diesel Engine 12V 2000 M61: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engine 12V 2000 M61: For Vessels With Unrestricted Continuous Operation (1A)wellington freitasNo ratings yet

- Diesel Engines 16V 4000 M53M63 1ADocument2 pagesDiesel Engines 16V 4000 M53M63 1AMario100% (1)

- DIESEL ENGINES 12V/16V 2000 M72: MarineDocument2 pagesDIESEL ENGINES 12V/16V 2000 M72: Marinenaufragato100% (1)

- MTU Gendrive Spec 4000G 03 3D3E W2ADocument4 pagesMTU Gendrive Spec 4000G 03 3D3E W2APetrus GunturNo ratings yet

- SPECS 710d-1993 (A62)Document6 pagesSPECS 710d-1993 (A62)RojasNo ratings yet

- Spek UnitDocument4 pagesSpek UnitDedi Irdana GeaNo ratings yet

- Jenbacher Type 6 Fs en Metric 2016Document2 pagesJenbacher Type 6 Fs en Metric 2016laiquz zamanNo ratings yet

- Gps Waukesha 7042 BrochureDocument2 pagesGps Waukesha 7042 BrochureAlan SantosNo ratings yet

- Re 79093Document4 pagesRe 79093Anonymous lIJl27QBXLNo ratings yet

- Ytg PDFDocument2 pagesYtg PDFHarshitShuklaNo ratings yet

- Diesel Engines 16V 4000 M63R/M63/M63L: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engines 16V 4000 M63R/M63/M63L: For Vessels With Unrestricted Continuous Operation (1A)bbssNo ratings yet

- Op Uc 101Document1 pageOp Uc 101Fabian SNo ratings yet

- MTU Gendrive Spec 4000Gx03 3F3H W2A 1 16Document4 pagesMTU Gendrive Spec 4000Gx03 3F3H W2A 1 16TapasNo ratings yet

- 20kva 30kva Silent Diesel Generator Price - JET POWER - MelissaDocument3 pages20kva 30kva Silent Diesel Generator Price - JET POWER - MelissaAsh mohamedNo ratings yet

- Mtu 12V 16V4000M90 1DSDocument2 pagesMtu 12V 16V4000M90 1DSzaki100% (1)

- Marine Spec 16V4000M63 R L 1ADocument3 pagesMarine Spec 16V4000M63 R L 1ACristian A.No ratings yet

- Diesel Engine 16V 2000 M61: MarineDocument2 pagesDiesel Engine 16V 2000 M61: MarinemnezamiNo ratings yet

- Em Rxyq TtjuDocument98 pagesEm Rxyq TtjuMichael OchoaNo ratings yet

- LDocument2 pagesLmohamed hamedNo ratings yet

- คู่มือซ่อม HondaCBR1100XX 1997 - 1998 (pdf.io)Document9 pagesคู่มือซ่อม HondaCBR1100XX 1997 - 1998 (pdf.io)George Sakonkiat PoonsiriNo ratings yet

- Technical Data Sheet: Marine Diesel Engine D2862LE496 (V12-2000)Document3 pagesTechnical Data Sheet: Marine Diesel Engine D2862LE496 (V12-2000)mlaouhi MajedNo ratings yet

- Innio Engine Type Sheet t2 en 2021 2Document2 pagesInnio Engine Type Sheet t2 en 2021 2Yasir JamilNo ratings yet

- Iwk 119071 VGF F18GLDocument2 pagesIwk 119071 VGF F18GLAlejandro MuñozNo ratings yet

- DIESEL ENGINES 12V/16V 2000 M93: MarineDocument2 pagesDIESEL ENGINES 12V/16V 2000 M93: MarinenaufragatoNo ratings yet

- INNIO Jenbacher Type 2 - 2019 - enDocument2 pagesINNIO Jenbacher Type 2 - 2019 - enMartin KratkyNo ratings yet

- Gaki-Papanastassiou Et Al 1997-Coastal Vulnerability Assessment to Sea-level Rise BαsedDocument4 pagesGaki-Papanastassiou Et Al 1997-Coastal Vulnerability Assessment to Sea-level Rise BαsedJoharsyahNo ratings yet

- 1L Ecoboost Engine Spec SheetDocument2 pages1L Ecoboost Engine Spec SheetmarranNo ratings yet

- (Page 1 of 2) : Liters (Cubic Inches)Document3 pages(Page 1 of 2) : Liters (Cubic Inches)menna567mahmoudNo ratings yet

- GE - Engine Type Sheet - Type 6 - EN - 2015 - RZDocument2 pagesGE - Engine Type Sheet - Type 6 - EN - 2015 - RZr.eddie.cookeNo ratings yet

- Kta 38 G7Document3 pagesKta 38 G7ophar100% (1)

- Service Literature: Corp. 9703 L2 Revised 08 2003Document28 pagesService Literature: Corp. 9703 L2 Revised 08 2003Sonaina KhanNo ratings yet

- 1401375295Document4 pages1401375295tomjones77No ratings yet

- Generator SizingDocument32 pagesGenerator Sizingjared100% (1)

- Specifications: 3516C - SS Marine PropulsionDocument5 pagesSpecifications: 3516C - SS Marine PropulsionJesus UrdanetaNo ratings yet

- 9190-Uspe 2x10200kw Wartsila 20v32ts Hfo Diesel GensetDocument19 pages9190-Uspe 2x10200kw Wartsila 20v32ts Hfo Diesel Gensetpradeep kumarNo ratings yet

- Ets Ust 3 Update 14 ScreenDocument2 pagesEts Ust 3 Update 14 ScreenFaizan MotiwalaNo ratings yet

- CAT 3208 Mrine Engine SpecificationDocument4 pagesCAT 3208 Mrine Engine SpecificationCher Wee67% (3)

- YALE (B877) GDP130EB LIFT TRUCK Service Repair Manual PDFDocument23 pagesYALE (B877) GDP130EB LIFT TRUCK Service Repair Manual PDFhfjsjekmmdNo ratings yet

- KAWASAKI ZX11 - General SpecificationsDocument1 pageKAWASAKI ZX11 - General SpecificationsRaúl Di LolloNo ratings yet

- Catalog Big Capacity AHU DX DuctedDocument28 pagesCatalog Big Capacity AHU DX DuctedBistok ManurungNo ratings yet

- WaukeshaDocument2 pagesWaukeshacarlos angelNo ratings yet

- Gv180ti Co Gen-FDocument2 pagesGv180ti Co Gen-FSilver SilverNo ratings yet

- 4000 MTU Gendrive Spec 4000GxV12 V16 V20Document5 pages4000 MTU Gendrive Spec 4000GxV12 V16 V20Muhammet KöseNo ratings yet

- Airwerks IntroDocument32 pagesAirwerks IntroRalph WamaeNo ratings yet

- Cond 48-60 CassetteDocument1 pageCond 48-60 Cassettemayoreo.veracruzNo ratings yet

- 1-3.5R LPG Service Manual & Parts ListDocument77 pages1-3.5R LPG Service Manual & Parts ListEDWARD MARINNo ratings yet

- Aida Ar2008 eDocument52 pagesAida Ar2008 eLuis ParaisoNo ratings yet

- STP330Document14 pagesSTP330waleedyehiaNo ratings yet

- Honda BF20D BAMJ PDFDocument147 pagesHonda BF20D BAMJ PDFJauharul Alam0% (1)

- Cummins Onan X1.7 and X2 Service Repair ManualDocument6 pagesCummins Onan X1.7 and X2 Service Repair ManualDean RimbaudNo ratings yet

- Cat Filter and Filter Application GuideDocument255 pagesCat Filter and Filter Application GuideJorgeSheperdNo ratings yet

- Investigating The Influences of Liquid LPG InjectiDocument9 pagesInvestigating The Influences of Liquid LPG InjectiΙωάννης ΖαφειράτοςNo ratings yet

- Kom Unit 1 Notes: Types of Constrained MotionsDocument7 pagesKom Unit 1 Notes: Types of Constrained MotionsParkunam RandyNo ratings yet

- Airbus Engine Mode Selector CrankDocument4 pagesAirbus Engine Mode Selector CrankJem SzeNo ratings yet

- RENK AED eDocument8 pagesRENK AED eZehraNo ratings yet

- Lift Energy ConsumptionDocument10 pagesLift Energy ConsumptionNguyễn Thế PhongNo ratings yet

- 2C EngineDocument6 pages2C EngineRv Pilongo100% (1)

- Heavy Equipment Component LifeDocument9 pagesHeavy Equipment Component LifeiversonNo ratings yet

- Automotive Industry Literature ReviewDocument7 pagesAutomotive Industry Literature Reviewdazelasif100% (1)

- Why Eaton Hydraulics? World-Class Brands.: From Off-Road To Industrial. Global DistributionDocument14 pagesWhy Eaton Hydraulics? World-Class Brands.: From Off-Road To Industrial. Global Distributioneaglego00No ratings yet

- GMG-GRS-DS-M-001 Rev.0 Data Sheet For Emergency Diesel GeneratorDocument14 pagesGMG-GRS-DS-M-001 Rev.0 Data Sheet For Emergency Diesel GeneratorRanu JanuarNo ratings yet

- Project Report Submitted ToDocument74 pagesProject Report Submitted ToCKEC-CSE IVNo ratings yet

- AC 23-8B Flight Test Guide App 1Document22 pagesAC 23-8B Flight Test Guide App 1Ladislao PazmanyNo ratings yet

- X2 1.6 - Teknik VerilerDocument5 pagesX2 1.6 - Teknik VerilerRamazanNo ratings yet

- Crossflow Propeller Speed Reduction Unit (PSRU) - US$4,945.00Document4 pagesCrossflow Propeller Speed Reduction Unit (PSRU) - US$4,945.00G.L. ZortmanNo ratings yet

- CrankshaftDocument12 pagesCrankshaftbereket tekleNo ratings yet

- RENR5912-01 G3616 Engine Electrical System PDFDocument2 pagesRENR5912-01 G3616 Engine Electrical System PDFJulian Rueda100% (1)

- lh202 Specification Sheet English PDFDocument6 pageslh202 Specification Sheet English PDFLincolNo ratings yet

- Art 293 - 1968 FIA Appendix J-EngDocument2 pagesArt 293 - 1968 FIA Appendix J-EngBlaze123xNo ratings yet

- Tension-Weld® Strapping Tool: Downloaded From Manuals Search EngineDocument36 pagesTension-Weld® Strapping Tool: Downloaded From Manuals Search EnginePepeNo ratings yet

- DVX 100Document4 pagesDVX 100Rishwanth ATN100% (1)

- Cleaned: Reviewer in Automotive ServicingDocument6 pagesCleaned: Reviewer in Automotive ServicingJinky BarbieNo ratings yet

- Electrical Propulsion SystemDocument15 pagesElectrical Propulsion SystemAngelito AndaNo ratings yet

- Thermo KingDocument4 pagesThermo KingYacine Mariche100% (3)

- 3577 InstructionsDocument8 pages3577 Instructionsعبدالله العمرانNo ratings yet

- Obd ServicesDocument2 pagesObd ServicesranasaudenrouteNo ratings yet

Innio Ets t3 Us en 2023 Screen Ijb-123003-En-us

Innio Ets t3 Us en 2023 Screen Ijb-123003-En-us

Uploaded by

eyaeyoutaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Innio Ets t3 Us en 2023 Screen Ijb-123003-En-us

Innio Ets t3 Us en 2023 Screen Ijb-123003-En-us

Uploaded by

eyaeyoutaCopyright:

Available Formats

JENBACHER TYPE 3

Efficient, durable, reliable

Long service intervals, maintenance-friendly engine design

and low fuel consumption ensure maximum efficiency in our

type 3 Jenbacher engines. Enhanced components prolong

service life even when using non-pipeline gases, such as

landfill gas. Our type 3 engines offer an outstanding service

interval with up to 80,000 operating hours until the major

overhaul. This engine type stands out in its 400 to 1,100 kW

power range due to its technical maturity and high degree

of reliability.

Reference installations

J316 AMCO Produce, Canada

Energy source Engine type Electrical output Thermal output Commissioning

Pipeline gas 1 x J316 2,900 MBTU/hr 4,094 MBTU/hr 2021

To support its energy- and heat-intensive hydroponic production, AMCO Produce turned to a combined heat and power (CHP)

solution centered on a single Jenbacher J316 engine powered by pipeline gas. Equipped with heat recovery systems, the new

cogeneration plant delivers 2,900 MBTU/hr of power and 4,094 MBTU/hr of heat to meet the 100-acre greenhouse facility’s

baseload demand and complement its thermal demand.

J320 Gasgreen Energía, Ecuador

Energy source Engine type Electrical output Commissioning

Landfill gas 2 x J320 17,060 MBTU/hr 2016, 2017

3 x J420

In 2016, two of INNIO’s Jenbacher J320 gensets began delivering 6,824 MBTU/hr of power running on renewable landfill gas from

the Gasgreen Energía landfill site. Based on that success, three Jenbacher J420 were added in 2017. Today, the power plant

delivers a combined 17,060 MBTU/hr of electricity to power more than 25,000 homes in Ecuador and annually saves 26 million

cubic meters of landfill gas from being released into the environment.*

* https://www.emgirs.gob.ec/index.php/noticiasep/398-quito-se-destaca-en-el-ecuador%02al-producir-energia-electrica-de-la-basura

J320 Shandong Minhe Biological Technology Co., LTD, China

Energy source Engine type Electrical output Thermal output Commissioning

Biogas 3 x J320 21,155 MBTU/hr 22,520 MBTU/hr 2009, 2018

1 x J620

The farm’s biogas power generation project uses chicken manure and sewage fermentation to produce biogas. Commissioned in

2009, the facility is powered by three Jenbacher J320 biogas-fueled engines, and a J620 biogas-fueled engine was added in 2018.

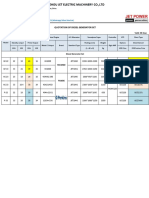

Technical data

Configuration V 70° Dimensions l x w x h (inch)

Bore (inch) 5.31 J312 190 x 70 x 90

Generator set J316 210 x 70 x 90

J320 230 x 70 x 100

Stroke (inch) 6.69

J312 190 x 90 x 90

Displacement / cylinder (cu.in) 148.5 Cogeneration system J316 210 x 90 x 90

J320 230 x 80 x 90

Speed (rpm) 1,800 (60 Hz) J312 480 x 100 x 110

Container 40-foot J316 480 x 100 x 110

Mean piston speed (in/s) 402 J320 480 x 100 x 110

Generator set, cogeneration

Scope of supply system, generator set / Weights empty (lbs)

cogeneration in container

J312 18,740

Generator set J316 22,490

Natural gas, flare gas, propane, J320 29,770

biogas, landfill gas, sewage gas,

Applicable gas types J312 21,830

special gases (e.g., coal mine gas,

Cogeneration system J316 24,910

coke gas, wood gas, pyrolysis gas) J320 30,870

Engine type J312 J316 J320 J312 46,370

No. of cylinders 12 16 20 Container 40-foot J316 53,870

Total displacement (cu.in) 1,782 2,376 2,970 J320 64,980

Outputs and efficiencies

Natural gas 1,800 rpm | 60 Hz

NOX < Type Pel (kW)1 Pth (MBTU/hr)² ηel (%)1 ηth (%)2 ηtot (%)

J312 635 2,627 40.1 48.7 88.8

1.0 g/bhp.hr J316 847 3,505 40.2 48.7 88.9

J320 1,062 4,382 40.3 48.7 89.1

J312 635 2,693 39.1 48.7 87.8

0.5 g/bhpr J316 847 3,590 39.2 48.7 87.8

J320 1,062 4,480 39.3 48.6 87.9

Biogas 1,800 rpm | 60 Hz

NOX < Type Pel (kW)1 Pth (MBTU/hr)² ηel (%)1 ηth (%)2 ηtot (%)

J312 635 2,566 39.7 47.1 86.8

1.0 g/bhp.hr J316 847 3,422 39.8 47.1 86.9

J320 1,062 4,272 39.9 47.0 86.9

J312 635 2,610 39.1 47.2 86.3

0.5 g/bhpr J316 847 3,480 39.2 47.2 86.3

J320 1,062 4,350 39.3 47.2 86.4

1

Technical data according to ISO 3046

2

Total heat output with a tolerance of +/- 8%, exhaust gas outlet temperature 120°C, for biogas gas outlet temperature 180°C

All data according to full load and subject to technical development and modification.

Further engine versions available on request.

I JB-1 23 003-EN-US

In general, “Ready for H2” Jenbacher units can be converted to operate on up to

100% hydrogen in the future. Details on the cost and timeline for a future conversion

may vary and need to be clarified individually.

© Copyright 2023 INNIO. Information provided is subject to change without notice.

INNIO, , Jenbacher, are trademarks in the European Union or

Contact us: elsewhere owned by INNIO Jenbacher GmbH & Co OG or one of its affiliates.

jenbacher.com/en/contact All other trademarks and company names are property of their respective owners.

jenbacher.us Jenbacher is part of the INNIO Group

You might also like

- Unimog U 1550 L / U 1550 L/37: Technical DataDocument2 pagesUnimog U 1550 L / U 1550 L/37: Technical Dataquzwzwvfxuyoiovwnc100% (1)

- Datasheet 390B4-GCH Rev 130422mjDocument7 pagesDatasheet 390B4-GCH Rev 130422mjKeshka KoteraNo ratings yet

- Engine Sheet Type 3 e 2015Document2 pagesEngine Sheet Type 3 e 2015Esteban Vasquez GiraldoNo ratings yet

- Innio BR t3 Update A4 en 2021 Update NovDocument2 pagesInnio BR t3 Update A4 en 2021 Update NovRogelio PerozoNo ratings yet

- Jms Type 3 Fs SP 2016Document2 pagesJms Type 3 Fs SP 2016Jorge SGNo ratings yet

- GE Jenbacher Type 3 New RatingsDocument2 pagesGE Jenbacher Type 3 New RatingsSunil WadekarNo ratings yet

- GE - Engine Type Sheet - Type 3 - EN - 2015 - RZDocument2 pagesGE - Engine Type Sheet - Type 3 - EN - 2015 - RZr.eddie.cookeNo ratings yet

- Ytg 202110Document2 pagesYtg 202110Mhamad AlloucheNo ratings yet

- Wacker Neuson LTN6Document2 pagesWacker Neuson LTN6Jessica Tatiana Muñoz Ortiz67% (3)

- A) 1, 2 Engine B) 3 Engine: ST ND RDDocument2 pagesA) 1, 2 Engine B) 3 Engine: ST ND RDPing ApiwatNo ratings yet

- DIESEL ENGINES 12V/16V 2000 M92: MarineDocument2 pagesDIESEL ENGINES 12V/16V 2000 M92: MarineAlexlo LopezNo ratings yet

- Flender Load GearsDocument2 pagesFlender Load GearsAli EsentürkNo ratings yet

- Diesel Engine 12V 2000 M61: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engine 12V 2000 M61: For Vessels With Unrestricted Continuous Operation (1A)wellington freitasNo ratings yet

- Diesel Engines 16V 4000 M53M63 1ADocument2 pagesDiesel Engines 16V 4000 M53M63 1AMario100% (1)

- DIESEL ENGINES 12V/16V 2000 M72: MarineDocument2 pagesDIESEL ENGINES 12V/16V 2000 M72: Marinenaufragato100% (1)

- MTU Gendrive Spec 4000G 03 3D3E W2ADocument4 pagesMTU Gendrive Spec 4000G 03 3D3E W2APetrus GunturNo ratings yet

- SPECS 710d-1993 (A62)Document6 pagesSPECS 710d-1993 (A62)RojasNo ratings yet

- Spek UnitDocument4 pagesSpek UnitDedi Irdana GeaNo ratings yet

- Jenbacher Type 6 Fs en Metric 2016Document2 pagesJenbacher Type 6 Fs en Metric 2016laiquz zamanNo ratings yet

- Gps Waukesha 7042 BrochureDocument2 pagesGps Waukesha 7042 BrochureAlan SantosNo ratings yet

- Re 79093Document4 pagesRe 79093Anonymous lIJl27QBXLNo ratings yet

- Ytg PDFDocument2 pagesYtg PDFHarshitShuklaNo ratings yet

- Diesel Engines 16V 4000 M63R/M63/M63L: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engines 16V 4000 M63R/M63/M63L: For Vessels With Unrestricted Continuous Operation (1A)bbssNo ratings yet

- Op Uc 101Document1 pageOp Uc 101Fabian SNo ratings yet

- MTU Gendrive Spec 4000Gx03 3F3H W2A 1 16Document4 pagesMTU Gendrive Spec 4000Gx03 3F3H W2A 1 16TapasNo ratings yet

- 20kva 30kva Silent Diesel Generator Price - JET POWER - MelissaDocument3 pages20kva 30kva Silent Diesel Generator Price - JET POWER - MelissaAsh mohamedNo ratings yet

- Mtu 12V 16V4000M90 1DSDocument2 pagesMtu 12V 16V4000M90 1DSzaki100% (1)

- Marine Spec 16V4000M63 R L 1ADocument3 pagesMarine Spec 16V4000M63 R L 1ACristian A.No ratings yet

- Diesel Engine 16V 2000 M61: MarineDocument2 pagesDiesel Engine 16V 2000 M61: MarinemnezamiNo ratings yet

- Em Rxyq TtjuDocument98 pagesEm Rxyq TtjuMichael OchoaNo ratings yet

- LDocument2 pagesLmohamed hamedNo ratings yet

- คู่มือซ่อม HondaCBR1100XX 1997 - 1998 (pdf.io)Document9 pagesคู่มือซ่อม HondaCBR1100XX 1997 - 1998 (pdf.io)George Sakonkiat PoonsiriNo ratings yet

- Technical Data Sheet: Marine Diesel Engine D2862LE496 (V12-2000)Document3 pagesTechnical Data Sheet: Marine Diesel Engine D2862LE496 (V12-2000)mlaouhi MajedNo ratings yet

- Innio Engine Type Sheet t2 en 2021 2Document2 pagesInnio Engine Type Sheet t2 en 2021 2Yasir JamilNo ratings yet

- Iwk 119071 VGF F18GLDocument2 pagesIwk 119071 VGF F18GLAlejandro MuñozNo ratings yet

- DIESEL ENGINES 12V/16V 2000 M93: MarineDocument2 pagesDIESEL ENGINES 12V/16V 2000 M93: MarinenaufragatoNo ratings yet

- INNIO Jenbacher Type 2 - 2019 - enDocument2 pagesINNIO Jenbacher Type 2 - 2019 - enMartin KratkyNo ratings yet

- Gaki-Papanastassiou Et Al 1997-Coastal Vulnerability Assessment to Sea-level Rise BαsedDocument4 pagesGaki-Papanastassiou Et Al 1997-Coastal Vulnerability Assessment to Sea-level Rise BαsedJoharsyahNo ratings yet

- 1L Ecoboost Engine Spec SheetDocument2 pages1L Ecoboost Engine Spec SheetmarranNo ratings yet

- (Page 1 of 2) : Liters (Cubic Inches)Document3 pages(Page 1 of 2) : Liters (Cubic Inches)menna567mahmoudNo ratings yet

- GE - Engine Type Sheet - Type 6 - EN - 2015 - RZDocument2 pagesGE - Engine Type Sheet - Type 6 - EN - 2015 - RZr.eddie.cookeNo ratings yet

- Kta 38 G7Document3 pagesKta 38 G7ophar100% (1)

- Service Literature: Corp. 9703 L2 Revised 08 2003Document28 pagesService Literature: Corp. 9703 L2 Revised 08 2003Sonaina KhanNo ratings yet

- 1401375295Document4 pages1401375295tomjones77No ratings yet

- Generator SizingDocument32 pagesGenerator Sizingjared100% (1)

- Specifications: 3516C - SS Marine PropulsionDocument5 pagesSpecifications: 3516C - SS Marine PropulsionJesus UrdanetaNo ratings yet

- 9190-Uspe 2x10200kw Wartsila 20v32ts Hfo Diesel GensetDocument19 pages9190-Uspe 2x10200kw Wartsila 20v32ts Hfo Diesel Gensetpradeep kumarNo ratings yet

- Ets Ust 3 Update 14 ScreenDocument2 pagesEts Ust 3 Update 14 ScreenFaizan MotiwalaNo ratings yet

- CAT 3208 Mrine Engine SpecificationDocument4 pagesCAT 3208 Mrine Engine SpecificationCher Wee67% (3)

- YALE (B877) GDP130EB LIFT TRUCK Service Repair Manual PDFDocument23 pagesYALE (B877) GDP130EB LIFT TRUCK Service Repair Manual PDFhfjsjekmmdNo ratings yet

- KAWASAKI ZX11 - General SpecificationsDocument1 pageKAWASAKI ZX11 - General SpecificationsRaúl Di LolloNo ratings yet

- Catalog Big Capacity AHU DX DuctedDocument28 pagesCatalog Big Capacity AHU DX DuctedBistok ManurungNo ratings yet

- WaukeshaDocument2 pagesWaukeshacarlos angelNo ratings yet

- Gv180ti Co Gen-FDocument2 pagesGv180ti Co Gen-FSilver SilverNo ratings yet

- 4000 MTU Gendrive Spec 4000GxV12 V16 V20Document5 pages4000 MTU Gendrive Spec 4000GxV12 V16 V20Muhammet KöseNo ratings yet

- Airwerks IntroDocument32 pagesAirwerks IntroRalph WamaeNo ratings yet

- Cond 48-60 CassetteDocument1 pageCond 48-60 Cassettemayoreo.veracruzNo ratings yet

- 1-3.5R LPG Service Manual & Parts ListDocument77 pages1-3.5R LPG Service Manual & Parts ListEDWARD MARINNo ratings yet

- Aida Ar2008 eDocument52 pagesAida Ar2008 eLuis ParaisoNo ratings yet

- STP330Document14 pagesSTP330waleedyehiaNo ratings yet

- Honda BF20D BAMJ PDFDocument147 pagesHonda BF20D BAMJ PDFJauharul Alam0% (1)

- Cummins Onan X1.7 and X2 Service Repair ManualDocument6 pagesCummins Onan X1.7 and X2 Service Repair ManualDean RimbaudNo ratings yet

- Cat Filter and Filter Application GuideDocument255 pagesCat Filter and Filter Application GuideJorgeSheperdNo ratings yet

- Investigating The Influences of Liquid LPG InjectiDocument9 pagesInvestigating The Influences of Liquid LPG InjectiΙωάννης ΖαφειράτοςNo ratings yet

- Kom Unit 1 Notes: Types of Constrained MotionsDocument7 pagesKom Unit 1 Notes: Types of Constrained MotionsParkunam RandyNo ratings yet

- Airbus Engine Mode Selector CrankDocument4 pagesAirbus Engine Mode Selector CrankJem SzeNo ratings yet

- RENK AED eDocument8 pagesRENK AED eZehraNo ratings yet

- Lift Energy ConsumptionDocument10 pagesLift Energy ConsumptionNguyễn Thế PhongNo ratings yet

- 2C EngineDocument6 pages2C EngineRv Pilongo100% (1)

- Heavy Equipment Component LifeDocument9 pagesHeavy Equipment Component LifeiversonNo ratings yet

- Automotive Industry Literature ReviewDocument7 pagesAutomotive Industry Literature Reviewdazelasif100% (1)

- Why Eaton Hydraulics? World-Class Brands.: From Off-Road To Industrial. Global DistributionDocument14 pagesWhy Eaton Hydraulics? World-Class Brands.: From Off-Road To Industrial. Global Distributioneaglego00No ratings yet

- GMG-GRS-DS-M-001 Rev.0 Data Sheet For Emergency Diesel GeneratorDocument14 pagesGMG-GRS-DS-M-001 Rev.0 Data Sheet For Emergency Diesel GeneratorRanu JanuarNo ratings yet

- Project Report Submitted ToDocument74 pagesProject Report Submitted ToCKEC-CSE IVNo ratings yet

- AC 23-8B Flight Test Guide App 1Document22 pagesAC 23-8B Flight Test Guide App 1Ladislao PazmanyNo ratings yet

- X2 1.6 - Teknik VerilerDocument5 pagesX2 1.6 - Teknik VerilerRamazanNo ratings yet

- Crossflow Propeller Speed Reduction Unit (PSRU) - US$4,945.00Document4 pagesCrossflow Propeller Speed Reduction Unit (PSRU) - US$4,945.00G.L. ZortmanNo ratings yet

- CrankshaftDocument12 pagesCrankshaftbereket tekleNo ratings yet

- RENR5912-01 G3616 Engine Electrical System PDFDocument2 pagesRENR5912-01 G3616 Engine Electrical System PDFJulian Rueda100% (1)

- lh202 Specification Sheet English PDFDocument6 pageslh202 Specification Sheet English PDFLincolNo ratings yet

- Art 293 - 1968 FIA Appendix J-EngDocument2 pagesArt 293 - 1968 FIA Appendix J-EngBlaze123xNo ratings yet

- Tension-Weld® Strapping Tool: Downloaded From Manuals Search EngineDocument36 pagesTension-Weld® Strapping Tool: Downloaded From Manuals Search EnginePepeNo ratings yet

- DVX 100Document4 pagesDVX 100Rishwanth ATN100% (1)

- Cleaned: Reviewer in Automotive ServicingDocument6 pagesCleaned: Reviewer in Automotive ServicingJinky BarbieNo ratings yet

- Electrical Propulsion SystemDocument15 pagesElectrical Propulsion SystemAngelito AndaNo ratings yet

- Thermo KingDocument4 pagesThermo KingYacine Mariche100% (3)

- 3577 InstructionsDocument8 pages3577 Instructionsعبدالله العمرانNo ratings yet

- Obd ServicesDocument2 pagesObd ServicesranasaudenrouteNo ratings yet