Professional Documents

Culture Documents

Lighting System

Lighting System

Uploaded by

jamie.crassOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lighting System

Lighting System

Uploaded by

jamie.crassCopyright:

Available Formats

417-01-i Exterior Lighting 417-01-i

SECTION 417-01 Exterior Lighting

CONTENTS PAGE

DESCRIPTION AND OPERATION

Exterior Lighting .................................................................................................................................................................. 417-01-2

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-2 Exterior Lighting 417-01-2

DESCRIPTION AND OPERATION

Exterior Lighting

NOTE:

The perimeter lighting feature can be enabled or disabled (if equipped). When enabled, the exterior lamps are illuminated when the UNLOCK button is

pressed on the remote keyless entry (RKE) transmitter. For additional information, refer to Section 501-14.

Battery Saver

NOTE:

Time-out is 1 minute if the vehicle has less than 80 km (50 miles).

The battery saver is internal to the smart junction box (SJB) and provides automatic shut-off of the headlamps and parking lamps after 10 minutes in order to

save battery voltage. A timer is started when the ignition switch is turned to the OFF position with the headlamp switch in the HEADLAMPS ON position,

or the headlamp switch is placed in the HEADLAMPS ON position with the ignition switch off. When the time-out period has elapsed, the voltage is

automatically shut off to the lamps by the battery saver.

The battery saver does not control the parking lamps if the headlamp switch is in the PARKING LAMPS ON position.

Lamp Assembly Condensation

Exterior lamps are vented to accommodate normal changes in pressure. Condensation can be a natural by-product of this design. When moist air enters the

lamp assembly through the vents, there is a possibility that condensation can occur if the temperature is cold. When normal condensation occurs, a thin film

of mist can form on the interior of the lens. The thin mist eventually clears and exits through the vents during normal operation. Time to clear the lens of

acceptable mist varies with ambient humidity and lamp types. Normal condensation clears from any lamp in 48 hours under dry conditions.

Do not replace a lamp assembly with acceptable levels of condensation such as:

• presence of thin mist (no streaks, drip marks or droplets are present)

• fine mist covers less than 50% of the lens

Examples of unacceptable moisture (usually caused by a lamp housing leak):

• water puddling inside the lamp

• large water droplets, drip marks or streaks present on the interior of the lens

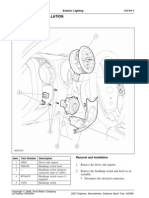

Headlamps

The headlamp system is a dual-beam pattern system. It consists of replaceable low/high beam bulbs. Vehicles may come equipped with aero-type

headlamps, or sealed beam type headlamps.

The smart junction box (SJB) supplies voltage to the headlamps when demanded. If the headlamps are on when the ignition switch is turned off, the battery

saver feature turns off the headlamps after 10 minutes have elapsed.

Autolamps

The autolamp system provides light sensitive automatic on/off control of the exterior lamps. The autolamp system keeps the exterior lamps on for a pre-

selected period of time after the ignition switch is turned to the OFF position (20 seconds is the factory default setting). The pre-selected time lapse is

adjustable up to approximately 3 minutes. For additional information, refer to Autolamps Time Delay Adjustment in this section.

Stoplamps

The stoplamp switch is located on the brake pedal assembly. The rear lamps and high mounted stoplamp are supplied voltage when the brake pedal is

applied. The rear lamps are combination stop/turn lamps.

Turn Signal/Hazard Lamps

When the multifunction switch is placed in the LH or RH TURN positions, the SJB routes voltage to the LH or RH turn signal lamps. The SJB then cycles

the voltage on and off approximately 80 times per minute. If a front or rear turn bulb is inoperative, the SJB cycles the voltage on and off approximately 160

times per minute.

The hazard switch is located on the center instrument panel finish panel. When the hazard switch is pressed, the SJB supplies voltage to all the turn lamps.

The SJB cycles the voltage on and off approximately 80 times per minute.

On vehicles with aero-type headlamps, the park/turn indicator lamp is integrated into the headlamp assembly.

On vehicles with sealed beam type headlamps, the park/turn indicator lamp is a separate assembly.

The rear lamps share functionality with the stoplamps.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-3 Exterior Lighting 417-01-3

DESCRIPTION AND OPERATION (Continued)

Parking Lamps

The SJB supplies voltage to the parking lamps when demanded.

On vehicles with aero-type headlamps, the front park/turn indicator lamp and side lamp are integrated into the headlamp assembly.

On vehicles with sealed beam type headlamps, the front park/turn indicator lamp is a separate assembly. The side lamp is also located within this assembly.

The rear parking lamps are located in the rear lamp assemblies.

Vehicles equipped with dual rear wheels have marker lamps located on the sides and rear of the pickup bed.

If equipped, the vehicle may have cab marker lamps located on the roof.

Fog Lamps

The fog lamp switch is integrated into the headlamp switch. When the fog lamp switch is engaged, the SJB provides ground for the fog lamp relay coil

(integrated into the SJB), which then energizes and routes voltage to the fog lamps. The fog lamps can be turned on when the ignition switch is in the RUN

or ACC position, the parking lamps are on, and the high beam headlamps are off.

Reversing Lamps

When the transmission is placed in REVERSE (R), the PCM (automatic transmission) or the reversing lamp switch (manual transmission) provides ground

for the reversing lamp relay coil. The reversing lamps receive voltage when the reversing lamp relay is energized. The reversing lamps are located within the

rear lamp assemblies.

Trailer Tow

The battery junction box (BJB) supplies voltage to the trailer tow stop/turn, parking and reversing lamps. When the vehicle's rear stop/turn or parking lamps

are illuminated, voltage is also supplied to a corresponding trailer tow relay (coil side) located in the BJB. When the reversing lamps are illuminated (the

reversing lamp relay is energized), voltage is also routed through BJB fuse 63 (15A) to the trailer tow connector for the trailer reversing lamps.

The trailer tow battery charge relay provides voltage to the trailer tow connector when the ignition switch is in the RUN position.

The vehicle may be equipped with a factory manufactured trailer tow electric module. For additional information, refer to Section 206-10.

On vehicles not equipped with a factory manufactured trailer tow electric module, the vehicle comes equipped with circuitry to support trailer tow electric

brakes.

Daytime Running Lamps (DRL)

The SJB can be configured to turn the DRL on for this vehicle. Refer to Section 418-01 for additional information on this programmable parameter.

The DRL system operates the low beam headlamps at a reduced intensity.

The SJB supplies pulse width modulated (PWM) voltage to illuminate the low beam headlamps at a reduced intensity when the following conditions are met:

• The ignition switch is in the RUN position.

• The headlamps have not been turned on by the autolamp system or the headlamp switch.

• The transmission is not in PARK (P) (automatic transmission).

• The parking brake is not applied (manual transmission).

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-i Exterior Lighting 417-01-i

SECTION 417-01 Exterior Lighting

CONTENTS PAGE

DIAGNOSIS AND TESTING

Autolamps ........................................................................................................................................................................... 417-01-2

Principles of Operation ................................................................................................................................................. 417-01-2

Inspection and Verification ........................................................................................................................................... 417-01-3

Symptom Chart ............................................................................................................................................................. 417-01-3

Pinpoint Tests ............................................................................................................................................................... 417-01-4

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-2 Exterior Lighting 417-01-2

DIAGNOSIS AND TESTING

Autolamps

Special Tool(s)

73III Automotive Meter

105-R0057 or equivalent

Vehicle Communication Module (VCM) and Integrated Diagnostic System (IDS) software

with appropriate hardware, or equivalent scan tool

Flex Probe Kit

105-R025C or equivalent

Principles of Operation

NOTE:

For additional information on the perimeter lighting feature, refer to Section 501-14.

NOTE:

The smart junction box (SJB) is also known as the generic electronic module (GEM).

Exterior Lighting

The SJB monitors the headlamp switch position by sending voltage reference signals on multiple circuits to the headlamp switch. There is one circuit for

each headlamp switch position. At any given time, one of the signal circuits is routed to ground.

If the SJB does not detect any of the inputs to the headlamp switch is active (routed to ground) for 5 seconds, the SJB turns on the exterior lights and keeps

them on for 10 minutes after the ignition switch is turned off (or 10 minutes from the time the SJB does not detect any headlamp switch input if the ignition

switch was already off). Additionally, if the SJB detects multiple circuits short to ground, the SJB implements a planned strategy depending on the multiple

inputs received.

If either of these situations occur, the SJB should NOT be ruled immediately as being at fault. This is normal behavior of the SJB design as it has detected a

fault with the inputs from the headlamp switch.

Autolamps Feature

The SJB also monitors the light sensor with a voltage reference signal. The light sensor input to the SJB varies with the ambient light conditions.

When the SJB receives an input from the headlamp switch indicating a request for the autolamps, the SJB monitors the light sensor for the ambient light

condition. If the SJB determines the ambient light level is dark, the SJB supplies voltage to the exterior lamps.

If the ignition switch is already in the RUN position and the vehicle enters a dark/lighted area (such as when entering/exiting a non-lighted tunnel during the

daytime), the transition from light to dark (or dark to light) needs to last 15 seconds before the SJB turns on or off the exterior lamps. This strategy is to

prevent the exterior lamps from unnecessarily flashing on and off.

The SJB does react quicker under extreme light conditions. If the SJB has detected a very dark condition, the exterior lamps are turned on after 1.5 seconds.

If the SJB has detected a very high ambient light level, the exterior lamps are turned off after 4 seconds.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-3 Exterior Lighting 417-01-3

DIAGNOSIS AND TESTING (Continued)

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection Chart

Mechanical Electrical

• Headlamp switch • Wiring, terminals or connectors

• Light sensor

• Smart junction box (SJB)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to the next step.

NOTE:

Make sure the headlamp switch is in the OFF position.

NOTE:

Make sure the multifunction switch is not in the HIGH BEAM position.

4. NOTE:

Make sure to use the latest scan tool software release.

If the cause is not visually evident, connect the scan tool to the data link connector (DLC).

5. NOTE:

The vehicle communication module (VCM) LED prove-out confirms power and ground from the DLC are provided to the VCM.

If the scan tool does not communicate with the VCM:

• Check the VCM connection to the vehicle.

• Check the scan tool connection to the VCM.

• Refer to Section 418-00, No Power To The Scan Tool, to diagnose no communication with the scan tool.

6. If the scan tool does not communicate with the vehicle:

• Verify the ignition key is in the ON position.

• Verify the scan tool operation with a known good vehicle.

• Refer to Section 418-00 to diagnose no response from the PCM.

7. Carry out the network test.

• If the scan tool responds with no communication for one or more modules, refer to Section 418-00.

• If the network test passes, retrieve and record the continuous memory DTCs.

8. Clear the continuous DTCs and carry out the self-test diagnostics for the smart junction box (SJB).

9. If the DTCs retrieved are related to the concern, go to DTC Charts. For all other DTCs, refer to Section 419-10.

10. If no DTCs related to the concern are retrieved, GO to Symptom Chart.

Symptom Chart

Symptom Chart

Condition Possible Sources Action

• No communication with the smart junction • Fuse • REFER to Section 418-00.

box (SJB) • Wiring, terminals or connectors

• SJB

• The autolamps are inoperative • Light sensor • GO to Pinpoint Test F.

• SJB

• The autolamps are on continuously • Wiring, terminals or connectors • GO to Pinpoint Test G.

• Light sensor

• Headlamp switch

• SJB

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-4 Exterior Lighting 417-01-4

DIAGNOSIS AND TESTING (Continued)

Symptom Chart (Continued)

Condition Possible Sources Action

• The autolamp time delay is inoperative • SJB • CHECK the SJB configuration and make

sure the autolamp feature is configured

correctly.

— If the SJB is configured correctly,

INSTALL a new SJB. REFER to

Section 419-10.

— If the SJB is not configured correctly,

CONFIGURE the SJB. REFER to

Section 418-01. TEST the system for

normal operation.

Pinpoint Tests

Pinpoint Test F: The Autolamps Are Inoperative

Refer to Wiring Diagrams Cell 85 Headlamps/Autolamps for schematic and connector information.

Normal Operation

When the headlamp switch is placed in the AUTOLAMPS ON position, the voltage signal is routed to ground. When the smart junction box (SJB) detects

the headlamp switch in the AUTOLAMPS ON position, the SJB monitors the light sensor input. The light sensor determines the amount of light based on

the input received from the ambient lighting conditions. When the ambient level has reached a point (determined by the internal programming of the SJB),

the SJB provides voltage to the headlamps, parking and license plate lamps.

If the SJB detects any faults with the inputs from the light sensor or the headlamp switch, the SJB faults the exterior lamps on.

This pinpoint test is intended to diagnose the following:

• Light sensor

• SJB

PINPOINT TEST F: THE AUTOLAMPS ARE INOPERATIVE

NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

Test Step Result / Action to Take

F1 CHECK THE MANUAL HEADLAMP OPERATION

• Place the headlamp switch in the HEADLAMPS ON position. Yes

• Do the headlamps operate correctly? GO to F2.

No

REFER to Headlamps in this section.

F2 CHECK FOR VOLTAGE TO THE LIGHT SENSOR

• Ignition OFF.

• Disconnect: Light Sensor C286 or C287.

• Ignition ON.

• Place the headlamp switch in the AUTOLAMPS ON position.

• On vehicles with electronic automatic temperature control (EATC),

measure the voltage between the light sensor C287-2, circuit VLF14

(BU/BN), harness side and ground.

Yes

INSTALL a new light sensor. REFER to Light Sensor in

this section. CLEAR the DTCs. REPEAT the self-test.

No

GO to F3.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-5 Exterior Lighting 417-01-5

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST F: THE AUTOLAMPS ARE INOPERATIVE (Continued)

F2 CHECK FOR VOLTAGE TO THE LIGHT SENSOR (Continued)

• On vehicles with manual temperature control, measure the voltage

between the light sensor C286-1, circuit VLF14 (BU/BN), harness side

and ground.

• Is the voltage approximately 5 volts?

F3 CHECK FOR CORRECT SJB OPERATION

• Disconnect all the SJB connectors.

Yes

• Check for:

INSTALL a new SJB. REFER to Section 419-10. TEST

— corrosion

the system for normal operation.

— damaged pins

— pushed-out pins No

• Connect all the SJB connectors and make sure they seat correctly. The system is operating correctly at this time. The

• Operate the system and verify the concern is still present. concern may have been caused by a loose or corroded

• Is the concern still present? connector. CLEAR the DTCs. REPEAT the self-test.

Pinpoint Test G: The Autolamps Are On Continuously

Refer to Wiring Diagrams Cell 85 Headlamps/Autolamps for schematic and connector information.

Normal Operation

The smart junction box (SJB) sends a reference voltage signal to the headlamp switch through circuit CLF19 (VT/GN) and a reference voltage signal to the

light sensor through circuit VLF14 (BU/BN). Ground for the headlamp switch is provided by circuit GD115 (BK/GY). Ground for the light sensor is

provided by circuit GD133 (BK).

When the headlamp switch is placed in the AUTOLAMPS ON position, the voltage signal is routed to ground. When the SJB detects the headlamp switch in

the AUTOLAMPS ON position, the SJB monitors the light sensor input. The light sensor determines the amount of light based on the input received from

the ambient lighting conditions. When the ambient level has reached a point (determined by the internal programming of the SJB), the SJB provides voltage

to the headlamps, parking and license plate lamps.

DTC Description Fault Trigger Conditions

• B1472 — Lamp Headlamp Input Circuit Short to Ground An on-demand DTC that sets when the SJB detects the headlamps on input

circuit is shorted to ground.

• B1696 — Autolamp On Circuit Short To Ground An on-demand DTC that sets when the SJB detects the autolamps on input

circuit shorted to ground.

• B1791 — Autolamp Sensor Input Circuit Open An on-demand DTC that sets when the SJB detects an open on the light

sensor input circuit.

• B1793 — Autolamp Sensor Input Circuit Short to Ground A continuous and on-demand DTC that sets when the SJB detects a short to

ground on the light sensor input circuit.

• B2A22 — Headlamp Off Circuit Open An on-demand DTC that sets when the SJB detects the headlamp switch off

circuit open.

This pinpoint test is intended to diagnose the following:

• Wiring, terminals or connectors

• Light sensor

• Headlamp switch

• SJB

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-6 Exterior Lighting 417-01-6

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST G: THE AUTOLAMPS ARE ON CONTINUOUSLY

NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

Test Step Result / Action to Take

G1 USE THE RECORDED DTCs FROM THE SJB SELF-TEST

• Check the recorded results from the SJB self-test. Yes

• Was DTC B1791 or B1793 recorded? For DTC B1791, GO to G7. For DTC B1793, GO to

G11.

No

GO to G2.

G2 CHECK THE SJB HEADLAMP SWITCH PIDs

• Enter the following diagnostic mode on the scan tool: SJB DataLogger.

• NOTE:

Make sure the headlamp switch is lined up in the correct position

when monitoring the PIDs.

Monitor the SJB headlamp switch input PIDs (HD_LMP_S2 and

HEAD_L) while moving the headlamp switch through all positions.

Refer to the following chart.

Headlamp Switch HD_LMP_S2 HEAD_L Expected

Position Expected Value Value

Autolamps AUTOLAMP OFF

OFF — OFF

Yes

Parklamp — — GO to G13.

Headlamp — HEADLAMP No

• Do the headlamp switch positions agree with the PIDs? GO to G3.

G3 CHECK THE HEADLAMP SWITCH

• Ignition OFF. Yes

• Disconnect: Headlamp Switch C205. GO to G4.

• Carry out the headlamp switch component test. Refer to Wiring

No

Diagrams Cell 149 for component testing.

INSTALL a new headlamp switch. REFER to

• Is the headlamp switch OK?

Headlamp Switch in this section. CLEAR the DTCs.

REPEAT the self-test.

G4 CHECK CIRCUIT GD115 (BK/GY) FOR AN OPEN

• Measure the resistance between the headlamp switch C205-1, circuit

GD115 (BK/GY), harness side and ground.

Yes

GO to G5.

No

REPAIR the circuit. Clear the DTCs. REPEAT the self-

• Is the resistance less than 5 ohms? test.

G5 CHECK THE HEADLAMP SWITCH INPUT CIRCUITS FOR A SHORT TO GROUND

• Disconnect: SJB C2280b.

• Measure the resistance between the headlamp switch, harness side Yes

and ground as follows: GO to G6.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-7 Exterior Lighting 417-01-7

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST G: THE AUTOLAMPS ARE ON CONTINUOUSLY (Continued)

G5 CHECK THE HEADLAMP SWITCH INPUT CIRCUITS FOR A SHORT TO GROUND (Continued)

Headlamp Switch Connector- Circuit

Pin

C205-9 CLF19 (VT/GN)

No

C205-8 CLF24 (YE/BU) REPAIR the circuit in question. CLEAR the DTCs.

• Are the resistances greater than 10,000 ohms? REPEAT the self-test.

G6 CHECK THE HEADLAMP SWITCH INPUT CIRCUITS FOR AN OPEN

• Measure the resistance between the headlamp switch, harness side

and the SJB, harness side as follows:

Headlamp Switch SJB Connector-Pin Circuit

Connector-Pin

C205-9 C2280b-50 CLF19 (VT/GN) Yes

GO to G13.

C205-4 C2280b-47 CLF23 (WH/VT)

No

C205-3 C2280b-31 CLS34 (GY) REPAIR the circuit in question. CLEAR the DTCs.

• Are the resistances less than 5 ohms? REPEAT the self-test.

G7 CHECK CIRCUIT GD133 (BK) FOR AN OPEN

• Ignition OFF.

• Disconnect: Light Sensor C286 or C287.

• On vehicles with EATC, measure the resistance between the light

sensor C287-4, circuit GD133 (BK), harness side and ground.

• On vehicles with manual climate control, measure the resistance

between the light sensor C286-2, circuit GD133 (BK), harness side

and ground.

Yes

GO to G8.

No

REPAIR the circuit. CLEAR the DTCs. REPEAT the self-

• Is the resistance less than 5 ohms? test.

G8 CHECK CIRCUIT VLF14 (BU/BN) FOR A SHORT TO VOLTAGE

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-8 Exterior Lighting 417-01-8

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST G: THE AUTOLAMPS ARE ON CONTINUOUSLY (Continued)

G8 CHECK CIRCUIT VLF14 (BU/BN) FOR A SHORT TO VOLTAGE (Continued)

• Disconnect: SJB C2280b.

• Ignition ON.

• On vehicles with EATC, measure the voltage between the light sensor

C287-2, circuit VLF14 (BU/BN), harness side and ground.

• On vehicles with manual climate control, measure the voltage

between the light sensor C286-1, circuit VLF14 (BU/BN), harness side

and ground.

Yes

REPAIR the circuit. CLEAR the DTCs. REPEAT the self-

test.

No

• Is any voltage present? GO to G9.

G9 CHECK CIRCUIT VLF14 (BU/BN) FOR AN OPEN

• Ignition OFF.

• On vehicles with EATC, measure the resistance between the light

sensor C287-2, circuit VLF14 (BU/BN), harness side and the SJB

C2280b-46, circuit VLF14 (BU/BN), harness side.

Yes

GO to G10.

• On vehicles with manual climate control, measure the resistance No

between the light sensor C286-1, circuit VLF14 (BU/BN), harness side REPAIR the circuit. CLEAR the DTCs. REPEAT the self-

and the SJB C2280b-46, circuit VLF14 (BU/BN), harness side. test.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-9 Exterior Lighting 417-01-9

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST G: THE AUTOLAMPS ARE ON CONTINUOUSLY (Continued)

G9 CHECK CIRCUIT VLF14 (BU/BN) FOR AN OPEN (Continued)

• Is the resistance less than 5 ohms?

G10 CHECK FOR VOLTAGE TO THE LIGHT SENSOR (DTC B1791)

• Connect: SJB C2280b.

• Ignition ON.

• Place the headlamp switch in the AUTOLAMPS ON position.

• On vehicles with EATC, measure the voltage between the light sensor

C287-2, circuit VLF14 (BU/BN), harness side and ground.

• On vehicles with manual climate control, measure the voltage

between the light sensor C286-1, circuit VLF14 (BU/BN), harness side

and ground.

Yes

INSTALL a new light sensor. REFER to Light Sensor in

this section. CLEAR the DTCs. REPEAT the self-test.

No

• Is the voltage approximately 5 volts? GO to G13.

G11 CHECK FOR VOLTAGE TO THE LIGHT SENSOR (DTC B1793)

• Disconnect: Light Sensor C286 or C287. Yes

• Ignition ON. INSTALL a new light sensor. REFER to Light Sensor in

• Place the headlamp switch in the AUTOLAMPS ON position. this section. CLEAR the DTCs. REPEAT the self-test.

• On vehicles with EATC, measure the voltage between the light sensor

No

C287-2, circuit VLF14 (BU/BN), harness side and ground.

GO to G12.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-10 Exterior Lighting 417-01-10

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST G: THE AUTOLAMPS ARE ON CONTINUOUSLY

G11 CHECK FOR VOLTAGE TO THE LIGHT SENSOR (DTC B1793) (Continued)

• On vehicles with manual temperature control, measure the voltage

between the light sensor C286-1, circuit VLF14 (BU/BN), harness side

and ground.

• Is the voltage approximately 5 volts?

G12 CHECK CIRCUIT VLF14 (BU/BN) FOR A SHORT TO GROUND

• Ignition OFF.

• Disconnect: SJB C2280b.

• On vehicles with EATC, measure the resistance between the light

sensor C287-2, circuit VLF14 (BU/BN), harness side and ground.

Yes

GO to G13.

• On vehicles with manual temperature control, measure the resistance No

between the light sensor C286-1, circuit VLF14 (BU/BN), harness side REPAIR the circuit. CLEAR the DTCs. REPEAT the self-

and ground. test.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-11 Exterior Lighting 417-01-11

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST G: THE AUTOLAMPS ARE ON CONTINUOUSLY

G12 CHECK CIRCUIT VLF14 (BU/BN) FOR A SHORT TO GROUND (Continued)

• Is the resistance greater than 10,000 ohms?

G13 CHECK FOR CORRECT SJB OPERATION

• Ignition OFF.

• Disconnect all the SJB connectors.

Yes

• Check for:

INSTALL a new SJB. REFER to Section 419-10. TEST

— corrosion

the system for normal operation.

— damaged pins

— pushed-out pins No

• Connect all the SJB connectors and make sure they seat correctly. The system is operating correctly at this time. The

• Operate the system and verify the concern is still present. concern may have been caused by a loose or corroded

• Is the concern still present? connector. CLEAR the DTCs. REPEAT the self-test.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-i Exterior Lighting 417-01-i

SECTION 417-01 Exterior Lighting

CONTENTS PAGE

DIAGNOSIS AND TESTING

Daytime Running Lamps (DRL) .......................................................................................................................................... 417-01-2

Principles of Operation ................................................................................................................................................. 417-01-2

Inspection and Verification ........................................................................................................................................... 417-01-2

Symptom Chart ............................................................................................................................................................. 417-01-3

Pinpoint Tests ............................................................................................................................................................... 417-01-3

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-2 Exterior Lighting 417-01-2

DIAGNOSIS AND TESTING

Daytime Running Lamps (DRL)

Special Tool(s)

Vehicle Communication Module (VCM) and Integrated Diagnostic System (IDS) software

with appropriate hardware, or equivalent scan tool

Principles of Operation

NOTE:

The smart junction box (SJB) is also known as the generic electronic module (GEM).

NOTE:

When installing a new SJB, it must be configured for this feature, if originally equipped. Refer to Section 418-01.

The SJB controls the DRL by using various inputs to determine whether or not the DRL should be illuminated. These inputs include:

• Ignition switch position

• Headlamp switch position

• Headlamps on or off

• Transmission gear selection (automatic transmission)

• Parking brake applied or released (manual transmission)

When the DRL is active, the SJB provides a pulse-width modulated (PWM) voltage to the low beam headlamps. This illuminates the headlamps at a reduced

intensity.

The SJB can be configured to turn the DRL on for this vehicle. Refer to Section 418-01 for additional information on this programmable parameter.

Inspection and Verification

1. Verify the customer concern.

2. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to the next step.

NOTE:

Make sure the headlamp switch is in the OFF position.

NOTE:

Make sure the multifunction switch is not in the HIGH BEAM position.

3. NOTE:

Make sure to use the latest scan tool software release.

If the cause is not visually evident, connect the scan tool to the data link connector (DLC).

4. NOTE:

The vehicle communication module (VCM) LED prove-out confirms power and ground from the DLC are provided to the VCM.

If the scan tool does not communicate with the VCM:

• Check the VCM connection to the vehicle.

• Check the scan tool connection to the VCM.

• Refer to Section 418-00, No Power To The Scan Tool, to diagnose no communication with the scan tool.

5. If the scan tool does not communicate with the vehicle:

• Verify the ignition key is in the ON position.

• Verify the scan tool operation with a known good vehicle.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-3 Exterior Lighting 417-01-3

DIAGNOSIS AND TESTING (Continued)

• Refer to Section 418-00 to diagnose no response from the PCM.

6. Carry out the network test.

• If the scan tool responds with no communication for one or more modules, refer to Section 418-00.

• If the network test passes, retrieve and record the continuous memory DTCs.

7. Check the smart junction box (SJB) and make sure the daytime running lamps (DRL) configuration is enabled.

8. Check the operation of the brake warning indicator by applying and releasing the parking brake.

• If the brake warning indicator does not operate correctly, refer to Section 413-01.

9. Check the operation of the PRNDL display by placing the gear selector lever in each of its positions.

• If the PRNDL display does not operate correctly, refer to Section 413-01.

10. If no DTCs related to the concern are retrieved, GO to Symptom Chart.

Symptom Chart

Symptom Chart

Condition Possible Sources Action

• The daytime running lamps (DRL) are • Exterior lighting system input/output • GO to Pinpoint Test AE.

inoperative • Smart junction box (SJB) configuration

• Ignition switch input

• Transmission gear input (automatic

transmission)

• Parking brake switch input (manual

transmission)

• SJB

• The daytime running lamps (DRL) are on • Parking brake switch input • GO to Pinpoint Test AE.

with the parking brake set — manual • SJB

transmission

• The daytime running lamps (DRL) are on • Transmission gear input • GO to Pinpoint Test AE.

with the transmission in PARK (P) — • SJB

automatic transmission

Pinpoint Tests

Pinpoint Test AE: The Daytime Running Lamps (DRL) Are Inoperative

Normal Operation

When the ignition switch is in the RUN position, the headlamps are not on (from the autolamp system or manual control from the headlamp switch), the

transmission is not in PARK (P) (automatic transmission) or the parking brake is not applied (manual transmission), the smart junction switch (SJB)

provides a pulse-width modulated (PWM) voltage to the low beam headlamps. This illuminates the headlamps at a reduced intensity.

This pinpoint test is intended to diagnose the following:

• Exterior lighting system input/output

• SJB configuration

• Ignition switch input

• Transmission gear input (automatic transmission)

• Parking brake switch input (manual transmission)

• SJB

PINPOINT TEST AE: THE DAYTIME RUNNING LAMPS (DRL) ARE INOPERATIVE

Test Step Result / Action to Take

AE1 CHECK FOR INCORRECT DRL OPERATION

• Ignition ON. Yes

• Place the headlamp switch in the OFF position. For vehicles with an automatic transmission, GO to

• If equipped with an automatic transmission, place the gear selector AE5. For vehicles with a manual transmission, GO to

lever in PARK (P). AE6.

• If equipped with a manual transmission, apply the parking brake.

No

• Are the DRL illuminated?

GO to AE2.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-4 Exterior Lighting 417-01-4

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST AE: THE DAYTIME RUNNING LAMPS (DRL) ARE INOPERATIVE (Continued)

AE2 VERIFY THE DRL OPERATION

• Ignition ON. Yes

• Place the headlamp switch in the OFF position. The system is operating correctly. INFORM the

• If equipped with an automatic transmission, place the gear selector customer of the conditions required for the DRL to

lever in any gear other than PARK (P). operate correctly.

• If equipped with a manual transmission, release the parking brake.

No

• Are the DRL illuminated?

GO to AE3.

AE3 CHECK THE OPERATION OF THE HEADLAMPS

• Place the headlamp switch in the HEADLAMPS ON position and Yes

observe the headlamps. GO to AE4.

• Do the headlamps operate correctly?

No

REFER to Headlamps in this section.

AE4 CHECK THE IGNITION SWITCH INPUT

• Place the headlamp switch in the OFF position. Yes

• Enter the following diagnostic mode on the scan tool: SJB DataLogger. For vehicles with an automatic transmission, GO to

• Monitor the SJB ignition switch PID (IGN SW) while cycling the AE5. For vehicles with a manual transmission, GO to

ignition switch through all its positions. AE6.

• Does the PID agree with the ignition switch positions?

No

REFER to Section 211-05 to diagnose the input from

the ignition switch.

AE5 CHECK THE TRANSMISSION GEAR INPUT

• Enter the following diagnostic mode on the scan tool: PCM or TCM Yes

DataLogger. GO to AE7.

• Monitor the PCM or TCM transmission gear status PID (TR) while

No

placing the gear selector lever through all its positions.

REFER to Section 307-01 or the Powertrain Control/

• Does the PID agree with the gear selection?

Emissions Diagnosis (PC/ED) manual to diagnose the

transmission range input.

AE6 CHECK THE BRAKE WARNING INDICATOR OPERATION

• Apply and release the parking brake while observing the brake Yes

warning indicator. GO to AE7.

• Does the brake warning indicator illuminate with the parking

No

brake applied and turn off with the parking brake released?

REFER to Section 413-01.

AE7 CHECK SJB FOR DRL CONFIGURATION

• Enter the following diagnostic mode on the scan tool: SJB Yes

Configuration. GO to AE8.

• Check the SJB configuration and make sure the DRL feature is enabled.

No

• Is the SJB DRL configuration enabled?

ENABLE the DRL configuration. TEST the system for

normal operation.

AE8 CHECK SJB CONFIGURATION

• Program the SJB with As-Built Data. Refer to Section 418-01. Yes

• If equipped with an automatic transmission, place the gear selector The system is operating correctly. The cause may have

lever in any gear other than PARK (P). been caused by an incorrectly configured SJB.

• If equipped with a manual transmission, release the parking brake.

No

• Does DRL feature operate?

INSTALL a new SJB. REFER to Section 419-10. TEST

the system for normal operation.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-i Exterior Lighting 417-01-i

SECTION 417-01 Exterior Lighting

CONTENTS PAGE

DIAGNOSIS AND TESTING

Diagnostic Trouble Code (DTC) Chart ................................................................................................................................ 417-01-2

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-2 Exterior Lighting 417-01-2

DIAGNOSIS AND TESTING

Diagnostic Trouble Code (DTC) Chart

Smart Junction Box (SJB) DTC Chart

DTC Description Action

B1472 Lamp Headlamp Input Circuit Short to Ground GO to Pinpoint Test D.

B1485 Brake Pedal Input Short to Battery GO to Pinpoint Test J.

B1510 Flash To Pass Switch Circuit Short to Ground GO to Pinpoint Test D.

B1578 Lamp Park Input Circuit Short to Ground GO to Pinpoint Test P.

B1696 Autolamp On Circuit Short To Ground GO to Pinpoint Test G.

B1791 Autolamp Sensor Input Circuit Open GO to Pinpoint Test G.

B1793 Autolamp Sensor Input Circuit Short to Ground GO to Pinpoint Test G.

B2031 Left Corner Lamp Output Circuit Failure GO to Pinpoint Test M.

B2032 Right Corner Lamp Output Circuit Failure GO to Pinpoint Test M.

B2044 Left Rear Stop Lamp Circuit Short to Ground GO to Pinpoint Test I.

B2045 Left Rear Stop Lamp Circuit Open If the lamp is inoperative, GO to Pinpoint Test I. If the lamp is

always on, GO to Pinpoint Test J.

B2046 Right Rear Stop Lamp Circuit Short to Ground GO to Pinpoint Test I.

B2047 Right Rear Stop Lamp Circuit Open If the lamp is inoperative, GO to Pinpoint Test I. If the lamp is

always on, GO to Pinpoint Test J.

B2071 Hazard Switch Signal Short to Ground GO to Pinpoint Test N.

B2254 Front Fog Lamp Switch Failure GO to Pinpoint Test S.

B2281 Right Turn Switch Short to Ground GO to Pinpoint Test L.

B2282 Left Turn Switch Short to Ground GO to Pinpoint Test L.

B2A22 Headlamp Off Circuit Open ADDRESS any other DTCs first. GO to Pinpoint Test D.

B2A23 High Beam Input Circuit Short to Ground GO to Pinpoint Test D.

B2A27 Right Front Turn Lamp Circuit Open GO to Pinpoint Test M.

B2A28 Right Front Turn Lamp Circuit Short to Ground GO to Pinpoint Test M.

B2A29 Left Front Turn Lamp Circuit Open GO to Pinpoint Test M.

B2A2A Left Front Turn Lamp Circuit Short to Ground GO to Pinpoint Test M.

B2A2B Left Corner Lamp Output Circuit Short to Ground GO to Pinpoint Test M.

B2A2C Right Corner Lamp Output Circuit Short to Ground GO to Pinpoint Test M.

B2A2E Right Front Lamp Low Beam Circuit Open If the low beam is inoperative, GO to Pinpoint Test B. If the low

beam is always on, GO to Pinpoint Test D.

B2A2F Right Front Lamp Low Beam Circuit Short to Ground GO to Pinpoint Test B.

B2A30 Left Front Lamp Low Beam Circuit Open If the low beam is inoperative, GO to Pinpoint Test B. If the low

beam is always on, GO to Pinpoint Test D.

B2A31 Left Front Lamp Low Beam Circuit Short to Ground GO to Pinpoint Test B.

All other DTCs — REFER to Section 419-10.

PCM DTC Chart

DTC Description Action

P1910 Reverse Lamp Control Circuit/Open If the reversing lamps are inoperative, GO to Pinpoint Test U. If

the reversing lamps are always on, GO to Pinpoint Test W.

All other DTCs — REFER to Powertrain Control/Emissions Diagnosis (PC/ED)

manual or Section 419-10.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-i Exterior Lighting 417-01-i

SECTION 417-01 Exterior Lighting

CONTENTS PAGE

DIAGNOSIS AND TESTING

Fog Lamps .......................................................................................................................................................................... 417-01-2

Principles of Operation ................................................................................................................................................. 417-01-2

Inspection and Verification ........................................................................................................................................... 417-01-2

Symptom Chart ............................................................................................................................................................. 417-01-3

Pinpoint Tests ............................................................................................................................................................... 417-01-3

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-2 Exterior Lighting 417-01-2

DIAGNOSIS AND TESTING

Fog Lamps

Special Tool(s)

73III Automotive Meter

105-R0057 or equivalent

Vehicle Communication Module (VCM) and Integrated Diagnostic System (IDS) software

with appropriate hardware, or equivalent scan tool

Flex Probe Kit

105-R025C or equivalent

Principles of Operation

NOTE:

The smart junction box (SJB) is also known as the generic electronic module (GEM).

The SJB monitors the headlamp switch position by sending a voltage reference signal to the headlamp switch. When the fog lamp switch is engaged, the

voltage reference signal is routed to ground.

The fog lamps can be turned on when the following conditions are met:

• The ignition switch is in the RUN or START position.

• The low beam headlamps or the parking lamps are on.

• The high beams are off.

When the SJB receives an input from the headlamp switch indicating a request for the fog lamps, the SJB provides ground to the fog lamp relay. When the

fog lamp relay is energized, voltage is routed to the fog lamps.

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of electrical damage.

Visual Inspection Chart

Electrical

• Smart junction box (SJB) fuse 21 (15A) (fog lamps)

• Wiring, terminals or connectors

• Bulb(s)

• Headlamp switch

• SJB

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to the next step.

NOTE:

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-3 Exterior Lighting 417-01-3

DIAGNOSIS AND TESTING (Continued)

Make sure the headlamp switch is in the OFF position.

NOTE:

Make sure the multifunction switch is not in the HIGH BEAM position.

4. NOTE:

Make sure to use the latest scan tool software release.

If the cause is not visually evident, connect the scan tool to the data link connector (DLC).

5. NOTE:

The vehicle communication module (VCM) LED prove-out confirms power and ground from the DLC are provided to the VCM.

If the scan tool does not communicate with the VCM:

• Check the VCM connection to the vehicle.

• Check the scan tool connection to the VCM.

• Refer to Section 418-00, No Power To The Scan Tool, to diagnose no communication with the scan tool.

6. If the scan tool does not communicate with the vehicle:

• Verify the ignition key is in the ON position.

• Verify the scan tool operation with a known good vehicle.

• Refer to Section 418-00 to diagnose no response from the PCM.

7. Carry out the network test.

• If the scan tool responds with no communication for one or more modules, refer to Section 418-00.

• If the network test passes, retrieve and record the continuous memory DTCs.

8. Clear the continuous DTCs and carry out the self-test diagnostics for the smart junction box (SJB).

9. If the DTCs retrieved are related to the concern, go to DTC Charts. For all other DTCs, refer to Section 419-10.

10. If no DTCs related to the concern are retrieved, GO to Symptom Chart.

Symptom Chart

Symptom Chart

Condition Possible Sources Action

• No communication with the smart junction • Fuse • REFER to Section 418-00.

box (SJB) • Wiring, terminals or connectors

• SJB

• Both fog lamps are inoperative • Fuse • GO to Pinpoint Test Q.

• Wiring, terminals or connectors

• Headlamp switch

• SJB

• An individual fog lamp is inoperative • Wiring, terminals or connectors • GO to Pinpoint Test R.

• The fog lamps are on continuously • Wiring, terminals or connectors • GO to Pinpoint Test S.

• Headlamp switch

• SJB

• The fog lamps on indicator is inoperative • Wiring, terminals or connectors • GO to Pinpoint Test T.

• Headlamp switch

• SJB

Pinpoint Tests

Pinpoint Test Q: Both Fog Lamps Are Inoperative

Refer to Wiring Diagrams Cell 86 Fog Lamps for schematic and connector information.

Normal Operation

The smart junction box (SJB) sends a reference signal to the headlamp switch through circuit CLF29 (BN) to monitor the fog lamp request. When the fog

lamp switch is engaged, the fog lamp switch routes the reference signal to ground.

When the SJB detects the fog lamps on request, the SJB provides ground to the fog lamp relay coil (integrated into the SJB). When the fog lamp relay is

energized, voltage is routed through circuit CLF21 (GY/VT) to the fog lamps. The fog lamps share a common ground through circuit GD122 (BK).

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-4 Exterior Lighting 417-01-4

DIAGNOSIS AND TESTING (Continued)

This pinpoint test is intended to diagnose the following:

• Fuse

• Wiring, terminals or connectors

• Headlamp switch

• SJB

PINPOINT TEST Q: BOTH FOG LAMPS ARE INOPERATIVE

NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

Test Step Result / Action to Take

Q1 CHECK THE FOG LAMP SWITCH PID

• Ignition ON.

Yes

• Enter the following diagnostic mode on the scan tool: SJB DataLogger.

GO to Q4.

• Monitor the SJB fog lamp switch PID (FOG SW) while engaging the

fog lamp switch. No

• Does the PID indicate the fog lamp switch is on? GO to Q2.

Q2 CHECK THE HEADLAMP SWITCH

• Ignition OFF. Yes

• Disconnect: Headlamp Switch C205. GO to Q3.

• Carry out the headlamp switch component test. Refer to Wiring

No

Diagrams Cell 149 for component testing.

INSTALL a new headlamp switch. REFER to

• Is the headlamp switch OK?

Headlamp Switch in this section. TEST the system for

normal operation.

Q3 CHECK CIRCUIT CLF29 (BN) FOR AN OPEN

• Disconnect: SJB C2280b.

• Measure the resistance between the headlamp switch C205-6, circuit

CLF29 (BN), harness side and the SJB C2280b-49, circuit CLF29

(BN), harness side.

Yes

GO to Q6.

No

REPAIR the circuit. TEST the system for normal

• Is the resistance less than 5 ohms? operation.

Q4 BYPASS THE SJB

• Ignition OFF. Yes

• Disconnect: SJB C2280e. REMOVE the jumper wire. VERIFY the SJB fuse 21

• Connect a fused (15A) jumper wire between the SJB C2280e-1, (15A) is OK. If OK, GO to Q6.

circuit CDC21 (GY/BN), harness side and the SJB C2280e-3, circuit

No

CLF21 (GY/VT), harness side.

REMOVE the jumper wire. GO to Q5.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-5 Exterior Lighting 417-01-5

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST Q: BOTH FOG LAMPS ARE INOPERATIVE (Continued)

Q4 BYPASS THE SJB (Continued)

• Ignition ON.

• Do the fog lamps illuminate?

Q5 CHECK THE GROUND CIRCUIT FOR AN OPEN

• Ignition OFF.

• Disconnect: Either Fog Lamp.

• Measure the resistance between the LH fog lamp C152-1, circuit

GD122 (BK), harness side and ground; or between the RH fog lamp

C162-1, circuit GD122 (BK), harness side and ground.

Yes

REMOVE the jumper wire. REPAIR circuit CLF21 (GY/

VT) for an open. TEST the system for normal operation.

No

REMOVE the jumper wire. REPAIR circuit GD122 (BK)

• Is the resistance less than 5 ohms? for an open. TEST the system for normal operation.

Q6 CHECK FOR CORRECT SJB OPERATION

• Disconnect all the SJB connectors.

Yes

• Check for:

INSTALL a new SJB. REFER to Section 419-10. TEST

— corrosion

the system for normal operation.

— damaged pins

— pushed-out pins No

• Connect all the SJB connectors and make sure they seat correctly. The system is operating correctly at this time. The

• Operate the system and verify the concern is still present. concern may have been caused by a loose or corroded

• Is the concern still present? connector.

Pinpoint Test R: An Individual Fog Lamp Is Inoperative

Refer to Wiring Diagrams Cell 86 Fog Lamps for schematic and connector information.

Normal Operation

When the fog lamp relay is energized, voltage is routed through circuit CLF21 (GY/VT) to the fog lamps. Ground is provided through circuit GD122 (BK).

This pinpoint test is intended to diagnose the following:

• Wiring, terminals or connectors

PINPOINT TEST R: AN INDIVIDUAL FOG LAMP IS INOPERATIVE

NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

NOTE:

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-6 Exterior Lighting 417-01-6

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST R: AN INDIVIDUAL FOG LAMP IS INOPERATIVE (Continued)

Make sure the bulb is good before continuing diagnostics.

Test Step Result / Action to Take

R1 CHECK THE GROUND CIRCUIT FOR AN OPEN

• Ignition OFF.

• Disconnect: Inoperative Fog Lamp.

• Measure the resistance between the LH fog lamp C152-1, circuit

GD122 (BK), harness side and ground; or between the RH fog lamp

C162-1, circuit GD122 (BK), harness side and ground.

Yes

REMOVE the jumper wire. REPAIR circuit CLF21 (GY/

VT) for an open. TEST the system for normal operation.

No

REMOVE the jumper wire. REPAIR circuit GD122 (BK)

• Is the resistance less than 5 ohms? for an open. TEST the system for normal operation.

Pinpoint Test S: The Fog Lamps Are On Continuously

Refer to Wiring Diagrams Cell 86 Fog Lamps for schematic and connector information.

Normal Operation

The smart junction box (SJB) sends a reference signal to the headlamp switch through circuit CLF29 (BN) to monitor the fog lamp request. When the fog

lamp switch is engaged, the fog lamp switch routes the reference signal to ground.

When the SJB detects the fog lamps on request, the SJB provides ground to the fog lamp relay coil (integrated into the SJB). When the fog lamp relay is

energized, voltage is routed through circuit CLF21 (GY/VT) to the fog lamps and the headlamp switch for the fog lamps on indicator.

• DTC B2254 (Front Fog Lamp Switch Failure) — is an on-demand DTC that sets when the SJB detects a short to ground from the fog lamp on input

circuit.

This pinpoint test is intended to diagnose the following:

• Wiring, terminals or connectors

• Headlamp switch

• SJB

PINPOINT TEST S: THE FOG LAMPS ARE ON CONTINUOUSLY

NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

Test Step Result / Action to Take

S1 CHECK FOR RECORDED SJB DTCs

• Check the recorded results from the SJB self-test. Yes

• Is DTC B2254 present? GO to S2.

No

GO to S4.

S2 CHECK THE HEADLAMP SWITCH

• Ignition OFF. Yes

• Disconnect: Headlamp Switch C205. GO to S3.

• Carry out the headlamp switch component test. Refer to Wiring

No

Diagrams Cell 149 for component testing.

INSTALL a new headlamp switch. REFER to

• Is the headlamp switch OK?

Headlamp Switch in this section. CLEAR the DTCs.

REPEAT the self-test.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-7 Exterior Lighting 417-01-7

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST S: THE FOG LAMPS ARE ON CONTINUOUSLY (Continued)

S3 CHECK CIRCUIT CLF29 (BN) FOR A SHORT TO GROUND

• Disconnect: SJB C2280b.

• Measure the resistance between the headlamp switch C205-6, circuit

CLF29 (BN), harness side and ground.

Yes

GO to S6.

No

REPAIR the circuit. CLEAR the DTCs. REPEAT the self-

• Is the resistance greater than 10,000 ohms? test.

S4 CHECK CIRCUIT CLF21 (GY/VT) FOR A SHORT TO VOLTAGE (TO THE HEADLAMP SWITCH)

• Ignition OFF. Yes

• Disconnect: SJB C2280a. GO to S5.

• Ignition ON.

No

• Do the fog lamps continue to illuminate?

REPAIR the circuit. TEST the system for normal

operation.

S5 CHECK CIRCUIT CLF21 (GY/VT) FOR A SHORT TO VOLTAGE (TO FOG LAMPS)

• Ignition OFF. Yes

• Disconnect: SJB C2280e. REPAIR the circuit. TEST the system for normal

• Ignition ON. operation.

• Do the fog lamps continue to illuminate?

No

GO to S6.

S6 CHECK FOR CORRECT SJB OPERATION

• Ignition OFF.

• Disconnect all the SJB connectors.

Yes

• Check for:

INSTALL a new SJB. REFER to Section 419-10. TEST

— corrosion

the system for normal operation.

— damaged pins

— pushed-out pins No

• Connect all the SJB connectors and make sure they seat correctly. The system is operating correctly at this time. The

• Operate the system and verify the concern is still present. concern may have been caused by a loose or corroded

• Is the concern still present? connector. CLEAR any DTCs. REPEAT the self-test.

Pinpoint Test T: The Fog Lamps On Indicator Is Inoperative

Refer to Wiring Diagrams Cell 86 Fog Lamps for schematic and connector information.

Normal Operation

When the smart junction box (SJB) detects the fog lamps on request, the SJB provides ground to the fog lamp relay coil (integrated into the SJB). When the

fog lamp relay is energized, voltage is routed through circuit CLF21 (GY/VT) to the fog lamps and to the headlamp switch for the fog lamps on indicator.

This pinpoint test is intended to diagnose the following:

• Wiring, terminals or connectors

• Headlamp switch

• SJB

PINPOINT TEST T: THE FOG LAMPS ON INDICATOR IS INOPERATIVE

NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-8 Exterior Lighting 417-01-8

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST T: THE FOG LAMPS ON INDICATOR IS INOPERATIVE (Continued)

Test Step Result / Action to Take

T1 CHECK THE HEADLAMP SWITCH

NOTE:

Make sure the headlamp switch is in the OFF position.

• Ignition OFF.

• Disconnect: Headlamp Switch C205.

• Connect a fused (5A) jumper wire between the headlamp switch

C205-6, circuit CLF29 (BN), harness side and ground.

• Ignition ON.

• NOTE:

Make sure the fog lamps are illuminated when taking a reading.

Measure the voltage between the headlamp switch C205-7, circuit

CLF21 (GY/VT), harness side and ground.

Yes

REMOVE the jumper wire. INSTALL a new headlamp

switch. REFER to Headlamp Switch in this section.

TEST the system for normal operation.

No

• Is the voltage greater than 10 volts? REMOVE the jumper wire. GO to T2.

T2 CHECK CIRCUIT CLF21 (GY/VT) FOR AN OPEN

• Ignition OFF. Yes

• Disconnect: SJB C2280a. GO to T3.

• Measure the resistance between the headlamp switch C205-7, circuit

No

CLF21 (GY/VT), harness side and the SJB C2280a-6, circuit CLF21

REPAIR the circuit. CLEAR the DTCs. REPEAT the self-

(GY/VT), harness side.

test.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-9 Exterior Lighting 417-01-9

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST T: THE FOG LAMPS ON INDICATOR IS INOPERATIVE (Continued)

T2 CHECK CIRCUIT CLF21 (GY/VT) FOR AN OPEN (Continued)

• Is the resistance less than 5 ohms?

T3 CHECK FOR CORRECT SJB OPERATION

• Disconnect all the SJB connectors.

Yes

• Check for:

INSTALL a new SJB. REFER to Section 419-10. TEST

— corrosion

the system for normal operation.

— damaged pins

— pushed-out pins No

• Connect all the SJB connectors and make sure they seat correctly. The system is operating correctly at this time. The

• Operate the system and verify the concern is still present. concern may have been caused by a loose or corroded

• Is the concern still present? connector. CLEAR any DTCs. REPEAT the self-test.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-i Exterior Lighting 417-01-i

SECTION 417-01 Exterior Lighting

CONTENTS PAGE

DIAGNOSIS AND TESTING

Headlamps .......................................................................................................................................................................... 417-01-2

Principles of Operation ................................................................................................................................................. 417-01-2

Inspection and Verification ........................................................................................................................................... 417-01-3

Symptom Chart ............................................................................................................................................................. 417-01-4

Pinpoint Tests ............................................................................................................................................................... 417-01-4

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-2 Exterior Lighting 417-01-2

DIAGNOSIS AND TESTING

Headlamps

Special Tool(s)

73III Automotive Meter

105-R0057 or equivalent

Vehicle Communication Module (VCM) and Integrated Diagnostic System (IDS) software

with appropriate hardware, or equivalent scan tool

Flex Probe Kit

105-R025C or equivalent

Principles of Operation

NOTE:

The smart junction box (SJB) is also known as the generic electronic module (GEM).

Exterior Lighting

The SJB monitors the headlamp switch position by sending voltage reference signals on multiple circuits to the headlamp switch. There is one circuit for

each headlamp switch position. At any given time, one of the signal circuits is routed to ground.

If the SJB does not detect any of the inputs to the headlamp switch is active (routed to ground) for 5 seconds, the SJB turns on the exterior lights and keeps

them on for 10 minutes after the ignition switch is turned off (or 10 minutes from the time the SJB does not detect any headlamp switch input if the ignition

switch was already off). Additionally, if the SJB detects multiple circuits short to ground, the SJB implements a planned strategy depending on the multiple

inputs received.

If either of these situations occur, the SJB should NOT be ruled immediately as being at fault. This is normal behavior of the SJB design as it has detected a

fault with the inputs from the headlamp switch.

High Beam and Flash-to-Pass

The SJB also monitors the multifunction switch for a flash-to-pass or high beam request. There are 2 voltage reference circuits which monitor this. When the

multifunction switch is in the FLASH-TO-PASS or HIGH BEAM position, the voltage signal is routed to ground.

NOTE:

The flash-to-pass feature does not require any input from the headlamp switch.

When the SJB receives an input requesting the headlamps on, the SJB supplies voltage to the low beams. If the low beams are on and the SJB receives a

request for high beams (or just a flash-to-pass request), the SJB energizes an internal relay which routes voltage to the headlamps.

Field-Effect Transistor (FET) Protection

The SJB utilizes a FET protective circuit strategy for many of its outputs (for example, the headlamp output circuit). Output loads (current level) are

monitored for excessive current (typically short circuits) and are shut down (turns off the voltage or ground provided by the module) when a fault is detected.

A continuous DTC is stored at that time of the fault. The circuit then resets after a customer demand of the function (switching the component on, battery

saver being energized). When an excessive circuit load occurs several times, the module shuts down the output until a repair procedure is carried out. At the

same time, the continuous DTC that was stored on the first failure, does not clear by a command to clear the continuous DTCs. The module does not allow

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-3 Exterior Lighting 417-01-3

DIAGNOSIS AND TESTING (Continued)

this code to be cleared or the circuit restored to normal operation until a successful on-demand self-test proves that the fault has been repaired. After the on-

demand self-test has successfully completed (no on-demand DTCs present), the continuous DTC clears and the circuit function returns.

Each circuit has three predefined levels of short circuit tolerance established in the module based on each circuits' capability. When the first or second level

is reached, the continuous DTC associated with the circuit sets along with DTC B106E. These DTCs may be cleared using the Clear DTC operation on the

scan tool as long as the fault itself has been corrected. If any of the circuits are shorted past the third level, then B106F and B1342 set along with the

associated continuous DTC. This DTC cannot be cleared and the module must be replaced.

The SJB FET protected output circuits for the headlamp system are for the LH low beam output and the RH low beam output circuits.

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection Chart

Mechanical Electrical

• Headlamp switch • Smart junction box (SJB) fuse(s):

• Multifunction switch — 7 (10A) (LH low beam)

— 8 (10A) (RH low beam)

— 23 (15A) (high beams)

• SJB

• Bulb(s)

• Wiring, terminals or connectors

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to the next step.

NOTE:

Make sure the headlamp switch is in the OFF position.

NOTE:

Make sure the multifunction switch is not in the HIGH BEAM position.

4. NOTE:

Make sure to use the latest scan tool software release.

If the cause is not visually evident, connect the scan tool to the data link connector (DLC).

5. NOTE:

The vehicle communication module (VCM) LED prove-out confirms power and ground from the DLC are provided to the VCM.

If the scan tool does not communicate with the VCM:

• Check the VCM connection to the vehicle.

• Check the scan tool connection to the VCM.

• Refer to Section 418-00, No Power To The Scan Tool, to diagnose no communication with the scan tool.

6. If the scan tool does not communicate with the vehicle:

• Verify the ignition key is in the ON position.

• Verify the scan tool operation with a known good vehicle.

• Refer to Section 418-00 to diagnose no response from the PCM.

7. Carry out the network test.

• If the scan tool responds with no communication for one or more modules, refer to Section 418-00.

• If the network test passes, retrieve and record the continuous memory DTCs.

8. Clear the continuous DTCs and carry out the self-test diagnostics for the smart junction box (SJB).

9. If the DTCs retrieved are related to the concern, go to DTC Charts. For all other DTCs, refer to Section 419-10.

10. If no DTCs related to the concern are retrieved, GO to Symptom Chart.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-4 Exterior Lighting 417-01-4

DIAGNOSIS AND TESTING (Continued)

Symptom Chart

Symptom Chart

Condition Possible Sources Action

• No communication with the smart junction • Fuse • REFER to Section 418-00.

box (SJB) • Wiring, terminals or connectors

• SJB

• Both low beams are inoperative • Incorrect aftermarket headlamp bulbs • NOTE:

Due to varying wattage ratings and resulting

current draw differences, certain aftermarket

headlamp bulbs may cause the SJB to shut

down the short circuit protection, resulting

in the low beams becoming inoperative.

Verify that the bulbs meet Ford

specifications.

INSTALL the correct bulbs. RUN the on-

demand self-test (required to clear certain

DTCs and reset the SJB). CORRECT any

unresolved DTCs. CLEAR all DTCs. TEST

the system for normal operation.

• SJB • CHECK for recorded SJB DTCs.

— If DTCs are present, REFER to DTC

Charts in this section.

— If no DTCs are present, INSTALL a

new SJB. REFER to Section 419-10.

TEST the system for normal operation.

• Both high beams are inoperative • Fuse • GO to Pinpoint Test A.

• Wiring, terminals or connectors

• Multifunction switch

• SJB

• One low beam headlamp is inoperative • Fuse • GO to Pinpoint Test B.

• Wiring, terminals or connectors

• SJB

• One high beam headlamp is inoperative • Wiring, terminals or connectors • GO to Pinpoint Test C.

• The headlamps are on continuously • Wiring, terminals or connectors • GO to Pinpoint Test D.

• Headlamp switch

• Multifunction switch

• SJB

• The flash-to-pass feature is inoperative • Wiring, terminals or connectors • GO to Pinpoint Test E.

• Multifunction switch

• SJB

Pinpoint Tests

Pinpoint Test A: Both High Beams Are Inoperative

Refer to Wiring Diagrams Cell 85 Headlamps/Autolamps for schematic and connector information.

Normal Operation

The smart junction box (SJB) sends a reference signal to the multifunction switch through circuit CLF17 (WH/OG). When the headlamp switch is in the

HEADLAMPS ON position and the multifunction switch is placed in the HIGH BEAM position, the signal is routed to ground through circuit GD115 (BK/

GY), indicating a high beam request. The SJB then energizes the high beam relay (integrated into the SJB) which supplies voltage to the headlamps through

circuit CLF08 (YE/VT).

This pinpoint test is intended to diagnose the following:

• Fuse

• Wiring, terminals or connectors

• Multifunction switch

• SJB

PINPOINT TEST A: BOTH HIGH BEAMS ARE INOPERATIVE

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-5 Exterior Lighting 417-01-5

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: BOTH HIGH BEAMS ARE INOPERATIVE (Continued)

NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

Test Step Result / Action to Take

A1 CHECK THE HIGH BEAM INDICATOR

• Ignition ON. Yes

• Place the headlamp switch in the HEADLAMPS ON position. GO to A5.

• Place the multifunction switch in the HIGH BEAM position.

No

• Does the high beam indicator illuminate?

GO to A2.

A2 CHECK THE MULTIFUNCTION SWITCH

• Place the headlamp switch in the OFF position.

• Ignition OFF.

• Disconnect: Multifunction Switch C202.

• Connect a fused (5A) jumper wire between the multifunction switch

C202-6, circuit CLF17 (WH/OG), harness side and the multifunction

switch C202-8, circuit GD115 (BK/GY), harness side.

Yes

REMOVE the jumper wire. INSTALL a new

multifunction switch. REFER to Section 211-05. TEST

the system for normal operation.

• Place the headlamp switch in the HEADLAMPS ON position.

• Ignition ON. No

• Do the high beams illuminate? REMOVE the jumper wire. GO to A3.

A3 CHECK CIRCUIT GD115 (BK/GY) FOR AN OPEN

• Ignition OFF.

• Measure the resistance between the multifunction switch C202-8,

circuit GD115 (BK/GY), harness side and ground.

Yes

GO to A4.

No

REPAIR the circuit. TEST the system for normal

• Is the resistance less than 5 ohms? operation.

A4 CHECK CIRCUIT CLF17 (WH/OG) FOR AN OPEN

• Disconnect: SJB C2280b. Yes

• Measure the resistance between the multifunction switch C202-6, GO to A6.

circuit CLF17 (WH/OG), harness side and the SJB C2280b-27, circuit

No

CLF17 (WH/OG), harness side.

REPAIR the circuit. TEST the system for normal

operation.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-6 Exterior Lighting 417-01-6

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: BOTH HIGH BEAMS ARE INOPERATIVE (Continued)

A4 CHECK CIRCUIT CLF17 (WH/OG) FOR AN OPEN (Continued)

• Is the resistance less than 5 ohms?

A5 CHECK CIRCUIT CLF08 (YE/VT) FOR AN OPEN

• Disconnect: SJB C2280e.

• Connect a fused (15A) jumper wire between the SJB C2280e-1,

circuit CDC21 (GY/BN), harness side and the SJB C2280e-2, circuit

CLF08 (YE/VT), harness side.

Yes

REMOVE the jumper wire. VERIFY the SJB fuse 23

(15A) is OK. If OK, GO to A6.

No

• Ignition ON. REMOVE the jumper wire. REPAIR the circuit. TEST

• Do the high beams illuminate? the system for normal operation.

A6 CHECK FOR CORRECT SJB OPERATION

• Disconnect all the SJB connectors.

Yes

• Check for:

INSTALL a new SJB. REFER to Section 419-10. TEST

— corrosion

the system for normal operation.

— damaged pins

— pushed-out pins No

• Connect all the SJB connectors and make sure they seat correctly. The system is operating correctly at this time. The

• Operate the system and verify the concern is still present. concern may have been caused by a loose or corroded

• Is the concern still present? connector.

Pinpoint Test B: One Low Beam Headlamp Is Inoperative

Refer to Wiring Diagrams Cell 85 Headlamps/Autolamps for schematic and connector information.

Normal Operation

When the smart junction box (SJB) detects the headlamp switch in the HEADLAMPS ON position and the multifunction switch in the LOW BEAM

position, the SJB provides voltage through circuits CLF04 (BN/BU) and CLF05 (BU/GN) to the LH and RH low beam headlamps, respectively. Ground is

supplied through circuits GD122 (BK) and GD124 (BK/VT) to the LH and RH headlamps, respectively.

DTC Description Fault Trigger Conditions

• B2A2E — Right Front Lamp Low Beam Circuit Open An on-demand DTC that sets when the SJB detects an open from the RH

low beam output circuit.

• B2A2F — Right Front Lamp Low Beam Circuit Short to Ground A continuous and on-demand DTC that sets when the SJB detects a short to

ground from the RH low beam output circuit.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-7 Exterior Lighting 417-01-7

DIAGNOSIS AND TESTING (Continued)

(Continued)

DTC Description Fault Trigger Conditions

• B2A30 — Left Front Lamp Low Beam Circuit Open An on-demand DTC that sets when the SJB detects an open from the LH

low beam output circuit.

• B2A31 — Left Front Lamp Low Beam Circuit Short to Ground A continuous and on-demand DTC that sets when the SJB detects a short to

ground from the LH low beam output circuit.

This pinpoint test is intended to diagnose the following:

• Fuse

• Wiring, terminals or connectors

• SJB

PINPOINT TEST B: ONE LOW BEAM HEADLAMP IS INOPERATIVE

NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

NOTE:

Due to varying wattage ratings and resulting current draw differences, certain aftermarket headlamp bulbs may cause the SJB to shut down the short circuit

protection, resulting in the low beams becoming inoperative. Verify that the bulbs meet Ford specifications. If the bulbs do not meet Ford specifications,

install the correct bulbs. Run the on-demand self-test (required to clear certain DTCs and reset the SJB). Correct any unresolved DTCs. Clear all DTCs.

Test the system for normal operation.

NOTE:

Make sure the headlamp bulb is good before continuing diagnostics.

Test Step Result / Action to Take

B1 USE THE RECORDED DTCs FROM THE SJB SELF-TEST

• Check the recorded results from the SJB self-test. Yes

• Were any DTCs recorded? For DTC B2A2E or B2A30, GO to B2. For DTC B2A2F

or B2A31, GO to B4. For all other DTCs, REFER to

DTC Charts in this section.

No

GO to B5.

B2 CHECK THE SJB HEADLAMP VOLTAGE SUPPLY CIRCUIT FOR VOLTAGE

• Ignition OFF.

• Disconnect: Inoperative Headlamp.

• Place the headlamp switch in the HEADLAMPS ON position.

• For vehicles with aerodynamic headlamps, measure the voltage

between the LH headlamp C1284-1, circuit CLF04 (BN/BU), harness

side and ground; or between the RH headlamp C1285-1, circuit

CLF05 (BU/GN), harness side and ground.

Yes

REPAIR ground circuit in question for an open. CLEAR

the DTCs. REPEAT the self-test.

• For vehicles with sealed beam headlamps, measure the voltage

between the LH headlamp C1021-3, circuit CLF04 (BN/BU), harness No

side and ground; or between the RH headlamp C1041-3, circuit VERIFY the SJB fuse 7 (10A) (LH low beam) or fuse 8

CLF05 (BU/GN), harness side and ground. (10A) is OK. If OK, GO to B3.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-8 Exterior Lighting 417-01-8

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST B: ONE LOW BEAM HEADLAMP IS INOPERATIVE (Continued)

B2 CHECK THE SJB HEADLAMP VOLTAGE SUPPLY CIRCUIT FOR VOLTAGE (Continued)

• Is the voltage greater than 10 volts?

B3 CHECK THE SJB HEADLAMP VOLTAGE SUPPLY CIRCUIT FOR AN OPEN

• Place the headlamp switch in the OFF position.

• Disconnect: SJB C2280e.

• For vehicles with aerodynamic headlamps, measure the resistance

between the LH headlamp C1284-1, circuit CLF04 (BN/BU), harness

side and the SJB C2280e-13, circuit CLF04 (BN/BU), harness side; or

between the RH headlamp C1285-1, circuit CLF05 (BU/GN), harness

side and the SJB C2280e-4, circuit CLF05 (BU/GN), harness side.

• For vehicles with sealed beam headlamps, measure the resistance

between the LH headlamp C1021-3, circuit CLF04 (BN/BU), harness

side and the SJB C2280e-13, circuit CLF04 (BN/BU), harness side; or

between the RH headlamp C1041-3, circuit CLF05 (BU/GN), harness

side and the SJB C2280e-4, circuit CLF05 (BU/GN), harness side.

Yes

GO to B5.

No

REPAIR the circuit in question. CLEAR the DTCs.

• Is the resistance less than 5 ohms? REPEAT the self-test.

B4 CHECK CIRCUIT CLF04 (BN/BU) (LH HEADLAMP) OR CIRCUIT CLF05 (BU/GN) (RH HEADLAMP) FOR A SHORT TO

GROUND

• Ignition OFF.

• Disconnect: SJB C2280e. Yes

• Disconnect: Inoperative Headlamp. GO to B5.

2008 F-250, 350, 450, 550 Super Duty, 7/2007

417-01-9 Exterior Lighting 417-01-9

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST B: ONE LOW BEAM HEADLAMP IS INOPERATIVE (Continued)