Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

12 viewsTesting Report

Testing Report

Uploaded by

hoiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- FD240 FD250 FD300: Forklift TruckDocument491 pagesFD240 FD250 FD300: Forklift TruckNguyễn Hữu ĐồngNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DanfossomrDocument30 pagesDanfossomrhoiNo ratings yet

- Bridon-Bekaert+Oil Gas+Catalog+July+2018Document27 pagesBridon-Bekaert+Oil Gas+Catalog+July+2018thiban130991No ratings yet

- Closed Swage Sockets National Swage ButtonsDocument1 pageClosed Swage Sockets National Swage ButtonshoiNo ratings yet

- 04 73037-38 PartslistDocument30 pages04 73037-38 PartslisthoiNo ratings yet

- Hu08 010 HTPDocument1 pageHu08 010 HTPhoiNo ratings yet

- Gear Code BookDocument81 pagesGear Code BookhoiNo ratings yet

- Testing ReportDocument17 pagesTesting ReporthoiNo ratings yet

- Chao Gia Cua Tri VietDocument1 pageChao Gia Cua Tri ViethoiNo ratings yet

- Sunstar SPS D-B1201Document86 pagesSunstar SPS D-B1201hoiNo ratings yet

- BasicsDocument170 pagesBasicshoiNo ratings yet

- Parts ListDocument19 pagesParts ListhoiNo ratings yet

- ActuatorsDocument37 pagesActuatorshoiNo ratings yet

- Trawlex Brochure 9992020 by PageDocument12 pagesTrawlex Brochure 9992020 by PagehoiNo ratings yet

- S-423T Super TerminatorDocument1 pageS-423T Super TerminatorhoiNo ratings yet

- 04 6750036 EL 180910 enDocument227 pages04 6750036 EL 180910 enhoiNo ratings yet

- Báo Giá Bộ Ly ChénDocument1 pageBáo Giá Bộ Ly ChénhoiNo ratings yet

- 00a 6720168 CONTENTS CHALLENGER280 PDFDocument1 page00a 6720168 CONTENTS CHALLENGER280 PDFhoiNo ratings yet

- 06e - DQC-Freigabeliste Schmieröle - Ausgabe - 09 - 2018 - de - enDocument27 pages06e - DQC-Freigabeliste Schmieröle - Ausgabe - 09 - 2018 - de - enhoiNo ratings yet

- A Full Range of Hydraulic Parts Such As: Pumps, Hydraulic Valves, Hoses, Steering Pumps, Lift Cylinders, Cylinder Repair Kits, Fittings, ..Document74 pagesA Full Range of Hydraulic Parts Such As: Pumps, Hydraulic Valves, Hoses, Steering Pumps, Lift Cylinders, Cylinder Repair Kits, Fittings, ..hoiNo ratings yet

- Ols 120Document1 pageOls 120hoiNo ratings yet

- 01b - 6720168-169 - CHAPTER1 - BA - 191130 - en (Us)Document190 pages01b - 6720168-169 - CHAPTER1 - BA - 191130 - en (Us)hoiNo ratings yet

- 00a 6720169 CONTENTS CHALLENGER280 PDFDocument1 page00a 6720169 CONTENTS CHALLENGER280 PDFhoiNo ratings yet

- Main Cylinder 250T PDFDocument1 pageMain Cylinder 250T PDFhoiNo ratings yet

- Main Cushion Cylinder 250T PDFDocument1 pageMain Cushion Cylinder 250T PDFhoiNo ratings yet

- 9 Hydraulic2006Document91 pages9 Hydraulic2006hoiNo ratings yet

- ServiceInfo15-WT-05 Rev ADocument38 pagesServiceInfo15-WT-05 Rev AhoiNo ratings yet

- Cushion Side Cylinder 250 T PDFDocument1 pageCushion Side Cylinder 250 T PDFhoiNo ratings yet

- Knock Out Cylinder 250 T PDFDocument1 pageKnock Out Cylinder 250 T PDFhoiNo ratings yet

- Main Side Cylinder 250T PDFDocument1 pageMain Side Cylinder 250T PDFhoiNo ratings yet

Testing Report

Testing Report

Uploaded by

hoi0 ratings0% found this document useful (0 votes)

12 views17 pagesOriginal Title

17676 Testing Report

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

12 views17 pagesTesting Report

Testing Report

Uploaded by

hoiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 17

TEST CERTIFICATE

Conceming examination, load test

and controlling of Spreader.

Examination made : 2013-09-03

Customer : Unico Vina JSC.

Enduser : Nam Hai Dinh Vu , Vietnam

Adjustable hoisting gear for ISO container 20° & 40’.

Type : EHSU

Serial Number : 17676.

Manufacturer : BROMMA

General drawing : BR1116125.

NOMRONS

Material : High Tensile Steel & Fine Grain Steel.

‘Spreader weight: 9 Tonne.

ao @

0. Load test carried out with a max. of 150% overload.

11 Safe Working Load (SWL) : Single 41 Tonne.

Test load of twistlocks to 40 tonne for serial number SINGLE : WS 5283 , WS 5280 ,

12. ws 5218 , WS 5295.

As a result of this examination we the undersigned find nothing which will prevent the use of

above load gear for the loads presented in the data sheet.

Remarks :

The load gear is to carry attached signs stating manufacturer, production number, year of

manufacture and SWL — max. load.

Enclosed: Spreader data sheet

BROMMA

2013-09-03

/)

gs

KHAIRUL FAIZI

Test Cer

cate QBI 16.0 Rev (01)

TWISTLOCK-CERTIFICATE

CUSTOMER. _ Unico Vina JSC

CUSTOMER ORDER NO. BRO-UNV13-01

BROMMA SPREADER / ORDER NO. 17676

DATE. 03" September 2013

This is to certify that the following twistlocks have been proof tested

to 40 tonne’s load.

No visible deformation occured.

The twistlocks have been stamped on the end face with a B/C

stamp and 40 tonne.

QTY. TYPE. DWG. MATERIAL. PARTNo. SERIALNo. MILL CODE

4PCS ISO 1002763 34CRNIMOG = 1002763 1. WS 5283 w22

2. WS 5280 w22

3. WS 5218 W22

4. WS 5295 w22

SIGN | KHAIRUL FAIZI

DATE | 03” September 2013

‘Twistlock Certificate_QE! 16.0 Rev (01)

MF IN-PROCESS -DIMENSION INSPECTION REPORT (Rev 3) BROMMA!

RTC

jue 17676 _JOustomer ie tnt ene vo. wet

[Mod Gis Cu_ JSANOM [en wc) 2

11. General Assembly

[Detail Spec refer to Order Production Drawing

Main Beam Main Beam No-

A 4S)

B ast

Location Design Tolerance: Actual Deviation Remarks:

‘AFront. Sts exes 33st xt

‘A-Back yo 7 Sist *F

B-Front igo Tou c

B-Back gee es “ROS Cc

‘C-Front (Zoe = i o

‘C-Back Da se Soe Oo

se t: Not =

|2, Dimensional Inspection Satisfactory | saristactory Rectify Result

[Above Dimensional inspection Result

WWote: The measurement point between

Jneadblock must be address botween center point | L-——~

lof the headblock twistlock pocket. Before

lonecking, QC must confirm the twistlock hole

|center markina

—fe = Inspected By = a z

Center Point ke ie

Name: A204 ame? (7h on,

Designation : Fab. Inspector [Designation : Supervisor

pate: Sere, pate: aly hie

IMF In-Proess Dimension Inspaction Repot_EI 7.0 Rev (03)

DIMENSIONAL AND VISUAL REPORT

rea — TE CRIES

(267 [Customer liam wat nia vo. yvreTwar

[Model CHEY [Prawing® jer wuetrsfaricle® len quia”

|1. General Assembly

Telescopic Beam Frame No Telescopic Beam No

‘A TSG Dy 7 0INY

B 1344F Dati DEERE

Location Design | Tolerance Deviation Remarks

lat (Top Side) TSaS rt +t

[a2 (Bottom Side) |) SOS 7 ras

bt (Top Side) TS88 7 7

|b2 (Bottom Side) SCS zy a

Tolescopic 6

[a1 (Top Side) L ru (exer aT

[az (Bottom Side) | / Tz TSG <\

[b1 (Top Side) (Seo = TSS rx

jb2 (Bottom Side) {CCS Ee 1 SO 2 AN.

Not

|2. Dimensional inspection Satisfactory | ssustactory Reetify Result

|Above Dimensional inspection Result _

3. Visual Welding Inspection

Visual Welding Inspection Result

os

Note : The Weld Quality / Visual Welding

|Acceptance Criteria shall comply according to EN

|/SO 5817 Table 1

Inspected By:

[Name : ADEA [Name VAD RUC

Designation : Fab. inspector| Designation : Supervisor

ate = S/¢ [13 Date: s/¢/i3

‘Telascopic Frame Dimensional Visual Report_QE! 7.0 Rev (02)

MF IN-PROCESS -MPI INSPECTION REPORT (Rev 3)

UIce

(et N66 _[eistomer hotn Iddt Di Yo, ech

Model Et -SVibrawing Ranieire [Artie ign ci2ge

}1. MAGNETIC PARTICLE INSPECTION (FRESH / RENEPEGT)

ITEM INSPECTED : AS SHOWN,

Test Equipment

(chemical Used Magnetic White Contaat Paint

[Equipment used Youe Magnets nk THE

[GleanerfRonover BC-5

Location: Judgment

7 ACCEPT esr

z ‘AQBEPP/ REJECT

3 ‘ACCEPT LREECT.

4 "ACCEPT RETECT

3 ‘ACCEPT REVEST

é ‘ACCEPT REIECT

T ‘ACCEPT ReseGT

e@ 3 ‘ACCEPT REIEGT

a ‘ACCEPT REJEST

92 ‘AGGEPT /REJEGE

33 ACCEPT / EJECT

4 ACCEPT [EJECT

10-1 ACCEPT REET

702 ‘ACCEPT REET

703 ‘ACCEPT REEST

0 ‘ACCEPT /REEET

Judgment -Aesept/ Reject

Visual Welding Inspection: Seisfectory? Not Satisfactory

Inspected By

Name uy

Designation Fab inspettoe

Qualification ASNT Level

Date of nspecion 3/8/13,

Note: Acceptance criteria ofthe weld quality shall comply with he requirements of BS EN 1231

{Al finishing and rough edges shal be smoothly rounded

[MF inProcess MP Inspection Report_QEI6.1 Rev (03)

MF IN-PROCESS -MPI INSPECTION REPORT (Rev 3)

[ane (4646 [Pustomer NICO / Nam HAL QwwH UUs VETNAW

|Modet HSV [Drewing #

mic rs fAmicte® | RR UWGITe

li. MAGNETIC PARTICLE INSPECTION ( RRESH REJNSPECT)

TTEM INSPECTED : AS SHOWN.

Test Equipment

(Chemical Used Magratve White Contrast Paint

Equipment Used oxo. Magnetic nk THE

[cieanerRemover SKC-8

wu

ACCEPT RESEGT

“ACCEPT / REJECT

‘ACCEPT? REJEGT

ACCEPT /RESEST

Location,

1

2

3

4

5 ‘ACCEPT REYEST,

6 ‘ACCEPT REJECT

7 ‘ACCEPT RIES

3s "ACCEPT / REJECT”

oT

82

93

4

0-1

302

"ACCEPT REJECT

‘ACCEPT / REJECT

‘ACCEPT REJECT

‘ACCEPT IREVEST

ACCEPT) REVEGT

ACCEPT) REdEST

103) [ACCEPT REIEET

104 ‘ACCEPT REJECT.

Judgment - Accept / Reject

‘Visual Welding Inspection: Satisfactory / Nal Satisfactory.

Inspected By

Name

Dengnaton Ho Mh

uaiicaton ASNT Lovell

Date of Inspection © 3/5//3

Note: Acceptance citeria ofthe weld quality shall comply withthe requirements of 8S EN 1291

{Al fishing and rough edges shal be smoothly rounded.

MF i-Process MPI Inspection Report EI 6.1 Rev (03)

TBU IN-PROCESS -MPI INSPECTION REPORT (Rev 4)

CRTC

Ene (FE76_|Customer Naw WAL Dl yu, Wietvan

Mode! GEV _|Prawing # wrcinf [Articte# Jan 131 ¢128

[1. MAGNETIC PARTICLE INSPECTION (FRESH/ CT)

ITEM INSPECTED : AS SHOWN

Telescopic B unit Frame No# Beam 1#

lescopic Beam Uni

BB [D722

Ao]

(chemical Used Magnafix White Contrast Paint

[Equipment Used Yore Magnetic nk THF

[GteanecRemover | Sxc-S

‘Location Judgment

1 ACCEPT / RESECT NA —

@ 2 ACCEPT / REJECT TNA

3 ACCEPT / REJECT NA-

4 ACCEPT I REZECTTNA

Judgment - Accept / Reject ——

Visual Welding Inspection: Satisfactory Not Satisfactory

Inspected By

Name

Designation Fab. Inspector

Qualification :ASNT Level it

Date of Inspection : /0/S//3,

Note: Acceptance criteria of the weld quality shall comply wth the requirements of BS EN 1291

Ail finishing and rough edges shall be smoothly rounded

‘TBU In-Process MPI Inspection Report_QEI 6.1 Rev (04)

TBU IN-PROCESS -MPI INSPECTION REPORT (Rev 4)

BROMMA

[sn # 136 16 [Customer vane at am

IModet Te ec lan cis [Article wit

lt. MAGNETIC PARTICLE INSPECTION (FRESH / RE-+NSPEGT)

ITEM INSPECTED : AS SHOWN

Judgment - Aveept / Reject

Visual Welding Inspection: Satisfactory J Not Satisfactory

Inspected By

Name A on

Designation

Qualification

Date of Inspection

Fab. Inspector

ASNT Level Il

(S/8/13

4

2

cai Frame No# Beami# | Beam 1#

copic Beam Uni

13444 Datel | OFtZF

Test Equipment

[Chemical Used Magnafiux White Contrast Paint

[Equipment Used Yoke Magnetic Ink THF

[CleaneriRemover SKC-S

@ Location Judgment

1 ACGEPTY REJECT / RAM

2 ROGER] REJECT / NA

3 ACCEPT / REJECT [NA

4 ‘ACCEPT [REGEGT NAT

Note: Acceptance criteria of the weld quality shall comply with the requirements of BS EN 1291

All finishing and rough edges shall be smoothly rounded,

TBU In-Process MPI Inspection Report_QEI 6.1 Rev (04)

BU IN-PROCESS -MPI INSPECTION REPORT (Rev 4) BROMMA

TATE

ISN # lietg _[Sustemer Asoo tht Di VU, fel AMA

Mode! Ett SO |Drawing # fonuteras [Article [en wire

1. MAGNETIC PARTICLE INSPECTION (ERESH/ RE-INSPECT)

ITEM INSPECTED : AS SHOWN

a ean Frame No# Beam t# | Beam 1#

‘elescopic Beam Uni

12444 barat | bdtet

Test Equipment

[Chemical Used Magnaflux White Contrast Paint

[Equipment Used ‘Yoke Magnetic ink 7HF

[CleaneriRemover SKC-S

e Location Judgment,

1 ACCEPT / REECE ARR

2 ACCEPT / REJECEARA

3 ‘ACCEPT / REJEGT INA

4 ACCEPT [REGEST PIA

Judgment - Accept / Re|

Visual Welding Inspection: Satisfactory / Not Sgtisfactory

Inspected By

Name

Designation SE ace

Qualification ASNT Level I

Date of Inspection : 1$/&//3

Note: Acceptance criteria of the weld quality shall comply with the requirements of BS EN 1291,

Al finishing and rough edges shall be smoothly rounded.

‘TBU In-Process MPI Inspection Report_QEI 6.1 Rev (04)

BROMMA

Project unico

End User - NANHATORRTVOL VET

Beam No. : SMPTST, SMPTSS

Serial Number 17678

Medel EHGU

Ultrasonic Testing Report-Main Beam Auto Weldin:

ert Tyee ‘Shale Boel Tee Jort

Wear Process ape we

Suracs Conaton ‘lean Sattactny

eas ‘Wall Paper Paste.

Probe o

Ultrasonic Testing Report-Main Beam - Top Plate

JOINT DETAILS

ro Matera Theses 8mm, p=20-s0mm

——<$<—<— ont ye Sinle Bevel ut Wess

Witang Process Fixcare

a Surface Gonaton Cleon Ststactony

Goupant Wal Pacer Pas

Probe w

ul ic }ort-Main Beam - Bottom Plate

JOINT DETAILS

as Metena emness 28mm, »=30- 50mm

dont Tee" Single Bove! But Yes

Wilang Procoss Pioccare

° ‘Surface Gnaiton Clean Sotetcony

oupiet Wat Pacer Paste:

Probe ©

Fellow ‘Searing &B

= ~ 8

- 2

8

aw onccr ——HKUSMA SM, 08008

sewey ANS DI Armee

lpn cote :Pa, 90 aL GRMYIBOPAB Rv?

*osptelon was cario ou on acasee ae ony.

2)Inspncn reno oped tte ie ot neocon.

srr

LUTRTORT ps Beam Wel) 8162 AE 4)

[BROMMA| 4

ra Tee ea PET (ear Wo Wass

ler User |Web Plate i - Batch No Rrort [Booth Number FABI-S

[Serial No. 1x6 to |Web Plate 1- Batch No W2rwS FE [Model mS

aa ‘Auto Joint (a) en

Sa wor

ieexa ai a

&

L,

7" Auton z=

i y

i

lL ™ x +7

| “ep

ane essen att

a

=a

formas TERS TU automa? PERSO =

[calibration Block V1,V2 & Bromma reference block we

jcc” meats —a 1) Raa

oe ceases onomsfe | owwimn: Cy ovat i

pensevenf

nee Sorte aie wit manu weld

cocoa lame maT heme

i omen naseoe tt =o =<

+ pen rata ured ett ie pcan eaten eX Urine =

patectinspoton: 16] FT pas of pet

T

Main Beam / UT npacon hac 7.0 Re (3)

‘MAIN BEAM UT INSPECTION REPORT BROMMA

Frame We eon be [wae W200, WF .

ender NAM FAT DINE EL, y TTA Ares rine tachie THEFT oath br fase

rain THERE es Peach THiaOFL esl 3

stent

= Autos in

somcnan [eum ror] ower [ tenet | cere | Meet

i i

Ls

Auto ont (0) =

Teo i —— =

eto ont) Soran oe Tope)

Rete A

eT

Faron EPOGHXT 7 USM Kraltiamer 7 EPOCH I ‘wun

eaiaion ck V2 8 emma reference lock ray)

a sa0%46n3 ee 2 sorrmsnecren oof inapeced ty Reinpeced oy:

senaty AWSOLL Ames MOHOWORFASH | Grenuneun: Gaara ‘venient: PASS/FAL

cence Cade Pa 8.DatBRNY/SOPAEL3 Rev? Sarre

ane ecto care xt wth manu weld Ls

2. Sheth deoving nto cle [ar WORD ORF ane

4 Aldine nme) [beseaon: HOT INSPECTOR eset

5 opeion cei acepored athe tine ct nection [tien pow VEL ewan

[pew otpecions 17 F 773 [omectinapecions

Main ur P/U iapcton Chehi 17.R(03)

rast at erent

(Free a Vineet encano | [20130 AG, [waar TOG, WE

fens veer ihn HBC Dini UG, Vie AA [range2-euenne [13130 AM [sooth number ab T08

[oes rine tonchne—T30206F hase T Sano TK

fwatasa-tiate —1130R06F oon abe DFE

> — Front View ‘eee

; - ise

a =e

& asco | ostumex ere [OO coat: ea

a te

dyabers

>

> Ue

: —.

i oh

3 + Suechr

Ms

— [int cece

:

=e fe

‘e Matera Thikness: 2+ QOmm bs 6 mm Ue

ie aden Lees

Ses Sse — Sab

| ee Set ie

tan —

fee senanrnterone

feo” nena Se

oc = omit

fom _‘netniannane

— (BS rorsemunn

ae ee

|S Inspection results as reported is at the time of inspection eer peeatendion 260 TLL.

[oste of mopection: 307 7773 [oat ofinpection =

‘elope tam PA /UT epochal 2879 Re 3b

SCTION REPORT.

[BRomma|

[Fore [NEO [Farge eacnno TOsO AG [weaeD Wy wee

ender WAR RAL SOE Vi Joneez-sncnno —[ 1.6780 Bry aco abe aaa

ooo [30306-E eter ‘eur ine Biz

ooo 130206 eon manta ba {32

‘om to

= Front View "

_ outes

* “ane [ne Fo W301 Jy

= Peter | tere | Oop nen wei

om me seta

i .

a Suebq

> ea

* Taare na

= or

2 Suet

“%

= = ~ a

Sul

a Mater Tekno 2 = 30 mm / 8= Yom Liv

je but =

Yesirg Pees; naldare

» Surface Condition: clean sygehr

A conta Wal ape /e

rote freien sce sete Seamings ange

ok mk 010m fhm

a 1s mm 08am fh dy 00m

|Fiaw Detector EPOCH XT / USM KK 35K / EPOCH III

atnion tok VIVEK Bromma erence

Jrccetireno ——= 3 mm sin

te rena poe nal

Milne reces; apne ve

Sb Surface Condition Cleon Spare

g Comte wee ee 212

rote see selina Smith tage

° 310mm oth eo

se Ts mm 88m a a

fowoxecor—— SEPOGRRT / UBWRESSX /EPOHTE

stents yxv28tmmarteems dct

fremavene usr steve Tagen Rica

Key ss amers Sn vam

eee eee mat: Cea onset a

ears EF ure :

2 i rit oon 20m one ie see we

2 See gett co co

1 Alte rest esti ran Sc mareTOR oon

onion retreat bee pin Som ae:

pre othepcion, 32] fT oe theo

“Tesco beam A/T iapacon hc 170 (03)

REPORT e

oo DH fforaet-tachno | TOTES AL [wou Wor, we

fens User Wim WAT VE U0, OETA — ares oxen No [130180 Bm [Boom nomber TAB ioe

[wes Fixex-monno —[T3OROG F [Most ERB W eran THERE

[webrinez-saenno [130206 F pewnnanter [927

oe bat

“out [BRaRa Fem | oo TO Yona

eet [ie [oom | REF [wana waa

———— fear wel

ps

ayaten

us

> Z aera naa

é be

i ae

Us

5 fare na

Z syahe|

= ‘aa zi

2 manner game tate 7 Ge

sani Teenie 7 Pama a

Welding Process: pid Are —— *,

> Surcecondton: Gen Syuhe

Comat. Wal operas

[ad le

robe Frequency Sie tettew Seannings8 Range,

oo 10 om - fh on

we 9s e8 am wx th em

[fowoaeaorT USM RESSR S/o, 7627

catatonic 128 toma ference

roceswen>———sannaonter ster? Rewpearay

senity AWS Aner Oven: PASE / Fa

crtncecode Pana onnraorsan3terz

ji UT rit ton 20 no gene wl

3. Sketching ot tose [none one pan ame

4. Alderson tine) [ewaraton NOT RSRECOR ostntin ROT SPECTOR

5 wipeion rents septs the tine spect Quen: row Tava [asasteaton POX UT LVEL

bse ot specton? 30/277:

[ose eespecton

"lei am UT npcton hat. 28720 8)

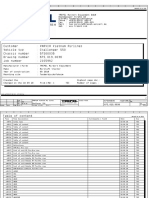

Single lft with one bracket

Proof loading with two cylinders

SINGLE LIFT WITH ONE BRACKET

Bromma Spreader EHSU

Customer Unico Vina JSC

Serial Number. 17676

General Assembly Drawing. 1116125

Safe Working Load 41 Tonne

Proof Load 150%

Tare Weight 9 Tonne

Weight of Test Equipment 2 Tonne

Cylinders Used 2

é a

U

@ Q@ © © ©)

[Pressure

[From Pump [Load In Tonne Measure point mm

lin Bar Load [Load

2 eyl. in each fin each

|A=71,2cm?_|Cylinder [Twistlock 1 2 3 4 5

101 7 2|_0 6 @ o o

203 15, ye A |e u o

266 19) |i is iE te 7

584 2 18) AS. Se 47 2

101 7 2 0 Lt T 2

UNDER SUPERVISION OF | SIGNATURE DATE

Equipment Name: Pressure Gauge (Hi-Foree HO 1)

Control Numer: C>3854 . .

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- FD240 FD250 FD300: Forklift TruckDocument491 pagesFD240 FD250 FD300: Forklift TruckNguyễn Hữu ĐồngNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DanfossomrDocument30 pagesDanfossomrhoiNo ratings yet

- Bridon-Bekaert+Oil Gas+Catalog+July+2018Document27 pagesBridon-Bekaert+Oil Gas+Catalog+July+2018thiban130991No ratings yet

- Closed Swage Sockets National Swage ButtonsDocument1 pageClosed Swage Sockets National Swage ButtonshoiNo ratings yet

- 04 73037-38 PartslistDocument30 pages04 73037-38 PartslisthoiNo ratings yet

- Hu08 010 HTPDocument1 pageHu08 010 HTPhoiNo ratings yet

- Gear Code BookDocument81 pagesGear Code BookhoiNo ratings yet

- Testing ReportDocument17 pagesTesting ReporthoiNo ratings yet

- Chao Gia Cua Tri VietDocument1 pageChao Gia Cua Tri ViethoiNo ratings yet

- Sunstar SPS D-B1201Document86 pagesSunstar SPS D-B1201hoiNo ratings yet

- BasicsDocument170 pagesBasicshoiNo ratings yet

- Parts ListDocument19 pagesParts ListhoiNo ratings yet

- ActuatorsDocument37 pagesActuatorshoiNo ratings yet

- Trawlex Brochure 9992020 by PageDocument12 pagesTrawlex Brochure 9992020 by PagehoiNo ratings yet

- S-423T Super TerminatorDocument1 pageS-423T Super TerminatorhoiNo ratings yet

- 04 6750036 EL 180910 enDocument227 pages04 6750036 EL 180910 enhoiNo ratings yet

- Báo Giá Bộ Ly ChénDocument1 pageBáo Giá Bộ Ly ChénhoiNo ratings yet

- 00a 6720168 CONTENTS CHALLENGER280 PDFDocument1 page00a 6720168 CONTENTS CHALLENGER280 PDFhoiNo ratings yet

- 06e - DQC-Freigabeliste Schmieröle - Ausgabe - 09 - 2018 - de - enDocument27 pages06e - DQC-Freigabeliste Schmieröle - Ausgabe - 09 - 2018 - de - enhoiNo ratings yet

- A Full Range of Hydraulic Parts Such As: Pumps, Hydraulic Valves, Hoses, Steering Pumps, Lift Cylinders, Cylinder Repair Kits, Fittings, ..Document74 pagesA Full Range of Hydraulic Parts Such As: Pumps, Hydraulic Valves, Hoses, Steering Pumps, Lift Cylinders, Cylinder Repair Kits, Fittings, ..hoiNo ratings yet

- Ols 120Document1 pageOls 120hoiNo ratings yet

- 01b - 6720168-169 - CHAPTER1 - BA - 191130 - en (Us)Document190 pages01b - 6720168-169 - CHAPTER1 - BA - 191130 - en (Us)hoiNo ratings yet

- 00a 6720169 CONTENTS CHALLENGER280 PDFDocument1 page00a 6720169 CONTENTS CHALLENGER280 PDFhoiNo ratings yet

- Main Cylinder 250T PDFDocument1 pageMain Cylinder 250T PDFhoiNo ratings yet

- Main Cushion Cylinder 250T PDFDocument1 pageMain Cushion Cylinder 250T PDFhoiNo ratings yet

- 9 Hydraulic2006Document91 pages9 Hydraulic2006hoiNo ratings yet

- ServiceInfo15-WT-05 Rev ADocument38 pagesServiceInfo15-WT-05 Rev AhoiNo ratings yet

- Cushion Side Cylinder 250 T PDFDocument1 pageCushion Side Cylinder 250 T PDFhoiNo ratings yet

- Knock Out Cylinder 250 T PDFDocument1 pageKnock Out Cylinder 250 T PDFhoiNo ratings yet

- Main Side Cylinder 250T PDFDocument1 pageMain Side Cylinder 250T PDFhoiNo ratings yet