Professional Documents

Culture Documents

Stps 40170 C

Stps 40170 C

Uploaded by

otnielsaririOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stps 40170 C

Stps 40170 C

Uploaded by

otnielsaririCopyright:

Available Formats

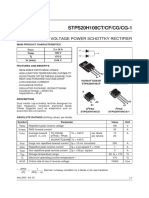

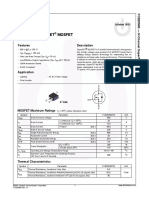

STPS40170C

Datasheet

170 V power Schottky rectifier

A1

Features

K

A2 • High junction temperature capability

• Low leakage current

• High voltage capabilities

• Good trade-off between leakage current and forward voltage drop

• Low thermal resistance

A2 A2 • High frequency operation

A1 K K

TO-220AB TO-247 A1 • Avalanche specification

K • ECOPACK®2 compliant for TO-220AB and TO-247, on demand for D²PAK

A2

Applications

D²PAK A1

• Switching diode

• SMPS

• DC/DC converter

• Telecom power

Description

This dual center tab Schottky rectifier is suited for high frequency switched mode

power supplies.

Packaged in TO-247, D²PAK and TO-247, the STPS40170C is optimized for use to

Product status link enhance the reliability in applications.

STPS40170C

Product summary

Symbol Value

IF(AV) 2 x 20 A

VRRM 170 V

Tj 175 °C

VF (typ.) 0.69 V

DS4412 - Rev 2 - June 2018 www.st.com

For further information contact your local STMicroelectronics sales office.

STPS40170C

Characteristics

1 Characteristics

Table 1. Absolute ratings (limiting values at 25 °C, unless otherwise specified, per diode)

Symbol Parameter Value Unit

VRRM Repetitive peak reverse voltage 170 V

IF(RMS) Forward rms current 60 A

Tc = 150 °C Per diode 20

IF(AV) Average forward current, δ = 0.5 square wave A

Tc = 145 °C Per device 40

IFSM Surge non repetitive forward current tp = 10 ms sinusoidal 250 A

PARM Repetitive peak avalanche power tp = 10 µs, Tj = 125 °C 1015 W

Tstg Storage temperature range -65 to +175 °C

Tj Maximum operating junction temperature range(1) 175 °C

1. (dPtot/dTj) < (1/Rth(j-a)) condition to avoid thermal runaway for a diode on its own heatsink.

Table 2. Thermal resistance parameters

Symbol Parameter Max. value Unit

Per diode 1.20

Rth(j-c) Junction to case

Total 0.85 °C/W

Rth(c) Coupling 0.50

When the diodes 1 and 2 are used simultaneously :

ΔTj(diode 1) = P(diode1) x Rth(j-c)(per diode) + P(diode 2) x Rth(c)

Table 3. Static electrical characteristics (per diode)

Symbol Parameter Test conditions Min. Typ. Max. Unit

Tj = 25 °C - 30 µA

IR(1) Reverse leakage current VR = VRRM

Tj = 125 °C - 7 30 mA

Tj = 25 °C - 0.92

IF = 20 A

Tj = 125 °C - 0.69 0.75

VF(2) Forward voltage drop V

Tj = 25 °C - 1.00

IF = 40 A

Tj = 125 °C - 0.79 0.86

1. Pulse test: tp = 5 ms, δ < 2%

2. Pulse test: tp = 380 µs, δ < 2%

To evaluate the conduction losses, use the following equation:

P = 0.64 x IF(AV) + 0.0055 x IF2(RMS)

For more information, please refer to the following application notes related to the power losses :

• AN604: Calculation of conduction losses in a power rectifier

• AN4021: Calculation of reverse losses on a power diode

DS4412 - Rev 2 page 2/15

STPS40170C

Characteristics (curves)

1.1 Characteristics (curves)

Figure 1. Average forward power dissipation versus Figure 2. Average forward current versus ambient

average forward current (per diode) temperature (δ = 0.5, per diode)

PF(AV)(W) IF(AV) (A)

22 22

δ=0.05 δ=0.1 δ=0.2 δ=0.5 δ=1.0

20 20

18 18

16 16

14 14

12 12

10 10

8 8

6 6

T

4 4

2 IF(AV) (A) IF(AV) (A) 2

δ = tp/T tp

0

0

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28

0 25 50 75 100 125 150 175

Figure 3. Normalized avalanche power derating versus Figure 4. Relative variation of thermal impedance junction

pulse duration (Tj = 125 °C) to case versus pulse duration

PARM (t p ) Z th(j-c) / R th(j-c)

PARM (10 µs) 1.0

1

0.9

0.8

0.7

0.1 0.6

0.5

0.4

0.01 0.3

0.2

Single pulse

0.1

t p(µs) t p(s)

0.001 0.0

1 10 100 1000 1.E-03 1.E-02 1.E-01 1.E+00

DS4412 - Rev 2 page 3/15

STPS40170C

Characteristics (curves)

Figure 5. Reverse leakage current versus reverse voltage Figure 6. Junction capacitance versus reverse voltage

applied (typical values, per diode) applied (typical values, per diode)

I R (µA) C(pF)

1.E+05

1000

F = 1 MHz

Tj = 150 °C VOSC = 30 mVRMS

1.E+04 Tj = 25 °C

Tj = 125 °C

1.E+03

Tj = 100 °C

1.E+02 Tj = 75 °C

100

Tj = 50 °C

1.E+01

Tj = 25 °C

1.E+00

VR(V) VR(V)

1.E-01

10

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170

1 10 100 1000

Figure 7. Forward voltage drop versus forward current Figure 8. Thermal resistance junction to ambient versus

(per diode) copper surface under tab

IF (A) Rth(j-a) (°C/W)

100.0 80

D²PAK

Tj = 125 °C 70

(maximum values) Epoxy printed board FR4, copper thickness = 35 µm

60

10.0 Tj = 125 °C

(typical values) 50

40

Tj = 25 °C

(maximum values) 30

1.0

20

10

SCu (cm²)

VF(V) 0

0.1

0 5 10 15 20 25 30 35 40

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2

DS4412 - Rev 2 page 4/15

STPS40170C

Package information

2 Package information

In order to meet environmental requirements, ST offers these devices in different grades of ECOPACK®

packages, depending on their level of environmental compliance. ECOPACK® specifications, grade definitions

and product status are available at: www.st.com. ECOPACK® is an ST trademark.

2.1 D²PAK package information

• Epoxy meets UL94, V0

• Cooling method: by conduction (C)

DS4412 - Rev 2 page 5/15

STPS40170C

D²PAK package information

Figure 9. D²PAK package outline

Note: This package drawing may slightly differ from the physical package. However, all the specified dimensions are

guaranteed.

DS4412 - Rev 2 page 6/15

STPS40170C

D²PAK package information

Table 4. D²PAK package mechanical data

Dimensions

Ref. Millimeters Inches

Min. Max. Min. Max.

A 4.36 4.60 0.172 0.181

A1 0.00 0.25 0.000 0.010

b 0.70 0.93 0.028 0.037

b2 1.14 1.70 0.045 0.067

c 0.38 0.69 0.015 0.027

c2 1.19 1.36 0.047 0.053

D 8.60 9.35 0.339 0.368

D1 6.90 8.00 0.272 0.311

D2 1.10 1.50 0.043 0.060

E 10.00 10.55 0.394 0.415

E1 8.10 8.90 0.319 0.346

E2 6.85 7.25 0.266 0.282

e 2.54 typ. 0.100

e1 4.88 5.28 0.190 0.205

H 15.00 15.85 0.591 0.624

J1 2.49 2.90 0.097 0.112

L 1.90 2.79 0.075 0.110

L1 1.27 1.65 0.049 0.065

L2 1.30 1.78 0.050 0.070

R 0.4 typ. 0.015

V2 0° 8° 0° 8°

DS4412 - Rev 2 page 7/15

STPS40170C

D²PAK package information

Figure 10. D²PAK recommended footprint (dimensions in mm)

16.90

12.20 5.08

2.54

1.60

3.50

9.75

DS4412 - Rev 2 page 8/15

STPS40170C

TO-247 package information

2.2 TO-247 package information

• Epoxy meets UL94, V0

• Cooling method: by conduction (C)

• Recommended torque value: 0.8 N·m

• Maximum torque value: 1.0 N·m

Figure 11. TO-247 package outline

A Heat-sink plane

E

∅P

S ∅R

L2

L1

L b1

b2

1 2 3 3 2 1

b c

A1 Back view

e

DS4412 - Rev 2 page 9/15

STPS40170C

TO-247 package information

Table 5. TO-247 package mechanical data

Dimensions

Ref. Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 4.85 5.15 0.191 0.203

A1 2.20 2.60 0.086 0.102

b 1.00 1.40 0.039 0.055

b1 2.00 2.40 0.078 0.094

b2 3.00 3.40 0.118 0.133

c 0.40 0.80 0.015 0.031

D 19.85 20.15 0.781 0.793

E 15.45 15.75 0.608 0.620

e 5.30 5.45 5.60 0.209 0.215 0.220

L 14.20 14.80 0.559 0.582

L1 3.70 4.30 0.145 0.169

L2 18.50 0.728

ØP 3.55 3.65 0.139 0.143

ØR 4.50 5.50 0.177 0.217

S 5.30 5.50 5.70 0.209 0.216 0.224

1. Inches dimensions given for reference only

DS4412 - Rev 2 page 10/15

STPS40170C

TO-220AB package information

2.3 TO-220AB package information

• Epoxy meets UL 94,V0

• Cooling method: by conduction (C)

• Recommended torque value: 0.55 N·m

• Maximum torque value: 0.70 N·m

Figure 12. TO-220AB package outline

Table 6. TO-220AB package mechanical data

Dimensions

Ref. Millimeters Inches

Min. Max. Min. Max.

A 4.40 4.60 0.173 0.181

b 0.61 0.88 0.240 0.035

b1 1.14 1.55 0.045 0.061

DS4412 - Rev 2 page 11/15

STPS40170C

TO-220AB package information

Dimensions

Ref. Millimeters Inches

Min. Max. Min. Max.

c 0.48 0.70 0.019 0.028

D 15.25 15.75 0.600 0.620

D1 1.27 typ. 0.050 typ.

E 10.00 10.40 0.394 0.409

e 2.40 2.70 0.094 0.106

e1 4.95 5.15 0.195 0.203

F 1.23 1.32 0.048 0.052

H1 6.20 6.60 0.244 0.260

J1 2.40 2.72 0.094 0.107

L 13.00 14.00 0.512 0.551

L1 3.50 3.93 0.138 0.155

L20 16.40 typ. 0.646 typ.

L30 28.90 typ. 1.138 typ.

θP 3.75 3.85 0.148 0.152

Q 2.65 2.95 0.104 0.116

DS4412 - Rev 2 page 12/15

STPS40170C

Ordering information

3 Ordering information

Table 7. Ordering information

Order code Marking Package Weight Base qty. Delivery mode

STPS40170CT STPS40170CT TO-220AB 1.95 g 50 Tube

STPS40170CG-TR STPS40170CG D2PAK 1.38 g 10000 Tape and reel

STPS40170CW STPS40170CW TO-247 4.36 g 30 Tube

DS4412 - Rev 2 page 13/15

STPS40170C

Revision history

Table 8. Document revision history

Date Version Changes

16-Sep-2005 1 Initial release.

Updated PARM value and removed "Normalized avalanche power derating"

01-Jun-2018 2

curves.

DS4412 - Rev 2 page 14/15

STPS40170C

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. All other product or service names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2018 STMicroelectronics – All rights reserved

DS4412 - Rev 2 page 15/15

You might also like

- Garis Panduan Electrical System Design & Installation For Architects & Engineers PDFDocument214 pagesGaris Panduan Electrical System Design & Installation For Architects & Engineers PDFSemifallen100% (1)

- Speaker TOADocument4 pagesSpeaker TOASenoPati KudusNo ratings yet

- STPS80170C: 170 V Power Schottky RectifierDocument9 pagesSTPS80170C: 170 V Power Schottky Rectifiern tanevarNo ratings yet

- STPS80H100CY Schottky RectifierDocument10 pagesSTPS80H100CY Schottky RectifierAnonymous oyUAtpKNo ratings yet

- STPS40170C High Voltage Power Schottky Rectifier Diode PDFDocument8 pagesSTPS40170C High Voltage Power Schottky Rectifier Diode PDFHưng HQNo ratings yet

- Stps 10120 CDocument9 pagesStps 10120 CLEWIS RODRIGUEZNo ratings yet

- Stps 20 S 100 CDocument12 pagesStps 20 S 100 CEnrico RotaNo ratings yet

- STPS30H100C: 100 V Power Schottky RectifierDocument12 pagesSTPS30H100C: 100 V Power Schottky RectifierPablo AllosiaNo ratings yet

- Hoja ValiosaDocument18 pagesHoja Valiosacarlosjamal95No ratings yet

- stps20s100cfp SCHOTTKY DIODEDocument7 pagesstps20s100cfp SCHOTTKY DIODEANDREASBOULNo ratings yet

- STTH1602C: DescriptionDocument15 pagesSTTH1602C: DescriptionAndrea MartinezNo ratings yet

- STPS40L45C: Low Drop Power Schottky RectifierDocument11 pagesSTPS40L45C: Low Drop Power Schottky Rectifiersasan hatamiNo ratings yet

- Trial TVDocument18 pagesTrial TVronal lopezNo ratings yet

- STPS20H100C: 100 V, 20 A Power Schottky RectifierDocument19 pagesSTPS20H100C: 100 V, 20 A Power Schottky RectifierTodor NakovNo ratings yet

- High Frequency DiodeDocument12 pagesHigh Frequency DiodeCarlos IbaNo ratings yet

- STPSC20H12C: 1200 V Power Schottky Silicon Carbide DiodeDocument10 pagesSTPSC20H12C: 1200 V Power Schottky Silicon Carbide DiodeshivguptaNo ratings yet

- TN6050-12PI: 60 A, 1200 V Standard SCRDocument11 pagesTN6050-12PI: 60 A, 1200 V Standard SCRluis lopezNo ratings yet

- STPS20H100CT/CF/CG/CG-1: High Voltage Power Schottky RectifierDocument7 pagesSTPS20H100CT/CF/CG/CG-1: High Voltage Power Schottky RectifierVicente MiróNo ratings yet

- Stps 30170 CDocument9 pagesStps 30170 CKichin_ANo ratings yet

- Probador CCFL-CreatronicaDocument6 pagesProbador CCFL-CreatronicasanlugoNo ratings yet

- STPS20H 100CTDocument7 pagesSTPS20H 100CTManuel G Medina LopezNo ratings yet

- Schott yDocument8 pagesSchott yDinalba(Formación) El Espíritu Santo ObraNo ratings yet

- Stps 2 H 100Document19 pagesStps 2 H 100WAN MOZESNo ratings yet

- STPS10170C: High Voltage Power Schottky RectifierDocument10 pagesSTPS10170C: High Voltage Power Schottky RectifierRicky Maulana FirdausNo ratings yet

- STPS20H100C: 100 V Power Schottky RectifierDocument17 pagesSTPS20H100C: 100 V Power Schottky RectifierMiguel GuzmanNo ratings yet

- STTH812Document11 pagesSTTH812rolando ojedaNo ratings yet

- STPS640C: Power Schottky RectifierDocument8 pagesSTPS640C: Power Schottky RectifierMax TeleNo ratings yet

- tn4050hp 12gy tr-2935903Document11 pagestn4050hp 12gy tr-2935903chawkigenieNo ratings yet

- Stps 30100 STDocument9 pagesStps 30100 STDerkis MarcanoNo ratings yet

- stth60rq06 M2yDocument12 pagesstth60rq06 M2yRahul SinghNo ratings yet

- STPS2045CTCFCGCFPCRDocument8 pagesSTPS2045CTCFCGCFPCROmaraye JoshuaNo ratings yet

- STTH 602 CDocument9 pagesSTTH 602 COmar MelchorNo ratings yet

- Borro ToDocument9 pagesBorro TomaugrysNo ratings yet

- STTH 102Document12 pagesSTTH 102Abel GaunaNo ratings yet

- 497 3542 5 DatasheetzDocument7 pages497 3542 5 DatasheetzOmar MelchorNo ratings yet

- Semiconductor Technical Data: 15 Ampere Complementary Silicon Power Transistors 200 VOLTS 200 WATTSDocument6 pagesSemiconductor Technical Data: 15 Ampere Complementary Silicon Power Transistors 200 VOLTS 200 WATTSpachanga imxNo ratings yet

- STPS1045D Eng TdsDocument8 pagesSTPS1045D Eng Tdsjohn9999_502754No ratings yet

- STTH2002C: High Efficiency Ultrafast DiodeDocument16 pagesSTTH2002C: High Efficiency Ultrafast DiodeAseng saputraNo ratings yet

- STTH5R06: Turbo 2 Ultrafast High Voltage RectifierDocument17 pagesSTTH5R06: Turbo 2 Ultrafast High Voltage RectifierGoran NovakovNo ratings yet

- STTH1R02 200V 1.5A U-FastDocument15 pagesSTTH1R02 200V 1.5A U-Fastrara221122raraNo ratings yet

- STTH1R02: 200 V - 1.5 A Ultrafast Recovery DiodeDocument15 pagesSTTH1R02: 200 V - 1.5 A Ultrafast Recovery DiodeAlex Nicole SanchezNo ratings yet

- STPS20L45C: Low Drop Power Schottky RectifierDocument9 pagesSTPS20L45C: Low Drop Power Schottky RectifierFabio SantanaNo ratings yet

- stpsc30g12 yDocument10 pagesstpsc30g12 yalhammadiree124No ratings yet

- btw69 1200Document9 pagesbtw69 1200Kumar ShresthaNo ratings yet

- BTW 67Document10 pagesBTW 67Wilber RojasNo ratings yet

- STB 120 N 4 LF 6Document18 pagesSTB 120 N 4 LF 6Manuel QuirozNo ratings yet

- STPS745: Main Product CharacteristicsDocument9 pagesSTPS745: Main Product CharacteristicsQadash NeharaNo ratings yet

- N-Channel 100 V, 0.0036 Typ., 110 A, Stripfet™ F7 Power Mosfet in A To-220 PackageDocument13 pagesN-Channel 100 V, 0.0036 Typ., 110 A, Stripfet™ F7 Power Mosfet in A To-220 PackageCarautotronica LaboratorioNo ratings yet

- Stp9Nk65Z Stp9Nk65Zfp: N-Channel 650 V, 1 Ω, 6.4 A, To-220, To-220Fp Zener-Protected Supermesh™ Power MosfetDocument16 pagesStp9Nk65Z Stp9Nk65Zfp: N-Channel 650 V, 1 Ω, 6.4 A, To-220, To-220Fp Zener-Protected Supermesh™ Power MosfetAndyMahataraNo ratings yet

- GB 20 B 60Document10 pagesGB 20 B 60Ivanilto Martins da CruzNo ratings yet

- Stps 340Document19 pagesStps 340Mariusz KaźmierczakNo ratings yet

- 20N60M2EP Mark STP20N60M2-EP 600V 13A FETDocument14 pages20N60M2EP Mark STP20N60M2-EP 600V 13A FETRuslanNo ratings yet

- Data SheetDocument8 pagesData SheetBenjaminNo ratings yet

- Fcb20N60: N-Channel Superfet MosfetDocument9 pagesFcb20N60: N-Channel Superfet MosfetEo GpNo ratings yet

- Interface Circuit - Relay and Lamp-Driver: FeaturesDocument20 pagesInterface Circuit - Relay and Lamp-Driver: FeaturesDarwwinNo ratings yet

- Stp130N6F7: N-Channel 60 V, 4.2 Mω Typ., 80 A Stripfet™ F7 Power Mosfet In A To-220 PackageDocument12 pagesStp130N6F7: N-Channel 60 V, 4.2 Mω Typ., 80 A Stripfet™ F7 Power Mosfet In A To-220 PackageOsmir MonteiroNo ratings yet

- 3049A-SIP12H: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersDocument6 pages3049A-SIP12H: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersАлександр АсауленкоNo ratings yet

- STPS2L40: 40 V, 2 A Low Drop Power Schottky RectifierDocument17 pagesSTPS2L40: 40 V, 2 A Low Drop Power Schottky RectifierNirmal NepalNo ratings yet

- STTH2003CT/CG/CF/CR/CFP: High Frequency Secondary RectifierDocument8 pagesSTTH2003CT/CG/CF/CR/CFP: High Frequency Secondary RectifierPușcă MartinNo ratings yet

- Fdb2532 - F085: N-Channel Powertrench Mosfet 150V, 79A, 16MDocument11 pagesFdb2532 - F085: N-Channel Powertrench Mosfet 150V, 79A, 16MSukandar TeaNo ratings yet

- Stp10Nk80Zfp Stp10Nk80Z - Stw10Nk80Z: N-Channel 800V - 0.78 - 9A - To-220/Fp-To-247 Zener-Protected Supermesh MosfetDocument15 pagesStp10Nk80Zfp Stp10Nk80Z - Stw10Nk80Z: N-Channel 800V - 0.78 - 9A - To-220/Fp-To-247 Zener-Protected Supermesh MosfetBlakeNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- TO-92 Encapsulate Adjustable Reference Source: Jiangsu Changjiang Electronics Technology Co., LTDDocument2 pagesTO-92 Encapsulate Adjustable Reference Source: Jiangsu Changjiang Electronics Technology Co., LTDArtem 521No ratings yet

- Catalogue Midea Giau Tran Noi Ong Gio PDFDocument50 pagesCatalogue Midea Giau Tran Noi Ong Gio PDFJorge BravoNo ratings yet

- Emf Question PaperDocument54 pagesEmf Question PaperRambabu DanduriNo ratings yet

- Installation Manual: Monocrystalline Modules and Polycrystalline ModulesDocument18 pagesInstallation Manual: Monocrystalline Modules and Polycrystalline ModulesSeba Santelices VillalobosNo ratings yet

- Schneider Atv303 PDFDocument112 pagesSchneider Atv303 PDFchidambaram kasiNo ratings yet

- Instrukcja Użytkownika Testera PocketDocument21 pagesInstrukcja Użytkownika Testera PocketDominik GołosNo ratings yet

- As 60044.1-2007 Instrument Transformers Current Transformers (IEC 60044-1 Ed.1.2 (2003) MOD)Document10 pagesAs 60044.1-2007 Instrument Transformers Current Transformers (IEC 60044-1 Ed.1.2 (2003) MOD)SAI Global - APAC0% (1)

- Ecoss G3 GFHE 0836-8.1I/016G.E: Fluid Cooler (Closed Circuit Cooler) Ecoss G3 - Apo Quantity 1 Unit(s)Document3 pagesEcoss G3 GFHE 0836-8.1I/016G.E: Fluid Cooler (Closed Circuit Cooler) Ecoss G3 - Apo Quantity 1 Unit(s)Rajkumar GulatiNo ratings yet

- Q.Peak Duo L-G5.2: Enduring High PerformanceDocument2 pagesQ.Peak Duo L-G5.2: Enduring High PerformanceNasaii AhmadNo ratings yet

- PHY5 January 2003Document2 pagesPHY5 January 2003api-3726022No ratings yet

- Module 08 Fixture IDocument34 pagesModule 08 Fixture ITai Shu Worn100% (1)

- Hyundai U-ACB NewDocument108 pagesHyundai U-ACB NewAlexander Wijesooriya100% (3)

- Khoi Ngo ResumeDocument3 pagesKhoi Ngo ResumeIchada PhamNo ratings yet

- Otc 25704 MS PDFDocument9 pagesOtc 25704 MS PDFObi MogboNo ratings yet

- Transformer Conductors and Overcurrent ProtectionDocument13 pagesTransformer Conductors and Overcurrent ProtectionsimonNo ratings yet

- McMaster-Carr Nail CatalogueDocument1 pageMcMaster-Carr Nail CatalogueKK0605No ratings yet

- ITT Vol 38 1963 02Document114 pagesITT Vol 38 1963 02Marian EnacheNo ratings yet

- HMP60 Datasheet B210851EN HDocument2 pagesHMP60 Datasheet B210851EN HJosué DomínguezNo ratings yet

- Anexo N VF BROKK SACDocument20 pagesAnexo N VF BROKK SACRicardo ChNo ratings yet

- Energy Sources in The PhilippinesDocument3 pagesEnergy Sources in The PhilippinesKriz BizNo ratings yet

- DC Servo Motor - MalDocument6 pagesDC Servo Motor - Malapi-19787379100% (1)

- Seko Dosing Pump ControllerDocument3 pagesSeko Dosing Pump ControllerVikrantNo ratings yet

- Rugged Auxiliary Charger (Rac) : Reducing The Battery Burden, Enhancing Operational EffectivenessDocument2 pagesRugged Auxiliary Charger (Rac) : Reducing The Battery Burden, Enhancing Operational EffectivenessАндрей ГусевNo ratings yet

- Snap-On Multimeter ManualDocument15 pagesSnap-On Multimeter ManualAdrianna ColonaNo ratings yet

- 60-03 CPR04 ManualDocument74 pages60-03 CPR04 Manualeariasz69No ratings yet

- TLP2701 Catalog en 20200401 ALQ00217Document77 pagesTLP2701 Catalog en 20200401 ALQ00217Rafael Rafael ReyesNo ratings yet

- Electrical Load ScheduleDocument14 pagesElectrical Load ScheduleAtty AttyNo ratings yet

- AA36-100 Tie Line Adapter - UnlockedDocument30 pagesAA36-100 Tie Line Adapter - UnlockedGeeNo ratings yet