Professional Documents

Culture Documents

SL 399 3 Iwt Opt-Out

SL 399 3 Iwt Opt-Out

Uploaded by

activitybookmarketplaceOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SL 399 3 Iwt Opt-Out

SL 399 3 Iwt Opt-Out

Uploaded by

activitybookmarketplaceCopyright:

Available Formats

Outdoor Sensor

(to master boiler)

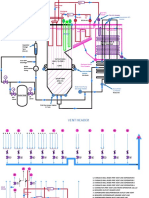

SL 40-399 G3

SL 40-399 G3 SL 40-399G3

subordinate

Master subordinate

and opt-out

Load 1 Load 2

Pump Pump

Secondary Loop

Sensor

(to master boiler)

RP

Domestic fill station with isolation valve closed

Cold

Hot or: fill tank

Water

Notes

– 3-Boiler in-line Multiplex racking system shown, IBC part M03-L-3".

System comes complete with Boiler racking, UPS 43-44 FC boiler

pumps, near boiler piping, isolation valves, and 3” manifold headers.

– Multiplex headers flange-to-flange dimension matches 3rd-party Low-

Low Headers (Hydraulic Separators)

– Recommended DHW opt-out pump UPS 43-100 on speed two, or

other pump sized for 28 gpm and 16 feet of head.

– Opt-out piping requires field modification of Multiplex piping.

DHW Sensor

well -to opt-out

IBC 399 3.2.opt-out

boiler

DRAWN BY DATE

BRAD POULSEN 18/10/2018

DESCRIPTION

IBC 115 XHO Multi-boiler multi-load installation with an Extra

Indirect Hot High OutputDATE

Indirect Tank on opt-out.

CAUTION: Thi s drawing is a simple schematic gui de to a successful i nstallat ion. There may be many necessary Water Tank 15/05/2015

components not shown here. We require that our boilers be installed by licensed and experienced trades people

who are familiar with the applicable local and national codes . Sy stem design is to be completed by an experienced

PAGE

hydronic designer or Engineer. It is necessary to carefully read and fol low the instal lation i nstructi ons that come

with the boiler along wi th the application drawing that fits your system. 1 OF 2

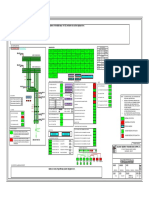

Master Boiler Middle Subordinate Boiler Subordinate Opt-Out Boiler

JA02 removed 120VAC

120VAC 120VAC

5 (HOT) (COM)

(HOT) (COM) (HOT) (COM)

G G G

black

AC in L

Field-wiring

black black

AC in L AC in L

Field-wiring

Field-wiring

white

Bundle

white white N

Bundle

Bundle

N N

Primary L yellow Boiler Primary L yellow Boiler Primary L yellow

white

Pump N white

Pump Pump N white

Pump Pump N Boiler Wiring Diagram

VS Pump Not used VS Pump Not used VS Pump Not used Pump

Load 1 pump Indirect pump

Load 2 pump

2

2

Programming Notes

– For Master Boiler, in Installer Setup menu set

Load 1 as DHW. Set Water ° From to Secondary

Factory- Factory- Factory- Loop.

installed installed installed – In the same Installer Setup menu set Loads 1

and 2 for desired values; use Zoning, or see Load

Pairing Tech Memo as needed.

– In the Installer Setup menus for DHW Opt-Out

Load 1 boiler, define Load 1 as DHW. Set Boiler Pump

dry contact to Off. Provisional recommendation for the

Load 2 DHW Tank Differential: 8°F.

dry contact – See memo Multiple Boiler Systems for full

1 1 details about network configuring. For the

Master Boiler only, in Installer Setup Menu /

3

MultiBoiler, turn Master Boiler to On, and define

boiler ID as “1”. Set boiler ID at subordinate

boilers to “2”and “3” respectively, leaving

Master Boiler Off.

– In Installer Setup Menu / Edit, for any load:

Maximum Supply Temperature acts as a high

limit.

Wiring Notes IBC 399 3.2.opt-out

1 – No external voltages to be applied to TB2 control terminal strip connections 1-20. DRAWN BY DATE

2 – Pump circuits are fused for a total draw of 5A; maximum amperage draw of 4A per pump is recommended. BRAD POULSEN 18/10/2018

3 – Outdoor sensor installed on a North-facing exterior wall for accurate exterior air temperature reading. DESCRIPTION

4 – Boiler network wires are polarity-sensitive, and must be twisted once per inch, and not be routed parallel to line voltage wires Multi-boiler multi-load installation with an Extra

5 – Boiler 2, being non-terminal in the network, has its Jumper A02 removed, as illustrated in Multiple Boiler Systems Tech Memo High OutputDATE

Indirect Tank on opt-out.

(or see Touch Screen manual page 25). 15/05/2015

CAUTION: Thi s drawing is a simple schematic gui de to a successful i nstallat ion. There may be many necessary components not shown here. We require that our boilers be installed by licensed PAGE

and experienced trades people who are fami liar wi th the applicable local and national codes. Sy stem design is to be completed by an experienced hydroni c designer or Engi neer. It is necessary to

carefully read and foll ow the install ation instructions that come with the boi ler along wit h the applicati on drawing t hat fits your system. 2 OF 2

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Tamd 63Document2 pagesTamd 63Cristiano NunesNo ratings yet

- All Engine Plumbing DiagramsDocument14 pagesAll Engine Plumbing DiagramsAndy ChalifouxNo ratings yet

- NTPC Uchahar Power Plant Boiler ExplosionDocument20 pagesNTPC Uchahar Power Plant Boiler ExplosionSatish Chavan100% (2)

- ASME PTC 4 Dan 4.1 DifferencesDocument3 pagesASME PTC 4 Dan 4.1 DifferencesPutri Hanifah SNo ratings yet

- Super Critical Boiler : Construction and WorkingDocument62 pagesSuper Critical Boiler : Construction and WorkingSai Krishna100% (1)

- SL 399 2-t SP-H Reverse-ReturnDocument2 pagesSL 399 2-t SP-H Reverse-ReturnactivitybookmarketplaceNo ratings yet

- SUPER CRITICAL BOILER (660 MW) at PROJECTDocument53 pagesSUPER CRITICAL BOILER (660 MW) at PROJECTWahedali SayyedNo ratings yet

- EHS I Način RadaDocument25 pagesEHS I Način Radasloba68No ratings yet

- Future Tissue Machine Block#10 - #12 Not Include in IKPP MB26 ProjectDocument1 pageFuture Tissue Machine Block#10 - #12 Not Include in IKPP MB26 ProjectShahNo ratings yet

- FW WTR SysDocument21 pagesFW WTR SysharisankarNo ratings yet

- ISO 10628 PFD Legend SheetDocument4 pagesISO 10628 PFD Legend SheetPrathmesh GujaratiNo ratings yet

- Berkas Baru Untuk DQ, IQ, OQDocument16 pagesBerkas Baru Untuk DQ, IQ, OQM MiftakhNo ratings yet

- RAK A - 1002V 4802V - en ScrewDocument2 pagesRAK A - 1002V 4802V - en ScrewPaul EbenezerNo ratings yet

- SL 399 4 Bboard DHWDocument2 pagesSL 399 4 Bboard DHWactivitybookmarketplaceNo ratings yet

- 11condensate ManagemetDocument12 pages11condensate ManagemetEduNo ratings yet

- FP Rev (D) 2018Document4 pagesFP Rev (D) 2018Heiberth Miguel Mora ReveloNo ratings yet

- LMS100 Cut AwayDocument1 pageLMS100 Cut Awayjcarella_1No ratings yet

- Case Study - Boiler ExplosionDocument18 pagesCase Study - Boiler ExplosionSatish ChavanNo ratings yet

- JC-22D Furnace Draft Controller BrochureDocument4 pagesJC-22D Furnace Draft Controller BrochureEli SantosNo ratings yet

- Adipala Power System Diagram (660 MW)Document1 pageAdipala Power System Diagram (660 MW)Budi WahyonoNo ratings yet

- Cirebon #1, Power System Diagram (660 MW X 1 Unit) PDFDocument1 pageCirebon #1, Power System Diagram (660 MW X 1 Unit) PDFDzikri LatifNo ratings yet

- RAK A - 01C1m 80C2 - en ScrollDocument4 pagesRAK A - 01C1m 80C2 - en ScrollPaul EbenezerNo ratings yet

- 6-981-B HRS050-HRS060Document15 pages6-981-B HRS050-HRS060Juan Carlos Peñaloza C.100% (1)

- Basic Instrument Contol PFD P ID HAZOP 0Document3 pagesBasic Instrument Contol PFD P ID HAZOP 0Ferdian AziziNo ratings yet

- 1 X TRIGON L Plus Boiler LLH 1VT 1CT Heating CircuitsDocument5 pages1 X TRIGON L Plus Boiler LLH 1VT 1CT Heating Circuitsadyro12No ratings yet

- Steam Cycle of Super-Critical Power PlantDocument11 pagesSteam Cycle of Super-Critical Power Plantreply2amit1986100% (2)

- Dry Vacuum Pump (LR/HR/UR Series) : FeaturesDocument4 pagesDry Vacuum Pump (LR/HR/UR Series) : FeaturesHảo UlvacNo ratings yet

- 5 Buffer Hopper D-PumpDocument4 pages5 Buffer Hopper D-PumpMithun Singh RajputNo ratings yet

- Dwg. No.10 - 42 20 DN002 - ERDocument4 pagesDwg. No.10 - 42 20 DN002 - ERSean Chen GyarinoNo ratings yet

- Boiler Flow Diagram With Drain and Vent HeaderDocument3 pagesBoiler Flow Diagram With Drain and Vent HeaderRAJKUMARNo ratings yet

- Condensate SystemDocument1 pageCondensate SystemAkhilesh VijayaKumarNo ratings yet

- Flowstation PHDocument5 pagesFlowstation PHFarid KerenNo ratings yet

- SELECTED Case Studies On BFW Pump and Steam TurbinesDocument9 pagesSELECTED Case Studies On BFW Pump and Steam TurbinesVijayNo ratings yet

- FeedwaterDocument55 pagesFeedwaternaresh977977100% (1)

- SOP For Boiler PassivationDocument2 pagesSOP For Boiler PassivationSAKTHIVEL MNo ratings yet

- Power Plant FDPDocument1 pagePower Plant FDPMR. HaddadNo ratings yet

- Om012 - Waldnieler Fruit JuiceDocument4 pagesOm012 - Waldnieler Fruit JuiceshekharshindeNo ratings yet

- Procedure For Condenser Vacuum PullingDocument4 pagesProcedure For Condenser Vacuum PullingPulkit Agarwal100% (1)

- Write Up On Atrs PDFDocument52 pagesWrite Up On Atrs PDFSCE Stage2No ratings yet

- Chilled Water Bridge Standard RevDocument1 pageChilled Water Bridge Standard RevQuynh NguyenNo ratings yet

- Your Basic Refrigeraion System: SVASD - MAY 26, 2011Document71 pagesYour Basic Refrigeraion System: SVASD - MAY 26, 2011RASHEED YUSUFNo ratings yet

- Typical 400kV TRF (HV) Bay View (GIS MODULE)Document1 pageTypical 400kV TRF (HV) Bay View (GIS MODULE)Amarjit KulkarniNo ratings yet

- FIGURE 10-17: Vapor and Combined Power CyclesDocument8 pagesFIGURE 10-17: Vapor and Combined Power CyclesBengü MNo ratings yet

- Hot Oil System DesignDocument25 pagesHot Oil System DesignnitantharaniNo ratings yet

- Boiler Pressure PartsDocument67 pagesBoiler Pressure PartsAmul PontingNo ratings yet

- Refrigerant Cycle Diagram: 5.1 Cooling Only: MFA-76CR, MFA-96CRDocument1 pageRefrigerant Cycle Diagram: 5.1 Cooling Only: MFA-76CR, MFA-96CRgrwgNo ratings yet

- 07 Primary Secondary PumpingDocument63 pages07 Primary Secondary PumpingMMMOH200No ratings yet

- Fire Fighting System in ERDocument38 pagesFire Fighting System in ERCua TranNo ratings yet

- Load Trails - WHRPPDocument22 pagesLoad Trails - WHRPPChanna BasavaNo ratings yet

- Quanto ENDocument18 pagesQuanto ENMuhammad SyaqirinNo ratings yet

- Dry Ash Handling PresentationDocument23 pagesDry Ash Handling PresentationAbderrahim AbarayNo ratings yet

- Column Relief Loads Calculations 1653386984Document9 pagesColumn Relief Loads Calculations 1653386984WillyOroscoMariscalNo ratings yet

- SBS Double Pump ChillerDocument1 pageSBS Double Pump ChillerYang John (Rich-Tech1688)No ratings yet

- Boiler & Aux Operation PMIDocument49 pagesBoiler & Aux Operation PMIsoumen mandalNo ratings yet

- How To Properly Size A Steam Trap: 'T Confuse The Size 'S EndDocument4 pagesHow To Properly Size A Steam Trap: 'T Confuse The Size 'S EndAdam Jin100% (1)

- Boiler Flow Diagram With Drain and Vent Header - PPSXDocument3 pagesBoiler Flow Diagram With Drain and Vent Header - PPSXAjay GandhiNo ratings yet

- INGM 427 Slides - 1 Pump Selection PDFDocument20 pagesINGM 427 Slides - 1 Pump Selection PDFCornelius RheedersNo ratings yet

- Boiler & Aux Operation PMIDocument53 pagesBoiler & Aux Operation PMInikesh ranjanNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Standards in PreparationDocument16 pagesStandards in Preparationnitvan82No ratings yet

- BR Company ProfileDocument31 pagesBR Company ProfilearefNo ratings yet

- Elrctrical Power Engineering SyllabusDocument75 pagesElrctrical Power Engineering Syllabusgishi_sjdc6983No ratings yet

- The Study ON Enhancing Efficiency OF Operating Thermal Power Plants IN Ntpc-IndiaDocument121 pagesThe Study ON Enhancing Efficiency OF Operating Thermal Power Plants IN Ntpc-IndiaPuri KumarNo ratings yet

- Laboratory Activity 1 - CandidatesDocument7 pagesLaboratory Activity 1 - CandidatesAdrian CamasosaNo ratings yet

- Building Laws Building Utilities - Unrecognizable TextDocument32 pagesBuilding Laws Building Utilities - Unrecognizable TextAe R ONNo ratings yet

- BurnDocument12 pagesBurnRenganathanMuthuswamy100% (1)

- Lista de Normas Api - RefinaciónDocument14 pagesLista de Normas Api - RefinaciónfaustomgNo ratings yet

- 2010 Edition of The ASME Boiler and Pressure Vessel Code (BPVC)Document6 pages2010 Edition of The ASME Boiler and Pressure Vessel Code (BPVC)kangsungjinNo ratings yet

- Hydro-Electric Power PlantDocument55 pagesHydro-Electric Power Plantneenu_tNo ratings yet

- Boiler InstructionsDocument56 pagesBoiler Instructionsprint masterNo ratings yet

- ChE Basic QuestionsDocument114 pagesChE Basic QuestionsKrizzete HernandezNo ratings yet

- EGB FireDocument5 pagesEGB FireAkshay A KumarNo ratings yet

- Steam Power Plants: Mitsubishi Heavy Industries, Ltd. Energy SystemsDocument10 pagesSteam Power Plants: Mitsubishi Heavy Industries, Ltd. Energy SystemsSagar SanasNo ratings yet

- Engineering Principles: Heat TransferDocument57 pagesEngineering Principles: Heat TransferAns_12102No ratings yet

- MachineDocument45 pagesMachineSage Capinlac OlajayNo ratings yet

- Thermal Lab ManualDocument41 pagesThermal Lab ManualcresjohnNo ratings yet

- Industrial Safety, Health and Welfare Act 1961Document18 pagesIndustrial Safety, Health and Welfare Act 1961Rooja BajracharyaNo ratings yet

- Kolbitsch PPPDocument23 pagesKolbitsch PPPradanpetricaNo ratings yet

- Flow Induced Vibration Handbook For Nuclear and Process Equipment Michel J Pettigrew Full Chapter PDFDocument69 pagesFlow Induced Vibration Handbook For Nuclear and Process Equipment Michel J Pettigrew Full Chapter PDFmongamaliina100% (5)

- Summer Training IN Andhra Pradesh Power Generation Corporation - (Apgenco)Document17 pagesSummer Training IN Andhra Pradesh Power Generation Corporation - (Apgenco)Goutham ReddyNo ratings yet

- Linear Fresnel Reflector-LFR - EDocument30 pagesLinear Fresnel Reflector-LFR - Eanon_350828923No ratings yet

- Boiler Turbine Dynamics in Power Plant ControlDocument12 pagesBoiler Turbine Dynamics in Power Plant ControlAmanjit SinghNo ratings yet

- Summer Training Report of Shree CementDocument28 pagesSummer Training Report of Shree Cementramsinghbeawar20% (5)

- Rankine Cycle PDFDocument41 pagesRankine Cycle PDFAlmeghalawy83% (12)

- Power Plant Engineering R K Hegde Download PDF ChapterDocument51 pagesPower Plant Engineering R K Hegde Download PDF Chapterjohn.price395100% (13)

- Steam Line Insulation Condition and Steam Trap Report of Co-Gen PlantDocument24 pagesSteam Line Insulation Condition and Steam Trap Report of Co-Gen PlantKuldeep RupareliaNo ratings yet

- Burner HandbookDocument169 pagesBurner HandbookDk Damo100% (8)

- RmrsDocument307 pagesRmrsramkumarNo ratings yet