Professional Documents

Culture Documents

Stockfit Proses Duramo SL 2

Stockfit Proses Duramo SL 2

Uploaded by

novanCopyright:

Available Formats

You might also like

- RE CHP 7B Water InfluxDocument59 pagesRE CHP 7B Water InfluxKaoru AmaneNo ratings yet

- BS en 1555-2 (2010)Document30 pagesBS en 1555-2 (2010)Sıddık SarıcalarNo ratings yet

- Stockfit Proses Duramo Speed 2-Os TpuDocument1 pageStockfit Proses Duramo Speed 2-Os TpunovanNo ratings yet

- PA66 Ultramid A4H BASFDocument2 pagesPA66 Ultramid A4H BASFAlan MoraisNo ratings yet

- Simarine Bitumen: Product Data SheetDocument2 pagesSimarine Bitumen: Product Data SheetPerseroan MustikaNo ratings yet

- NC-559-ASM, No-Clean Solder Paste: Product Data SheetDocument2 pagesNC-559-ASM, No-Clean Solder Paste: Product Data SheetAkhmad MukhsinNo ratings yet

- Mipatherm: Technical Data Sheet Page 1 / 2 Intended UseDocument2 pagesMipatherm: Technical Data Sheet Page 1 / 2 Intended UseJM TorricoNo ratings yet

- 2305-00 Simacrylic CoatingDocument2 pages2305-00 Simacrylic CoatingSAEFUDDIN SAEFUDDINNo ratings yet

- 2024 1 U11 Ta24 Pip 064 4 P11806 Ad1 PP UttmDocument3 pages2024 1 U11 Ta24 Pip 064 4 P11806 Ad1 PP Uttminjoker fxNo ratings yet

- Max TDS 20211013Document30 pagesMax TDS 20211013Wong SimpangNo ratings yet

- Specifications - Valveworks USA Model VW-FC Gate Valve - MODEL FC BROCHUREDocument3 pagesSpecifications - Valveworks USA Model VW-FC Gate Valve - MODEL FC BROCHUREIdrisNo ratings yet

- Terlux 2802 TRDocument2 pagesTerlux 2802 TRDouglas AndradeNo ratings yet

- Pa66 PropDocument2 pagesPa66 ProprajuhaveriNo ratings yet

- Aro PumpDocument8 pagesAro PumpRizalino BrazilNo ratings yet

- Test Items Specification Obtained Required: ConclutionDocument17 pagesTest Items Specification Obtained Required: Conclutionعمير اعجاز وڑائچNo ratings yet

- 0 ISA Hoja de Especificación ISA de Valvula de Control 1Document2 pages0 ISA Hoja de Especificación ISA de Valvula de Control 1Yerson SepúlvedaNo ratings yet

- 8340A SILVA SPAR (2301)Document2 pages8340A SILVA SPAR (2301)4canNo ratings yet

- Pressure Safety Valve List - WTP: Doc No. Rev DateDocument1 pagePressure Safety Valve List - WTP: Doc No. Rev DateAsima Jaya TamaNo ratings yet

- Tafa 30TDocument4 pagesTafa 30TSidgrunionNo ratings yet

- Rma 223Document2 pagesRma 223Sergio ChicNo ratings yet

- Acri 700 Finish G S Rev (1409)Document2 pagesAcri 700 Finish G S Rev (1409)Trịnh Minh KhoaNo ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- PC Calibre Injection Molding SettingsDocument1 pagePC Calibre Injection Molding SettingsMitja GorseNo ratings yet

- T-78 Technical Data SheetDocument2 pagesT-78 Technical Data SheetCarlos GuerraNo ratings yet

- Fire Chief HoseDocument4 pagesFire Chief HoseAnandNo ratings yet

- Control Valves Data Sheet: Client: PlantDocument1 pageControl Valves Data Sheet: Client: PlantAnoNo ratings yet

- Ultramid: PA6-GF20 FRDocument2 pagesUltramid: PA6-GF20 FRLjubivoje MićićNo ratings yet

- 160MM B-TypeDocument1 page160MM B-TypeSatyam SinghNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Series 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionseeeNo ratings yet

- Pm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationDocument3 pagesPm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationjulianoNo ratings yet

- Ab 135Document2 pagesAb 135entesharat.tarasht3No ratings yet

- Molins: Technical Data SheetDocument2 pagesMolins: Technical Data SheetsasidharkanthetiNo ratings yet

- 001TDS Bannoh 1500 QDDocument2 pages001TDS Bannoh 1500 QDali maulanaNo ratings yet

- XDS Range BrochureDocument8 pagesXDS Range BrochureJose QuincosNo ratings yet

- CT-1205C-SMT Datasheet - MAGNETIC BUZZER INDICATOR - CUI IncDocument3 pagesCT-1205C-SMT Datasheet - MAGNETIC BUZZER INDICATOR - CUI IncrstramirezNo ratings yet

- Manual Intended Use: Piinline Plus AQR/AQR Low PressureDocument5 pagesManual Intended Use: Piinline Plus AQR/AQR Low PressureMario PortillaNo ratings yet

- 1.2. Sample - Datasheet Antisurge ValveDocument1 page1.2. Sample - Datasheet Antisurge ValveMuhammad FauzanNo ratings yet

- CMP - UnymarineDocument1 pageCMP - UnymarineChristinaNo ratings yet

- 8250 RUST INHIBITIVE OIL CK Rev (1409) PDFDocument2 pages8250 RUST INHIBITIVE OIL CK Rev (1409) PDFTrịnh Minh KhoaNo ratings yet

- 3302-00 Simacrylic FinishDocument2 pages3302-00 Simacrylic FinishSAEFUDDIN SAEFUDDINNo ratings yet

- Ultramid® A3HG5 en SI - Product DatasheetDocument2 pagesUltramid® A3HG5 en SI - Product Datasheetshahin_723No ratings yet

- TIS 0502-01 EnglishDocument11 pagesTIS 0502-01 Englisheddy9499No ratings yet

- CE BasicDocument28 pagesCE Basicpapbtm btm100% (1)

- 【英文】SDCコート#402TエコGDocument2 pages【英文】SDCコート#402TエコGDocholosoNo ratings yet

- Perf0537 BER5Document1 pagePerf0537 BER5Bernardo Rodríguez SalgueraNo ratings yet

- Name: Name: Name: Name: ABS710 ABS710 ABS710 ABS710Document2 pagesName: Name: Name: Name: ABS710 ABS710 ABS710 ABS710DiegoTierradentroNo ratings yet

- Pa6 GF30 - Basf Ultramid B3WG6Document2 pagesPa6 GF30 - Basf Ultramid B3WG6armandoNo ratings yet

- Glair G30 Series Tech Data Sheet 2017 PBDocument3 pagesGlair G30 Series Tech Data Sheet 2017 PBBowser DoskaNo ratings yet

- Lampiran Pengecatan Struktur BajaDocument6 pagesLampiran Pengecatan Struktur BajaBalimbukNo ratings yet

- Topcoat F69: Coatings For Aircraft Structure ProtectionDocument4 pagesTopcoat F69: Coatings For Aircraft Structure Protection김도균No ratings yet

- 1.9.1.2-80T - 18 8 Stainless SteelDocument4 pages1.9.1.2-80T - 18 8 Stainless SteelDevan ShanmughaNo ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- Severn GloconDocument6 pagesSevern GloconAmit Surti0% (1)

- PD - COA Art Board 310 GSM 285 - 20170728165654Document1 pagePD - COA Art Board 310 GSM 285 - 20170728165654Rantidaista Ayunin WalidainiNo ratings yet

- TDS SV3 SV3 240325Document2 pagesTDS SV3 SV3 240325barritojaiNo ratings yet

- Debeer 900Document8 pagesDebeer 900avikaryNo ratings yet

- CT-1205-SMT Datasheet - MAGNETIC BUZZER TRANSDUCER - CUI IncDocument3 pagesCT-1205-SMT Datasheet - MAGNETIC BUZZER TRANSDUCER - CUI IncrstramirezNo ratings yet

- Hempadur Zinc 17360Document2 pagesHempadur Zinc 17360Bang OchimNo ratings yet

- Barrier 80Document5 pagesBarrier 80Biju_PottayilNo ratings yet

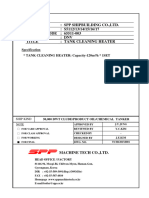

- Hm-01 Tank Cleaning HeaterDocument59 pagesHm-01 Tank Cleaning HeaterMayan De la CruzNo ratings yet

- FW24 & SS25 New Calendar Commercialization Mar 18 - 2024Document3 pagesFW24 & SS25 New Calendar Commercialization Mar 18 - 2024novanNo ratings yet

- BPM VPM StandardDocument1 pageBPM VPM StandardnovanNo ratings yet

- Toe Cap Comparison - SuperstarDocument2 pagesToe Cap Comparison - SuperstarnovanNo ratings yet

- Sockliner Comparison - SuperstarDocument2 pagesSockliner Comparison - SuperstarnovanNo ratings yet

- Chapter 2 Defect AssociationsDocument7 pagesChapter 2 Defect AssociationsNesh N. López MeléndezNo ratings yet

- Dosage - Chapter 14Document57 pagesDosage - Chapter 14kaukau4ever100% (1)

- How Does The Ocean BufferDocument5 pagesHow Does The Ocean Bufferapi-222503660No ratings yet

- Design of Schottky Diode Using SilvacoDocument7 pagesDesign of Schottky Diode Using SilvacoJesús MartínezNo ratings yet

- CBRC HandOuts-CSE Age, Work, MixtureDocument6 pagesCBRC HandOuts-CSE Age, Work, MixtureRoselleNo ratings yet

- Study of Wetland For Management of Acid Mine Drainage On The Porphyry Copper-Gold Mine in IndonesiaDocument6 pagesStudy of Wetland For Management of Acid Mine Drainage On The Porphyry Copper-Gold Mine in IndonesiaWaterman Sulistyana100% (1)

- A Guide To Fiber-Reinforced Polymer Trail BridgesDocument108 pagesA Guide To Fiber-Reinforced Polymer Trail BridgesThiago Campos de MeloNo ratings yet

- Jee 2014 Booklet3 HWT Solutions Ionic EquilibriumDocument3 pagesJee 2014 Booklet3 HWT Solutions Ionic EquilibriumvarunkohliinNo ratings yet

- Geiger-Müller TubeDocument7 pagesGeiger-Müller TubeprinceNo ratings yet

- Carl Zeiss Axio Scope A1 Manual ServicioDocument122 pagesCarl Zeiss Axio Scope A1 Manual ServicioDanniel SchaafNo ratings yet

- Eect of Electrode Thickness On Bottom-Contact Pentacene Thin-Film TransistorsDocument4 pagesEect of Electrode Thickness On Bottom-Contact Pentacene Thin-Film TransistorskanchankonwarNo ratings yet

- Leespring EngguideDocument27 pagesLeespring EngguideAnonymous h6qnMVb8eNo ratings yet

- Chemical Engineering 03 2016 PDFDocument96 pagesChemical Engineering 03 2016 PDFThái Xuân Quang100% (1)

- Pyridine SynthesisDocument5 pagesPyridine Synthesismeng1usaNo ratings yet

- Testing Solid Insulation of Electrical Equipment: Facilities Instructions, Standards, and Techniques Volume 3-1Document69 pagesTesting Solid Insulation of Electrical Equipment: Facilities Instructions, Standards, and Techniques Volume 3-1denzil_1000100% (12)

- Ivantchenko - GEANT4 LOW ENERGY Geant4 EM PackagesDocument34 pagesIvantchenko - GEANT4 LOW ENERGY Geant4 EM PackagesForeverSleepingNo ratings yet

- 1999 Biology Paper I Marking SchemeDocument5 pages1999 Biology Paper I Marking Schemetramysss100% (1)

- White CementDocument11 pagesWhite CementLdiabiNo ratings yet

- Technical Report of Lab 1 Tablet LatestDocument5 pagesTechnical Report of Lab 1 Tablet LatestHasni Abdul RahimNo ratings yet

- Unit-Iv: Separation of Solids From FluidsDocument74 pagesUnit-Iv: Separation of Solids From Fluidsyouga Sri100% (1)

- Column Design With ExcelDocument72 pagesColumn Design With ExcelAsifIqbalNo ratings yet

- 5310 Mass Diffusion and Droplet EvaporationDocument8 pages5310 Mass Diffusion and Droplet EvaporationTushar PanchalNo ratings yet

- Thermal Barrier CoatingsDocument11 pagesThermal Barrier CoatingsNidhi Vyas100% (1)

- Finned Tube Heat Exchangers Type WRW and WRW-WDocument8 pagesFinned Tube Heat Exchangers Type WRW and WRW-WBOREBGKNo ratings yet

- Test Report 20122018Document21 pagesTest Report 20122018jamal nasirNo ratings yet

- FTM930-931 E+hDocument6 pagesFTM930-931 E+hmiklitsaNo ratings yet

- 2-Diffusivity Equation-Linear PDFDocument30 pages2-Diffusivity Equation-Linear PDFLoh Chun LiangNo ratings yet

- Real-Time PCR Assays For Detection and Quantitation of Porcine and Bovine DNA in Gelatin Mixtures and Gelatin CapsulesDocument5 pagesReal-Time PCR Assays For Detection and Quantitation of Porcine and Bovine DNA in Gelatin Mixtures and Gelatin CapsulesAri DewiyantiNo ratings yet

Stockfit Proses Duramo SL 2

Stockfit Proses Duramo SL 2

Uploaded by

novanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stockfit Proses Duramo SL 2

Stockfit Proses Duramo SL 2

Uploaded by

novanCopyright:

Available Formats

Page 34 Of 46

Model Name DURAMO SL 2

Article No & All Article

STOCKFIT PROCESS

Stage Development

Process Imformation

No Stockfit Process Remark

Pressure Chemical Temp. Time

Setting Midsole and OS Rubber

1 Midsole :020 50C IM

OS RUBBER : 65A 40 SO AW NM

Cleaner

2 OS Rubber CLEANER M3 55 - 60 °C

Chamber 1 1'00" - 1'10"

Primer

TU 136 SPL + 3%

45-50 °C

Midsole (Bottom Area) UNIDUREE 1001 RN

3

WPM 907 + 2%

OS Rubber 60-65 °C

POWDER

Chamber 2 1'20" - 1'30"

Cement

Midsole (Bottom Area) WA-03 55 - 60 °C

4

OS Rubber Roller Coater WA-03 60-65 °C

Chamber 3 1'30"-2'00"

5 Attaching Midsole to Rubber 50℃ Min

Up I : 20-25 kg/cm², Up II

6 :35-40 kg/cm²

Universal Press 45℃ Min 10" - 12" Temp. During Pressing

Side/Toe Heel :35-

40kg/cm²

7 Temp : 10-15°C Max, Time : 3'00"-3'20"

Chiller

Temp Surface : Max 25°C

NOTE

Untuk Midsole/Unitsole yang ada painting dan akan di prosses di stockfitting

/assembling, untuk area bonding harus dipoles Non UV Primer

Midsole/Outsole Black Color + Black Toner Max 3%

Midsole/Outsole White Color + White Toner 3%

1 2 3 4 5 6 7

BSOM Version 00 (Dec 2021, BSOM Version 02 (Jan 2022) PT.PARKLAND WORLD INDONESIA

You might also like

- RE CHP 7B Water InfluxDocument59 pagesRE CHP 7B Water InfluxKaoru AmaneNo ratings yet

- BS en 1555-2 (2010)Document30 pagesBS en 1555-2 (2010)Sıddık SarıcalarNo ratings yet

- Stockfit Proses Duramo Speed 2-Os TpuDocument1 pageStockfit Proses Duramo Speed 2-Os TpunovanNo ratings yet

- PA66 Ultramid A4H BASFDocument2 pagesPA66 Ultramid A4H BASFAlan MoraisNo ratings yet

- Simarine Bitumen: Product Data SheetDocument2 pagesSimarine Bitumen: Product Data SheetPerseroan MustikaNo ratings yet

- NC-559-ASM, No-Clean Solder Paste: Product Data SheetDocument2 pagesNC-559-ASM, No-Clean Solder Paste: Product Data SheetAkhmad MukhsinNo ratings yet

- Mipatherm: Technical Data Sheet Page 1 / 2 Intended UseDocument2 pagesMipatherm: Technical Data Sheet Page 1 / 2 Intended UseJM TorricoNo ratings yet

- 2305-00 Simacrylic CoatingDocument2 pages2305-00 Simacrylic CoatingSAEFUDDIN SAEFUDDINNo ratings yet

- 2024 1 U11 Ta24 Pip 064 4 P11806 Ad1 PP UttmDocument3 pages2024 1 U11 Ta24 Pip 064 4 P11806 Ad1 PP Uttminjoker fxNo ratings yet

- Max TDS 20211013Document30 pagesMax TDS 20211013Wong SimpangNo ratings yet

- Specifications - Valveworks USA Model VW-FC Gate Valve - MODEL FC BROCHUREDocument3 pagesSpecifications - Valveworks USA Model VW-FC Gate Valve - MODEL FC BROCHUREIdrisNo ratings yet

- Terlux 2802 TRDocument2 pagesTerlux 2802 TRDouglas AndradeNo ratings yet

- Pa66 PropDocument2 pagesPa66 ProprajuhaveriNo ratings yet

- Aro PumpDocument8 pagesAro PumpRizalino BrazilNo ratings yet

- Test Items Specification Obtained Required: ConclutionDocument17 pagesTest Items Specification Obtained Required: Conclutionعمير اعجاز وڑائچNo ratings yet

- 0 ISA Hoja de Especificación ISA de Valvula de Control 1Document2 pages0 ISA Hoja de Especificación ISA de Valvula de Control 1Yerson SepúlvedaNo ratings yet

- 8340A SILVA SPAR (2301)Document2 pages8340A SILVA SPAR (2301)4canNo ratings yet

- Pressure Safety Valve List - WTP: Doc No. Rev DateDocument1 pagePressure Safety Valve List - WTP: Doc No. Rev DateAsima Jaya TamaNo ratings yet

- Tafa 30TDocument4 pagesTafa 30TSidgrunionNo ratings yet

- Rma 223Document2 pagesRma 223Sergio ChicNo ratings yet

- Acri 700 Finish G S Rev (1409)Document2 pagesAcri 700 Finish G S Rev (1409)Trịnh Minh KhoaNo ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- PC Calibre Injection Molding SettingsDocument1 pagePC Calibre Injection Molding SettingsMitja GorseNo ratings yet

- T-78 Technical Data SheetDocument2 pagesT-78 Technical Data SheetCarlos GuerraNo ratings yet

- Fire Chief HoseDocument4 pagesFire Chief HoseAnandNo ratings yet

- Control Valves Data Sheet: Client: PlantDocument1 pageControl Valves Data Sheet: Client: PlantAnoNo ratings yet

- Ultramid: PA6-GF20 FRDocument2 pagesUltramid: PA6-GF20 FRLjubivoje MićićNo ratings yet

- 160MM B-TypeDocument1 page160MM B-TypeSatyam SinghNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Series 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionseeeNo ratings yet

- Pm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationDocument3 pagesPm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationjulianoNo ratings yet

- Ab 135Document2 pagesAb 135entesharat.tarasht3No ratings yet

- Molins: Technical Data SheetDocument2 pagesMolins: Technical Data SheetsasidharkanthetiNo ratings yet

- 001TDS Bannoh 1500 QDDocument2 pages001TDS Bannoh 1500 QDali maulanaNo ratings yet

- XDS Range BrochureDocument8 pagesXDS Range BrochureJose QuincosNo ratings yet

- CT-1205C-SMT Datasheet - MAGNETIC BUZZER INDICATOR - CUI IncDocument3 pagesCT-1205C-SMT Datasheet - MAGNETIC BUZZER INDICATOR - CUI IncrstramirezNo ratings yet

- Manual Intended Use: Piinline Plus AQR/AQR Low PressureDocument5 pagesManual Intended Use: Piinline Plus AQR/AQR Low PressureMario PortillaNo ratings yet

- 1.2. Sample - Datasheet Antisurge ValveDocument1 page1.2. Sample - Datasheet Antisurge ValveMuhammad FauzanNo ratings yet

- CMP - UnymarineDocument1 pageCMP - UnymarineChristinaNo ratings yet

- 8250 RUST INHIBITIVE OIL CK Rev (1409) PDFDocument2 pages8250 RUST INHIBITIVE OIL CK Rev (1409) PDFTrịnh Minh KhoaNo ratings yet

- 3302-00 Simacrylic FinishDocument2 pages3302-00 Simacrylic FinishSAEFUDDIN SAEFUDDINNo ratings yet

- Ultramid® A3HG5 en SI - Product DatasheetDocument2 pagesUltramid® A3HG5 en SI - Product Datasheetshahin_723No ratings yet

- TIS 0502-01 EnglishDocument11 pagesTIS 0502-01 Englisheddy9499No ratings yet

- CE BasicDocument28 pagesCE Basicpapbtm btm100% (1)

- 【英文】SDCコート#402TエコGDocument2 pages【英文】SDCコート#402TエコGDocholosoNo ratings yet

- Perf0537 BER5Document1 pagePerf0537 BER5Bernardo Rodríguez SalgueraNo ratings yet

- Name: Name: Name: Name: ABS710 ABS710 ABS710 ABS710Document2 pagesName: Name: Name: Name: ABS710 ABS710 ABS710 ABS710DiegoTierradentroNo ratings yet

- Pa6 GF30 - Basf Ultramid B3WG6Document2 pagesPa6 GF30 - Basf Ultramid B3WG6armandoNo ratings yet

- Glair G30 Series Tech Data Sheet 2017 PBDocument3 pagesGlair G30 Series Tech Data Sheet 2017 PBBowser DoskaNo ratings yet

- Lampiran Pengecatan Struktur BajaDocument6 pagesLampiran Pengecatan Struktur BajaBalimbukNo ratings yet

- Topcoat F69: Coatings For Aircraft Structure ProtectionDocument4 pagesTopcoat F69: Coatings For Aircraft Structure Protection김도균No ratings yet

- 1.9.1.2-80T - 18 8 Stainless SteelDocument4 pages1.9.1.2-80T - 18 8 Stainless SteelDevan ShanmughaNo ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- Severn GloconDocument6 pagesSevern GloconAmit Surti0% (1)

- PD - COA Art Board 310 GSM 285 - 20170728165654Document1 pagePD - COA Art Board 310 GSM 285 - 20170728165654Rantidaista Ayunin WalidainiNo ratings yet

- TDS SV3 SV3 240325Document2 pagesTDS SV3 SV3 240325barritojaiNo ratings yet

- Debeer 900Document8 pagesDebeer 900avikaryNo ratings yet

- CT-1205-SMT Datasheet - MAGNETIC BUZZER TRANSDUCER - CUI IncDocument3 pagesCT-1205-SMT Datasheet - MAGNETIC BUZZER TRANSDUCER - CUI IncrstramirezNo ratings yet

- Hempadur Zinc 17360Document2 pagesHempadur Zinc 17360Bang OchimNo ratings yet

- Barrier 80Document5 pagesBarrier 80Biju_PottayilNo ratings yet

- Hm-01 Tank Cleaning HeaterDocument59 pagesHm-01 Tank Cleaning HeaterMayan De la CruzNo ratings yet

- FW24 & SS25 New Calendar Commercialization Mar 18 - 2024Document3 pagesFW24 & SS25 New Calendar Commercialization Mar 18 - 2024novanNo ratings yet

- BPM VPM StandardDocument1 pageBPM VPM StandardnovanNo ratings yet

- Toe Cap Comparison - SuperstarDocument2 pagesToe Cap Comparison - SuperstarnovanNo ratings yet

- Sockliner Comparison - SuperstarDocument2 pagesSockliner Comparison - SuperstarnovanNo ratings yet

- Chapter 2 Defect AssociationsDocument7 pagesChapter 2 Defect AssociationsNesh N. López MeléndezNo ratings yet

- Dosage - Chapter 14Document57 pagesDosage - Chapter 14kaukau4ever100% (1)

- How Does The Ocean BufferDocument5 pagesHow Does The Ocean Bufferapi-222503660No ratings yet

- Design of Schottky Diode Using SilvacoDocument7 pagesDesign of Schottky Diode Using SilvacoJesús MartínezNo ratings yet

- CBRC HandOuts-CSE Age, Work, MixtureDocument6 pagesCBRC HandOuts-CSE Age, Work, MixtureRoselleNo ratings yet

- Study of Wetland For Management of Acid Mine Drainage On The Porphyry Copper-Gold Mine in IndonesiaDocument6 pagesStudy of Wetland For Management of Acid Mine Drainage On The Porphyry Copper-Gold Mine in IndonesiaWaterman Sulistyana100% (1)

- A Guide To Fiber-Reinforced Polymer Trail BridgesDocument108 pagesA Guide To Fiber-Reinforced Polymer Trail BridgesThiago Campos de MeloNo ratings yet

- Jee 2014 Booklet3 HWT Solutions Ionic EquilibriumDocument3 pagesJee 2014 Booklet3 HWT Solutions Ionic EquilibriumvarunkohliinNo ratings yet

- Geiger-Müller TubeDocument7 pagesGeiger-Müller TubeprinceNo ratings yet

- Carl Zeiss Axio Scope A1 Manual ServicioDocument122 pagesCarl Zeiss Axio Scope A1 Manual ServicioDanniel SchaafNo ratings yet

- Eect of Electrode Thickness On Bottom-Contact Pentacene Thin-Film TransistorsDocument4 pagesEect of Electrode Thickness On Bottom-Contact Pentacene Thin-Film TransistorskanchankonwarNo ratings yet

- Leespring EngguideDocument27 pagesLeespring EngguideAnonymous h6qnMVb8eNo ratings yet

- Chemical Engineering 03 2016 PDFDocument96 pagesChemical Engineering 03 2016 PDFThái Xuân Quang100% (1)

- Pyridine SynthesisDocument5 pagesPyridine Synthesismeng1usaNo ratings yet

- Testing Solid Insulation of Electrical Equipment: Facilities Instructions, Standards, and Techniques Volume 3-1Document69 pagesTesting Solid Insulation of Electrical Equipment: Facilities Instructions, Standards, and Techniques Volume 3-1denzil_1000100% (12)

- Ivantchenko - GEANT4 LOW ENERGY Geant4 EM PackagesDocument34 pagesIvantchenko - GEANT4 LOW ENERGY Geant4 EM PackagesForeverSleepingNo ratings yet

- 1999 Biology Paper I Marking SchemeDocument5 pages1999 Biology Paper I Marking Schemetramysss100% (1)

- White CementDocument11 pagesWhite CementLdiabiNo ratings yet

- Technical Report of Lab 1 Tablet LatestDocument5 pagesTechnical Report of Lab 1 Tablet LatestHasni Abdul RahimNo ratings yet

- Unit-Iv: Separation of Solids From FluidsDocument74 pagesUnit-Iv: Separation of Solids From Fluidsyouga Sri100% (1)

- Column Design With ExcelDocument72 pagesColumn Design With ExcelAsifIqbalNo ratings yet

- 5310 Mass Diffusion and Droplet EvaporationDocument8 pages5310 Mass Diffusion and Droplet EvaporationTushar PanchalNo ratings yet

- Thermal Barrier CoatingsDocument11 pagesThermal Barrier CoatingsNidhi Vyas100% (1)

- Finned Tube Heat Exchangers Type WRW and WRW-WDocument8 pagesFinned Tube Heat Exchangers Type WRW and WRW-WBOREBGKNo ratings yet

- Test Report 20122018Document21 pagesTest Report 20122018jamal nasirNo ratings yet

- FTM930-931 E+hDocument6 pagesFTM930-931 E+hmiklitsaNo ratings yet

- 2-Diffusivity Equation-Linear PDFDocument30 pages2-Diffusivity Equation-Linear PDFLoh Chun LiangNo ratings yet

- Real-Time PCR Assays For Detection and Quantitation of Porcine and Bovine DNA in Gelatin Mixtures and Gelatin CapsulesDocument5 pagesReal-Time PCR Assays For Detection and Quantitation of Porcine and Bovine DNA in Gelatin Mixtures and Gelatin CapsulesAri DewiyantiNo ratings yet