Professional Documents

Culture Documents

A Digital Signal Processing Algorithm On Read Out Circuit For Electrical Capacitance Tomography

A Digital Signal Processing Algorithm On Read Out Circuit For Electrical Capacitance Tomography

Uploaded by

Dodi SudianaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Digital Signal Processing Algorithm On Read Out Circuit For Electrical Capacitance Tomography

A Digital Signal Processing Algorithm On Read Out Circuit For Electrical Capacitance Tomography

Uploaded by

Dodi SudianaCopyright:

Available Formats

A Digital Signal Processing Algorithm on Read Out

Circuit for Electrical Capacitance Tomography

Arba'i YUSUf, ,2, Dodi Sudiana', Agus Santoso Tamsir', Harry Sudibyo S'

'Department of Electrical Engineering, Universitas Indonesia, Depok, Indonesia

2C_ Tech Labs, Edwar Technology Co, Tangerang, Indonesia

e-mail: arbai@c-techlabs.com;dodi.sudiana@ui.ac.id;agus.tamsir@gmail.com;harisudi@eng.ui.ac.id

Abstract-The research relates to tomography technique based amplifier, and controlling input offset and gain. Digital signal

on electrical mass properties measurement. This study proposed processing is needed to overcome the shortcoming of existing

electronic design of read out circuit (ROC) for signal processing analog circuit. This research introduces an electronics design

in electrical capacitance tomography. The method is to capture namely read out circuit (ROC) to process signal based on high

the excitation and detection signal simultaneously using high speed analog-to-digital converter (ADC) and FIFO memory.

speed analog-to-digital-converter (ADC) then save its reading The method is to capture the excitation and detection signal

to first-in-first-out (FIFO) memory. From the two signals, simultaneously using high speed ADC then save its reading to

magnitude and phase can be determined. Therefore, calculation first-in-first-out (FIFO) memory. From the two signals,

magnitude and phase can determined. Therefore, calculation of

of capacitance and conductivity of object inside sensor is done

capacitance and impedance of object inside sensor is done using

using math equation.

math equation. With this method, the system can be used not

only to measure capacitance, but also to measure conductivity of

Keywords-electrical capacitance tomography, read out circuit,

the object.

high speed ADC, signal processing, zero derivative method.

1. INTRODUCTION

II. DIGITAL SIGNAL PROCESSING M ETHOD

Tomography is two or three dimensional image visualization

technique based on signal measurement from the sensor. There A. Theory of Operation

are several kinds of tomography technique, viz. acoustic An electrical capacitance tomography (ECT) uses a sine

tomography, radiation tomography, and electrical tomography wave signal for excitation electrode, while detection electrode

[1]. Acoustic tomography is based on sound wave measurement; also measures a sine wave signal which contains amplitude,

whereas radiation tomography is based on radiation wave frequency, and phase information. It is assumed that the

measurement; and electrical tomography is based on electrical excitation signal is V;sin(wt) and detection signal is ll"sin(wt)

mass properties measurement. The principle of electrical that has period (dt!) and the t difference is (dtz) as shown in

capacitance tomography (Figure 1) is injection of square wave Figure 2.

or sine wave signal into electrode, which will cause fringing

electric field inside sensor area. Then, the signal is detected by V !:<_________________

dt1. ____________ !

~

detector to be further processed and reconstructed into image

using soft computing algorithm.

V

Source

t1 t2 t3 t4

Figure 2. Method to calculate magnitude, frequ ency, and signal phase

Figure I. Principle of electrical capacitance tomography (ECT) The method to process the signal is to capture detection

signal (Va) and excitation signal (VJ simultaneously to

Previous design [2,3] use an analog circuit that has many determine magnitude, frequency, and phase of the signal. It

associated problems such as noise, component mis-match on should be done frrst by identifying location "t" of the peak of

978-1-5090-2597-8/16/$31.00 ©2016 IEEE 1166

Authorized licensed use limited to: Universitas Indonesia. Downloaded on January 14,2024 at 12:15:11 UTC from IEEE Xplore. Restrictions apply.

both of signals, hence obtaining f], I], t3 and t4. From the feedback, ZSl and ZS2 are parasitic impedance from coaxial

excitation signal, period and frequency can be calculated. cable, and sensor screen.

Moreover from both of signals (excitation and detection), angle

can be calculated. The equation is expressed as: Rf

1 Cf

[ = -d- ; dtl = t3 - tl (1 )

tl ts Zx

d t2

8 = -360; d t2 =

d tl

t2 - tl

where [ is frequency output, ts is time sampling of ADC, d tl is

(2)

~ ~ZS1

Vit)

the difference between t3 and tb d t2 is the difference between

t2 and tb 8 is the angle of the signal. The impedance (Zx) can

Figure 3. Charge amplifier circuit

be calculated from excitation voltage (Vi) divided by detection

voltage (Vo) and multiplied by the impedance of feedback

B. Digital Peak Detection

components on the OpAmp (Rff fCf ) , as shown in following

equation: Signal from charge amplifier circuit is in sine wave form.

To make the signal further processable, magnitude value of

Vi signal voltage must be captured. There are two methods for

Zx = -Zf (3)

v" magnitude detection; first, using analog peak detection which

produce DC (direct current) voltage value. Second, using digital

The impedance of feedback components can be calculated as: peak detection as described in this work.

RfXc 1 Magnitude detection in the digital signal processing is very

Zf = Rf + Xc; Xc = wCf (4) important, it is used to find the position of t], t2, t3 and t4, so that

the frequency and phase signal can be calculated. The method

Where, Rf is feedback resistance, Xc is reactance of feedback of digital peak detection in this work is zero-derivative method,

capacitance, Cf is capacitance feedback, and w is angular viz. measures the slope of the function at a single point using

first derivative. First derivative is commonly used to identify

frequency of the signal.

the slope at a particular point is negative, positive, or zero of the

The impedance Zx contains resistance (real value RESR ) and

nonlinear function as depicted in Figure 4.

reactance (imaginary value jX) where it can be written as:

f(x)

Zx = R ESR + jX (5)

f(x)=O

The imaginary value can be of capacitance or inductance depend f(x)=maximum

on electrode and object material inside the sensor. In this work

only capacitance and impedance of the capacitance sensor is

measured, thus the equation (5) can be rewritten as equation (6),

and also rewritten as equation (7) if consisting sinusoidal signal.

j

Zx = R ESR - wC

(6)

Zx = Zxcos8 + jZ x sin8 (7)

From the equation (7) real and imaginary value can be found and f(x)=o

expressed as: [ (x)=minimum x

RESR = Zx cos 8 (8)

Figure 4. First derivative to detect slope at particular point

-1

Cx = wZx sin8 (9) The signal excitation and detection in the electrical

capacitance tomography system is sine wave as [(x) = sin x.

Where, Zx is impedance of the object, RESR is resistance of the The maximum and minimum value occurs at the point at which

object, Cx is capacitance of the object, measured inside sensor. the first derivative is zero. The first derivative of sine wave

The signal from detection electrode is too small and difficult function can be expressed as:

to analyze so that the electronic circuit such as charge amplifier

circuit as depicted in Figure 3 is needed. The charge amplifier [(x) = sinx (10)

circuit has a function to convert the current from detection

electrode into voltage signal. Viet) and v,,(t) are sine wave ['(x) = cosx (11)

signal input and output respectively, Z x is object impedance will

Based on the first derivative, the max and min value of the

be measured, Rf and Cf are resistance and capacitance

signal occurs at every 0.5rr, 1.5rr, 2.5rr, 3.5rr, etc. Signal on

digital signal processing is discrete value and dependant on

20161£££ Region 10 Conference (T£NCON) - Proceedings of the International Conference 1167

Authorized licensed use limited to: Universitas Indonesia. Downloaded on January 14,2024 at 12:15:11 UTC from IEEE Xplore. Restrictions apply.

sampling time of the ADC, so that the equation (11) can be excitation signal is also rising the signal-to-noise-ratio (SNR)

expressed as: [6].

Based on consideration of several above factors , the

['(Xi) = COS (Xi ~~ 360) (12) feedback resistance and capacitance are 22Kn and 22pF

respectively, the frequency excitation is 500KHz, and the

Where Xi is number of data, fin is frequency input, Is is amplitude signal excitation is 2l.6 Vp-p. The system

frequency sampling of ADC. The equation (12) could be used in performance is also determined by characteristic of ADC. In

one condition, viz. the first value of the function must be zero or this work, a 12-bit, sampling rate up to 53 MSPS of ADC chip

close to zero : f(xo) == O. Consequently, the trigger is necessary ads807, which has an input range of 3 Vp-p and SNR of 67.5

to be arranged close to zero to obtain the first data equal or close dB is used. Subsequently, these parameters will be obtained: the

to zero. settling time of the charge amplifier circuit is 3.7 flS, the

sensitivity is 0.38 VpF-l , the upper limit of capacitance

measurement is 3 pF, and the upper limit of conductivity

III. READ OUT CIRCUIT D ESJGN

measurement is 15 .9 flSm-l .

Read out circuit (ROC) has a function to capture the signal A capacitance sensor is used to examine and verify the

from electrode sensor and process it into capacitance and signal-processing algorithm on the read out circuit design. It

impedance. Read out circuit use two high speed analog-to- could measure capacitance and conductivity of the object inside

digital conversion (ADC), two memories FIFO (first-in- first- sensor at the same time.

out), and one microcontroller as shown in Figure 5. High speed

ADC is used to capture both signals simultaneously with

sampling rate of 20 MSPS (mega samples per second). The IV. EXPERJMENTAL RESULTS

microcontroller cannot fetch data from ADC directly, because The experiment was conducted with a 8 channel circular

the input output (VO) port only 1.5 Mbps of speed. Hence, sensor with 13.5 cm diameter and 4.5x7.2 cm of electrode

another device to bridge ADC and microcontroller such as dimension, whose cross-sectional diagram is shown in Figure 6.

FIFO memory is required. Memory FIFO is used as temporary The electrodes in the sensor can act as excitation or detection

buffer, to save the digital data from ADC with the same clock source depend on which one the electrode pair was activated.

of ADC and FIFO. In this work, a microcontroller being used is Capacitance reading retreived from electrode pairs C I -2, C I -3, . . .,

atxmega 16-bit bus with clock speed of 32MHz, which has a Cl_S, C2-3, C24, .. .,C2-S, C34, C3-S, .. . C3-S, so on until C7-s. In

function to analyze and process the signal into capacitance and general, N electrode sensor offers N(N - 1)/2 independent

impedance. capacitance data measurement. Hence, the number of

independent capacitance measurement for eight electrodes is 28

r-:::-1

L:-J----------1-- ------, I

data. To getting all data measurement, each electrode pair

measured one by one manually until the last measurement data.

...I I

~

e

"8g vessel

~

screen

Figure 6. Cross-sectional of8 channel capacitance sensor

Figure 5. Circuit diagram of read out circuit

A photograph of prototype ofread out circuit (ROC), eight

There are several factors that should be considered In channel capacitance sensor, and several phantom are shown in

developing read out circuit, which will be guarantee good Figure 7. To investigate the result, specific phantom has been

linearity and sensitivity. Some factors such as the chosen of made from pvc with diameter 2.5 cm and 6 cm, and also square

electronics parameters, frequency, and amplitude of signal phantom with dimension 4.2x8 cm. Phantom was filled up with

excitation. The capacitance and resistance feedback cannot be solid salt (er=15).

too large to offer shorter settling time [4]. A higher excitation

frequency is proportional to higher sensitivity, faster data

collection rates, and also reducing the effect of conductivity of

the object measured inside sensor [5]. A higher amplitude of

1168 20161£££ Region 10 Conference (T£NCON) - Proceedings of the International Conference

Authorized licensed use limited to: Universitas Indonesia. Downloaded on January 14,2024 at 12:15:11 UTC from IEEE Xplore. Restrictions apply.

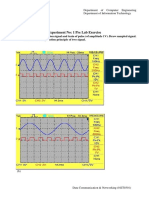

The signal was interfered by some noise from environment,

thus the digital signal filtering is needed to make signal smooth

and easy to process. As an example is digital peak detection,

which requires a signal free from noise. The result is shown in

Figure 8.

c=e=-c~[

1.2

iL E

.eo 52

(jj

~

u Z:-

c

rn :2

'<3

~ 0.8 4g-g

()

8

(bJ 0.6

Figure 7. Photograph of (a) Read Out Circuit (ROC) and sensor Prototype; (b)

Phantom used in experiment 0.4

In the following experiment is used a direct digital O.2 e - W I T J!!I r - W - j - ]!III T t1

synthesizer (DDS) that has function to generate the excitation o 10 15 20 25 30

Number of Data

signal set to 500 KHz, 21.6 Vpp. Meanwhile, the ADC

Figure 9. Capacitance and conductivity measurement for 8 electrode sensor

sampling rate is set to 20MSPS (50 ns of time sampling), thus

resulting 40 digital data for a signal cycle. Each signal To validate the read out circuit system, image reconstruction

processing involves 200 sampling points (5 signal cycle) to is carried out. For image reconstruction, capacitance

guarantee desirable measurement. The fetching data from measurement is normalized using equation:

memory FIFO to microcontroller is about I f.lS each data bits, Cr - C1

thus it takes 200 f.lS for all sampling point. The processing signal nc = -C- 1

- (13)

including conversion digital data into voltage, digital signal

filtering, digital peak detection, and calculation phase, Where nc is normalized capacitance, Cr is measured

capacitance, impedance, and conductivity will takes about 95.8 capacitance, C1 is capacitance at empty calibration. Empty

ms. In this way, it will takes 96 ms to measure one capacitance calibration is when the sensor filled with low permittivity

impedance, and conductivity. With such amount of time, it is material, which is dry rice (1:r=3.5). Iterative Linear Back

too slow if implemented in ECT data acquisition system. Projection (ILBP) algorithm was used to reconstruct all data

However it is currently not a concern of the work. This work patterns, and not discussed in this paper. Thorough explanation

focuses on digital signal processing implemented on read out about algorithm's implementation can be found in [10].

circuit (ROC) for ECT system. The speed of measurement data Capacitance and conductivity measurement of the 8-electrode

sensor are described in Figure 9. Adjacent pair electrode give

could be increased by replacing the micro controller with high

capacitance and conductivity measurement up to 1.39 pF and 7.2

speed digital signal processor (DSP), using field programmable

f.lSm-1 respectively; while opposite pair electrode give

gate array (FPGA), or using complex programmable logic

capacitance and conductivity measurement of 0.22 pF and 1.1

device (CPLD) being used by other researchers [7-9]. f.lSm-1 respectively.

10 0.4 The image reconstruction from several phantoms are shown

in Figure 10, which is divided into four experiment. The circle

0.3 rod with diameter of 6 cm yields a good reconstructed image.

On the contrary, image reconstruction of square rod with

0.2

dimension of 4.2x8 cm is not good enough. The left and the right

?: 0.1 ?: sides attracted to the edge of the sensor, so that the image looks

ill, a little bloated. In the last experiment, the circle rod with

~

F 2

g ."

> diameter of 2.5 cm yields good image reconstruction even

c c

.Q

§

a though there is some noise in the edge of the sensor.

.~ -0.12

w -2 ,3

-0.2

-4

-6 -0.3

-8 ~- r ' (- r r ~ r r V. r r ,{~---l: _O . 4

o ~ ~ W W 100 1~ 1~ 1W 1W 200

Number of Data

Figure 8. Result of digital peak detection

20161£££ Region 10 Conference (T£NCON) - Proceedings of the International Conference 1169

Authorized licensed use limited to: Universitas Indonesia. Downloaded on January 14,2024 at 12:15:11 UTC from IEEE Xplore. Restrictions apply.

[7] Zhang, X., Wang, H., Cui, Z. and Tang, L., 2007, September. A novel

ECT system based on FPGA and DSP. In Innovative Computing,

Information and Control , 2007. ICICIC'07. Second Intemational

Conference on (pp. 510-510). IEEE.

[8] Muttakin, I., Yusuf, A. , Rohmadi, R. , Widada, W. and Taruno, W.P. ,

2015. Design and simulation of quadrature phase detection in electrical

capacitance volume tomography. TELKOMNIKA (Telecommunication

Computing Electronics and Control), 13(1), pp.55-64.

[9] Xu, L., Zhou, H., Cao, Z. and Yang, W., 2013. A digital switching

demodulator for electrical capacitance tomography. Instrumentation and

Measurement, IEEE Transactions on, 62(5), pp.1025-1033.

[10] Herdian, H. , Muttakin, I., Saputra, A., Yusuf, A., Widada, W. and Taruno,

W.P. , 2015, November. Hardware implementation of linear back-

projection algorithm for capacitance tomography. In 2015 4th

Figure 10. Image reconstruction for several phantom Intemational Conference on Instrumentation, Communications,

Information Technology, and Biomedical Engineering (ICICI-BME) (pp.

124-129). IEEE.

V. CONCLUSION

The prototype of read out circuit (ROC) for signal processing

based on high speed ADC and memory FIFO for electrical

capacitance tomography has been assembled. The ROC can be

used not only to measure capacitance, but also to measure

conductivity of object inside sensor. The measurement

sensitivity is 0.38 VpF-I, the upper limit of capacitance

measurement is 3 pF, and the upper limit of conductivity

measurement is 15.9 f.lSm-l. The speed of digital signal

processing that use microcontroller is too slow, it will takes 96

ms for one measurement. The speed could be increased by

replacing the microcontroller using DSP, FPGA, or CPLD.

Experimental result shows that image reconstruction was good

enough so that the pattern is observable, although still with some

obscurities.

ACKNOWLEDGEMENT

Author would like to thank to all persons who kindly

contributed to this research. This work was supported by a grant

from Hibah PITTA DRPM Universitas Indonesia; grant number:

2076!UN2.R12IHKP.05.00/2016.

REFERENCES

[I] Beck, M.S., 2012. Process Tomography: Principles, Techniques and

Applications. ButtelWorth-Heinemann.

[2] Yusuf, A., Muttakin, I. , Widada, W., & Taruno, W. P. (2014, October).

Analysis of single excitation signal for high speed ECVT data acquisition

system. In Information Technology and Electrical Engineering (IClTEE),

2014 6th Intemational Conference on (pp. 1-6). IEEE.

[3] Yusuf, A. , Muttakin, I., Rudin, A., Widada, W., & Taruno, W. P. (2014,

October). Single signal conditioning multi electrode for ECVT data

acquisition system. In TENCON 2014-2014 IEEE Region 10 Conference

(pp. 1-6). IEEE.

[4] Gonzalez-Nakazawa, A., Gamio, J.C. and Yang, W. , 2005. Transient

processes and noise in a tomography system: an analytical case study.

Sensors Joumal, IEEE, 5(2), pp.321-329.

[5] Yang, W.Q. , Stott, A.L. and Beck, M.S. , 1994, June. High frequency and

high resolution capacitance measuring circuit for process tomography. In

Circuits, Devices and Systems, lEE Proceedings- (Vol. 141, No.3, pp.

215-219). lET.

[6] Zhou, H., Xu, L., Cao, Z., Liu, X. and Liu, S., 2013. A complex

programmable logic device-based high-precision electrical capacitance

tomography system. Measurement Science and Technology, 24(7),

p.074006.

1170 20161££E Region 10 Conference (T£NCON) - Proceedings of the International Conference

Authorized licensed use limited to: Universitas Indonesia. Downloaded on January 14,2024 at 12:15:11 UTC from IEEE Xplore. Restrictions apply.

You might also like

- Auto Irrigation System With GSM NotificationDocument14 pagesAuto Irrigation System With GSM NotificationRakesh Menon0% (1)

- A Method of Measuring RLC Components For Microcontroller Systems - 15470Document4 pagesA Method of Measuring RLC Components For Microcontroller Systems - 154701004 NAGAJOTHI PNo ratings yet

- Lab.3 - CODEC, Echo and AliasingDocument12 pagesLab.3 - CODEC, Echo and AliasingTsega TeklewoldNo ratings yet

- Ec102: Electronics & Communication Laboratory List of ExperimentsDocument95 pagesEc102: Electronics & Communication Laboratory List of Experimentsaryan kumarNo ratings yet

- EI2004 Smart Pixels OCTDocument12 pagesEI2004 Smart Pixels OCTLuc FroehlyNo ratings yet

- Lock-In Amplifier ReportDocument14 pagesLock-In Amplifier ReportDaniel VergaraNo ratings yet

- Lab 2Document4 pagesLab 2Israr AhmadNo ratings yet

- ECG Articulo Por Medio de DebuchisDocument7 pagesECG Articulo Por Medio de DebuchisjcamilorendonNo ratings yet

- Phy Expt Lab Manual For AdoorDocument43 pagesPhy Expt Lab Manual For AdoorssddsdsNo ratings yet

- OscilloscopeDocument5 pagesOscilloscopetechieindiaNo ratings yet

- Performance Enhancement of Capacitive-Type Torque Sensor by Using Resonant CircuitDocument10 pagesPerformance Enhancement of Capacitive-Type Torque Sensor by Using Resonant CircuitM. T.No ratings yet

- Delaying Analogue Quadrature Signals in Sin/ Cos EncodersDocument6 pagesDelaying Analogue Quadrature Signals in Sin/ Cos EncodersAilton SorlagNo ratings yet

- C. Instrumentation For Electrical Bioimpedance MeasurementsDocument32 pagesC. Instrumentation For Electrical Bioimpedance MeasurementsDmitriyNo ratings yet

- 1 CS2403 Two MarksDocument19 pages1 CS2403 Two MarkssakthirsivarajanNo ratings yet

- Name:-Rahul Vora: Enroll No: - 92000103089Document12 pagesName:-Rahul Vora: Enroll No: - 92000103089RAHUL VORANo ratings yet

- Modullation PPT NewDocument58 pagesModullation PPT NewMayank TripathiNo ratings yet

- AD and DA Converter PrinciplesDocument18 pagesAD and DA Converter PrincipleskarkeraNo ratings yet

- Definition of Signal States: (1 / Duration Baud Rate)Document33 pagesDefinition of Signal States: (1 / Duration Baud Rate)SSNo ratings yet

- Application FFT-LVDTDocument6 pagesApplication FFT-LVDTnapoleon_velasc3617No ratings yet

- Experiment 6: Pulse Code Modulation: T x T t + 2x (t) cos 4πf t + 2x (t) cos 6πf t + - . .) x (t) T t)Document6 pagesExperiment 6: Pulse Code Modulation: T x T t + 2x (t) cos 4πf t + 2x (t) cos 6πf t + - . .) x (t) T t)Pruthvi TrinathNo ratings yet

- Exam 1 BPSK Modulation and Demodulation With Carrier Frequency OffsetDocument4 pagesExam 1 BPSK Modulation and Demodulation With Carrier Frequency Offsetkaranbir123No ratings yet

- Measurement of Amplitude, Time Period and Frequency Using CroDocument8 pagesMeasurement of Amplitude, Time Period and Frequency Using Crodhanisha100% (1)

- Digital Pulse Processor Using A Moving Average TechniqueDocument3 pagesDigital Pulse Processor Using A Moving Average TechniqueHung Tran VietNo ratings yet

- A DSSS Super-Regenerative ReceiverDocument4 pagesA DSSS Super-Regenerative ReceiverbaymanNo ratings yet

- Digital Signal Processing NotesDocument12 pagesDigital Signal Processing NotesDanial ZamanNo ratings yet

- A New Algorithm For A High-Modulation Frequency and High-Speed Digital Lock-In AmplifierDocument7 pagesA New Algorithm For A High-Modulation Frequency and High-Speed Digital Lock-In AmplifierVicNo ratings yet

- GPS Signal Structure: - SourcesDocument23 pagesGPS Signal Structure: - Sourcessoumya_cu100% (2)

- UCK304E ElectricalExperiments Experiment2 Lab FileDocument7 pagesUCK304E ElectricalExperiments Experiment2 Lab Filey.komurcu921No ratings yet

- Equal Precision CounterDocument5 pagesEqual Precision CounterTadasNo ratings yet

- Emi Lab Manual 1650425604Document32 pagesEmi Lab Manual 1650425604uurhrjirgehNo ratings yet

- Imeko WC 2000 TC4 P114Document4 pagesImeko WC 2000 TC4 P114Marouane SbaiNo ratings yet

- DC ManualDocument62 pagesDC ManualnavecNo ratings yet

- Digital Signal Processing SamplingDocument66 pagesDigital Signal Processing Samplingsyazo93No ratings yet

- SeminarDocument200 pagesSeminarMudassarNo ratings yet

- Ofdm PrencipleDocument18 pagesOfdm PrencipleAhmed FadulNo ratings yet

- Lab ManualDocument56 pagesLab ManualNarendra ReddyNo ratings yet

- Cathode Ray Oscilloscope ExperimentDocument10 pagesCathode Ray Oscilloscope ExperimentHenok BelaynehNo ratings yet

- Chapter 3 Waveform Coding Techniques PDFDocument33 pagesChapter 3 Waveform Coding Techniques PDFEunielyn SecretoNo ratings yet

- TNE30003 Communication Principles: SamplingDocument41 pagesTNE30003 Communication Principles: SamplingTiến DũngNo ratings yet

- Ec1351 - Digital CommunicationDocument27 pagesEc1351 - Digital CommunicationjackdbomberNo ratings yet

- Vu 2016Document4 pagesVu 2016Deekshitha KgNo ratings yet

- A Simple Diagram For Data Transmission Using Manchester CodeDocument4 pagesA Simple Diagram For Data Transmission Using Manchester CodeMarcelo do ValleNo ratings yet

- Jnanavikas Institute of Technology: Mr. Shubas S.RDocument76 pagesJnanavikas Institute of Technology: Mr. Shubas S.RAbhishek nNo ratings yet

- Spread - Spectrum Modulation: Chapter-7Document22 pagesSpread - Spectrum Modulation: Chapter-7Deepika kNo ratings yet

- Cathode Ray Oscilloscope (CRO)Document8 pagesCathode Ray Oscilloscope (CRO)Swarnadip SahaNo ratings yet

- Institutional PAASCU ECE515FL Activity1Document14 pagesInstitutional PAASCU ECE515FL Activity1Edward Amoyen AbellaNo ratings yet

- Communication SystemsDocument24 pagesCommunication Systemstalha4400573No ratings yet

- An Electrical Impedance Tomography System For Current Pulse MeasurementsDocument3 pagesAn Electrical Impedance Tomography System For Current Pulse MeasurementsYassine AbdessamiaNo ratings yet

- Introduction To Digital CommunicationsDocument44 pagesIntroduction To Digital CommunicationsKvnsumeshChandraNo ratings yet

- Practicas de OsciloscopioDocument9 pagesPracticas de OsciloscopiokarolcoNo ratings yet

- Pattern Analysis of Different ECG SignalDocument4 pagesPattern Analysis of Different ECG SignalngovantamcuteNo ratings yet

- 9 Ieee Conf Soa 2015Document7 pages9 Ieee Conf Soa 2015Lokanath TripathyNo ratings yet

- Chapter 3 Oscilloscope ApplicationDocument21 pagesChapter 3 Oscilloscope ApplicationMariaNo ratings yet

- 07 - ART - Determination of Frequency Characteristics of High Voltage Dividers in Frequency DomainDocument4 pages07 - ART - Determination of Frequency Characteristics of High Voltage Dividers in Frequency DomainLove for gamesNo ratings yet

- In-Depth Analysis of Cardiac Signals Using Novel Equipment and SoftwareDocument6 pagesIn-Depth Analysis of Cardiac Signals Using Novel Equipment and SoftwareHoracio DorantesNo ratings yet

- Fundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level SystemsFrom EverandFundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level SystemsNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Finisher s1 SM PDFDocument108 pagesFinisher s1 SM PDFReneeNo ratings yet

- Ieee Innovative Improvements in Electronic Engineering Laboratory Education Using Electronic Mini Lab (Eml) - A Case StudyDocument5 pagesIeee Innovative Improvements in Electronic Engineering Laboratory Education Using Electronic Mini Lab (Eml) - A Case StudyVikas DongreNo ratings yet

- 00 Fundamentals of Logic Design, Enhanced Edition JR Charles H Roth (2) (055-085)Document31 pages00 Fundamentals of Logic Design, Enhanced Edition JR Charles H Roth (2) (055-085)3bduallah.40.ayadNo ratings yet

- Stephan Ventilator ABV ServiceDocument23 pagesStephan Ventilator ABV Servicebashaar ahmedNo ratings yet

- MPX 5 BBCDocument40 pagesMPX 5 BBCkruna123No ratings yet

- Demo Project On LDR Based Street LightDocument18 pagesDemo Project On LDR Based Street LightHarsh SinghNo ratings yet

- Thesis Report - Exploring Memristor TopologiesDocument59 pagesThesis Report - Exploring Memristor TopologiesSerdar BenderliNo ratings yet

- Transistors TutorialDocument3 pagesTransistors Tutorialarness22No ratings yet

- Industrial Electronics LaboratoryDocument31 pagesIndustrial Electronics LaboratoryEd Carlo RamisNo ratings yet

- 100 IC CircuitsDocument60 pages100 IC CircuitsGicu CapatinaNo ratings yet

- Automatic Changeover SwitchDocument16 pagesAutomatic Changeover SwitchAjaySharma100% (1)

- Automotive Servicing NC II CGDocument36 pagesAutomotive Servicing NC II CGChristine Grace Espallardo JungcoNo ratings yet

- Q4 - M1 Identify Different Kinds of Technical Drawings FinalDocument25 pagesQ4 - M1 Identify Different Kinds of Technical Drawings FinalcadamariahNo ratings yet

- All Question Paper ECDDocument63 pagesAll Question Paper ECDHakimuddin BohariNo ratings yet

- Microwind 3.5 BRDocument2 pagesMicrowind 3.5 BRJonathan Arley Torres CastañedaNo ratings yet

- Computer Technology Full SyllabusDocument51 pagesComputer Technology Full Syllabusabhinavgiri17No ratings yet

- 1.5-Ghz Prescaler For Frequency Meters: R. BönschDocument3 pages1.5-Ghz Prescaler For Frequency Meters: R. BönschCarlos Molins LopezNo ratings yet

- Lab Report InstrumentationDocument9 pagesLab Report InstrumentationNur Razanah Mohd YasinNo ratings yet

- 12-Bit High Speed Multiplying D/A Converter DAC312Document15 pages12-Bit High Speed Multiplying D/A Converter DAC312Jim LiebNo ratings yet

- Ebooks SolutionsmanualsDocument5 pagesEbooks SolutionsmanualsBHUVANESWARI A0% (2)

- PEET2.0 Sell Sheet - LoResDocument4 pagesPEET2.0 Sell Sheet - LoResazrockclimberNo ratings yet

- BCD To 7-Segment DecoderDocument12 pagesBCD To 7-Segment DecoderAshwini AshwiniNo ratings yet

- ANALOG CIRCUITS-Syllabus KtunotesDocument9 pagesANALOG CIRCUITS-Syllabus Ktunotesdrn86686No ratings yet

- Integrated Circuit - Classification: IC TypesDocument5 pagesIntegrated Circuit - Classification: IC TypesUmaNo ratings yet

- AY22-23-AET512-Course SpecificationsDocument5 pagesAY22-23-AET512-Course Specificationsayesha humeraNo ratings yet

- 04 - Logic Gates TutorialsDocument12 pages04 - Logic Gates TutorialsPokharali KanchhaNo ratings yet

- B&O Beosound MK3Document96 pagesB&O Beosound MK3Mersin ZeljkovićNo ratings yet

- Mr2920 DatasheetDocument19 pagesMr2920 DatasheetflorianguillouNo ratings yet

- FP0Document20 pagesFP0ROMAJUSTE1No ratings yet