Professional Documents

Culture Documents

Solution Annealing (HT) Procedure Asipl

Solution Annealing (HT) Procedure Asipl

Uploaded by

tushartech009Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solution Annealing (HT) Procedure Asipl

Solution Annealing (HT) Procedure Asipl

Uploaded by

tushartech009Copyright:

Available Formats

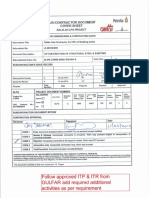

SIECO ENGINEERS PVT. LTD.

BANGALORE.

QA. DEPT TEST PROCEDURE DOC:QA-TP- 03/R1

SOLUTION ANNEALING

Project P-007

Equipment/System DELAY TANK

Equipment Number SCO-007

Document Number QA-TP- 03-007/R1

Document Revision R1

PROTOCOL APPROVAL

COMPANY’S NAME NAME DATE SIGNATURE

DESIGNATION

Prepared by SIECO PALANIYAPPAN 28.02.2013

SIECO SSR 28.02.2013

Reviewed by

BARC R. C. SHARMA 05/03/13

Approved by

DOCUMENT REVISION HISTORY

Revision History Log

Revision Date Issued by Description

R0 04.07.2012 QA Standard TP

R1 28.02.2013 QA Standard TP

Prepared By: PP Approved By: SSR Page 1 of 2

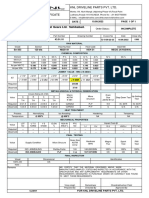

SIECO ENGINEERS PVT. LTD.

BANGALORE.

QA. DEPT TEST PROCEDURE DOC:QA-TP- 03/R1

1. Scope:

The scope of this procedure shall apply to the dished ends of delay tank.

2. Purpose:

The purpose of this method is to ensure restoration of corrosion properties due

to carbide precipitation which impairs the corrosion resistance of stainless

steel. It also ensures homogenous micro-structure and uniform mechanical

properties.

3. Test Procedure

Cleaning: The surface shall be cleaned to remove oil, grease and other

foreign material by chemical/mechanical means.

Dish ends to be loaded in to the electric furnace

The charging temperature shall be 300 deg c & temperature shall be

raised from 150 to 200 deg c/ hr.

Solution annealing shall be carried in electric furnace only. The

Temperature range shall be maintained between 1050 deg C-1080 deg C.

The temperature shall be slowly increased to 1050 -1080 deg C and

holding at this temperature for 1 hr/inch thickness or minimum 30min

whichever is higher.

Finally open the furnace door, unload the dishes and immediately carry

quenching.

Carry out Rapid quenching using dimineralised water until temperature

drops to <300deg C.

Prepared By: PP Approved By: SSR Page 2 of 2

You might also like

- The English Fluency FormulaDocument46 pagesThe English Fluency Formulaabdulsamad94% (18)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- P15340-CYD-PI-SP-0006 - Rev.1 (Specification For Fabrication, Erection & Testing of Piping System)Document43 pagesP15340-CYD-PI-SP-0006 - Rev.1 (Specification For Fabrication, Erection & Testing of Piping System)Saiful AmreeNo ratings yet

- DISI-QA-ITPG-ME-MS-004 Rev 0, ITP For Field Application For External Heat-Shrinkable Coating of Steel Pipe Fitting and JointsDocument5 pagesDISI-QA-ITPG-ME-MS-004 Rev 0, ITP For Field Application For External Heat-Shrinkable Coating of Steel Pipe Fitting and JointsJamal Budeiri0% (1)

- Tie in Procedure Rev. BDocument8 pagesTie in Procedure Rev. BgenjiNo ratings yet

- Reflex Level Gauge 1410783 TC - 16039.000Document1 pageReflex Level Gauge 1410783 TC - 16039.000bmprduNo ratings yet

- 1TB03300 300C04 STC Itp Me 0004Document4 pages1TB03300 300C04 STC Itp Me 0004heerkhanheerkhan435No ratings yet

- QAP For Pipes For Hydrant and Sprinkler SystemDocument3 pagesQAP For Pipes For Hydrant and Sprinkler SystemCaspian DattaNo ratings yet

- AHPS-QA-PWPS-098 Rev.01Document23 pagesAHPS-QA-PWPS-098 Rev.01anandNo ratings yet

- KLD 00 4500399734 ZV P23 00030 0000 02 Fabrication, Installation & Testing of Structural SteelDocument5 pagesKLD 00 4500399734 ZV P23 00030 0000 02 Fabrication, Installation & Testing of Structural SteelRana AsifNo ratings yet

- Qa/Qc Procedure: PGB/HO/19/2015/0094Document2 pagesQa/Qc Procedure: PGB/HO/19/2015/0094saffririzal4237No ratings yet

- Test Package: Pt. TTN (Tambang Tondano Nusajaya)Document18 pagesTest Package: Pt. TTN (Tambang Tondano Nusajaya)unto gunungNo ratings yet

- CS PLATE-TS NO-SA-516-2-222051-R0 - Dish End Plate (Commented 3Document2 pagesCS PLATE-TS NO-SA-516-2-222051-R0 - Dish End Plate (Commented 3PRADEEP GAIKWADNo ratings yet

- For Construction: Reliance Bangladesh LNG & Power LimitedDocument21 pagesFor Construction: Reliance Bangladesh LNG & Power LimitedCaspian DattaNo ratings yet

- RFI Welding TestDocument18 pagesRFI Welding TestDimas agungNo ratings yet

- 1TB03300 300C04 STC Itp Me 0002Document4 pages1TB03300 300C04 STC Itp Me 0002heerkhanheerkhan435No ratings yet

- Initial Product/Process Change Notification: Document #:IPCN23483XA Issue Date:01 Jul 2021Document7 pagesInitial Product/Process Change Notification: Document #:IPCN23483XA Issue Date:01 Jul 2021Douglas AlbertNo ratings yet

- Procedure No. L&T/ Kkro / Mech / WP 01: Procedure For Wps / PQR & Welder QualificationDocument6 pagesProcedure No. L&T/ Kkro / Mech / WP 01: Procedure For Wps / PQR & Welder QualificationdiptiNo ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- Water Tightness test-WP - FINALDocument10 pagesWater Tightness test-WP - FINALPrasad ChowdaryNo ratings yet

- BARGE SPEC-signedDocument7 pagesBARGE SPEC-signedganeshcivil1984No ratings yet

- Sc13003-p5003-q03-0003 - Itp Sea Water Intake SystemDocument17 pagesSc13003-p5003-q03-0003 - Itp Sea Water Intake SystemDwi Mulyanti DwimulyantishopNo ratings yet

- AEPCOM-QAP-3281-58548 Rev 1Document3 pagesAEPCOM-QAP-3281-58548 Rev 1VIVEK TIWARINo ratings yet

- Itp PipingDocument12 pagesItp PipingCak Nhass100% (1)

- 1TB03300 300C04 STC Itp Me 0008Document4 pages1TB03300 300C04 STC Itp Me 0008heerkhanheerkhan435No ratings yet

- Water Tightness test-WPDocument10 pagesWater Tightness test-WPPrasad ChowdaryNo ratings yet

- Cp5-Itp CWC RomanuDocument22 pagesCp5-Itp CWC RomanuherdiansyahNo ratings yet

- HFY 3800 0000 VED 192 QC PD 0004 - A Hardness Test Procedure - Code BDocument14 pagesHFY 3800 0000 VED 192 QC PD 0004 - A Hardness Test Procedure - Code BMohamed FarisNo ratings yet

- Kok04200 Material TracabilityDocument41 pagesKok04200 Material Tracabilityqamar qateebNo ratings yet

- Itp STR Slpg-Q-0000-24001-032-001-4-ADocument11 pagesItp STR Slpg-Q-0000-24001-032-001-4-AsivagnanamNo ratings yet

- O2 Analyzer - Document - REV-B - 24-03-2018 PDFDocument10 pagesO2 Analyzer - Document - REV-B - 24-03-2018 PDFambeshNo ratings yet

- (Part 1 of 7) - WPS Attachment 1 To 2Document84 pages(Part 1 of 7) - WPS Attachment 1 To 2ihajar9No ratings yet

- Procedure For Electrode Baking: Larsen & Toubro Limited - Ecc Division Work Procedures Sepco Iii Project, JharsugudaDocument4 pagesProcedure For Electrode Baking: Larsen & Toubro Limited - Ecc Division Work Procedures Sepco Iii Project, JharsugudadiptiNo ratings yet

- Qa/Qc Procedure: PGB/HO/19/2015/0094Document2 pagesQa/Qc Procedure: PGB/HO/19/2015/0094saffririzal4237No ratings yet

- BGRL (Satara-Sangli) - Spur Spread-3 - JP-Arc Strike - R0 - Code A - 26.02.2021Document6 pagesBGRL (Satara-Sangli) - Spur Spread-3 - JP-Arc Strike - R0 - Code A - 26.02.2021Aditya IngawaleNo ratings yet

- P4 Forwarding NoteDocument1 pageP4 Forwarding NoteIlayaraja MKNo ratings yet

- Procedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectionDocument10 pagesProcedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectiondiptiNo ratings yet

- 0279STX N WM PW01 Qa Pro 0011 A02Document12 pages0279STX N WM PW01 Qa Pro 0011 A02praveen 0064No ratings yet

- Project Quality History Card - Mechanical: S E L, P, IDocument15 pagesProject Quality History Card - Mechanical: S E L, P, ImuthuNo ratings yet

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01Document392 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01Neil JavierNo ratings yet

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150Document150 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150QC ManagerNo ratings yet

- Welders List For VesselDocument1 pageWelders List For VesselHanuman RaoNo ratings yet

- 028120-SPL-007 Pipeline Protective Coatings Rev. CDocument12 pages028120-SPL-007 Pipeline Protective Coatings Rev. CRokan Pipeline100% (1)

- Inspection & Test Plan: For Non Slam Check Valve (Axial Type)Document4 pagesInspection & Test Plan: For Non Slam Check Valve (Axial Type)Jeroan AyamNo ratings yet

- Open DrainDocument6 pagesOpen DrainMohammad MohseniNo ratings yet

- Imir 1714Document1 pageImir 1714abhijit007beraNo ratings yet

- IONE-1B03-SP-PR-0002 PROCESS PROCESS DESCRIPTION For UNIT 03 Rev.0 Code 2 TransmittalDocument10 pagesIONE-1B03-SP-PR-0002 PROCESS PROCESS DESCRIPTION For UNIT 03 Rev.0 Code 2 Transmittalyusuf.yuzuakNo ratings yet

- PC N 20151016001Document4 pagesPC N 20151016001Aaqib RasoolNo ratings yet

- Hx8815-Qc-Pc-Misc-015 Rev. E2Document8 pagesHx8815-Qc-Pc-Misc-015 Rev. E2Selva SelvaaNo ratings yet

- ITP - Distribution TransformerDocument6 pagesITP - Distribution TransformerOsman AbdoutNo ratings yet

- Uaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileDocument20 pagesUaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileABHIJITH M SNo ratings yet

- Specification Pipeline WeldingDocument15 pagesSpecification Pipeline WeldingOktavianusHeru100% (2)

- ZADCO-Mechanical Equipment SpecificationDocument83 pagesZADCO-Mechanical Equipment SpecificationNAMONo ratings yet

- T10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Document13 pagesT10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Thắng NguyễnNo ratings yet

- For Approval: Jawaharpur Vidyut Utpadan Nigam LimitedDocument6 pagesFor Approval: Jawaharpur Vidyut Utpadan Nigam Limitedsanjayprakash1979No ratings yet

- BPX-G-G-WE-029 Specification For Pipeline, Flowlines, WellpDocument38 pagesBPX-G-G-WE-029 Specification For Pipeline, Flowlines, WellpdonaldoguerreroNo ratings yet

- JNKIN-026-001 - Study ReportDocument20 pagesJNKIN-026-001 - Study ReportJayeshNo ratings yet

- Punjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateDocument1 pagePunjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateargmsfNo ratings yet

- P6 Forwarding NoteDocument1 pageP6 Forwarding NoteIlayaraja MKNo ratings yet

- RFCC-T-GC-PC-0250 Method Statement For RG-RX Installation WorkDocument70 pagesRFCC-T-GC-PC-0250 Method Statement For RG-RX Installation WorkHerberth SilitongaNo ratings yet

- Global Hotel Review Benchmark Q1 2022Document136 pagesGlobal Hotel Review Benchmark Q1 2022Anna KustrzepaNo ratings yet

- Technical Aptitude Questions EbookDocument175 pagesTechnical Aptitude Questions EbookpandeysharadNo ratings yet

- Vision and Mission of The Department of Civil Engineering VisionDocument2 pagesVision and Mission of The Department of Civil Engineering VisionAnithaNo ratings yet

- Applied Mechanics PDFDocument348 pagesApplied Mechanics PDFabdukadir442100% (1)

- Chapter 6 Open MethodsDocument58 pagesChapter 6 Open MethodsAbdul AzizNo ratings yet

- 2018 ICpEP CpE Challenge Mechanics ProgrammingDocument7 pages2018 ICpEP CpE Challenge Mechanics ProgrammingCha FigueroaNo ratings yet

- Resistance To Stress-Corrosion Cracking of Heat-Treatable Aluminum AlloysDocument4 pagesResistance To Stress-Corrosion Cracking of Heat-Treatable Aluminum AlloysJORGE ARTURO TORIBIO HUERTA100% (1)

- Modern CryptographyDocument18 pagesModern CryptographyAmar SawriNo ratings yet

- Venturimeter and Orifice MeterDocument5 pagesVenturimeter and Orifice MeterVrushiket Patil100% (1)

- TJ Dimacali, "From The Sea To The Stars: The Forgotten Journeys of The Philippines' Ancient Explorers"Document30 pagesTJ Dimacali, "From The Sea To The Stars: The Forgotten Journeys of The Philippines' Ancient Explorers"MIT Comparative Media Studies/Writing100% (1)

- IESL Charter PresentationDocument21 pagesIESL Charter PresentationChamin SubhawickramaNo ratings yet

- Product CatalogDocument12 pagesProduct CatalogLe Kim Khoi PhiNo ratings yet

- The Z Transform: Chapter 11Document33 pagesThe Z Transform: Chapter 11santaimenNo ratings yet

- Quiz On Normal DistrributionDocument2 pagesQuiz On Normal Distrributiongulafshan100% (1)

- TIBCO Administrator™: Server Configuration GuideDocument297 pagesTIBCO Administrator™: Server Configuration Guidepankaj somNo ratings yet

- 02-06 Thesis Examples Blackberry 7th HourDocument1 page02-06 Thesis Examples Blackberry 7th Hourapi-228538378No ratings yet

- ZXSS10 Network Design Scheme (LLD) - Template - 361048Document16 pagesZXSS10 Network Design Scheme (LLD) - Template - 361048Mahmoud KarimiNo ratings yet

- Montessori MethodDocument4 pagesMontessori MethodRida ButtNo ratings yet

- Testing of Hypothesis - DPPDocument2 pagesTesting of Hypothesis - DPPnick peakNo ratings yet

- Stakeholder AnalysisDocument5 pagesStakeholder Analysisapi-491761735No ratings yet

- Using The Correct Control LimitsDocument3 pagesUsing The Correct Control LimitsMilton ObandoNo ratings yet

- 01a.supplier Evaluation Form For Raw Material & VendorDocument3 pages01a.supplier Evaluation Form For Raw Material & VendorPurchase RG FibrotechNo ratings yet

- DS LabDocument46 pagesDS LabKamalStarkNo ratings yet

- FALLON 1987 Constructivist Coherence Theory of Constitutional InterpretationDocument99 pagesFALLON 1987 Constructivist Coherence Theory of Constitutional InterpretationcarriewydraNo ratings yet

- Sample Army Risk Assessment FormDocument3 pagesSample Army Risk Assessment FormToufeeq AbrarNo ratings yet

- All About S4Hana CODocument9 pagesAll About S4Hana COPrakash PrakyNo ratings yet

- Keynote Proficient End-Of-Year Test A: Paper 1: Reading and Use of EnglishDocument4 pagesKeynote Proficient End-Of-Year Test A: Paper 1: Reading and Use of EnglishamtenistaNo ratings yet

- Bell Online Modular Delta InformationDocument19 pagesBell Online Modular Delta InformationSarah Gordon0% (1)

- Criteria C B A AD: Score Scale ScoreDocument2 pagesCriteria C B A AD: Score Scale ScoreDanna Valentina Obispo NinaNo ratings yet