Professional Documents

Culture Documents

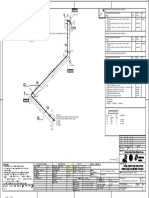

M-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water Return

M-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water Return

Uploaded by

Hesi KusumaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water Return

M-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water Return

Uploaded by

Hesi KusumaCopyright:

Available Formats

FABRICATION MATERIALS STANDARD DETAIL REFERENCE DRAWINGS

N

UP

PT COMPONENT DESCRIPTION N.S. ITEM CODE QTY DETAIL OF HEAVY WELDING BOSSES FOR THREADED CONNECTIONS AE-036175

NO (INS)

AWAY AWAY CONSTRUCTION-NOTES AND DETAILS FOR ISOMETRIC PIPING AD-036627

CONT. ON 1 Pipe , ASME B36.10M , BE , ASTM A106-B , SMLS, FBE LINED, 6 PPPXXPPX0282306 18.9 M INSULATION DETAILS FOR HOT PIPING AA-036911

DWG: CB-767101-004 F5 G12 B13 SCH/THK S-40 INSULATION DETAILS FOR COLD PIPING AA-036913

LINE: 6"-CWR-6634-1LE2W FLANGE JOINT: ABJED0930-F1355

2 Sockolet , MSS SP-97 , CL 3000 , SWE , ASTM B564 (UNS 6X3/4 PPOXXSOC0018766 1 INSTALLATION OF JACK SCREWS FOR FLANGED JOINTS AC-036630

N06625)

TOWARD TOWARD

E 117405 006 NOTES

DOWN N 133656 3 90 Deg. LR Elbow , ASME B16.9 , BW , ASTM A234 Gr. WPB , 6 PPBXXE9L0022530 2 1. MATERIAL SHOWN WITH A BROKEN LINE AND SPOOLS LISTED IN THE SAUDI ARAMCO

EL +27710 SMLS, FBE Lined, SCH/THK S-40 FABRICATION LIST ARE NOT TO BE FURNISHED BY THE VENDOR.

4 Nipple , ASME B36.19M , PE , ASTM B444 (UNS N06625) Gr.1 , 3/4 PPOXXNIP0025686 1 2. PIPING DETAILS SHALL BE CUT AT ALL POINTS MARKED F.W. (FIELD WELD).

4" Long , SMLS, SCH/THK S-40S 3. EACH FABRICATED SECTION SHALL BE CLEARLY MARKED WITH ITS CODE NUMBER.

5 WN Flg. , ASME B16.5 , CL 150 , FF , ASTM A105N , FBE Lined, 6 PPFXXWNX0109498 4 4. UNLESS OTHERWISE NOTED. (A) ALL DIMENSIONS ARE TO CL.OR FACE OF FLANGES.

(B) BOLT HOLES ON FLANGES STRADDLE CL. WELDING ELBOWS ARE LONG RADIUS.

SCH/THK S-40

1

5. FABRICATION SHALL BE IN ACCORDANCE WITH SAUDI ARAMCO SPECIFICATION 01-SAMSS-10.

6"NS

6 WP01-6-400-6 6 WP01 2

<2>

6. GASKET ALLOWANCE 3MM (6MM W/INS GASKET)

3410

7 WP01-6-250-6 6 WP01 1 7. PIPING MATERIAL IS

8 SH09-6-100-350 6 SH09 1 PIPE SIZE SCHEDULE SPECIFICATION

9 SH01-6-100-300 6 SH01 1 6" S-40 1LE2W

S9 10 WP01-6-350-6 6 WP01 1 0.75" S-40S 1LE2W

710

811 KP4BDDB4481

SH01 / ORI=E

8. WELDING STRESS RELIEF- NO

S10 RADIOGRAPHY % 100% X-RAY X SPOT X-RAY 01-SAMSS-10

KP4BDDB4481 9. HYDROSTATIC TEST - YES X NO

WP01 / ORI=E THE SHOP HYDROSTATIC TEST SHALL BE CARRIED OUT ON PIECES HAVING ALL ENDS FLANGED.

HYDROSTATIC TEST PRESSURE 450 (PSIG)

10. ALL PIPING MATERIAL IS IN ACCORDANCE WITH SAUDI ARAMCO ENGINEERING SPECIFICATION SAES-L-105

AND PROJECT PIPE MATERIAL SPECIFICATION DOC. NO. CS-771326, CLASS 1LE2W

ALL EXCEPTIONS ARE NOTED ON THE ISOMETRIC.

11. INSULATION REQUIRED YES NO X

INSULATION SHOWN ON DRAWING NA

12. ALL ELEVATIONS ARE IN MILLIMETERS AND REFER TO THE LOWEST ASTRONOMICAL TIDE (LAT) DATUM.

13. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS UNLESS NOTED OTHERWISE.

5763

14. FW - DENOTES FIELD WELD WITH NO CUTTING ALLOWANCE.

FFW - DENOTES FIELD FIT WELD WITH 75mm CUTTING ALLOWANCE FOR ONSHORE APPLICATION

AND 300mm FOR OFFSHORE. CUTTING ALLOWANCE TO BE ADDED TO THE DIMENSION SHOWN

15. ALL THREADED JOINTS TO BE SEAL WELDED AS PER SAES-L-110 PAR. 9.4

16. WEAR PAD FOR ALL FBE COATED PIPING SHALL BE FULLY WELDED TO PIPE PRIOR TO FBE COATING.

INTERNAL FBE LINING SHALL BE DONE AFTER SPOOL FABRICATION & COMPLETION OF ALL HOT WORKS

S6 ERECTION MATERIALS

17. PLATFORM PREFIX PROVIDED IN ISO IS IN COMPLAINCE WITH INTERNAL MODELLING

KP4ACDB544 PT N.S. GUIDE AND SAME SHALL BE REMOVED BEFORE ASBUILT.

COMPONENT DESCRIPTION ITEM CODE QTY

WP01 / ORI=E NO (INS)

18. THIS DRAWING HAS BEEN CREATED USING A DATA CENTRIC SMARTPLANT 3D SYSTEM AND

DO NOT WELD BOTTOM STOP 11 Plug Round Head , ASME B16.11 , NPT THD , ASTM B564 (UNS 3/4 PPOXXPLR0000587 1 COORDINATES MENTIONED IN THE ISOMETRIC REFERS TO LOCAL PLATFORM GRID COORDINATES

N06625) (REFER EQUIPMENT LAYOUT FOR LOCAL COORDINATES).

12 GASKET , 150# , FF , ASME B16.21 , 1.6 MM THK , SYNTHETIC 6 PPXPGGFF0001078 2 19. NDE & PWHT DETAILS SHOWN IN THE DRAWING ARE BASED ON MAIN LINE SIZE.

NDE & PWHT REQUIREMENTS FOR BRANCHES / ASSOCIATED PIPE SIZES SHALL REFER TO

S8 FIBER APPROVED PROJECT NDE PLAN (DOC.No. D7068-D7394-AOC-QC-004) & APPROVED WPS REPECTIVELY

707 KP4ACDB544 13 STD BLT & 2 HHEX NUT , ASTM A193 GRADE B7 / ASTM A194 GRADE 3/4 PPXPBSB20011972 16 20. PROTECTIVE COATING SYSTEM ONLY SPECIFIED IN THE DRAWING.

SH09 / ORI=E 2H , COATED WITH CERAMIC FLUOROPOLYMER - 105 mm Length FINAL COLOR CODING SHALL BE FOLLOWED BASED ON APPROVED PAINTING PROCEDURE

(D7068-D7394-AOC-QC-049). CS, SS, 6MO AND ALLOY 20 PIPES UNDER SPLASH ZONE

14 Gate Valve , API 602 , CL 800 , SW X THD , Body ASTM B564 3/4 PPXPVGAV0011375 1 SHALL BE PAINTED WITH APCS-19C PAINTING SYSTEM.

808 809 UNS N06625 , HW Op. , BB , Trim Inc 625 + HF , OS&Y 21. PIPE SUPPORT DETAILS REFER PIPE SUPPORT STD.NO. CC-776199-001.

F5 G12 B13

22. INSULATION REQUIREMENTS SHALL BE AS PER CE-776269-001.

ABJED0930-02

23 .THIS NOTE IS APPLICABLE ONLY FOR LINES CONTANING CLAD PUP PIECE IN FBE PIPING.

FLANGE JOINT: ABJED0930-F1356 WHEREVER PWHT IS APPLICABLE, PWHT SHALL BE PERFORMED ON SHOP WELD ONLY.

POST FBE COATING, PWHT SHALL NOT BE PERFORMED ON FIELD WELDS.

1652

24 . BOLT TENSIONING REQUIREMENT SEE DOC.CE-771326-001 PAR. 5.0.

703 704 25 . NACE / HIC SEE DOC.CE-771326-001 APPENDIX-3.

316

705 706 005

3

E 116792

6 REFERENCE DRAWINGS

29 003 DWG CONTROL SHEET FOR J.O.10-12201-0002 CD-761325

004 PIPING PLAN CA-768365-019

007 1 F5

>

P&ID NO. CA-771240-002

<1 HYDROSTATIC TEST DIAGRAM CA-762415-001

8 103

S7 78 102 STRESS REPORT DOCUMENT NO. NA

KP4ACDB542 008

501 2

WP01 / ORI=D 61 6X3/4"NS PRODUCTION PLATFORM

4 BR02-0.75

04 ORI=W/N

45

S6 501

702 14

KP4ACDB540 11 SPINDLE ORI NORTH

WP01 / ORI=D NC

CONT. ON B0 13-FEB-22 ISSUED FOR CONSTRUCTION MKL UW 15/02/22

VALVE RECAP: ABJED0930-V01 IW

DWG: CB-767101-002 REV DATE DESCRIPTION DRN CHK ENG DATE

ABJED0930-01

LINE: 6"-CWR-6634-1LE2W 64

30 CUT PIPE LENGTH

E 108436

P.T. McDERMOTT INDONESIA

N 133656

PT IDENT CODE LNG N.S. E.P. E.P. REMARKS BATAM INDONESIA

EL +17200 NO (MM) (INS)

REVISION VALIDATION

316 F5

701 1 PPPXXPPX0282306 8335 6" BE BE 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

2 PPPXXPPX0282306 10509 6" BE BE

THIS REVISION NO.

001 REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

6"NS 10-12201-0002-661

3 84

JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

68 10-12201-0002 CONSTRUCTION UNTIL CERTIFIED AND DATED

L +1

E SAUDI ARABIAN OIL COMPANY

002

ISOM 6"-CWR-6634-1LE2W

DRAWING TYPE

ISO

COOLING WATER RETURN

ABJED0930-02 GAS OIL SEPARATION PLANT (GOSP-4)

ABJED0930-01

SPOOL NO: MARJAN SAUDI ARABIA

NOTES CONT.: SCALE : NTS SIZE : A3 FACILITY.: MRJN GOSP-4 PP

SCREWED JOINT SPOOL TAG/SPOOL RECAP

SPEC : 1LE2W INST JOB NO.: 64251-B5201

WELD NUMBER PIECE NUMBER

MATERIAL: CS + FBE QTY SPOOL : 2

BUTT WELD/JOINT 1 PARTS LIST No.

WEIGHT: FAB- MAT: EREC - MAT: TOTAL LB Loose M-CB-767101-A-0930-LB MATERIAL COLOR : NO COLOR

SOCKET WELD FLANGE JOINT

Kg 597 2.5 599.5 INSTALL ONSHORE SB Loose M-CB-767101-A-0930-SB PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

INSULATION DESIGN OPERATING TEST TEST MEDIUM INSULATION RADIOGRAPHY % PWHT PAINT SPEC MATERIAL TYPE LINE ID PLATFORM PREFIX

FW

FFW

FIELD WELD

FIELD FIT WELD

TRACED PIPE TEMP. (DEG. F) PRESS. (PSIG) TEMP. (DEG. F) PRESS. (PSIG) PRESS. (PSIG) MEDIUM TYPE Thk (MM) YES / NO CWR-6634-U04 U4-P4-PP 631 L CB-767101 003 00

PIPE SUPPORT PROJECT NO. ISOMETRIC DRAWING NO. SHEET REVISION

OSW OFFSHORE WELD INLINE SUPPORT ATTACHMENT 50/200 200 120 30 450 WATER NA NA 100% NO APCS 1B CS + FBE 6"-CWR-6634-1LE2W D7068 M-CB-767101-A-0930 003 B0

AMIndiarto 2022/02/14

You might also like

- Asme B31.8 Nozzles CalcDocument16 pagesAsme B31.8 Nozzles CalcSAMER OSMANNo ratings yet

- Parts Catalogue Moteur MitsubishiDocument152 pagesParts Catalogue Moteur MitsubishiFedi Klei100% (5)

- M-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Document1 pageM-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Hesi KusumaNo ratings yet

- M-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03Document1 pageM-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03Hesi KusumaNo ratings yet

- C533131003VDocument1 pageC533131003VMohamed Wasim ShaikhNo ratings yet

- R901085037P00Document1 pageR901085037P00Rene HebaNo ratings yet

- TB 661291 001Document1 pageTB 661291 001Khalid OnlyNo ratings yet

- M-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Document1 pageM-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Hesi KusumaNo ratings yet

- R901085036P00Document1 pageR901085036P00Rene HebaNo ratings yet

- Coating FultsDocument4 pagesCoating FultsAhmed BoraeyNo ratings yet

- R901085031P00Document1 pageR901085031P00Rene HebaNo ratings yet

- TB-659651-003 Rev 0F1Document1 pageTB-659651-003 Rev 0F1Khalid OnlyNo ratings yet

- R82-002 - Done 5Document1 pageR82-002 - Done 5rsmjuleyNo ratings yet

- T013482001V0F1Document1 pageT013482001V0F1haseebrazvi1No ratings yet

- Erection Materials: DetailDocument1 pageErection Materials: DetailMohammed Omer AliNo ratings yet

- T013458001V0F1Document1 pageT013458001V0F1haseebrazvi1No ratings yet

- R901085032P00Document1 pageR901085032P00Rene HebaNo ratings yet

- R901085028P00Document1 pageR901085028P00Rene HebaNo ratings yet

- TB-659770-002 Rev 0F1Document1 pageTB-659770-002 Rev 0F1Khalid OnlyNo ratings yet

- T013515002V0F1Document1 pageT013515002V0F1haseebrazvi1No ratings yet

- Notes: M-CB-767101-A-0865 00 004Document1 pageNotes: M-CB-767101-A-0865 00 004Hesi KusumaNo ratings yet

- T013512001V0F1Document1 pageT013512001V0F1haseebrazvi1No ratings yet

- TB-659631-001 Rev 0F2Document1 pageTB-659631-001 Rev 0F2Khalid OnlyNo ratings yet

- T013519001V0F1Document1 pageT013519001V0F1haseebrazvi1No ratings yet

- T013514003V0F1Document1 pageT013514003V0F1haseebrazvi1No ratings yet

- Piping IsometricDocument1 pagePiping IsometricAshish JagtapNo ratings yet

- T013482002V0F1Document1 pageT013482002V0F1haseebrazvi1No ratings yet

- T013514004V0F1Document1 pageT013514004V0F1haseebrazvi1No ratings yet

- T013461001V0F1Document1 pageT013461001V0F1haseebrazvi1No ratings yet

- 01Document1 page01Reno Reza GumilangNo ratings yet

- 4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Document1 page4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- South Refineries Company: Basrah Refinery Upgrading Project ProjectDocument5 pagesSouth Refineries Company: Basrah Refinery Upgrading Project ProjectBasem AlsaftliNo ratings yet

- Profile RT 21-060-004Document4 pagesProfile RT 21-060-004Marcus AntoniusNo ratings yet

- 1/1 P055AZOR-05P00-1353-51 A A-2: 3c 248 HV 10 Shop ASME B31.3Document1 page1/1 P055AZOR-05P00-1353-51 A A-2: 3c 248 HV 10 Shop ASME B31.3Deshwa SaravananNo ratings yet

- SCM Sof Smop 56 Is 0321 0210 - 26110210 - 01Document1 pageSCM Sof Smop 56 Is 0321 0210 - 26110210 - 01Reno Reza GumilangNo ratings yet

- NA2159Document2 pagesNA2159Bogdan RusuNo ratings yet

- 4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Document2 pages4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- PL +6734 PL +7057: Issued For ConstructionDocument1 pagePL +6734 PL +7057: Issued For Constructionadisus1515No ratings yet

- 01Document1 page01Reno Reza GumilangNo ratings yet

- D43 P 11004 21 - Rev02fDocument1 pageD43 P 11004 21 - Rev02fSajeed ZaheerNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- Lista de Materiales: Item Diam Cant DescripcionDocument1 pageLista de Materiales: Item Diam Cant DescripcionMarcia IturraNo ratings yet

- JI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1Document1 pageJI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1weerachai phosoongNo ratings yet

- 3 Conn. To 306F-851A/TSTCR2 2 in RFFE 300 G1 B2 SA1 306TEDocument1 page3 Conn. To 306F-851A/TSTCR2 2 in RFFE 300 G1 B2 SA1 306TESunil Kumar GuptaNo ratings yet

- Piping List, Line Sizing and Tie-In Point...Document2 pagesPiping List, Line Sizing and Tie-In Point...Hiếu Nguyên100% (2)

- U22 Valve List 2 - April 2024 (3 Units)Document3 pagesU22 Valve List 2 - April 2024 (3 Units)Mohd Effiezool YaserNo ratings yet

- F001.ang10.wp513 3 01SS001 N 0001Document1 pageF001.ang10.wp513 3 01SS001 N 0001Reno Reza GumilangNo ratings yet

- Bill of Materials: RDMP Ru V Balikpapan RDMP Balikpapan JoDocument1 pageBill of Materials: RDMP Ru V Balikpapan RDMP Balikpapan JoRiyadiNo ratings yet

- 26-000-2-02-00001 FL 581574-1-R01-ModelDocument1 page26-000-2-02-00001 FL 581574-1-R01-ModelMartinAlexisGonzálezVidalNo ratings yet

- Kenwood krc-335 365 465 565Document18 pagesKenwood krc-335 365 465 565Lan HoangNo ratings yet

- StanadyneDocument1 pageStanadyneJunior IungNo ratings yet

- SF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsDocument2 pagesSF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsSENTHILNo ratings yet

- Bill of Materials N N: 4 1C1W ATM AMB 3.5 65 - V - A N 5Document1 pageBill of Materials N N: 4 1C1W ATM AMB 3.5 65 - V - A N 5chandraditya firmansyahNo ratings yet

- SCM Sof Smop 56 Is 0321 0211 - 26110211 - 01Document1 pageSCM Sof Smop 56 Is 0321 0211 - 26110211 - 01Reno Reza GumilangNo ratings yet

- C254977001P Rev01cDocument1 pageC254977001P Rev01cRAJA MOHD IRFAN KHANNo ratings yet

- KAAR COW PW IC NTU FZS DWG STR 24622 Rev.01 PDFDocument1 pageKAAR COW PW IC NTU FZS DWG STR 24622 Rev.01 PDFSatyanarayana MukkuNo ratings yet

- SCM Sof Smop 56 Is 0323 0001 - 61030001 - 01Document1 pageSCM Sof Smop 56 Is 0323 0001 - 61030001 - 01Reno Reza GumilangNo ratings yet

- Bill of Materials N NDocument1 pageBill of Materials N Nchandraditya firmansyahNo ratings yet

- Pipe Support: 1. Paddle Flange Detail 8. 1 EA: Bill of MaterialsDocument1 pagePipe Support: 1. Paddle Flange Detail 8. 1 EA: Bill of MaterialscostonzNo ratings yet

- Planos Electricos Invertex 2 Serie 31875 UpDocument23 pagesPlanos Electricos Invertex 2 Serie 31875 UpHéctorHernándezDíazNo ratings yet

- Shaper CuttersDocument79 pagesShaper CuttersMickloSoberanNo ratings yet

- Technical Article: Above Weights Are As Per Clause 5.2 of IS 1786 1985Document1 pageTechnical Article: Above Weights Are As Per Clause 5.2 of IS 1786 1985abou bakarNo ratings yet

- Tech QuizDocument12 pagesTech QuizKamasani PraveenaNo ratings yet

- MCI Price List 2017Document4 pagesMCI Price List 2017Saurabh DangariaNo ratings yet

- Industrial Ball Valve Price Sheet 12-18-20Document33 pagesIndustrial Ball Valve Price Sheet 12-18-20John Cally PrudenteNo ratings yet

- Assign - 6 - Chemical Formulae, Equations, Calculations 1 QPDocument2 pagesAssign - 6 - Chemical Formulae, Equations, Calculations 1 QPDiya JNo ratings yet

- Plano Hidraulico 329D PDFDocument10 pagesPlano Hidraulico 329D PDFJhonVictorNo ratings yet

- SSV&ESD Control System ManualDocument24 pagesSSV&ESD Control System Manualmostefa brahimi100% (2)

- Meyer Attatchment Parts Catalogue 6-5206n - 156153 - V1Document23 pagesMeyer Attatchment Parts Catalogue 6-5206n - 156153 - V1ПетрNo ratings yet

- 021-QUOT-WSG-XI-2022-Mitra Terminal Kaltim (Magnetic Separator&Metal D)Document2 pages021-QUOT-WSG-XI-2022-Mitra Terminal Kaltim (Magnetic Separator&Metal D)dprakoso79No ratings yet

- Mill Test Certificate: 7.00 MM 3-Phase Chevron Indented P.C Single Wire, Low RelaxationDocument1 pageMill Test Certificate: 7.00 MM 3-Phase Chevron Indented P.C Single Wire, Low RelaxationJun Xian WaiNo ratings yet

- EOS00870Document1 pageEOS00870Sirleh SalehNo ratings yet

- Common Tools and ProcessesDocument16 pagesCommon Tools and Processesメルヴリッ クズルエタNo ratings yet

- Machine Design - Kulkarni Sir Classroom NotesDocument84 pagesMachine Design - Kulkarni Sir Classroom NotesIKA ASTHANo ratings yet

- AK025 COMPELTAMIENTORUNNINGBESCorrida 18 JULDocument7 pagesAK025 COMPELTAMIENTORUNNINGBESCorrida 18 JULIvan Ricardo CarballoNo ratings yet

- CONTI Leandro A PDFDocument3 pagesCONTI Leandro A PDFJethro PalmaNo ratings yet

- Instruction Manual HV2-210 PDFDocument36 pagesInstruction Manual HV2-210 PDFHilario Gastala Jr.100% (1)

- 7 Global Golden Rules of Safety - Rule 4 - Machinery & Rotary Part Protection - DraftDocument7 pages7 Global Golden Rules of Safety - Rule 4 - Machinery & Rotary Part Protection - DraftPedro ViegasNo ratings yet

- Iso 5752 2021Document13 pagesIso 5752 2021Santiago RodaNo ratings yet

- BoqDocument45 pagesBoqShabbir OsmaniNo ratings yet

- Parts Catalogue For Professional Embroidery Machine PR600 PR600 CDocument43 pagesParts Catalogue For Professional Embroidery Machine PR600 PR600 CcinthiaNo ratings yet

- PlanoDocument1 pagePlanoYosmell Fritzan Paz UrbizagasteguiNo ratings yet

- Installation Instruction E-Slide E-Straight Crossing 2021-03Document2 pagesInstallation Instruction E-Slide E-Straight Crossing 2021-03Dan STEFANNo ratings yet

- Esquema D9T - (Power Train System) (Interactive)Document14 pagesEsquema D9T - (Power Train System) (Interactive)DavidNo ratings yet

- Saph 440Document1 pageSaph 440rinkumax2003100% (1)

- HWZ220 XCVB 0 EngDocument2 pagesHWZ220 XCVB 0 EngnejibNo ratings yet

- ARTCO QuoteDocument5 pagesARTCO QuoteAravind AravindNo ratings yet

- Suburban Tractor: Here's What It CostsDocument11 pagesSuburban Tractor: Here's What It CostsWojtek WywiałNo ratings yet