Professional Documents

Culture Documents

Notes: M-CB-767101-A-0865 00 004

Notes: M-CB-767101-A-0865 00 004

Uploaded by

Hesi KusumaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Notes: M-CB-767101-A-0865 00 004

Notes: M-CB-767101-A-0865 00 004

Uploaded by

Hesi KusumaCopyright:

Available Formats

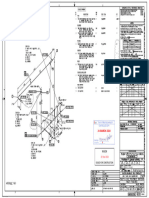

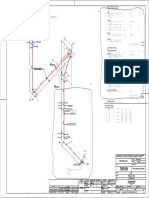

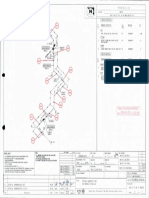

UP

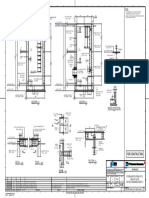

FABRICATION MATERIALS STANDARD DETAIL REFERENCE DRAWINGS

N PT

NO

COMPONENT DESCRIPTION N.S.

(INS)

ITEM CODE QTY DETAIL OF HEAVY WELDING BOSSES FOR THREADED CONNECTIONS AE-036175

AWAY AWAY CONSTRUCTION-NOTES AND DETAILS FOR ISOMETRIC PIPING AD-036627

1 Pipe , ASME B36.10M , BE , ASTM A106-B , SMLS, FBE LINED, 6 PPPXXPPX0282306 20.9 M INSULATION DETAILS FOR HOT PIPING AA-036911

SCH/THK S-40 INSULATION DETAILS FOR COLD PIPING AA-036913

2 90 Deg. LR Elbow , ASME B16.9 , BW , ASTM A234 Gr. WPB , 6 PPBXXE9L0022530 3 INSTALLATION OF JACK SCREWS FOR FLANGED JOINTS AC-036630

SMLS, FBE Lined, SCH/THK S-40

TOWARD TOWARD

NOTES

DOWN

3 45 Deg. LR Elbow , ASME B16.9 , BW , ASTM A234 Gr. WPB , 6 PPBXXE4L0021875 1 1. MATERIAL SHOWN WITH A BROKEN LINE AND SPOOLS LISTED IN THE SAUDI ARAMCO

SMLS, FBE Lined, SCH/THK S-40 FABRICATION LIST ARE NOT TO BE FURNISHED BY THE VENDOR.

4 WN Flg. , ASME B16.5 , CL 150 , FF , ASTM A105N , FBE Lined, 6 PPFXXWNX0109498 8 2. PIPING DETAILS SHALL BE CUT AT ALL POINTS MARKED F.W. (FIELD WELD).

SCH/THK S-40 3. EACH FABRICATED SECTION SHALL BE CLEARLY MARKED WITH ITS CODE NUMBER.

5 WP01-6-250-6 6 WP01 3 4. UNLESS OTHERWISE NOTED. (A) ALL DIMENSIONS ARE TO CL.OR FACE OF FLANGES.

(B) BOLT HOLES ON FLANGES STRADDLE CL. WELDING ELBOWS ARE LONG RADIUS.

6 SH01-6-100-300 6 SH01 1 5. FABRICATION SHALL BE IN ACCORDANCE WITH SAUDI ARAMCO SPECIFICATION 01-SAMSS-10.

7 WP01-6-350-6 6 WP01 3 6. GASKET ALLOWANCE 3MM (6MM W/INS GASKET)

8 SH09-6-100-350 6 SH09 2 7. PIPING MATERIAL IS

PIPE SIZE SCHEDULE SPECIFICATION

6" S-40 1LE2W

NO

S5 6 8. WELDING STRESS RELIEF-

02

90 28 RADIOGRAPHY % 100% X-RAY X SPOT X-RAY 01-SAMSS-10

KP4BDDB4251 13 E L+ 9. HYDROSTATIC TEST - YES X NO

WP01 / ORI=D THE SHOP HYDROSTATIC TEST SHALL BE CARRIED OUT ON PIECES HAVING ALL ENDS FLANGED.

002 2

6"NS HYDROSTATIC TEST PRESSURE 450 (PSIG)

99

FLANGE JOINT: ABJDD0865-F1271 44 001 10. ALL PIPING MATERIAL IS IN ACCORDANCE WITH SAUDI ARAMCO ENGINEERING SPECIFICATION SAES-L-105

AND PROJECT PIPE MATERIAL SPECIFICATION DOC. NO. CS-771326, CLASS 1LE2W

F4 316 ALL EXCEPTIONS ARE NOTED ON THE ISOMETRIC.

S7 11. INSULATION REQUIRED YES NO X

32 CONT. ON

F4 G9 B10 24 DWG: CB-767101-003

INSULATION SHOWN ON DRAWING NA

KP4BDDB3536 12. ALL ELEVATIONS ARE IN MILLIMETERS AND REFER TO THE LOWEST ASTRONOMICAL TIDE (LAT) DATUM.

WP01 / ORI=D LINE: 6"-CWR-6634-1LE2W

701 13. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS UNLESS NOTED OTHERWISE.

1 E 117405

97 > 14. FW - DENOTES FIELD WELD WITH NO CUTTING ALLOWANCE.

13 <1 N 133656 FFW - DENOTES FIELD FIT WELD WITH 75mm CUTTING ALLOWANCE FOR ONSHORE APPLICATION

S8 EL +27710 AND 300mm FOR OFFSHORE. CUTTING ALLOWANCE TO BE ADDED TO THE DIMENSION SHOWN

KP4BDDA4396 003 15. ALL THREADED JOINTS TO BE SEAL WELDED AS PER SAES-L-110 PAR. 9.4

702

SH09 / ORI=D 16. WEAR PAD FOR ALL FBE COATED PIPING SHALL BE FULLY WELDED TO PIPE PRIOR TO FBE COATING.

F4 INTERNAL FBE LINING SHALL BE DONE AFTER SPOOL FABRICATION & COMPLETION OF ALL HOT WORKS

85

1 703 004 ABJDD0865-01 ERECTION MATERIALS

3 S5 17. PLATFORM PREFIX PROVIDED IN ISO IS IN COMPLAINCE WITH INTERNAL MODELLING

PT COMPONENT DESCRIPTION N.S. ITEM CODE QTY GUIDE AND SAME SHALL BE REMOVED BEFORE ASBUILT.

804 ABJDD0865-02 KP4BDDA2422 NO (INS)

18. THIS DRAWING HAS BEEN CREATED USING A DATA CENTRIC SMARTPLANT 3D SYSTEM AND

WP01 / ORI=D 9 GASKET , 150# , FF , ASME B16.21 , 1.6 MM THK , SYNTHETIC 6 PPXPGGFF0001078 3 COORDINATES MENTIONED IN THE ISOMETRIC REFERS TO LOCAL PLATFORM GRID COORDINATES

S7 S6 FIBER (REFER EQUIPMENT LAYOUT FOR LOCAL COORDINATES).

18 10 STD BLT & 2 HHEX NUT , ASTM A193 GRADE B7 / ASTM A194 GRADE 3/4 PPXPBSB20011972 24

KP4BDDA2424 38 KP4BDDB3536

19. NDE & PWHT DETAILS SHOWN IN THE DRAWING ARE BASED ON MAIN LINE SIZE.

707 NDE & PWHT REQUIREMENTS FOR BRANCHES / ASSOCIATED PIPE SIZES SHALL REFER TO

WP01 / ORI=D 806 SH01 / ORI=D 2H , COATED WITH CERAMIC FLUOROPOLYMER - 105 mm Length APPROVED PROJECT NDE PLAN (DOC.No. D7068-D7394-AOC-QC-004) & APPROVED WPS REPECTIVELY

20. PROTECTIVE COATING SYSTEM ONLY SPECIFIED IN THE DRAWING.

8 808 FINAL COLOR CODING SHALL BE FOLLOWED BASED ON APPROVED PAINTING PROCEDURE

91 705 (D7068-D7394-AOC-QC-049). CS, SS, 6MO AND ALLOY 20 PIPES UNDER SPLASH ZONE

S7 SHALL BE PAINTED WITH APCS-19C PAINTING SYSTEM.

KP4BDDA4396 21. PIPE SUPPORT DETAILS REFER PIPE SUPPORT STD.NO. CC-776199-001.

1

005 > S8 WP01 / ORI=D 22. INSULATION REQUIREMENTS SHALL BE AS PER CE-776269-001.

<2 3

16 KP4BDDA2424 23 .THIS NOTE IS APPLICABLE ONLY FOR LINES CONTANING CLAD PUP PIECE IN FBE PIPING.

2 006 WHEREVER PWHT IS APPLICABLE, PWHT SHALL BE PERFORMED ON SHOP WELD ONLY.

007 SH09 / ORI=D POST FBE COATING, PWHT SHALL NOT BE PERFORMED ON FIELD WELDS.

FLANGE JOINT: ABJDD0865-F1272 10 24 . BOLT TENSIONING REQUIREMENT SEE DOC.CE-771326-001 PAR. 5.0.

<3 43 25 . NACE / HIC SEE DOC.CE-771326-001 APPENDIX-3.

F4 >

1

F4 G9 B10 6 009

S5 31

KP4BDDB4178 ABJDD0865-03

008 REFERENCE DRAWINGS

WP01 / ORI=D 1 2

96 010 DWG CONTROL SHEET FOR J.O.10-12201-0002 CD-761325

F4 PIPING PLAN CA-768365-019

FLANGE JOINT: ABJDD0865-F1273 P&ID NO. CA-771240-002

3 8 HYDROSTATIC TEST DIAGRAM CA-762415-001

1 50 F4 G9 B10

45.0° 1

> STRESS REPORT DOCUMENT NO. NA

<4 ABJDD0865-04

709

PRODUCTION PLATFORM

2

012

33

235

<5> 1 011

6"NS 013

235

F4 14.02.22

B0 10-FEB-22 ISSUED FOR CONSTRUCTION SM

CONT. ON REV DATE DESCRIPTION DRN CHK ENG DATE

DWG: CB-763095-001

LINE: 12"-CWR-6629-1LE2W CUT PIPE LENGTH

E 96077

P.T. McDERMOTT INDONESIA

PT IDENT CODE LNG N.S. E.P. E.P. REMARKS BATAM INDONESIA

N 132295 NO (MM) (INS)

EL +27791 REVISION VALIDATION

1 PPPXXPPX0282306 8005 6" BE BE 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

2 PPPXXPPX0282306 9668 6" BE BE

THIS REVISION NO.

REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

3 PPPXXPPX0282306 728 6" BE BE 10-12201-0002- 661

4 PPPXXPPX0282306 2287 6" BE BE

5 PPPXXPPX0282306 150 6" BE BE

JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

10-12201-0002 CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

ISOM 6"-CWR-6634-1LE2W

DRAWING TYPE

ISO

ABJDD0865-04

ABJDD0865-03 COOLING WATER RETURN

ABJDD0865-02 GAS OIL SEPARATION PLANT (GOSP-4)

ABJDD0865-01

SPOOL NO: MARJAN SAUDI ARABIA

NOTES CONT.: SCALE : NTS SIZE : A3 FACILITY.: MRJN GOSP-4 PP

SCREWED JOINT SPOOL TAG/SPOOL RECAP

SPEC : 1LE2W INST JOB NO.: 64251-B5201

WELD NUMBER PIECE NUMBER

MATERIAL: CS + FBE QTY SPOOL : 4

BUTT WELD/JOINT 1 PARTS LIST No.

WEIGHT: FAB- MAT: EREC - MAT: TOTAL LB Loose M-CB-767101-A-0865-LB MATERIAL COLOR : NO COLOR

SOCKET WELD FLANGE JOINT

Kg 714.2 714.2 INSTALL ONSHORE SB Loose PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

INSULATION DESIGN OPERATING TEST TEST MEDIUM INSULATION RADIOGRAPHY % PWHT PAINT SPEC MATERIAL TYPE LINE ID PLATFORM PREFIX

FW

FFW

FIELD WELD

FIELD FIT WELD

TRACED PIPE TEMP. (DEG. F) PRESS. (PSIG) TEMP. (DEG. F) PRESS. (PSIG) PRESS. (PSIG) MEDIUM TYPE Thk (MM) YES / NO CWR-6634-U04 U4-P4-PP 631 L CB-767101 004 00

PIPE SUPPORT PROJECT NO. ISOMETRIC DRAWING NO. SHEET REVISION

OSW OFFSHORE WELD INLINE SUPPORT ATTACHMENT 50/200 200 120 30 450 WATER NA NA 100% NO APCS 1B CS + FBE 6"-CWR-6634-1LE2W D7068 M-CB-767101-A-0865 004 B0

ssuhaimi 2022/02/10

1

You might also like

- Haier in India Building Presence in A Mass Market Beyond ChinaDocument14 pagesHaier in India Building Presence in A Mass Market Beyond ChinaArun Kumar80% (5)

- R82-002 - Done 5Document1 pageR82-002 - Done 5rsmjuleyNo ratings yet

- R901085032P00Document1 pageR901085032P00Rene HebaNo ratings yet

- R901085028P00Document1 pageR901085028P00Rene HebaNo ratings yet

- R901085031P00Document1 pageR901085031P00Rene HebaNo ratings yet

- R901085036P00Document1 pageR901085036P00Rene HebaNo ratings yet

- R901085037P00Document1 pageR901085037P00Rene HebaNo ratings yet

- D43 P 11004 21 - Rev02fDocument1 pageD43 P 11004 21 - Rev02fSajeed ZaheerNo ratings yet

- C254977001P Rev01cDocument1 pageC254977001P Rev01cRAJA MOHD IRFAN KHANNo ratings yet

- M-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Document1 pageM-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Hesi KusumaNo ratings yet

- SF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsDocument2 pagesSF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsSENTHILNo ratings yet

- M-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Document1 pageM-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Hesi KusumaNo ratings yet

- Bill of Materials: Standard Detail Reference DrawingsDocument8 pagesBill of Materials: Standard Detail Reference Drawingsadeelaslam1211No ratings yet

- M-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03Document1 pageM-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03Hesi KusumaNo ratings yet

- SF6-A-100-450-100-6-CS: Bill of MaterialsDocument7 pagesSF6-A-100-450-100-6-CS: Bill of MaterialsSENTHILNo ratings yet

- T013482002V0F1Document1 pageT013482002V0F1haseebrazvi1No ratings yet

- Bill of Materials: Standard Detail Reference DrawingsDocument11 pagesBill of Materials: Standard Detail Reference DrawingsSENTHILNo ratings yet

- Coating FultsDocument4 pagesCoating FultsAhmed BoraeyNo ratings yet

- Mark Up Priority 5Document11 pagesMark Up Priority 5SAGARNo ratings yet

- T013512001V0F1Document1 pageT013512001V0F1haseebrazvi1No ratings yet

- C533131003VDocument1 pageC533131003VMohamed Wasim ShaikhNo ratings yet

- M-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water ReturnDocument1 pageM-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water ReturnHesi KusumaNo ratings yet

- BB 016304 001Document1 pageBB 016304 001Abir MohdNo ratings yet

- T013514004V0F1Document1 pageT013514004V0F1haseebrazvi1No ratings yet

- HS372221 26 Pip Iso 0168 0000 1 - Rm01aDocument1 pageHS372221 26 Pip Iso 0168 0000 1 - Rm01aibrahim qasimovNo ratings yet

- Axens Technip India Ltd. Mumbai, India.: Bill of MaterialDocument9 pagesAxens Technip India Ltd. Mumbai, India.: Bill of MaterialSiddhu DudwadkarNo ratings yet

- Appendix IDocument6 pagesAppendix IkarthickmectrNo ratings yet

- Fabrication Materials: Saudi Arabian Oil CompanyDocument8 pagesFabrication Materials: Saudi Arabian Oil CompanyD7mey XNo ratings yet

- PipelineDocument9 pagesPipelineRhoteram VikkuNo ratings yet

- State Highway FEDERAL AID PROJECT NO. STBG-9999-07 (384) : Plan and Profile of ProposedDocument66 pagesState Highway FEDERAL AID PROJECT NO. STBG-9999-07 (384) : Plan and Profile of Proposedcharles blairNo ratings yet

- BLDG PlanDocument1 pageBLDG PlanMax BenizaNo ratings yet

- Tupi BV: Cosco (Dalian)Document3 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Piping Isometric - 7Document1 pagePiping Isometric - 7CosminMarianNo ratings yet

- Eastern Avenue Plans at 90 PercentDocument170 pagesEastern Avenue Plans at 90 PercentDistrict Department of TransportationNo ratings yet

- Tal Wsa PNG Iso 1P020807 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1P020807 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- Tupi BV: Cosco (Dalian)Document3 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Ms DD 4850 Civ DWG 0403 - Rev0Document1 pageMs DD 4850 Civ DWG 0403 - Rev0Dita Ardi NNo ratings yet

- T013515002V0F1Document1 pageT013515002V0F1haseebrazvi1No ratings yet

- Pages From AMDP01LP2100 Rev01 CommentsDocument1 pagePages From AMDP01LP2100 Rev01 CommentsOkas PaskalNo ratings yet

- PRDDocument1 pagePRDChetan PatilNo ratings yet

- Bill of Materials: 331U15-OWS-002-02-1Document1 pageBill of Materials: 331U15-OWS-002-02-1PT Bumi Liputan PusakaNo ratings yet

- GAS-TECH Engineering Services LTDDocument1 pageGAS-TECH Engineering Services LTDMustafaNo ratings yet

- Tupi BV: Cosco (Dalian)Document4 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- 172 I1909e 000 46 DW 0109Document2 pages172 I1909e 000 46 DW 0109Jose Carlos Moraga LópezNo ratings yet

- 12lba52br002 Rev0Document1 page12lba52br002 Rev0ruralashishNo ratings yet

- 20GHB20-BR001-03 Rev0 0001 240426 141615Document2 pages20GHB20-BR001-03 Rev0 0001 240426 141615philippeballina2810No ratings yet

- Visio-GT-STELL CALENDER PDFDocument140 pagesVisio-GT-STELL CALENDER PDFRobi Muklis AlimudinNo ratings yet

- T013482001V0F1Document1 pageT013482001V0F1haseebrazvi1No ratings yet

- Tal Wsa PNG Iso 1SF058302 - 01 - A01 - 00Document1 pageTal Wsa PNG Iso 1SF058302 - 01 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- Angloamerican: 0 Ec Emitido para Construccion JGM 06-Sep-19Document1 pageAngloamerican: 0 Ec Emitido para Construccion JGM 06-Sep-19Pedro ChaucaNo ratings yet

- Prefabricación Tubería, MontajeDocument26 pagesPrefabricación Tubería, MontajeGilberto Montiel CornelioNo ratings yet

- 01 - General Tracker-1Document4 pages01 - General Tracker-1MAGED ELSADIGNo ratings yet

- 115V Bus Section Cb-A601 Protn. Panel: B P EA-381703 HA556 3-1313003.05 4400004657Document1 page115V Bus Section Cb-A601 Protn. Panel: B P EA-381703 HA556 3-1313003.05 4400004657Anonymous BZQOJwWIh6No ratings yet

- Mosaic Townhomes MapDocument1 pageMosaic Townhomes MapPatricia May Valente CarayapNo ratings yet

- T013519001V0F1Document1 pageT013519001V0F1haseebrazvi1No ratings yet

- Desarea: L84M04: Cont. OnDocument1 pageDesarea: L84M04: Cont. Onrumahorbo1974No ratings yet

- Job No. 26418: CollahuasiDocument1 pageJob No. 26418: Collahuasicutcnc.concepcionNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe Length, Add Detail Support As Per Site ConditionsDocument1 pageReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe Length, Add Detail Support As Per Site ConditionsNguyenCanhBaoNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthDocument2 pagesReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthNguyenCanhBaoNo ratings yet

- 036909C 2BPR01 Iso SCS 23252 01 1S4 CDocument3 pages036909C 2BPR01 Iso SCS 23252 01 1S4 CNguyenCanhBaoNo ratings yet

- Final Stilt Floor Plan 16042022Document1 pageFinal Stilt Floor Plan 16042022rajesh lankaNo ratings yet

- Case Digests in PropertyDocument95 pagesCase Digests in PropertyRemelyn SeldaNo ratings yet

- 1 Measurement 2020 ModuleDocument16 pages1 Measurement 2020 ModuleNajibah AtiqahNo ratings yet

- Lisa Olle Declaration in SupportDocument5 pagesLisa Olle Declaration in SupportMikey CampbellNo ratings yet

- Senator Jinggoy Ejercito EstradaDocument7 pagesSenator Jinggoy Ejercito EstradaNatsudeeNo ratings yet

- Concrete Mixer Machine TSCM-260 RichonDocument7 pagesConcrete Mixer Machine TSCM-260 RichonAngin MalamNo ratings yet

- Procedure For HORCM and RAIDCOMDocument4 pagesProcedure For HORCM and RAIDCOMdennisNo ratings yet

- Read The Following Text and Answer The QuestionsDocument10 pagesRead The Following Text and Answer The QuestionsNixon RestrepoNo ratings yet

- Moves That Make You Feel Great: Calf Stretch Chair SquatDocument2 pagesMoves That Make You Feel Great: Calf Stretch Chair Squatnotsosafe89No ratings yet

- Nomad SchoolDocument10 pagesNomad SchoolERUA HACKATHONNo ratings yet

- Power System Protection - Part 07Document10 pagesPower System Protection - Part 07shashikant yadavNo ratings yet

- Regents Cells and Human BodyDocument8 pagesRegents Cells and Human Bodyapi-303120399No ratings yet

- Lector Aspergillus LFARDR IFU - EnglishDocument2 pagesLector Aspergillus LFARDR IFU - EnglishMelissa MelendezNo ratings yet

- Safety, Efficacy, and Mechanisms of Action of Cannabinoids in Neurological Disorders.Document9 pagesSafety, Efficacy, and Mechanisms of Action of Cannabinoids in Neurological Disorders.Sindy Licette PiñeroNo ratings yet

- 09 PDFDocument20 pages09 PDFEr R K MehtaNo ratings yet

- Soap and DetergentsDocument19 pagesSoap and DetergentsChewy Choco100% (1)

- Spesifikasi Produk - Yumizen H500Document1 pageSpesifikasi Produk - Yumizen H500Dexa Arfindo PratamaNo ratings yet

- 7th History Workbook English Medium Maharashtra BoardDocument12 pages7th History Workbook English Medium Maharashtra Boardpankarvi6100% (1)

- Introduction To Finance Markets Investments and Financial Management 15th Edition Melicher Norton Solution ManualDocument19 pagesIntroduction To Finance Markets Investments and Financial Management 15th Edition Melicher Norton Solution ManualberthaNo ratings yet

- Wiley American Anthropological AssociationDocument3 pagesWiley American Anthropological AssociationSimeon Pol'shinNo ratings yet

- Math10 SLHT, Q3, WK8, M10SP-IIIg-h-1Document7 pagesMath10 SLHT, Q3, WK8, M10SP-IIIg-h-1Justiniano SalicioNo ratings yet

- Curriculum Vitae of Supramaniyan KumarDocument4 pagesCurriculum Vitae of Supramaniyan KumarSupramaniyan kumarNo ratings yet

- OPT B1plus U09 Grammar HigherDocument1 pageOPT B1plus U09 Grammar HigherJacobo GutierrezNo ratings yet

- Catalyst Ie3100 Rugged Series DsDocument20 pagesCatalyst Ie3100 Rugged Series Ds吳竣民No ratings yet

- RSTWS LTE Market View CMW500 Communication Test FunctionDocument131 pagesRSTWS LTE Market View CMW500 Communication Test FunctionHong ShanNo ratings yet

- Saudi Aramco Typical Inspection Plan: Cross Country Buried Pipeline (Mainline) SATIP-L-450-04 3-Jul-18 MechanicalDocument12 pagesSaudi Aramco Typical Inspection Plan: Cross Country Buried Pipeline (Mainline) SATIP-L-450-04 3-Jul-18 Mechanicalkarthi51289No ratings yet

- Work Shop Practice-Ii: Diploma in Mechanical EngineeringDocument36 pagesWork Shop Practice-Ii: Diploma in Mechanical EngineeringLEAGUE OF WARLORDSNo ratings yet

- T5ax6f 5CR7Document1 pageT5ax6f 5CR7HannOtto Store0% (1)

- Akashic Brotherhood 4 PrintDocument33 pagesAkashic Brotherhood 4 Printmdamascus75643No ratings yet