Professional Documents

Culture Documents

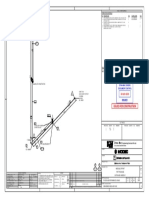

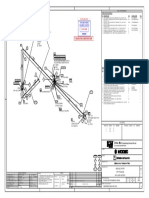

M-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03

M-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03

Uploaded by

Hesi KusumaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03

M-CB-767102-A-1800 00 001 CB-767102: Gas Oil Separation Plant (Gosp-4) ABAEA1800-01 ABAEA1800-02 ABAEA1800-03

Uploaded by

Hesi KusumaCopyright:

Available Formats

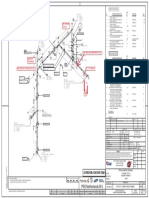

FABRICATION MATERIALS STANDARD DETAIL REFERENCE DRAWINGS

N

UP

PT COMPONENT DESCRIPTION N.S. ITEM CODE QTY DETAIL OF HEAVY WELDING BOSSES FOR THREADED CONNECTIONS AE-036175

NO (INS)

AWAY AWAY CONSTRUCTION-NOTES AND DETAILS FOR ISOMETRIC PIPING AD-036627

1 Pipe , ASME B36.10M , BE , ASTM A106-B , SMLS, SCH/THK S-80 2 PPPXXPPX0036985 1.0 M INSULATION DETAILS FOR HOT PIPING AA-036911

2 Red. Tee , ASME B16.9 , BW , ASTM A234 Gr. WPB , SMLS, 2X1 PPBXXTER0027074 1 INSULATION DETAILS FOR COLD PIPING AA-036913

SCH/THK S-80 x S-80 INSTALLATION OF JACK SCREWS FOR FLANGED JOINTS AC-036630

3 90 Deg. LR Elbow , ASME B16.9 , BW , ASTM A234 Gr. WPB , 2 PPBXXE9L0014145 1

TOWARD TOWARD

NOTES

DOWN

SMLS, SCH/THK S-80 1. MATERIAL SHOWN WITH A BROKEN LINE AND SPOOLS LISTED IN THE SAUDI ARAMCO

4 WN Flg. , ASME B16.5 , CL 150 , RF , ASTM A105N, SCH/THK 2 PPFXXWNX0105110 5 FABRICATION LIST ARE NOT TO BE FURNISHED BY THE VENDOR.

S-80 2. PIPING DETAILS SHALL BE CUT AT ALL POINTS MARKED F.W. (FIELD WELD).

5 WP01-2-150-5.54 2 WP01 2 3. EACH FABRICATED SECTION SHALL BE CLEARLY MARKED WITH ITS CODE NUMBER.

4. UNLESS OTHERWISE NOTED. (A) ALL DIMENSIONS ARE TO CL.OR FACE OF FLANGES.

(B) BOLT HOLES ON FLANGES STRADDLE CL. WELDING ELBOWS ARE LONG RADIUS.

5. FABRICATION SHALL BE IN ACCORDANCE WITH SAUDI ARAMCO SPECIFICATION 01-SAMSS-10.

6. GASKET ALLOWANCE 3MM (6MM W/INS GASKET)

CONT. ON

7. PIPING MATERIAL IS

DWG: CB-763079-003

LINE: 2"-FO-6922-1CS2P PIPE SIZE SCHEDULE SPECIFICATION

E 150463 2" S-80 1CS2P

N 164032

EL +14695

2"NS

8. WELDING STRESS RELIEF- NO

3

RADIOGRAPHY % 100% X-RAY X SPOT X-RAY 01-SAMSS-10

25 9. HYDROSTATIC TEST - YES X NO

2X2"NS THE SHOP HYDROSTATIC TEST SHALL BE CARRIED OUT ON PIECES HAVING ALL ENDS FLANGED.

HYDROSTATIC TEST PRESSURE 450 (PSIG)

S5 10. ALL PIPING MATERIAL IS IN ACCORDANCE WITH SAUDI ARAMCO ENGINEERING SPECIFICATION SAES-L-105

AND PROJECT PIPE MATERIAL SPECIFICATION DOC. NO. CS-771326, CLASS 1CS2P

KP4ACDA4472 ALL EXCEPTIONS ARE NOTED ON THE ISOMETRIC.

WP01 / ORI=D ABAEA1800-01 11. INSULATION REQUIRED YES NO X

FLANGE JOINT: ABAEA1800-F2208 INSULATION SHOWN ON DRAWING NA

9

23 12. ALL ELEVATIONS ARE IN MILLIMETERS AND REFER TO THE LOWEST ASTRONOMICAL TIDE (LAT) DATUM.

FLANGE JOINT: ABAEA1800-F2209 13. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS UNLESS NOTED OTHERWISE.

14. FW - DENOTES FIELD WELD WITH NO CUTTING ALLOWANCE.

203

:88

FFW - DENOTES FIELD FIT WELD WITH 75mm CUTTING ALLOWANCE FOR ONSHORE APPLICATION

1 AND 300mm FOR OFFSHORE. CUTTING ALLOWANCE TO BE ADDED TO THE DIMENSION SHOWN

LL

F4 G8 B9 FA 701

15. ALL THREADED JOINTS TO BE SEAL WELDED AS PER SAES-L-110 PAR. 9.4

FLANGE JOINT: ABAEA1800-F2210 16. WEAR PAD FOR ALL FBE COATED PIPING SHALL BE FULLY WELDED TO PIPE PRIOR TO FBE COATING.

3 INTERNAL FBE LINING SHALL BE DONE AFTER SPOOL FABRICATION & COMPLETION OF ALL HOT WORKS

25 ERECTION MATERIALS

6 001 <1> 1 17. PLATFORM PREFIX PROVIDED IN ISO IS IN COMPLAINCE WITH INTERNAL MODELLING

PT COMPONENT DESCRIPTION N.S. ITEM CODE QTY GUIDE AND SAME SHALL BE REMOVED BEFORE ASBUILT.

TAIL UP NO (INS)

6 18. THIS DRAWING HAS BEEN CREATED USING A DATA CENTRIC SMARTPLANT 3D SYSTEM AND

OPEN 1 002 F4 G8 B9 6 Spectacle Blind , STD.DWG. AD-036633-001 , CL 150 , RF , 2 PPDXXF8X0008164 1 COORDINATES MENTIONED IN THE ISOMETRIC REFERS TO LOCAL PLATFORM GRID COORDINATES

>

F4 G8 B10 <2 ASTM A105N (REFER EQUIPMENT LAYOUT FOR LOCAL COORDINATES).

11

VALVE RECAP: ABAEA1800-V01

7 Plug Round Head , ASME B16.11 , NPT THD , ASTM A105N 1 PPOXXPLR0000747 1 19. NDE & PWHT DETAILS SHOWN IN THE DRAWING ARE BASED ON MAIN LINE SIZE.

NDE & PWHT REQUIREMENTS FOR BRANCHES / ASSOCIATED PIPE SIZES SHALL REFER TO

25

3

ABAEA1800-02 8 SP. WOUND GSKT , 150# , RF , ASME B16.20 , 0.175" THK , TYPE 2 PPXPGSPW0009455 6 APPROVED PROJECT NDE PLAN (DOC.No. D7068-D7394-AOC-QC-004) & APPROVED WPS REPECTIVELY

316 SS, WINDINGS, FLEXIBLE GRAPHITE FILLER WITH CS OUTER 20. PROTECTIVE COATING SYSTEM ONLY SPECIFIED IN THE DRAWING.

2 RING FINAL COLOR CODING SHALL BE FOLLOWED BASED ON APPROVED PAINTING PROCEDURE

(D7068-D7394-AOC-QC-049). CS, SS, 6MO AND ALLOY 20 PIPES UNDER SPLASH ZONE

1 004 003 9 STD BLT & 2 HHEX NUT , ASTM A193 GRADE B7 / ASTM A194 GRADE 5/8 PPXPBSB20011968 16 SHALL BE PAINTED WITH APCS-19C PAINTING SYSTEM.

2X1"NS >

FALL 1:88 005 <3 2H , COATED WITH CERAMIC FLUOROPOLYMER - 85 mm Length 21. PIPE SUPPORT DETAILS REFER PIPE SUPPORT STD.NO. CC-776199-001.

0

14 10 STD BLT & 2 HHEX NUT , ASTM A193 GRADE B7 / ASTM A194 GRADE 5/8 PPXPBSB20011970 4 22. INSULATION REQUIREMENTS SHALL BE AS PER CE-776269-001.

F4 G8

2H , COATED WITH CERAMIC FLUOROPOLYMER - 95 mm Length 23 .THIS NOTE IS APPLICABLE ONLY FOR LINES CONTANING CLAD PUP PIECE IN FBE PIPING.

EL

+1 3 006 501 13 11 Check Valve Swing , API 594 , CL 150 , RF , Body A216-WCB , 2 PPXPVCHS0006657 1 WHEREVER PWHT IS APPLICABLE, PWHT SHALL BE PERFORMED ON SHOP WELD ONLY.

POST FBE COATING, PWHT SHALL NOT BE PERFORMED ON FIELD WELDS.

46

79 SPINDLE ORI SOUTH Body BC , Trim 8 24 . BOLT TENSIONING REQUIREMENT SEE DOC.CE-771326-001 PAR. 5.0.

E1

4 ORIENT HANDLE WEST 12 Ball Valve , API 6D , CL 150 , Flgd., RF , Body A216-WCB , 2 PPXPVBAV0020623 1 25 . NACE / HIC SEE DOC.CE-771326-001 APPENDIX-3.

EL 924 NC Lever Op. , RB , Soft Seat , Trim SS 410

501 +1 3

FA 51 4681 VALVE RECAP: ABAEA1800-V02 13 Ball Valve , API 6D , CL 800 , SW X THD , Body ASTM A105N , 1 PPXPVBAV0022861 1

ONE END PIPE SHALL BE

LL

1 :10 7

Lever Op. , RB , Soft Seat , Trim SS 410 (PE Nipple on SW

0 end) REFERENCE DRAWINGS

BEVEL END TO CONNECT 007 155

CONT. ON DWG CONTROL SHEET FOR J.O.10-12201-0002 CD-761325

WITH BEVEL END OF

702 PIPING PLAN CA-768365-002

REDUCING TEE 22 DWG: CB-767102-002

7 LINE: 2"-FO-8819-1CS2P P&ID NO. CA-775966-001

<4 HYDROSTATIC TEST DIAGRAM CA-742713-001

> E 149103

2"N 1 N 163407 STRESS REPORT DOCUMENT NO. NA

ABAEA1800-03 S 008

EL +14673

S5 21 G8 B9 PRODUCTION PLATFORM

4

KP4ACDA4471

WP01 / ORI=D

FLANGE JOINT: ABAEA1800-F2212

F4 G8 B9

FLANGE JOINT: ABAEA1800-F2211 12

SPINDLE ORI EAST

ORIENT HANDLE SOUTH B0 06-APR-22 ISSUED FOR CONSTRUCTION MKL UW 07/04/22

178 IW

0.6° DOWN REV DATE DESCRIPTION DRN CHK ENG DATE

VALVE RECAP: ABAEA1800-V03

CUT PIPE LENGTH

P.T. McDERMOTT INDONESIA

PT IDENT CODE LNG N.S. E.P. E.P. REMARKS BATAM INDONESIA

NO (MM) (INS)

REVISION VALIDATION

1 PPPXXPPX0036985 428 2" BE BE 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

2 PPPXXPPX0036985 125 2" BE BE

THIS REVISION NO.

REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

3 PPPXXPPX0036985 125 2" BE BE 10-12201-0002-661

4 PPPXXPPX0036985 300 2" BE BE JOB ORDER/EWO NO.

THIS REVISION IS NOT TO BE USED FOR

10-12201-0002 CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

ISOM 2"-FO-8819-1CS2P

DRAWING TYPE

ISO

ABAEA1800-03 FUEL OIL

ABAEA1800-02 GAS OIL SEPARATION PLANT (GOSP-4)

ABAEA1800-01

SPOOL NO: MARJAN SAUDI ARABIA

NOTES CONT.: SCALE : NTS SIZE : A3 FACILITY.: MRJN GOSP-4 PP

SCREWED JOINT SPOOL TAG/SPOOL RECAP

SPEC : 1CS2P INST JOB NO.: 64251-B5201

WELD NUMBER PIECE NUMBER

MATERIAL: CS QTY SPOOL : 3

BUTT WELD/JOINT 1 PARTS LIST No.

WEIGHT: FAB- MAT: EREC - MAT: TOTAL LB Loose M-CB-767102-A-1800-LB MATERIAL COLOR : NO COLOR

SOCKET WELD FLANGE JOINT

Kg 23.1 35.5 58.7 INSTALL ONSHORE SB Loose M-CB-767102-A-1800-SB PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

INSULATION DESIGN OPERATING TEST TEST MEDIUM INSULATION RADIOGRAPHY % PWHT PAINT SPEC MATERIAL TYPE LINE ID PLATFORM PREFIX

FW

FFW

FIELD WELD

FIELD FIT WELD

TRACED PIPE TEMP. (DEG. F) PRESS. (PSIG) TEMP. (DEG. F) PRESS. (PSIG) PRESS. (PSIG) MEDIUM TYPE Thk (MM) YES / NO FO-8819-U04 U4-P4-PP 631 L CB-767102 001 00

PIPE SUPPORT PROJECT NO. ISOMETRIC DRAWING NO. SHEET REVISION

OSW OFFSHORE WELD INLINE SUPPORT ATTACHMENT 50/158 150 102 65 450 WATER NA NA 100% NO APCS 1B CS 2"-FO-8819-1CS2P D7068 M-CB-767102-A-1800 001 B0

AMIndiarto 2022/04/05

You might also like

- High Five HabitDocument20 pagesHigh Five HabitOmonusi OmoladeNo ratings yet

- Urban Land Use - Community-Based PlanningDocument316 pagesUrban Land Use - Community-Based PlanningAnonymous 5poler100% (1)

- M-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Document1 pageM-CB-767101-A-0929 00a 002 CB-767101: Gas Oil Separation Plant (Gosp-4) ABJED0929-01 ABJED0929-02 ABJED0929-03Hesi KusumaNo ratings yet

- M-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Document1 pageM-CB-767101-A-0900 00a 001 CB-767101: ABJED0900-02 ABJED0900-03 ABJED0900-04Hesi KusumaNo ratings yet

- M-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water ReturnDocument1 pageM-CB-767101-A-0930 00 003 CB-767101: ISOM 6"-CWR-6634-1LE2W Cooling Water ReturnHesi KusumaNo ratings yet

- TB-659651-003 Rev 0F1Document1 pageTB-659651-003 Rev 0F1Khalid OnlyNo ratings yet

- R901085037P00Document1 pageR901085037P00Rene HebaNo ratings yet

- R901085036P00Document1 pageR901085036P00Rene HebaNo ratings yet

- Notes: M-CB-767101-A-0865 00 004Document1 pageNotes: M-CB-767101-A-0865 00 004Hesi KusumaNo ratings yet

- R901085031P00Document1 pageR901085031P00Rene HebaNo ratings yet

- R82-002 - Done 5Document1 pageR82-002 - Done 5rsmjuleyNo ratings yet

- C533131003VDocument1 pageC533131003VMohamed Wasim ShaikhNo ratings yet

- R901085032P00Document1 pageR901085032P00Rene HebaNo ratings yet

- R901085028P00Document1 pageR901085028P00Rene HebaNo ratings yet

- T013512001V0F1Document1 pageT013512001V0F1haseebrazvi1No ratings yet

- T013482002V0F1Document1 pageT013482002V0F1haseebrazvi1No ratings yet

- Coating FultsDocument4 pagesCoating FultsAhmed BoraeyNo ratings yet

- C254977001P Rev01cDocument1 pageC254977001P Rev01cRAJA MOHD IRFAN KHANNo ratings yet

- SF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsDocument2 pagesSF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsSENTHILNo ratings yet

- T013519001V0F1Document1 pageT013519001V0F1haseebrazvi1No ratings yet

- T013514004V0F1Document1 pageT013514004V0F1haseebrazvi1No ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- TB 661291 001Document1 pageTB 661291 001Khalid OnlyNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- D43 P 11004 21 - Rev02fDocument1 pageD43 P 11004 21 - Rev02fSajeed ZaheerNo ratings yet

- Piping Isometric - 3Document1 pagePiping Isometric - 3CosminMarianNo ratings yet

- SF6-A-100-450-100-6-CS: Bill of MaterialsDocument7 pagesSF6-A-100-450-100-6-CS: Bill of MaterialsSENTHILNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument2 pagesFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Appendix IDocument6 pagesAppendix IkarthickmectrNo ratings yet

- T013482001V0F1Document1 pageT013482001V0F1haseebrazvi1No ratings yet

- T013458001V0F1Document1 pageT013458001V0F1haseebrazvi1No ratings yet

- Tal Wsa PNG Iso 1P020807 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1P020807 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- T013515002V0F1Document1 pageT013515002V0F1haseebrazvi1No ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument2 pagesFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- 3 Tail North 29 G4 Conn. To SKID-229/EQUI/GS-6901A/N1 W 1695.0 N 2650.0 EL +2970.0Document41 pages3 Tail North 29 G4 Conn. To SKID-229/EQUI/GS-6901A/N1 W 1695.0 N 2650.0 EL +2970.0cerebralnomadNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- Bill of Materials: Standard Detail Reference DrawingsDocument11 pagesBill of Materials: Standard Detail Reference DrawingsSENTHILNo ratings yet

- Planos Electricos Invertex 2 Serie 31875 UpDocument23 pagesPlanos Electricos Invertex 2 Serie 31875 UpHéctorHernándezDíazNo ratings yet

- PipelineDocument9 pagesPipelineRhoteram VikkuNo ratings yet

- 0468 Asom20 00TQ 0001 001 BDocument14 pages0468 Asom20 00TQ 0001 001 BDenny AgusNo ratings yet

- 15-501-EP-LI-001 - REV.1 (Line List)Document3 pages15-501-EP-LI-001 - REV.1 (Line List)Umair A. KhanNo ratings yet

- Bill of Materials: 331U15-OWS-002-02-1Document1 pageBill of Materials: 331U15-OWS-002-02-1PT Bumi Liputan PusakaNo ratings yet

- 4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Document2 pages4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- TR-DM-MI-0218: Issued For ConstructionDocument2 pagesTR-DM-MI-0218: Issued For ConstructionMarcellino YohanesNo ratings yet

- T013514003V0F1Document1 pageT013514003V0F1haseebrazvi1No ratings yet

- Diesel Pipeline: S7 S6B TYBE-2Document1 pageDiesel Pipeline: S7 S6B TYBE-2jibran42No ratings yet

- 01 E02STB007-W146693-03-0 - BC - Stress UpdateDocument1 page01 E02STB007-W146693-03-0 - BC - Stress Update86tejas100% (1)

- 26-000-2-02-00001 FL 581574-1-R01-ModelDocument1 page26-000-2-02-00001 FL 581574-1-R01-ModelMartinAlexisGonzálezVidalNo ratings yet

- Erection Drawing SST 36MDocument14 pagesErection Drawing SST 36MyuwonoNo ratings yet

- TB-659631-001 Rev 0F2Document1 pageTB-659631-001 Rev 0F2Khalid OnlyNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- 0479 Tec20 92DJ 21256 001Document3 pages0479 Tec20 92DJ 21256 001Dimmy mariano de limaNo ratings yet

- Profile RT 21-060-004Document4 pagesProfile RT 21-060-004Marcus AntoniusNo ratings yet

- e C7328 - 1F PDFDocument6 pagese C7328 - 1F PDFmina fawzyNo ratings yet

- NN BlokDocument3 pagesNN BlokMarko ŽivkovićNo ratings yet

- 4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Document1 page4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- 3D PV 2017 BrochureDocument6 pages3D PV 2017 BrochurehabilNo ratings yet

- JI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1Document1 pageJI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1weerachai phosoongNo ratings yet

- HS372221 26 Pip Iso 0168 0000 1 - Rm01aDocument1 pageHS372221 26 Pip Iso 0168 0000 1 - Rm01aibrahim qasimovNo ratings yet

- 2326 B 0019Document5 pages2326 B 0019Anonymous AA30q4No ratings yet

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Breaking Forth: Dominion Chapel International ChurchesDocument11 pagesBreaking Forth: Dominion Chapel International ChurchesWuese DanielNo ratings yet

- Pain Management ServiceDocument4 pagesPain Management ServiceTaeng GoNo ratings yet

- Thermodynamics Group A-1Document60 pagesThermodynamics Group A-1kadebiyiojoNo ratings yet

- Rotonivo: Series RN 3000 / 6000Document34 pagesRotonivo: Series RN 3000 / 6000Strato VariusNo ratings yet

- Eaton Emergency Lighting Self Contained Safety Micropoint 2 Recessed Datasheet enDocument2 pagesEaton Emergency Lighting Self Contained Safety Micropoint 2 Recessed Datasheet enOjog Ciprian AlinNo ratings yet

- CD 101Document4 pagesCD 101Kevin EspinosaNo ratings yet

- Manual For 90-Degree Failsafe-Actuators - ABFSQT 1 Introduction / CommentsDocument9 pagesManual For 90-Degree Failsafe-Actuators - ABFSQT 1 Introduction / Comments蒋波No ratings yet

- (The Correlation of Organizational Role Stressors With Stress Level of ICU NursesDocument18 pages(The Correlation of Organizational Role Stressors With Stress Level of ICU NursesAnggriani Puspita AyuNo ratings yet

- Spelling RulesDocument15 pagesSpelling RulesTâm Thanh CaoNo ratings yet

- Wednesday, July 15, 2015 EditionDocument14 pagesWednesday, July 15, 2015 EditionFrontPageAfricaNo ratings yet

- Note On NMHPDocument23 pagesNote On NMHPDeepak MalhotraNo ratings yet

- Set A Deptals 2ND Sem Sy 2022 2023Document8 pagesSet A Deptals 2ND Sem Sy 2022 2023MARITES FRANCISCONo ratings yet

- KASHISHDocument65 pagesKASHISHRavileen AnandNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01Document2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01ThylaneNo ratings yet

- Director Manager Payroll CPP in Seattle WA Resume Michael HoernerDocument1 pageDirector Manager Payroll CPP in Seattle WA Resume Michael HoernerMichaelHoerner2No ratings yet

- CHCCCS011 Learner Guide V5.0Document51 pagesCHCCCS011 Learner Guide V5.0RupinderNo ratings yet

- Housing (Front) - Remove: Disassembly and AssemblyDocument4 pagesHousing (Front) - Remove: Disassembly and AssemblyMbahdiro KolenxNo ratings yet

- Building Maintenance ChecklistDocument5 pagesBuilding Maintenance ChecklistcajaroNo ratings yet

- G-Conservation of EnergyDocument2 pagesG-Conservation of EnergySung ParkNo ratings yet

- Sugar Production in Uttar Pradesh Over The Last 10 YearsDocument3 pagesSugar Production in Uttar Pradesh Over The Last 10 YearsAryan KediaNo ratings yet

- IMECE2018-87738: Thermal Behavior of Soils Under Tidal Effect: A Case Study in Guayaquil, EcuadorDocument7 pagesIMECE2018-87738: Thermal Behavior of Soils Under Tidal Effect: A Case Study in Guayaquil, EcuadorRemigio VasconezNo ratings yet

- Barbara Pym Excellent WomenDocument10 pagesBarbara Pym Excellent WomenCecilia KennedyNo ratings yet

- Data Spare PartDocument8 pagesData Spare Partagung setiawanNo ratings yet

- Azidus Laboratories - BA BE Capabilities Slide Deck - Feb 2019 PDFDocument35 pagesAzidus Laboratories - BA BE Capabilities Slide Deck - Feb 2019 PDFDeepakNo ratings yet

- Tonicity Determination: Hypertonicity, Hypotonicity and IsotonicityDocument4 pagesTonicity Determination: Hypertonicity, Hypotonicity and IsotonicityAbegailNo ratings yet

- AD-310 Service Manual: More User Manuals OnDocument119 pagesAD-310 Service Manual: More User Manuals OnRodolfoArayaCarvajalNo ratings yet

- Sony ST-SA3ESDocument64 pagesSony ST-SA3ESNanoUrraNo ratings yet

- Higher Tier: London Examinations IGCSEDocument32 pagesHigher Tier: London Examinations IGCSESaleha RiazNo ratings yet