Professional Documents

Culture Documents

IATF vs. CSR vs. Business

IATF vs. CSR vs. Business

Uploaded by

goran969Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IATF vs. CSR vs. Business

IATF vs. CSR vs. Business

Uploaded by

goran969Copyright:

Available Formats

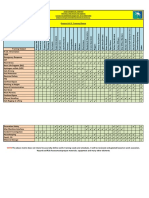

Processes

Continous improvment

Business Management

Production processes

Change Management

Quality Suppoort of

QMS Management

Human Resources

Customer Quality

Supplier Quality

New Launches

Stellantis

Mainetnance

Production

-FCA General Stellantis Business

Logistic

Ford VW Renault Nissan

HSE

EMEA/LA Motors -PSA Quality

CSR CSR CSR CSR

TAM CSR CSR Manual

CSR

4 Context of the Organization

4.1 Understanding the organization and its context X X X X X X X X X X X X X X X X

4.2 Understanding the needs and expectations of interested parties X X X X X X X X X X X X X X X X

4.3.1 Determining

4.3 Determining the

the scope

scope ofof the

the quality

quality management

management system –

system X X X X

Supplemental X

4.3.2 Customer-specific requirements X X X

4.4 Quality management system and its processes X X X

4.4.1.1 Conformance of products and processes X X

4.4.1.2 Product safety X X X

5. Leadership

5.1 Leadership and commitment X X X

5.1.1 General X

5.1.1.1 Corporate responsibility X X X X

5.1.1.2 Process effectiveness and efficiency X

5.1.1.3 Process owners X X X

5.1.2 Customer focus X X X

5.2 Policy X X X X

5.2.1 Establishing the quality policy X X

X X

X X X X

5.3.1 Organizational roles, responsibilities, and authorities –Supplemental X X X X X

5.3.2 Responsibility and authority for product requirements and corrective

X

actions X X X

6 Planning

6.1 Actions to address risks and opportunities X X X X

6.1.2.1 Risk analysis X X

6.1.2.2. Preventive action X

6.1.2.3 Contingency plans X X X

6.2 Quality objectives and planning to achieve them X X X X X X X X X X X X X

6.2.2.1 Quality objectives and planning to achieve them - supplemental X

6.3 Planning of changes X

7 Support

7.1 Resources X X X X

7.1.1 General X

7.1.2 People X X

7.1.3 Infrastructure X X X

7.1.3.1 Plant, facility, and equipment planning X X X X

7.1.4 Environment for the operation of processes X X X X

7.1.4.1 Environment for the operation of processes - supplemental X

7.1.5 Monitoring and measuring resources X X

7.1.5.1 General X X

7.1.5.1.1 Measurement system analysis X X

7.1.5.2. Measurement traceability X

7.1.5.2.1 Calibration/verification records X

7.1.5.3 Laboratory requirements (title) X

7.1.5.3.1 Internal laboratory X

7.1.5.3.2 External laboratory X

7.1.6 Organizational knowledge X X

7.2 Competence X X

7.2.1 Competence - Suplemental X X

7.2.2 Competence - on the job training X X

7.2.3 Internal auditor competency X X

7.2.4 Second-party auditor competency X X

7.3 Awareness X X

7.3.1 Awarness - supplemental X

7.3.2 Employee motivation and empowerment X

7.4 Communication X X X

7.5 Documented Information X X

7.5.1 General X X X

7.5.1.1 Quality management system documentation X X

Kopia dokumentu pobrana do edycji ( 31-03-2020 13:47:06) - Dariusz Kowalczyk

7.5.2 Creating and Updating X X

7.5.3.2.1 Record retention X X X X

7.5.3.2.2 Engineering specificaitons X X

8. Operation

8.1 Operational planning and control X X X X

8.1.1 Operational planning and control —supplemental X X

8.1.2 Confidenciality X X

8.2 Requirements for products and services X

8.2.1 Customer communication X X X X

8.2.1.1 Customer communication —supplemental X X X X X X X

8.2.2 Determination of requirements related to products and services X X X X

8.2.2.1 Determining the requirements related to products and services -

X X

supplemental

8.2.3 Review of requirements related to products and services X

8.2.3.1.1 Review of the requirements for products and services —

X X

supplemental X

8.2.3.1.2 Customer-designated special characteristics X X X X X X

8.2.3.1.3 Organization manufacturing feasibility X X

8.2.4 Changes to requirements for products and services X X

8.3 Design and development of products and services X X

8.3.1 General

8.3.1.1 Design and development of products and services –supplemental X

8.3.2 Design and development planning X X X X

8.3.2.1 Design and development planning - supplemental X X X X

8.3.2.2 Product design skills

8.3.2.3 Development of products with embedded software X X

8.3.3 Design and development inputs X

8.3.3.1 Product design input

8.3.3.2 Manufacturing process design input X

8.3.3.3 Special characteristics X X

8.3.4 Design and development controls X X X

8.3.4.1 Monitoring X

8.3.4.2 Design and development validation X

8.3.4.3 Prototype programme X X X

8.3.4.4 Product approval process X X X X X X

8.3.5 Design and development outputs X X

8.3.5.1 Design and development outputs –supplemental X X

8.3.5.2 Manufacturing process design output X X

8.3.6 Design and development changes X X X

8.3.6.1 Design and development changes -supplemental X X X X

8.4 Control of externally provided processes, products and services

8.4.1 General

8.4.1.1 General -supplemental

8.4.1.2 Supplier selection process X X X

8.4.1.3 Customer-directed sources (also known as “Directed–Buy”) X X

8.4.2 Type and extent of control X X X

8.4.2.1 Type and extent of control –supplemental X X X

8.4.2.2 Statutory and regulatory requirements X X

8.4.2.3 Supplier quality management system requirements X X X X

8.4.2.3.1 Automotive product-related software or automotive products with

X

embedded software

8.4.2.4 Supplier monitoring X X X

8.4.2.4.1 Second-party audits X X X X

8.4.2.5 Supplier development X X X

8.4.3 Information for external providers X

8.4.3.1 Information for external providers -supplemental X X

8.5 Production and service provision

8.5.1 Control of production and service provision X X X X X X

8.5.1.1 Control plan X X X X X

8.5.1.2 Standardised work –operator instructions and visual standards X X X X X

8.5.1.3 Verification of job set-ups X

8.5.1.4 Verification after shutdown X X

8.5.1.5 Total productive maintenance X

8.5.1.6 Management of production tooling and manufacturing, test,

X X

inspection tooling and equipment X X

8.5.1.7 Production scheduling X

8.5.2 Identification and traceability X X X

8.5.2.1 Identification and traceability —supplemental X X X

8.5.3 Property belonging to customers or external providers X X X

Kopia dokumentu pobrana do edycji ( 31-03-2020 13:47:06) - Dariusz Kowalczyk

8.5.4 Preservation X X X

8.5.4.1 Preservation -supplemental X

8.5.5 Post-delivery activities X X

8.5.5.1 Feedback of information from service X X

8.5.5.2 Service agreement with customer X

8.5.6 Control of changes X X X X X

8.5.6.1 Control of changes - supplemental X X X X

8.5.6.1.1 Temporary change of process controls X X

8.6 Release of products and services X X

8.6.1 Release of products and services —supplemental X X X

8.6.2 Layout inspection and functional testing X X X X X

8.6.3 Appearance items X X

8.6.4 Verification and acceptance of conformity of externally provided

X X

products and services

8.6.5 Statutory and regulatory conformity X X

8.6.6 Acceptance criteria X X X

8.7 Control of nonconforming outputs X X X

8.7.1.1 Customer authorization for concession X X

8.7.1.2 Control of nonconforming product –customer specified process X

8.7.1.3 Control of suspect product X

8.7.1.4 Control of reworked product X

8.7.1.5 Control of repaired product X

8.7.1.6 Customer notification X

8.7.1.7 Nonconforming product disposition X X

9 Performance evaluation

9.1 Monitoring, measurement, analysis and evaluation X X

9.1.1 General X X

9.1.1.1 Monitoring and measurement of manufacturing processes X X X X

9.1.1.2 Identification of statistical tools X X

9.1.1.3 Application of statistical concepts X

9.1.2 Customer satisfaction X X X

9.1.2.1 Customer satisfaction –supplemental X X X X X X

9.1.3 Analysis and evaluation X X X X X X X X X X X X X X X

9.1.3.1 Prioritization X X

9.2 Internal audit X X X

9.2.2.1 Internal audit programme X

9.2.2.2 Quality management system audit X

9.2.2.3 Manufacturing process audit X X X X

9.2.2.4 Product audit X X X

9.3 Management review X X

9.3.1 General X X

9.3.1.1 Management review –supplemental X X X

9.3.2 Management review inputs X

9.3.2.1 Management review inputs –supplemental X X

9.3.3 Management review outputs X X

9.3.3.1 Management review outputs –supplemental X

10 Improvement

10.1 General X X X X X X X X X X X X X X X

10.2 10.2.1, 10.2.2 Nonconformity and Corrective Action X X

10.2.3 Problem solving X X X

10.2.4 Error-proofing X X X

10.2.5 Warranty management systems X X X X

10.2.6 Customer complaints and field failure test analysis X X

10.3 Continual Improvement X X

10.3.1 Continual improvement - supplemental X

28 31 33 13 17 11 25 24 10 22 8 24 7

Kopia dokumentu pobrana do edycji ( 31-03-2020 13:47:06) - Dariusz Kowalczyk

Finance

IT

0

X X 16

X X 16

1

1

3

1

1

2

0

1

1

3

1

3

2

2

2

2

3

4

3

0

2

2

1

1

X X 15

1

1

0

X 3

1

1

X 3

2

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

Kopia dokumentu pobrana do edycji ( 31-03-2020 13:47:06) - Dariusz Kowalczyk

1

1

2

1

1

1

3

3

2

2

1

1

2

1

1

X 1

X 1

X 1

1

1

X 1

X 1

X 1

X 1

1

1

1

1

1

1

3

1

1

1

2

2

0

0

0

X 1

0

2

2

0

1

1

1

1

1

0

1

0

4

2

X 4

1

1

1

2

1

1

1

1

Kopia dokumentu pobrana do edycji ( 31-03-2020 13:47:06) - Dariusz Kowalczyk

2

1

1

1

1

3

3

1

1

1

1

1

2

1

1

2

1

1

1

1

1

1

1

0

0

1

3

1

1

1

1

X X 15

2

1

1

1

1

1

1

1

1

1

1

1

1

X X 15

1

1

2

1

1

1

1

6 7 8

Kopia dokumentu pobrana do edycji ( 31-03-2020 13:47:06) - Dariusz Kowalczyk

You might also like

- EHQMS Process MatrixDocument2 pagesEHQMS Process MatrixAbdullahKhan100% (6)

- QMS Process Matrix & ApplicationDocument2 pagesQMS Process Matrix & ApplicationSaravana kumar NagarajanNo ratings yet

- Raci MatrixDocument4 pagesRaci MatrixIslam WayNo ratings yet

- ProcessesDocument6 pagesProcessessumitgupta30523No ratings yet

- Global Attire LTD.: Organization ChartDocument3 pagesGlobal Attire LTD.: Organization ChartJamil HossainNo ratings yet

- ITIL Edition 2011 - COBIT 5 - Mapping-22Document1 pageITIL Edition 2011 - COBIT 5 - Mapping-22Jeovanny MeraNo ratings yet

- PM One Page FlowchartDocument1 pagePM One Page FlowchartMuhammad FajarNo ratings yet

- Raci Matrix: Yasm RslesDocument1 pageRaci Matrix: Yasm RslesxfireloveNo ratings yet

- Itil V3 Cobit V4.1 Mapping OverviewDocument8 pagesItil V3 Cobit V4.1 Mapping OverviewDwdroo DiwokNo ratings yet

- PDFDocument1 pagePDFsameeh kadourahNo ratings yet

- Rec-C-001 Sequence and Interaction Model - Copyrighted 2003 Patricia C RavanelloDocument1 pageRec-C-001 Sequence and Interaction Model - Copyrighted 2003 Patricia C RavanelloRafael PerezNo ratings yet

- PM One Page FlowchartDocument1 pagePM One Page FlowchartbenNo ratings yet

- Skill Matrix AirfreightDocument9 pagesSkill Matrix AirfreightitoitNo ratings yet

- Aval Aase 2324 FinalDocument1 pageAval Aase 2324 Finalguihermatador45No ratings yet

- Logistic Support Analysis (LSA) : TitleDocument26 pagesLogistic Support Analysis (LSA) : Titlenebodepa lyftNo ratings yet

- Folded BrochureDocument2 pagesFolded BrochureraghavendraNo ratings yet

- 12 PSPO - APAC - MayDocument1 page12 PSPO - APAC - Maychellappan29No ratings yet

- PM One Page FlowchartDocument1 pagePM One Page FlowchartGustavo CedenoNo ratings yet

- Training MatrixDocument2 pagesTraining MatrixAmeerHamzaWarraichNo ratings yet

- Poster Process Map Itil PDFDocument1 pagePoster Process Map Itil PDFdeba8012No ratings yet

- Iso 9001-2015 Audit Plan & Schedule Revision 5Document1 pageIso 9001-2015 Audit Plan & Schedule Revision 5AliNo ratings yet

- Base Enterprise Value Map PDFDocument1 pageBase Enterprise Value Map PDFjvr001100% (1)

- QMS Audit Plan & Schedule: Clauses NoDocument1 pageQMS Audit Plan & Schedule: Clauses NosbtharanNo ratings yet

- Responsibility Matrix PDFDocument1 pageResponsibility Matrix PDFNour MerjaniNo ratings yet

- MP 2.1.3 Matrix of Tasks AssignmentDocument4 pagesMP 2.1.3 Matrix of Tasks AssignmentenfrspitNo ratings yet

- HR Recruiting and Hiring WorkflowDocument1 pageHR Recruiting and Hiring WorkflowPhone SSBNo ratings yet

- Integral University, Lucknow Department of Commerce and Business Management Study and Evaluation Scheme Program: BBA Retail Management Semester-IIIDocument8 pagesIntegral University, Lucknow Department of Commerce and Business Management Study and Evaluation Scheme Program: BBA Retail Management Semester-IIIsaurabhsonaNo ratings yet

- Mindmap For Operational Transparency in SAP: Supply Chain MindmappingDocument1 pageMindmap For Operational Transparency in SAP: Supply Chain MindmappingobNo ratings yet

- Itil, CobitDocument1 pageItil, CobitParvez2zNo ratings yet

- HSE Training Matrix DraftDocument11 pagesHSE Training Matrix DraftSudeepDPoojaryNo ratings yet

- Problem-Solving ModelDocument1 pageProblem-Solving Modelsahand adib moradi langeroodiNo ratings yet

- On Job Annual Training Plan 2023Document3 pagesOn Job Annual Training Plan 2023Kashif ButtNo ratings yet

- I.04 Inspectors Qualification MatrixDocument2 pagesI.04 Inspectors Qualification MatrixKashif KhanNo ratings yet

- ElectronicDoc Cyc MatrixDocument1 pageElectronicDoc Cyc MatrixIceman_81No ratings yet

- ECommerce Basics 1667870298Document1 pageECommerce Basics 1667870298Thanh UzumakiNo ratings yet

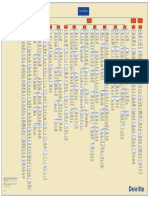

- Value-Map TM DeloitteDocument1 pageValue-Map TM DeloitteHugo SalazarNo ratings yet

- Performance Manage MenDocument1 pagePerformance Manage MenmariaaltammamNo ratings yet

- Epc Epcm ChartDocument1 pageEpc Epcm ChartjcerignaleNo ratings yet

- GOLDENHORN ONEGRC Three Lines of Defence Mapping 1580023424Document1 pageGOLDENHORN ONEGRC Three Lines of Defence Mapping 1580023424Gurcan KarayelNo ratings yet

- Technical Descriptor (How) : Raw Score Relative WeightDocument1 pageTechnical Descriptor (How) : Raw Score Relative WeightAlodia FarichaiNo ratings yet

- Value Chain Map ITIL4Document2 pagesValue Chain Map ITIL4Belem PianaNo ratings yet

- Project Management Services - Nycproject Deliverables Raci Matrix (Updated 07/14/14)Document4 pagesProject Management Services - Nycproject Deliverables Raci Matrix (Updated 07/14/14)Venkataramanan SNo ratings yet

- Jsu T5 Bi K1Document1 pageJsu T5 Bi K1MOHD FAHMI BIN ABD ALIAN MoeNo ratings yet

- Risk Intelligence Map Health Care Providers (Old)Document1 pageRisk Intelligence Map Health Care Providers (Old)mattsaavedradNo ratings yet

- 13 - Business Management-1744-2 MBA SyllabiDocument32 pages13 - Business Management-1744-2 MBA Syllabimauryaritesh66No ratings yet

- Embedded Project WorksheetDocument4 pagesEmbedded Project WorksheetcammanderNo ratings yet

- Matrik PelatihanDocument1 pageMatrik PelatihanYogi RadityaNo ratings yet

- Skill Matrix 2023Document23 pagesSkill Matrix 2023Bondville ComplienceNo ratings yet

- Mba (3year) July2008Document80 pagesMba (3year) July2008Kumar NaiduNo ratings yet

- Ecossistema-Martech & AdtechDocument1 pageEcossistema-Martech & AdtechGuilherme HepperNo ratings yet

- TNA - Monthly Training Report Kelas Paralel - 2020 - Subcont - PUPDocument1 pageTNA - Monthly Training Report Kelas Paralel - 2020 - Subcont - PUPMuhamad Rizki AzisNo ratings yet

- Process 3.0vDocument1 pageProcess 3.0vict hmisNo ratings yet

- Cops Organigramme Lapd 2Document2 pagesCops Organigramme Lapd 2Nicolas LapaluNo ratings yet

- Struktur Organigram Update 190122Document1 pageStruktur Organigram Update 190122Febram EzyNo ratings yet

- Materials Management: Login To Opsdog To Purchase The Full Workflow Template (Available in PDF, VisioDocument1 pageMaterials Management: Login To Opsdog To Purchase The Full Workflow Template (Available in PDF, VisioJyotsana VyasNo ratings yet

- 0202 Microsoft Team System Roles and SecurityDocument1 page0202 Microsoft Team System Roles and SecurityJorge Enrique Rico MarulandaNo ratings yet

- Project Reoprt On Greenpanel - GagandeepDocument126 pagesProject Reoprt On Greenpanel - GagandeepGagandeep SinghNo ratings yet

- Advertising Companies in IndiaDocument2 pagesAdvertising Companies in Indiagaurav20587No ratings yet

- Interlink Interchange Reimbursement Fees April2012Document3 pagesInterlink Interchange Reimbursement Fees April2012rosekjarNo ratings yet

- The Relationship Between Corporate Strategy and Capital StructureDocument2 pagesThe Relationship Between Corporate Strategy and Capital StructureAnonymous DR0y6OXufA0% (1)

- PR-1159 - Commissioning and Start-UpDocument117 pagesPR-1159 - Commissioning and Start-Upalokc100% (1)

- Vietnam Think Finance Webinar 3 Nov 2020Document79 pagesVietnam Think Finance Webinar 3 Nov 2020Nhật LinhNo ratings yet

- Assignment SCMDocument5 pagesAssignment SCMSidraSarfraz100% (1)

- The Dividend Month PremiumDocument55 pagesThe Dividend Month PremiumAdeniyi AleseNo ratings yet

- Surveillance 02 Audit Report (Remote) - BRSU TABANAN BALI PDFDocument20 pagesSurveillance 02 Audit Report (Remote) - BRSU TABANAN BALI PDFTantie WidyaNo ratings yet

- Multi Blade (Turbomachinery) MillingDocument5 pagesMulti Blade (Turbomachinery) MillingnaninoNo ratings yet

- Flexible Budgets, Standard Costs, and Variance AnalysisDocument121 pagesFlexible Budgets, Standard Costs, and Variance AnalysisRodil Ricardo Mansueto100% (1)

- Analysis - Leadership - Culture - Outlook - Business Model - Strategy - Customer Interface - RecommendationsDocument40 pagesAnalysis - Leadership - Culture - Outlook - Business Model - Strategy - Customer Interface - RecommendationsvNo ratings yet

- Acc Gr12 June 2009 Answer Sheets BlankDocument18 pagesAcc Gr12 June 2009 Answer Sheets BlankSam ChristieNo ratings yet

- Test Bank For Macroeconomics in Modules 4th Edition Paul Krugman Robin Wells Full DownloadDocument25 pagesTest Bank For Macroeconomics in Modules 4th Edition Paul Krugman Robin Wells Full Downloadmichaelbirdgznspejbwa100% (25)

- The Business Research Process: An OverviewDocument24 pagesThe Business Research Process: An OverviewsatahNo ratings yet

- CHAPTER 2.1 Strategic Financial ManagementDocument23 pagesCHAPTER 2.1 Strategic Financial ManagementKarl BarnuevoNo ratings yet

- BS 1757 Power-Driven Mobile CranesDocument51 pagesBS 1757 Power-Driven Mobile CranesAsh TurnerNo ratings yet

- How Sourcing Excellence Can Lower Hospital CostsDocument12 pagesHow Sourcing Excellence Can Lower Hospital CostsDenise Cheung100% (1)

- New Microsoft Office Power Point Presentation On NestleDocument86 pagesNew Microsoft Office Power Point Presentation On NestlesameenNo ratings yet

- 2009 - Building A Sustainable Plan Webinar - PresentationDocument24 pages2009 - Building A Sustainable Plan Webinar - PresentationsaifasadNo ratings yet

- CH 01Document37 pagesCH 01maneata_5No ratings yet

- Factors Influencing The Growth of Sari-Sari Store Business in Pantay Matanda Tanauan City Batangas Abm 3Document13 pagesFactors Influencing The Growth of Sari-Sari Store Business in Pantay Matanda Tanauan City Batangas Abm 3Bayani Vicencio100% (2)

- A Guide To Measures of Trade Openness and PolicyDocument39 pagesA Guide To Measures of Trade Openness and PolicyMohammad Abu-OdehNo ratings yet

- Example Answer - Closing ChecklistDocument5 pagesExample Answer - Closing Checklistryan rookerNo ratings yet

- Restaurant Startup Costs - 2022117215548Document5 pagesRestaurant Startup Costs - 2022117215548Naison StanleyNo ratings yet

- Marginal CostingDocument9 pagesMarginal CostingJoydip DasguptaNo ratings yet

- Financial Statment of Chenab LimitedDocument13 pagesFinancial Statment of Chenab LimitedShakeel AhmadNo ratings yet

- Pmbok Guide Part 1Document86 pagesPmbok Guide Part 1neil_scribd2012No ratings yet

- Name: Abhishek Kumar Employee ID: 162225: Fixed Compensation Variable Compensation Total Cash CompensationDocument3 pagesName: Abhishek Kumar Employee ID: 162225: Fixed Compensation Variable Compensation Total Cash CompensationManish KumarNo ratings yet

- 4.0 Impact of Brexit On Our CompanyDocument7 pages4.0 Impact of Brexit On Our CompanyatoshkhujayevNo ratings yet