Professional Documents

Culture Documents

Saudagar 2007

Saudagar 2007

Uploaded by

Fathia AlkelaeCopyright:

Available Formats

You might also like

- List of Important Topics For NEET PG by DbmciDocument7 pagesList of Important Topics For NEET PG by Dbmcimanmohansai bache57% (7)

- Patrick TB Ch16Document50 pagesPatrick TB Ch16Chemistix100% (4)

- Advanced Tribology 2008Document1,033 pagesAdvanced Tribology 2008Fathia AlkelaeNo ratings yet

- Dna Replication and Protein Synthesis Lesson PlanDocument10 pagesDna Replication and Protein Synthesis Lesson Planapi-356227663100% (2)

- Acido Lactico SSFDocument10 pagesAcido Lactico SSFJuan Oviedo Ingenieria AgroindustrialNo ratings yet

- Pilot-Scale Lactic Acid Production Via Batch Culturing of Lactobacillus Sp. RKY2 Using Corn Steep Liquor As A Nitrogen SourceDocument6 pagesPilot-Scale Lactic Acid Production Via Batch Culturing of Lactobacillus Sp. RKY2 Using Corn Steep Liquor As A Nitrogen SourcekopisusumantapNo ratings yet

- Omay 2012Document8 pagesOmay 201215041168No ratings yet

- Modeling of Batch Fermentation Kinetics For Succinic Acid Production by Mannheneimia SucciniciproducensDocument9 pagesModeling of Batch Fermentation Kinetics For Succinic Acid Production by Mannheneimia SucciniciproducensRyuuara Az-ZahraNo ratings yet

- Optimization of Lactic Acid Production in SSF by Lactobacillus Amylovorus NRRL B-4542 Using Taguchi MethodologyDocument7 pagesOptimization of Lactic Acid Production in SSF by Lactobacillus Amylovorus NRRL B-4542 Using Taguchi MethodologyAraveetiCSReddyNo ratings yet

- Factors Regulating Production of Glucose Oxidase by Aspergillus NigerDocument5 pagesFactors Regulating Production of Glucose Oxidase by Aspergillus NigerI. Murali KrishnaNo ratings yet

- Lactic Acid Production From Waste PotatoDocument14 pagesLactic Acid Production From Waste Potatohariss123a63No ratings yet

- Impact of Methyl Jasmonate On Squalene Bio Synthesis in MicroalgaDocument5 pagesImpact of Methyl Jasmonate On Squalene Bio Synthesis in MicroalgaGerman ColqueNo ratings yet

- Hydrolsis NyamplungDocument7 pagesHydrolsis NyamplungVenny AgustinNo ratings yet

- Kinetic Simple GoodDocument11 pagesKinetic Simple GoodReza MahoorNo ratings yet

- Effect of Enzyme Treated Copra Meal On Nutritive Value, Reducing Sugars and Oligosaccharides As PrebioticsDocument4 pagesEffect of Enzyme Treated Copra Meal On Nutritive Value, Reducing Sugars and Oligosaccharides As PrebioticsthesijNo ratings yet

- Production and characterization of thermostable α-amylase from a newly isolated strain of Bacillus subtilis Kibge-HarDocument15 pagesProduction and characterization of thermostable α-amylase from a newly isolated strain of Bacillus subtilis Kibge-HarBashuki MishraNo ratings yet

- Lactic Acid Production From Simultaneous Saccharification and Fermentation of Cassava Starch by Lactobacillus Plantarum MSUL 903Document5 pagesLactic Acid Production From Simultaneous Saccharification and Fermentation of Cassava Starch by Lactobacillus Plantarum MSUL 903Sacha INchi CentreNo ratings yet

- Influencia de PHDocument13 pagesInfluencia de PHDavid SantiagoNo ratings yet

- Optimized Methodology For Alkaline and Enzyme-Assisted Extraction of Protein From Sacha Inchi (Plukenetia Volubilis) Kernel CakeDocument8 pagesOptimized Methodology For Alkaline and Enzyme-Assisted Extraction of Protein From Sacha Inchi (Plukenetia Volubilis) Kernel CakeNancy GonzalezNo ratings yet

- 19.physicochemical Properties of Defatted RambutanDocument6 pages19.physicochemical Properties of Defatted RambutangramdagpinNo ratings yet

- Anti Fungal in BreadDocument6 pagesAnti Fungal in BreadRufa Lara MendezNo ratings yet

- Enzymatic Hydrolysis of Wheat Gluten by Proteases and Properties of The Resulting HydrolysatesDocument5 pagesEnzymatic Hydrolysis of Wheat Gluten by Proteases and Properties of The Resulting HydrolysatesPadmini RajuNo ratings yet

- s10068 016 0030 XDocument6 pagess10068 016 0030 X0231810025 YANERIS MARCELA MORELO BELLIDO ESTUDIANTE ACTIVONo ratings yet

- Determination of Sialic Acids in Infant Formula by Chromatographic MethodsDocument10 pagesDetermination of Sialic Acids in Infant Formula by Chromatographic MethodsSze JackNo ratings yet

- Ijmer 46065258 PDFDocument7 pagesIjmer 46065258 PDFIJMERNo ratings yet

- JCTM 2024 59 1 2 23-22 pp15-22Document8 pagesJCTM 2024 59 1 2 23-22 pp15-22UNSNo ratings yet

- Article WJPPS 1596215781 01 August 2020Document14 pagesArticle WJPPS 1596215781 01 August 2020h_rivaiNo ratings yet

- 4 - Choubane S., Khelil O. Et Cheba B. 2015, African Journal of BiotechnologyDocument6 pages4 - Choubane S., Khelil O. Et Cheba B. 2015, African Journal of BiotechnologyOmar KHELILNo ratings yet

- Acido LacticoDocument9 pagesAcido LacticoJuan Victor ChampeNo ratings yet

- Production of Lipase Using Cassava Peel and Sunflower Oil in Solid-State Fermentation - Preliminary StudyDocument7 pagesProduction of Lipase Using Cassava Peel and Sunflower Oil in Solid-State Fermentation - Preliminary StudyAgriculturaldavidNo ratings yet

- Isolation and Bioprocess Optimization of HalophiliDocument25 pagesIsolation and Bioprocess Optimization of Halophilisalin MajumdarNo ratings yet

- Tmp33e7 TMPDocument6 pagesTmp33e7 TMPFrontiersNo ratings yet

- ABAB 2006 SeparationDocument13 pagesABAB 2006 SeparationJulieth Cardona C.No ratings yet

- Articulo 1 PDFDocument19 pagesArticulo 1 PDFJennifer A. PatiñoNo ratings yet

- Proposal Project f4 DrafDocument6 pagesProposal Project f4 Drafaiman farhanaNo ratings yet

- Natamycin 6Document6 pagesNatamycin 6Ευαγγελία ΘεοχάρηNo ratings yet

- Determination of Propionates and Propionic Acid in Bread Samples Using High Performance Liquid ChromatographyDocument6 pagesDetermination of Propionates and Propionic Acid in Bread Samples Using High Performance Liquid ChromatographytheijesNo ratings yet

- Mal J Microbiol 2015112163-169Document8 pagesMal J Microbiol 2015112163-169keneth john manayagaNo ratings yet

- Cellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateDocument5 pagesCellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateHamka NurkayaNo ratings yet

- Molasses 14Document11 pagesMolasses 14Tabish AliNo ratings yet

- tmp4E2F TMPDocument13 pagestmp4E2F TMPFrontiersNo ratings yet

- Acidophilus and Lactobacillus Casei of Human Intestinal OriginDocument6 pagesAcidophilus and Lactobacillus Casei of Human Intestinal Originmmoradi55No ratings yet

- Fermentation and Recovery of L-Glutamic - Acid - FromDocument8 pagesFermentation and Recovery of L-Glutamic - Acid - FromPrachi BhoirNo ratings yet

- 2006 Uruakpa Canola Carrageenan NetworkDocument5 pages2006 Uruakpa Canola Carrageenan NetworkckwxbxdwtjNo ratings yet

- Coelho2011 Acid LacticDocument12 pagesCoelho2011 Acid Lacticlfiguaranarregoces12No ratings yet

- AA Cocoa LiquorsDocument8 pagesAA Cocoa LiquorsJonathan Torres PezoNo ratings yet

- PectinasasDocument9 pagesPectinasascarolasbdNo ratings yet

- Rapid Screening Procedures For Identification of Succinic Acid ProducersDocument10 pagesRapid Screening Procedures For Identification of Succinic Acid ProducersEdward AlexanderNo ratings yet

- Purification of A Synthetic Oligonucleotide by Anion Exchange Chromatography Method Optimisation and Scale-UpDocument10 pagesPurification of A Synthetic Oligonucleotide by Anion Exchange Chromatography Method Optimisation and Scale-UpMike BudimanNo ratings yet

- Optimization of A Fed-Batch Fermentation Process For Production of Bleomycin by Streptomyces Mobaraensis ATCC 15003Document6 pagesOptimization of A Fed-Batch Fermentation Process For Production of Bleomycin by Streptomyces Mobaraensis ATCC 15003jmrozo3No ratings yet

- Lactulose SpctroDocument4 pagesLactulose SpctroDr-Asad RazaNo ratings yet

- 15 PDFDocument7 pages15 PDFPradeep PereraNo ratings yet

- Im 2009Document8 pagesIm 2009Jesus C. MendozaNo ratings yet

- B.K.M.lakshmi, Et Al TraducccionDocument10 pagesB.K.M.lakshmi, Et Al TraducccionArturo PeñablassiNo ratings yet

- Biomass and Bioenergy: Research PaperDocument10 pagesBiomass and Bioenergy: Research PaperPaulina Lpz JrzNo ratings yet

- Biosynthesis of Protease From Lactobacillus Paracasei: Kinetic Analysis of Fermentation ParametersDocument5 pagesBiosynthesis of Protease From Lactobacillus Paracasei: Kinetic Analysis of Fermentation ParametersGovGovsNo ratings yet

- Repeated PH-stat Fed-Batch Fermentation For RhamnolipidDocument9 pagesRepeated PH-stat Fed-Batch Fermentation For Rhamnolipidsidikmar1425No ratings yet

- Optimized Lipase-Catalyzed Synthesis of Adipate Ester in A Solvent-Free SystemDocument7 pagesOptimized Lipase-Catalyzed Synthesis of Adipate Ester in A Solvent-Free SystemGizeleBaldoNo ratings yet

- El-Gendy 2013 - RSM For Sugarcane FermentationDocument10 pagesEl-Gendy 2013 - RSM For Sugarcane FermentationAyu RatnasariNo ratings yet

- Batch and Continuous Culture of Lactococcus LactisDocument9 pagesBatch and Continuous Culture of Lactococcus LactisJose Luis Sarabia ArellanoNo ratings yet

- Proponoic AcidDocument7 pagesProponoic AcidAnonymous SUbBZzNo ratings yet

- Fermentation 04 00079Document9 pagesFermentation 04 00079CHIRANJEEVINo ratings yet

- Microbiology in Dairy Processing: Challenges and OpportunitiesFrom EverandMicrobiology in Dairy Processing: Challenges and OpportunitiesNo ratings yet

- Advances in Dairy ProductsFrom EverandAdvances in Dairy ProductsFrancesco ContoNo ratings yet

- Effects of Heat Treatments On Microstructure and Properties of Nickel-Aluminum Bronze Fabricated by Centrifugal CastingDocument9 pagesEffects of Heat Treatments On Microstructure and Properties of Nickel-Aluminum Bronze Fabricated by Centrifugal CastingFathia AlkelaeNo ratings yet

- Laser Powder Bed Fusion and Post Processing of Alloy C22Document16 pagesLaser Powder Bed Fusion and Post Processing of Alloy C22Fathia AlkelaeNo ratings yet

- Fabricating Superior NiAl Bronze Components Through Wire Arc Additive ManufacturingDocument14 pagesFabricating Superior NiAl Bronze Components Through Wire Arc Additive ManufacturingFathia AlkelaeNo ratings yet

- The Effects of Production Methods On The Microstructures and Mechanical Properties of An Aluminum BronzeDocument10 pagesThe Effects of Production Methods On The Microstructures and Mechanical Properties of An Aluminum BronzeFathia AlkelaeNo ratings yet

- TEM STUDY OF PRECIPITATES IN LASER CLAD Ni-A1 BRONZEDocument6 pagesTEM STUDY OF PRECIPITATES IN LASER CLAD Ni-A1 BRONZEFathia AlkelaeNo ratings yet

- Characterization of Phases in A Nickel-Aluminium BronzeDocument7 pagesCharacterization of Phases in A Nickel-Aluminium BronzeFathia AlkelaeNo ratings yet

- The Influence of Alloying, Temperature and Related Effects On The Stacking Fault EnergyDocument33 pagesThe Influence of Alloying, Temperature and Related Effects On The Stacking Fault EnergyFathia AlkelaeNo ratings yet

- Temperature Dependence of Stacking Fault Energy in Close-Packed Metals and AlloysDocument17 pagesTemperature Dependence of Stacking Fault Energy in Close-Packed Metals and AlloysFathia AlkelaeNo ratings yet

- Eth-31148-02 (Nitrogen Doped)Document160 pagesEth-31148-02 (Nitrogen Doped)Fathia AlkelaeNo ratings yet

- Control of Residual Oxygen The Process Atmosphere During Laser-Powder Bed Fusion Processing of Ti-6Al-4VDocument10 pagesControl of Residual Oxygen The Process Atmosphere During Laser-Powder Bed Fusion Processing of Ti-6Al-4VFathia AlkelaeNo ratings yet

- Tribological Characteristics of Nickel-Aluminium Bronze CuAl10Ni5Fe4 Against 30CrMnSiA Steel After The Prior Corrosion TreatmentDocument6 pagesTribological Characteristics of Nickel-Aluminium Bronze CuAl10Ni5Fe4 Against 30CrMnSiA Steel After The Prior Corrosion TreatmentFathia AlkelaeNo ratings yet

- Tribological and Mechanical Characterization of Nickel Aluminium Bronze (NAB) Manufactured by Laser Powder-Bed Fusion (L-PBF)Document10 pagesTribological and Mechanical Characterization of Nickel Aluminium Bronze (NAB) Manufactured by Laser Powder-Bed Fusion (L-PBF)Fathia AlkelaeNo ratings yet

- Four Point BendingDocument307 pagesFour Point BendingFathia AlkelaeNo ratings yet

- Prediction of DLC Friction Lifetime Based On A Local Archard Factor Density ApproachDocument17 pagesPrediction of DLC Friction Lifetime Based On A Local Archard Factor Density ApproachFathia AlkelaeNo ratings yet

- Bibc102, Metabolic Biochemistry: Gen-Sheng Feng Fall, 2010Document14 pagesBibc102, Metabolic Biochemistry: Gen-Sheng Feng Fall, 2010cool_trainerNo ratings yet

- Team Motivation FMGE Coaching Academy: Mock Test - 3Document23 pagesTeam Motivation FMGE Coaching Academy: Mock Test - 3abhishiktaNo ratings yet

- L&G Belts Cross RefDocument31 pagesL&G Belts Cross RefashielanieNo ratings yet

- Biosurfactants From YeastDocument18 pagesBiosurfactants From YeastoniatrdNo ratings yet

- Syllabus For BiochemistryDocument8 pagesSyllabus For BiochemistryJenny Lyn Nebres100% (1)

- Biochemical and Functional Properties ofDocument347 pagesBiochemical and Functional Properties ofValeria OlmedoNo ratings yet

- Preparatory Problems International Chemistry Olympiad 2013Document77 pagesPreparatory Problems International Chemistry Olympiad 2013RSLNo ratings yet

- Proteins and Amino AcidsDocument50 pagesProteins and Amino Acidsraddag100% (2)

- Protein Synthesis Paper Lab InstructionsDocument11 pagesProtein Synthesis Paper Lab Instructionsapi-292473508No ratings yet

- Ib Notes 1,2,3,4,5,6Document31 pagesIb Notes 1,2,3,4,5,6Kashish Doshi100% (2)

- Amino Acid CatabolismDocument24 pagesAmino Acid CatabolismAnonymous 0ha8TmNo ratings yet

- Lecture 1 - Molecular Genetics and Gene ExpressionDocument12 pagesLecture 1 - Molecular Genetics and Gene ExpressionChn ypNo ratings yet

- Chapter 23: Nucleotide Metabolism: MatchingDocument14 pagesChapter 23: Nucleotide Metabolism: MatchingAbe345123No ratings yet

- The Molecular Basis of InheritanceDocument35 pagesThe Molecular Basis of Inheritanceprehealthhelp80% (5)

- Ribosomes and Protein SynthesisDocument12 pagesRibosomes and Protein SynthesisSulfeekker AhamedNo ratings yet

- (Boschke F.L.) Medicinal ChemistryDocument157 pages(Boschke F.L.) Medicinal ChemistryJo ShuNo ratings yet

- DNA MCQsDocument5 pagesDNA MCQsfafa salahNo ratings yet

- Biology FSC Chapter 2Document15 pagesBiology FSC Chapter 2Diana PriyaNo ratings yet

- Role of Toxins in Pathogenesis: Pl. Path. 111 (Cr. Hrs. 3+1)Document26 pagesRole of Toxins in Pathogenesis: Pl. Path. 111 (Cr. Hrs. 3+1)Pravin KhaireNo ratings yet

- MODULE 4 Metabolism of Cabohydrate Fats and Proteins Biochem 2nd Sem 2020 2021 1Document19 pagesMODULE 4 Metabolism of Cabohydrate Fats and Proteins Biochem 2nd Sem 2020 2021 1Shaira BayubayNo ratings yet

- TranslationDocument1 pageTranslationGianne AbcedeNo ratings yet

- Biochemistry Final Review OutlinesDocument22 pagesBiochemistry Final Review Outlineslacey100% (1)

- 09 Chapter2 PDFDocument31 pages09 Chapter2 PDFRamNo ratings yet

- Mevalonic Acid PathwayDocument4 pagesMevalonic Acid PathwayChandra ReddyNo ratings yet

- Enzymes of Dna ReplicationDocument7 pagesEnzymes of Dna ReplicationSevdred CadelinaNo ratings yet

- TEAS 6 Science by KellyDocument22 pagesTEAS 6 Science by KellyLily Garcia100% (1)

- Ref 48 35. FernandesDocument10 pagesRef 48 35. FernandesJuan Jose Vega AlbaNo ratings yet

Saudagar 2007

Saudagar 2007

Uploaded by

Fathia AlkelaeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudagar 2007

Saudagar 2007

Uploaded by

Fathia AlkelaeCopyright:

Available Formats

L25 Orthogonal

Copyright © 2007 byArray

Humanaand Clavulanic

Press Inc. Acid 345

All rights of any nature whatsoever reserved.

0273-2289/1559-0291 (Online)/07/136:345–360/$30.00

A Statistical Approach Using L25 Orthogonal

Array Method to Study Fermentative

Production of Clavulanic Acid by

Streptomyces clavuligerus MTCC 1142

PARAG S. SAUDAGAR AND REKHA S. SINGHAL*

Food and Fermentation Technology Department, University Institute

of Chemical Technology, Matunga, Mumbai 400 019, India,

E-mail: rekha@udct.org

Received February 15, 2006; Revised April 13, 2006;

Accepted April 20, 2006.

Abstract

Clavulanic acid is a naturally occurring antibiotic produced by Streptomy-

ces clavuligerus. The present work reports on clavulanic acid production by

Streptomyces clavuligerus MTCC 1142 using one-factor-at-a-time and L25 orthogo-

nal array. The one-factor-at-a-time method was adopted to investigate the effect

of media components (i.e., carbon source, nitrogen source and inoculum

concentration) and environmental factors such as pH for clavulanic acid

production. Production of clavulanic acid by Streptomyces clavuligerus was

investigated using seven different carbon sources (viz. glucose, sucrose,

modified starch, rice-bran oil, soybean oil, palm oil, and glycerol) and six

different nitrogen sources (viz. peptone, yeast extract, ammonium chloride,

ammonium carbonate, sodium nitrate and potassium nitrate). A maximum

yield of 140 µg/mL clavulanic acid was obtained in the medium containing

soybean oil as a carbon source and yeast extract as nitrogen source. Subse-

quently, the concentration of soybean flour, soybean oil, dextrin, yeast extract

and K2HPO4 were optimized using L25 orthogonal array method. The final

optimized medium produced 500 µg/mL clavulanic acid at the end of 96 h

as compared to 140 µg/mL before optimization. Synthesis of precursor

molecules as a metabolic driving force is of considerable importance in anti-

biotic synthesis. Attempts to increase the clavulanic acid synthesis by manipu-

lating the anaplerotic flux on C3 and C5 precursors by supplementing the

medium with arginine, ornithine, proline, valine, leucine, isoleucine, pyru-

*Author to whom all correspondence and reprint requests should be addressed.

Applied Biochemistry and Biotechnology 345 Vol. 136, 2007

346 Saudagar and Singhal

vic acid and α-ketoglutarate were successful. Supplementing the optimized

medium with 0.1 M arginine and 0.1 M leucine increased the yield of

clavulanic acid further to 1100 µg/mL and 1384 µg/mL respectively.

Index Entries: Clavulanic acid; β-lactamases; fermentation; L25 orthogonal

array; anaplerotic flux; amino acid precursors.

Introduction

Widespread use of β-lactam class of antibiotics such as penicillin and

cephlosporins to combat bacterial infections has led to the emergence of

bacterial strains resistant to these drugs. Resistance to β-lactam is conferred

upon bacteria via β-lactamases. To overcome the acquired resistance, anti-

biotics can be co-administered with clavulanic acid, a potent inhibitor of

bacterial β-lactamases (1). Clavulanic acid is a naturally occurring antibi-

otic produced by Streptomyces clavuligerus. Clavulanic acid binds irrevers-

ibly with the enzyme to give a stable complex (2), thereby making it inactive.

The β-lactamases inhibitory activity of clavulanic acid is related to its 3R,

5R stereochemistry. The combined effective action of the β-lactamase inhibi-

tor and antibacterial agent, make clavulanic acid very important both clini-

cally and economically. Many investigators have attempted to obtain

optimal submerged cultures for antibiotic production from different fungi

such as erythromycin from Saccharospora erythraea (3,4) and cephamycin

from Streptomyces clavuligerus (5). To the best of our knowledge, the nutri-

tional requirements and environmental conditions for submerged culture

of S. clavuligerus for clavulanic acid production using orthogonal matrix is

not demonstrated.

Medium optimization by the one-factor-at-time method involves

changing one variable (nutrients, pH, temperature, etc.) while fixing the

others at a certain arbitrary levels (6). Because most industrial experiments

usually involve a significant number of factors, a full factorial design

results in a large number of experiments. To reduce the number of experi-

ments to a practical level, only a small set from all the possibilities is selected.

Taguchi constructed a special set of general design guidelines for factorial

experiments that cover many applications (6). The method uses a special set

of arrays called orthogonal arrays, which stipulate the way of conducting

the minimal number of experiments, and give the full information of all the

factors that affect the performance parameter. Although there are many

standard orthogonal arrays available, each of the arrays is meant for a

specific number of independent design variables and levels. The additive

assumption of the Taguchi design implies that the individual or main

effects of the independent variables on performance parameter are sepa-

rable. Under this assumption, the effect of each factor can be linear, qua-

dratic, or may have higher order, but the model assumes the absence of any

cross product effects (interactions) among the individual factors. That

means the effect of independent variable 1 on performance parameter does

not depend on the different level settings of any other independent vari-

Applied Biochemistry and Biotechnology Vol. 136, 2007

L25 Orthogonal Array and Clavulanic Acid 347

Fig. 1. Biosynthetic pathway for clavulanic acid (21).

ables and vice versa. The crux of the orthogonal arrays method lies in choos-

ing the level combinations of the input design variables for each experi-

ment.

The present work deals with optimization of the process for clavulanic

acid production by S. clavuligerus MTCC 1142 using a statistically based

experimental design. In the first step, the one-factor-at-a-time method was

used to investigate the effect of media constituents such as carbon source,

nitrogen source, and inoculum concentration. Subsequently, in the second

step, concentration of the medium components was optimized using an

orthogonal matrix method. The biosynthesis of clavulanic acid (Fig. 1) has

not been fully elucidated, although many intermediates and enzymes

involved in the biosynthetic pathway have been identified (7,8). An attempt

is made to increase the yield of clavulanic acid by supplementing the fermen-

tation medium with different amino acids.

Materials and Methods

Media Components

Glucose, sucrose, glycerol, yeast extract, ammonium carbonate, ammo-

nium chloride, sodium nitrate, potassium nitrate, potassium dihydrogen

phosphate, L-arginine, l-proline, L-pyruvic acid, L-ornithine, and α-keto-

glutarate were purchased from M/S Hi-Media Limited, Mumbai, India.

Soybean oil, palm oil and rice bran oil were purchased from Nature Fresh

Limited, Mumbai.

Maintenance of the Microbial Culture and Fermentative Production

of Clavulanic Acid

The MTCC 1142 strain of S. clavuligerus was procured from MTCC,

Chandigarh, India. Clavulanic acid production was carried out in two

stages. In the first stage, cells were grown in the seed culture, and in the

second stage, seed culture was inoculated into the fermentation medium

for clavulanic acid production. S. clavuligerus MTCC 1142 was maintained

Applied Biochemistry and Biotechnology Vol. 136, 2007

348 Saudagar and Singhal

on slants of a defined medium containing 0.4% yeast extract, 1% malt

extract, 0.4% glucose and 2% agar with a pH adjusted to 7.2 ± 0.2. The

slants grown at 25°C for 4 d were used for inoculation into a seed culture

medium (1% soybean flour, 2% dextrin, 0.2% soybean oil, pH was adjusted

to 7.0 ± 0.2). For the preliminary studies 2% of seed culture grown for 48 h

in an incubator shaker at 25°C and at 200 rpm was used for inoculation into

the production medium.

Fermentative Production of Clavulanic Acid

The medium designed by Lee et al. (9) was modified and used in the

present study. Composition of the medium used was 1.1% soybean flour,

1.2% rice bran oil, 0.6% dextrin, 0.25% peptone and 0.25% KH2PO4 with a

pH adjusted to 7.0 ± 0.2. Effect of different carbon and nitrogen sources was

studied using the one-factor-at-time method. All the initial fermentation

runs used 2% inoculum at 25°C in an incubator shaker at 200 rpm for 96 h.

L25 orthogonal array was further used to optimize the concentrations of the

best carbon source and nitrogen source.

Optimization of Fermentation Medium

Using the One-Factor-at-a-Time Method

Effect of Different Carbon Sources

In the medium selected, rice bran oil was substituted with six different

carbon sources viz. glucose, sucrose, modified starch, soybean oil, palm oil,

and glycerol at 0.6–4.8% and studied for clavulanic acid production. Fifty

milliliters of the autoclaved medium (pH 7.0 ± 0.2) was inoculated with 2%

seed culture of S. clavuligerus MTCC 1142 and incubated for 96 h in an

incubator shaker at 200 rpm and at 25°C.

2.4.2. Effect of Different Nitrogen Sources

Peptone was substituted with five different nitrogen sources (viz. yeast

extract, ammonium carbonate, ammonium chloride, sodium nitrate and

potassium nitrate in the concentration range of 0.125–1.0%) and studied for

clavulanic acid production in the similar way as described previously.

Effect of Inoculum Size

The optimized fermentation medium was supplemented with differ-

ent concentrations of the seed culture medium (2%, 4%, 6% 8% and 10%)

and studied for clavulanic acid production.

Optimization Using the L25-Orthogonal Array

The design for the L25-orthogonal array was developed and analyzed

using “MINITAB 13.30” software. Table 1 depicts the L25-orthogonal array

design, which was used in the present study. All experiments were per-

formed in at least triplicate.

Applied Biochemistry and Biotechnology Vol. 136, 2007

L25 Orthogonal Array and Clavulanic Acid 349

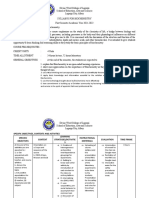

Table 1

L25 Orthogonal Array for Clavulanic Acida Production

Components Media constituents g/100mL

RUN A B C D E A B C D E Yield µg/mL

1 1 1 1 1 1 1.1 0.4 0.2 0.250 0.050 103.90 ± 2.0

2 1 2 2 2 2 1.1 0.8 0.4 0.500 0.100 83.28 ± 4.0

3 1 3 3 3 3 1.1 1.2 0.6 1.000 0.200 100.78 ± 2.3

4 1 4 4 4 4 1.1 1.6 0.8 1.500 0.250 135.15 ± 3.1

5 1 5 5 5 5 1.1 2.0 1 2.000 0.300 168.75 ± 2.6

6 2 1 2 3 4 2.2 0.4 0.4 1.000 0.250 131.25 ± 2.0

7 2 2 3 4 5 2.2 0.8 0.6 1.500 0.300 155.46 ± 0.9

8 2 3 4 5 1 2.2 1.2 0.8 2.000 0.050 144.53 ± 3.2

9 2 4 5 1 2 2.2 1.6 1.0 0.250 0.100 137.50 ± 2.5

10 2 5 1 2 3 2.2 2.0 0.2 0.500 0.200 153.90 ± 3.0

11 3 1 3 5 2 4.4 0.4 0.6 2.000 0.100 164.84 ± 2.4

12 3 2 4 1 3 4.4 0.8 0.8 0.250 0.200 217.96 ± 2.0

13 3 3 5 2 4 4.4 1.2 1.0 0.500 0.250 237.50 ± 1.6

14 3 4 1 3 5 4.4 1.6 0.2 1.000 0.300 229.68 ± 1.0

15 3 5 2 4 1 4.4 2.0 0.4 1.500 0.050 187.50 ± 1.8

16 4 1 4 2 5 6.6 0.4 0.8 0.500 0.300 219.53 ± 2.1

17 4 2 5 3 1 6.6 0.8 1.0 1.000 0.050 256.25 ± 2.3

18 4 3 1 4 2 6.6 1.2 0.2 1.500 0.100 303.90 ± 2.4

19 4 4 2 5 3 6.6 1.6 0.4 2.000 0.200 293.75 ± 2.9

20 4 5 3 1 4 6.6 2.0 0.6 0.250 0.250 322.65 ± 1.4

21 5 1 5 4 3 8.8 0.4 1.0 1.500 0.200 504.75 ± 3.4

22 5 2 1 5 4 8.8 0.8 0.2 2.000 0.250 416.40 ± 3.0

23 5 3 2 1 5 8.8 1.2 0.4 0.250 0.300 377.34 ± 1.5

24 5 4 3 2 1 8.8 1.6 0.6 0.500 0.050 337.50 ± 2.6

25 5 5 4 3 2 8.8 2.0 0.8 1.000 0.100 327.34 ± 0.5

a

Experimental data are mean ± S.D. of triple determination.

A, soybean flour; B, soybean oil; C, dextrin; D, yeast extract; E, K2HPO4

Effect of pH on Clavulanic Acid Production

Effect of pH on clavulanic acid production was studied by varying the

initial pH of the fermentation medium optimized using L25 orthogonal array

in the pH range of 5.0–8.5.

Effect of Amino Acids on Clavulanic Acid Production

The biosynthetic pathway (Fig. 1) for the clavulanic acid synthesis is

not clearly understood. The effect of variation of anaplerotic flux on the C3

(pyruvate) and C5 (arginine) precursor on clavulanic acid production by S.

clavuligerus was determined by supplementing the production media with

different amino acids (viz. l-arginine, L-ornithine, l-proline, L-valine, L-leu-

cine), pyruvic acid and α-ketoglutarate at 0.05–2 M and studied for

clavulanic acid production as described previously.

Applied Biochemistry and Biotechnology Vol. 136, 2007

350 Saudagar and Singhal

Quantification of Clavulanic Acid in the Broth

Clavulanic acid in the fermentation broth was estimated spectropho-

tometrically as described by Bird et al. (10), and used by Kwon and Kim (11)

and Mayer and Deckwer (12). The assay method is based on the reaction of

clavulanic acid with imidazole that results in formation of 1-(4-aza-8-hy-

droxy-6-oxo) oct-2-en-l-oyl-imidazole, which shows absorbance at 312 nm.

The method is applicable to clavulanate concentrations as low as 2 µg/mL

and is specific for intact clavulanate in presence of degradation products.

Fermentation broth was clarified by centrifugation at 10,000g at 4°C for 25

min. To the supernatant in test tubes, 2 mL of imidazole reagent (8.25 g

imidazole in 100 mL water, pH adjusted to 6.8 ± 0.02 with 5 M HCl) was

added. The tubes were stoppered, and contents were mixed by vortexing

on a cyclomixer, and subsequently immersed in water bath at 30°C for 12

min. The tubes were then removed and cooled rapidly to 20°C. The optical

density at 312 nm was measured in 1-cm cells using mixture of 1 mL water

and 2 mL imidazole reagent as reference. Augmentin (intravenous injec-

tion containing 100 mg of clavulanic acid and 500 mg of amoxicillin) was

used as the standard.

Growth of S. clavuligerus MTCC 1142

Because the culture broth contained insoluble components in soybean

flour, it was impossible to measure the optical density or dry cell weight.

Therefore cell concentration was correlated to intracellular nucleic acid

concentration using diphenylamine (DPA) method as developed by Bur-

ton (13). Heating with strong acid converts the deoxyribose of DNA to

furfural. DPA reacts with furfural to give a deep blue coloured compound

providing a measure of nucleic acids present. Fermentation broth was clari-

fied by centrifugation at 10,000g at 4°C for 25 min. The supernatant was

separated and to the cell pellet so obtained, 5 mL of citrate-phosphate buffer,

pH 6.8 was added. The cell suspension was then sonicated for 20 min using

Branson probe sonifier 450 to disrupt the cells. The suspension was centri-

fuged at 16,000g at 4°C for 25 min. To 1 mL supernatant in the test tube, 2

mL DPA reagent (1.5 g DPA in 100 mL glacial acetic acid and 15 mL of

concentrated sulfuric acid; 0.5 mL of 2% ethanal was added to the DPA

reagent on the day of the test) was added and vortexed to get an uniform

solution. The tubes were immersed in a boiling water bath for 10 min and

then checked for absorbance at 595 nm.

Results and Discussion

Optimization Using One-Factor-at-a-Time

Figure 2 documents the effect of different carbon sources on clavulanic

acid production. The medium was supplemented with lipids and carbohy-

drates as carbon sources. Carbohydrates are the simplest energy sources

for growth and secondary metabolite production. However, rapid catabo-

Applied Biochemistry and Biotechnology Vol. 136, 2007

L25 Orthogonal Array and Clavulanic Acid 351

Fig. 2. Effect of different carbon sources on clavulanic acid production (experimen-

tal data are mean ± S.D. of triple determination) in Streptomyces clavuligerus MTCC

1142.

lism of glucose, sucrose and modified starch resulted in an increase in the

biomass (Fig. 3) but a decrease in clavulanic acid production (Fig. 2). These

results are in accordance to those reported by Revilla et al. (14) for penicillin

production in P. chrysogenum and Aharonowitz and Demain (15) for cepha-

losporin biosynthesis in S. clavuligerus.

Addition of a low-solubility carbon source such as oil is a method of

avoiding carbon catabolite regulation. In the present study, lipids were

found to act as better carbon sources for production of clavulanic acid by

S. Clavuligerus. It can be seen from Fig. 2 that 4.8% soybean oil and 4.8% of

palm oil supported maximum production of 139 µg/mL of clavulanic acid.

1.2% glycerol and 2.4% rice bran oil gave a yield of 111.5 µg/mL and 120

µg/mL of clavulanic acid, respectively. The addition of oil to a growth

medium is also preferred on an energy basis, as typical oil contains approx

2.25 times the energy of glucose on a weight-to-weight basis (15).

Figure 4 documents the effect of different nitrogen sources on

clavulanic acid production. Of the six nitrogen sources selected, the inor-

ganic nitrogen sources, such as ammonium chloride, ammonium carbon-

ate, sodium nitrate, and potassium nitrate, did not have a major effect on

clavulanic acid. Organic nitrogen sources such as peptone and yeast extract

had a major impact on clavulanic acid production. Yeast extract at 0.5%

supported maximum yield of 112 µg/mL clavulanic acid.

Clavulanic acid production increased with increasing the inoculum

concentration and was optimized to 4%. There was no further increase in the

yield with further increasing the inoculum concentration to 6%, 8% and 10%.

Applied Biochemistry and Biotechnology Vol. 136, 2007

352 Saudagar and Singhal

Fig. 3. Effect of different carbon sources on the growth (experimental data are mean

± S.D. of triple determination) of Streptomyces clavuligerus.

Fig. 4. Effect of different nitrogen sources on clavulanic acid production (experimen-

tal data are mean ± S.D. of triple determination) in Streptomyces clavuligerus MTCC 1142.

The composition of the basal media used for L25 Orthogonal array was

4.8% soybean oil, 4.4% soy flour, 0.5%yeast extract, 0.6% dextrin and 0.25%

KH2PO4.

Applied Biochemistry and Biotechnology Vol. 136, 2007

L25 Orthogonal Array and Clavulanic Acid 353

Optimization Using L25 Orthogonal Array

Once the best carbon and nitrogen sources were selected, the medium

was subjected to final optimization using L25 orthogonal array. The param-

eters optimized involved concentrations of soybean flour, soybean oil,

dextrin, yeast extract, and K2HPO4. The concentrations for the media com-

ponents were selected based on the basal media composition that was

optimized using one factor at a time. Table 2 represents the response table

for means (larger is better) and for signal to noise ratio obtained with L25

orthogonal array. The last two rows in the tables document the delta values

and ranks for the system. Rank and delta values help to assess which factors

have the greatest effect on the response characteristic of interest. Delta

measures the size of the effect by taking the difference between the highest

and lowest characteristic average for a factor. A higher delta value indicates

greater effect of that component. “Rank” orders the factors from the great-

est effect (based on the delta values) to the least effect on the response

characteristic. The order in which the individual components selected in

the present study effect the fermentation process can be ranked as soybean

flour > dextrin > yeast extract > K2HPO4 > soybean oil, suggesting that

soybean flour had a major effect and soybean oil had least effect on

clavulanic acid production by S. clavuligerus. Figures 5 and 6 represent the

main effect plots for the system. Main effects plots show how each factor

affects the response characteristic. A main effect is present when different

levels of a factor affect the characteristic differently. MINITAB creates the

main effects plot by plotting the characteristic average for each factor level.

These averages are the same as those displayed in the response (Table 2).

A line connects the points for each factor. When the line is horizontal (par-

allel to the x axis), then there is no main effect present. Each level of the

factor affects the characteristic in the same way and the characteristic aver-

age is the same across all factor levels. When the line is not horizontal

(parallel to the x axis), then there is a main effect present. Different levels

of the factor affect the characteristic differently. The greater the difference

in the vertical position of the plotted points (the more the line is not parallel

to the x axis), the greater the magnitude of the main effect. In the present

study it can be seen that for each of the five variables at five levels, we find

that one level increases the mean compared to the other level. This differ-

ence is a main effect, i.e., soybean flour at level 5, soybean oil at level 3,

dextrin at level 5, yeast extract at level 4, and K2HPO4 at level 3, shows a

main effect. These levels also represent the optimal concentrations of the

individual components in the medium.

Response tables can also be used to predict the optimal levels of each

component used in the study. To obtain the optimized levels or composi-

tion of each factor, the intuitive analysis based on statistical calculations is

shown in Table 2. Table 3 documents the final medium for clavulanic acid

production by S. clavuligerus. To confirm these results, experiments were

carried out using these nutrient concentrations and it was observed that the

Applied Biochemistry and Biotechnology Vol. 136, 2007

354

Table 2

Response Table for Means and S/N Ratio

A B C D E

Applied Biochemistry and Biotechnology

Level

Mean S/N ratio Mean S/N ratio Mean S/N ratio Mean S/N ratio Mean S/N ratio

1 118.375 41.194 227.656 45.633 241.562 46.669 231.875 46.315 205.937 45.546

2 144.531 43.181 225.875 45.915 214.625 45.425 206.344 45.412 203.374 45.094

354

3 207.500 46.261 232.812 46.393 216.25 45.796 209.062 45.625 257.031 46.847

4 279.219 48.838 226.719 46.506 208.905 45.942 260.156 47.172 248.594 47.011

5 395.468 51.817 232.03 46.845 263.75 47.459 237.656 46.767 230.156 46.793

Delta 277.093 10.623 6.937 1.211 54.845 2.033 53.812 1.759 53.657 1.916

Rank 1 5 2 3 4

Vol. 136, 2007

Saudagar and Singhal

L25 Orthogonal Array and Clavulanic Acid 355

Fig. 5. Main effects plot for means.

Fig. 6. Main effects plot for S/N ratio.

Table 3

Composition of the Final Optimized Medium

for Clavulanic Acid Production Using

S. clavuligerus MTCC 1142

Component Quantity %

Soybean flour 8.8

Soybean oil 1.2

Dextrin 1

Yeast extract 1.5

K2HPO4 0.2

pH 7.0 ± 0.2

Inoculum size 4

Temperature 25°C

Applied Biochemistry and Biotechnology Vol. 136, 2007

356 Saudagar and Singhal

Fig. 7. Batch studies for clavulanic acid production in Streptomyces clavulaigerus

MTCC 1142 .

mean value obtained was 500 µg/mL as compared to 493.53 predicted

using MINITAB for the same composition. The final optimized medium

produced 500 µg/mL clavulanic acids at the end of 96 h as compared to

140 µg/mL before optimization (Fig. 7). This implied that the selected

conditions were the most suitable in practice.

Effect of pH

It can be seen from the Fig. 8 that pH plays an important role as it

affects both growth as well as clavulanic acid production. It was observed

that pH of 7.0 ± 0.2 supported maximum clavulanic acid production of 500

µg/mL, whereas a pH of 7.5 resulted in maximum cell growth (140 µg/mL

nucleic acid). pH above 7.5 and below 6.0 decreased the yield of clavulanic

acid to 200 µg/mL and 290 µg/mL, respectively, indicating degradation of

clavulanic acid at higher and lower pH values.

Effect of Amino Acids on Production of Clavulanic Acid

Figure 9 illustrates the effect of varying concentrations (0.01 M to 0.2 M)

of different amino acids on clavulanic acid production by S. clavuligerus

MTCC 1142. It was observed that, all the amino acids except L-valine when

supplemented in the medium increased the yield of clavulanic acid at

optimal concentrations. At higher concentrations, a decrease in antibiotic

production was observed, thus explaining the concentration dependent

stimulation of clavulanic acid. L-arginine (0.1 M), L- proline (0.2M), DL-leucine

(0.2 M), and pyruvic acid (0.1 M) had a greater stimulatory effect on clavulanic

acid production as compared to L-ornithine (0.2 M), α-ketoglutarate (0.1 M),

L-valine (0.1 M), dl-isoleucine (0.2 M). The possible reasons for the observed

results can be explained with respect to the biosynthetic pathway for

clavulanic acid production. It is well documented that pyruvate acts as C3

precursor, whereas arginine acts as the C5 precursor for clavulanic acid

Applied Biochemistry and Biotechnology Vol. 136, 2007

L25 Orthogonal Array and Clavulanic Acid 357

Fig. 8. Effect of pH (experimental data are mean ± S.D. of triple determination) on

growth and clavulanic acid production in Streptomyces clavuligerus MTCC 1142.

Fig. 9. Effect of stimulators (experimental data are mean ± S.D. of triple determina-

tion) on clavulanic acid production in Streptomyces clavuligerus MTCC 1142.

production (17). Radiolabeled feeding experiments have indicated argin-

ine and ornithine to be efficiently incorporated into clavulanic acid structure

(18,19). Addition of L-proline, l-leucine, pyruvic acid, and α-ketoglutarate

decreased the anaplerotic flux on pyruvate (C3 precursor) for the synthesis

of these amino acids, thus diverting the pathway to clavulanic acid produc-

tion. L-leucine and L-arginine were found to be the most efficient precursor

Applied Biochemistry and Biotechnology Vol. 136, 2007

358 Saudagar and Singhal

for clavulanic acid production and increased the yield of clavulanic acid

from 500 µg/mL to 1400 µg/mL and 1100 µg/mL (Fig. 7), suggesting maxi-

mum flux to flow through synthesis of L-leucine and L-arginine from pyru-

vate during the normal metabolism in S. clavuligerus. Supplementing the

medium with L-valine decreased the yield of clavulanic acid, which may be

attributed to a simultaneous increase in the yield of cephamycin (another

β-lactam produced by S. clavuligerus), as L-valine is reported to be the pre-

cursor for cephamycin production (20).

Conclusions

Using the one-factor at-a-time method and the orthogonal matrix

method, it was possible to determine optimal operating conditions to obtain

maximum production of clavulanic acid in S. Clavuligerus. Supplementing

arginine, proline, leucine, α-ketoglutarate and pyruvic acid decreased the

anaplerotic carbon flux of pyruvate to the synthesis of these amino acids,

thus allowing more C3 precursor for clavulanic acid. Arginine, 0.1 M and

0.1 M leucine increase clavulanic acid production from 500 µg/mL to 1100

µg/mL and 1400 µg/mL, respectively.

Acknowledgment

This work was supported by University Grant Commission (UGC),

India.

References

1. Mayer, A. F. and Deckwer, W. D. (1996) Simultaneous production and decomposi-

tion of clavulanic acid during Streptomyces clavuligerus cultivations. Appl. Microbiol.

Biotechnol. 20, 41–46.

2. Liras, P. and Rodriguez-Garcia, A. (2000) Clavulanic acid, a β-lactamase inhibitor:

biosynthesis and molecular genetics. Appl. Microbiol. Biotechnol. 54, 467–475.

3. McDermott, J. F., Lethbridge, G., and Bushell, M. E. (1993) Estimation of kinetics

constants and elucidation of trends in growth and erythromycin production in batch

and continuous cultures of Saccharospora erythraea using curve-fitting technique.

Enzyme Microb. Technol. 15, 657–663.

4. Bhattactacharjee, S., Ananta, K., and Mandal, S. K. (2002) Alkaline phosphatase and

erythromycin production by Saccharospora erythraea. Indian J. Microbiol. 42, 67–72.

5. Park, S., Momose, I., Tsunoda, K., and Okabe, M. (1994) Enhancement of cephamycin

C production using soybean oil as a sole carbon source. Appl. Microbiol. Biotechnol. 40,

773–779.

6. Xu, C. P., Kim, S. W., Hwang, H. J., Choi, J. W., and Yun, J. W. (2003) Optimization

of submerged culture conditions for mycelial growth and exobiopolymer production

by Paecilomyces tenuipes C240. Process Biochem. 38, 1025–1030.

7. Salowe, S. P., Krol, W. J., Iwata-Reuyl, D., and Townsend, C. A. (1991) Elucidation of

the order of oxidation and identification of an intermediate in the multistep

clavaminate synthetase reaction. Biochemistry 30, 2281–2292.

8. Valentine, B. P., Bailey, C. R., Doherty, A., et al. (1993) Evidence that arginine is later

metabolic intermediate than ornithine in the biosynthesis of clavulanic acid by Strep-

tomyces clavuligerus. J. Chem. Soc. Chem. Commun. 15, 1210–1211.

Applied Biochemistry and Biotechnology Vol. 136, 2007

L25 Orthogonal Array and Clavulanic Acid 359

9. Lee, S. D., Park, S. W., Oh, K. K., Hong, S. I., and Kim, S. W. (2002) Improvement in

production of clavulanic acid by mutant Sterptomyces clavuligerus. Lett. Appl. Microbiol.

Biotechnol. 34, 370–375.

10. Bird, A. E., Bellis, J. M., and Gasson, B. C. (1982) Spectrophotometric assay of

clavulanic acid by reaction with imidazole. Analyst 107, 1241–1245.

11. Kwon, H. J. and Kim, S. U. (1998) Enhanced biosynthesis of clavulanic acid in Strep-

tomyces clavuligerus due to oxidative challenge by redox-cycling agents. Appl.

Microbiol. Biotechnol. 49, 77–83.

12. Mayer, A. F. and Deckwer, W. D. (1996) Ion-pair adsorption chromatography for

process purposes basic equilibrium studies for the recovery of clavulanic acid by

using quaternary ammonium salts. J. Chromatogr. A 741, 185–203.

13. Burton, K. A. (1956) Study of conditions and mechanism of diphenylamine reaction

for colorimetric estimation of deoxyribonucleic acid. Biochem. J. 62(2), 314–323.

14. Revilla, G., Lopez-Niety, M. J., Luengo, J. M., and Martin, J. F. (1984) Carbon catabolite

repression of penicillin biosynthesis by Penicillin chrysogenum. J. Antibiot.37, 781–789.

15. Aharonowitz, Y. and Demain, A. L. (1978) Carbon catabolite repression of cephalosporin

production in Streptomyces clavuligerus. Antimicrob.Agents Chemother. 4, 159–164.

16. Stowell, J. D. (1987) The application of oils and fats in an antibiotic process, in Carbon

Substrates in Biotechnology (Stowell, J. D., Beardsmore, A. J., Keevil, C. W., and Wood-

ward, J. R., eds.). IRL Press, Oxford, UK: pp. 139–159.

17. Ivest, P. R. and Bushell, M. E. (1997) Manipulation of physiology of clavulanic acid

production in Streptomyces clavuligerus. Microbiology 143, 3573–3579.

18. Townsend, C. A. and Ho, M. F. (1985) Biosynthesis of clavulanic acid: origin of C5

unit. J. Am. Chem. Soc. 107, 1065–1066.

19. Romero, J., Liras, P., and Martin, J. F. (1986) Utilization of ornithine and arginine as

specific precursors of clavulanic acid. Appl. Environ. Microbiol. 52, 892–897.

20. Shu-Jen, D. and Basch, J.. (1999) Cephalosporin, in Encyclopedia of Bioprocess Technol-

ogy. Wiley Interscience, New York: pp. 560–569.

21. Jenson, S. E. and Paradkar, A. S. (1999) Biosynthesis and molecular genetics of

clavulanic acid. Antonie van Leeuwenhoek 75, 125–133.

Applied Biochemistry and Biotechnology Vol. 136, 2007

You might also like

- List of Important Topics For NEET PG by DbmciDocument7 pagesList of Important Topics For NEET PG by Dbmcimanmohansai bache57% (7)

- Patrick TB Ch16Document50 pagesPatrick TB Ch16Chemistix100% (4)

- Advanced Tribology 2008Document1,033 pagesAdvanced Tribology 2008Fathia AlkelaeNo ratings yet

- Dna Replication and Protein Synthesis Lesson PlanDocument10 pagesDna Replication and Protein Synthesis Lesson Planapi-356227663100% (2)

- Acido Lactico SSFDocument10 pagesAcido Lactico SSFJuan Oviedo Ingenieria AgroindustrialNo ratings yet

- Pilot-Scale Lactic Acid Production Via Batch Culturing of Lactobacillus Sp. RKY2 Using Corn Steep Liquor As A Nitrogen SourceDocument6 pagesPilot-Scale Lactic Acid Production Via Batch Culturing of Lactobacillus Sp. RKY2 Using Corn Steep Liquor As A Nitrogen SourcekopisusumantapNo ratings yet

- Omay 2012Document8 pagesOmay 201215041168No ratings yet

- Modeling of Batch Fermentation Kinetics For Succinic Acid Production by Mannheneimia SucciniciproducensDocument9 pagesModeling of Batch Fermentation Kinetics For Succinic Acid Production by Mannheneimia SucciniciproducensRyuuara Az-ZahraNo ratings yet

- Optimization of Lactic Acid Production in SSF by Lactobacillus Amylovorus NRRL B-4542 Using Taguchi MethodologyDocument7 pagesOptimization of Lactic Acid Production in SSF by Lactobacillus Amylovorus NRRL B-4542 Using Taguchi MethodologyAraveetiCSReddyNo ratings yet

- Factors Regulating Production of Glucose Oxidase by Aspergillus NigerDocument5 pagesFactors Regulating Production of Glucose Oxidase by Aspergillus NigerI. Murali KrishnaNo ratings yet

- Lactic Acid Production From Waste PotatoDocument14 pagesLactic Acid Production From Waste Potatohariss123a63No ratings yet

- Impact of Methyl Jasmonate On Squalene Bio Synthesis in MicroalgaDocument5 pagesImpact of Methyl Jasmonate On Squalene Bio Synthesis in MicroalgaGerman ColqueNo ratings yet

- Hydrolsis NyamplungDocument7 pagesHydrolsis NyamplungVenny AgustinNo ratings yet

- Kinetic Simple GoodDocument11 pagesKinetic Simple GoodReza MahoorNo ratings yet

- Effect of Enzyme Treated Copra Meal On Nutritive Value, Reducing Sugars and Oligosaccharides As PrebioticsDocument4 pagesEffect of Enzyme Treated Copra Meal On Nutritive Value, Reducing Sugars and Oligosaccharides As PrebioticsthesijNo ratings yet

- Production and characterization of thermostable α-amylase from a newly isolated strain of Bacillus subtilis Kibge-HarDocument15 pagesProduction and characterization of thermostable α-amylase from a newly isolated strain of Bacillus subtilis Kibge-HarBashuki MishraNo ratings yet

- Lactic Acid Production From Simultaneous Saccharification and Fermentation of Cassava Starch by Lactobacillus Plantarum MSUL 903Document5 pagesLactic Acid Production From Simultaneous Saccharification and Fermentation of Cassava Starch by Lactobacillus Plantarum MSUL 903Sacha INchi CentreNo ratings yet

- Influencia de PHDocument13 pagesInfluencia de PHDavid SantiagoNo ratings yet

- Optimized Methodology For Alkaline and Enzyme-Assisted Extraction of Protein From Sacha Inchi (Plukenetia Volubilis) Kernel CakeDocument8 pagesOptimized Methodology For Alkaline and Enzyme-Assisted Extraction of Protein From Sacha Inchi (Plukenetia Volubilis) Kernel CakeNancy GonzalezNo ratings yet

- 19.physicochemical Properties of Defatted RambutanDocument6 pages19.physicochemical Properties of Defatted RambutangramdagpinNo ratings yet

- Anti Fungal in BreadDocument6 pagesAnti Fungal in BreadRufa Lara MendezNo ratings yet

- Enzymatic Hydrolysis of Wheat Gluten by Proteases and Properties of The Resulting HydrolysatesDocument5 pagesEnzymatic Hydrolysis of Wheat Gluten by Proteases and Properties of The Resulting HydrolysatesPadmini RajuNo ratings yet

- s10068 016 0030 XDocument6 pagess10068 016 0030 X0231810025 YANERIS MARCELA MORELO BELLIDO ESTUDIANTE ACTIVONo ratings yet

- Determination of Sialic Acids in Infant Formula by Chromatographic MethodsDocument10 pagesDetermination of Sialic Acids in Infant Formula by Chromatographic MethodsSze JackNo ratings yet

- Ijmer 46065258 PDFDocument7 pagesIjmer 46065258 PDFIJMERNo ratings yet

- JCTM 2024 59 1 2 23-22 pp15-22Document8 pagesJCTM 2024 59 1 2 23-22 pp15-22UNSNo ratings yet

- Article WJPPS 1596215781 01 August 2020Document14 pagesArticle WJPPS 1596215781 01 August 2020h_rivaiNo ratings yet

- 4 - Choubane S., Khelil O. Et Cheba B. 2015, African Journal of BiotechnologyDocument6 pages4 - Choubane S., Khelil O. Et Cheba B. 2015, African Journal of BiotechnologyOmar KHELILNo ratings yet

- Acido LacticoDocument9 pagesAcido LacticoJuan Victor ChampeNo ratings yet

- Production of Lipase Using Cassava Peel and Sunflower Oil in Solid-State Fermentation - Preliminary StudyDocument7 pagesProduction of Lipase Using Cassava Peel and Sunflower Oil in Solid-State Fermentation - Preliminary StudyAgriculturaldavidNo ratings yet

- Isolation and Bioprocess Optimization of HalophiliDocument25 pagesIsolation and Bioprocess Optimization of Halophilisalin MajumdarNo ratings yet

- Tmp33e7 TMPDocument6 pagesTmp33e7 TMPFrontiersNo ratings yet

- ABAB 2006 SeparationDocument13 pagesABAB 2006 SeparationJulieth Cardona C.No ratings yet

- Articulo 1 PDFDocument19 pagesArticulo 1 PDFJennifer A. PatiñoNo ratings yet

- Proposal Project f4 DrafDocument6 pagesProposal Project f4 Drafaiman farhanaNo ratings yet

- Natamycin 6Document6 pagesNatamycin 6Ευαγγελία ΘεοχάρηNo ratings yet

- Determination of Propionates and Propionic Acid in Bread Samples Using High Performance Liquid ChromatographyDocument6 pagesDetermination of Propionates and Propionic Acid in Bread Samples Using High Performance Liquid ChromatographytheijesNo ratings yet

- Mal J Microbiol 2015112163-169Document8 pagesMal J Microbiol 2015112163-169keneth john manayagaNo ratings yet

- Cellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateDocument5 pagesCellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateHamka NurkayaNo ratings yet

- Molasses 14Document11 pagesMolasses 14Tabish AliNo ratings yet

- tmp4E2F TMPDocument13 pagestmp4E2F TMPFrontiersNo ratings yet

- Acidophilus and Lactobacillus Casei of Human Intestinal OriginDocument6 pagesAcidophilus and Lactobacillus Casei of Human Intestinal Originmmoradi55No ratings yet

- Fermentation and Recovery of L-Glutamic - Acid - FromDocument8 pagesFermentation and Recovery of L-Glutamic - Acid - FromPrachi BhoirNo ratings yet

- 2006 Uruakpa Canola Carrageenan NetworkDocument5 pages2006 Uruakpa Canola Carrageenan NetworkckwxbxdwtjNo ratings yet

- Coelho2011 Acid LacticDocument12 pagesCoelho2011 Acid Lacticlfiguaranarregoces12No ratings yet

- AA Cocoa LiquorsDocument8 pagesAA Cocoa LiquorsJonathan Torres PezoNo ratings yet

- PectinasasDocument9 pagesPectinasascarolasbdNo ratings yet

- Rapid Screening Procedures For Identification of Succinic Acid ProducersDocument10 pagesRapid Screening Procedures For Identification of Succinic Acid ProducersEdward AlexanderNo ratings yet

- Purification of A Synthetic Oligonucleotide by Anion Exchange Chromatography Method Optimisation and Scale-UpDocument10 pagesPurification of A Synthetic Oligonucleotide by Anion Exchange Chromatography Method Optimisation and Scale-UpMike BudimanNo ratings yet

- Optimization of A Fed-Batch Fermentation Process For Production of Bleomycin by Streptomyces Mobaraensis ATCC 15003Document6 pagesOptimization of A Fed-Batch Fermentation Process For Production of Bleomycin by Streptomyces Mobaraensis ATCC 15003jmrozo3No ratings yet

- Lactulose SpctroDocument4 pagesLactulose SpctroDr-Asad RazaNo ratings yet

- 15 PDFDocument7 pages15 PDFPradeep PereraNo ratings yet

- Im 2009Document8 pagesIm 2009Jesus C. MendozaNo ratings yet

- B.K.M.lakshmi, Et Al TraducccionDocument10 pagesB.K.M.lakshmi, Et Al TraducccionArturo PeñablassiNo ratings yet

- Biomass and Bioenergy: Research PaperDocument10 pagesBiomass and Bioenergy: Research PaperPaulina Lpz JrzNo ratings yet

- Biosynthesis of Protease From Lactobacillus Paracasei: Kinetic Analysis of Fermentation ParametersDocument5 pagesBiosynthesis of Protease From Lactobacillus Paracasei: Kinetic Analysis of Fermentation ParametersGovGovsNo ratings yet

- Repeated PH-stat Fed-Batch Fermentation For RhamnolipidDocument9 pagesRepeated PH-stat Fed-Batch Fermentation For Rhamnolipidsidikmar1425No ratings yet

- Optimized Lipase-Catalyzed Synthesis of Adipate Ester in A Solvent-Free SystemDocument7 pagesOptimized Lipase-Catalyzed Synthesis of Adipate Ester in A Solvent-Free SystemGizeleBaldoNo ratings yet

- El-Gendy 2013 - RSM For Sugarcane FermentationDocument10 pagesEl-Gendy 2013 - RSM For Sugarcane FermentationAyu RatnasariNo ratings yet

- Batch and Continuous Culture of Lactococcus LactisDocument9 pagesBatch and Continuous Culture of Lactococcus LactisJose Luis Sarabia ArellanoNo ratings yet

- Proponoic AcidDocument7 pagesProponoic AcidAnonymous SUbBZzNo ratings yet

- Fermentation 04 00079Document9 pagesFermentation 04 00079CHIRANJEEVINo ratings yet

- Microbiology in Dairy Processing: Challenges and OpportunitiesFrom EverandMicrobiology in Dairy Processing: Challenges and OpportunitiesNo ratings yet

- Advances in Dairy ProductsFrom EverandAdvances in Dairy ProductsFrancesco ContoNo ratings yet

- Effects of Heat Treatments On Microstructure and Properties of Nickel-Aluminum Bronze Fabricated by Centrifugal CastingDocument9 pagesEffects of Heat Treatments On Microstructure and Properties of Nickel-Aluminum Bronze Fabricated by Centrifugal CastingFathia AlkelaeNo ratings yet

- Laser Powder Bed Fusion and Post Processing of Alloy C22Document16 pagesLaser Powder Bed Fusion and Post Processing of Alloy C22Fathia AlkelaeNo ratings yet

- Fabricating Superior NiAl Bronze Components Through Wire Arc Additive ManufacturingDocument14 pagesFabricating Superior NiAl Bronze Components Through Wire Arc Additive ManufacturingFathia AlkelaeNo ratings yet

- The Effects of Production Methods On The Microstructures and Mechanical Properties of An Aluminum BronzeDocument10 pagesThe Effects of Production Methods On The Microstructures and Mechanical Properties of An Aluminum BronzeFathia AlkelaeNo ratings yet

- TEM STUDY OF PRECIPITATES IN LASER CLAD Ni-A1 BRONZEDocument6 pagesTEM STUDY OF PRECIPITATES IN LASER CLAD Ni-A1 BRONZEFathia AlkelaeNo ratings yet

- Characterization of Phases in A Nickel-Aluminium BronzeDocument7 pagesCharacterization of Phases in A Nickel-Aluminium BronzeFathia AlkelaeNo ratings yet

- The Influence of Alloying, Temperature and Related Effects On The Stacking Fault EnergyDocument33 pagesThe Influence of Alloying, Temperature and Related Effects On The Stacking Fault EnergyFathia AlkelaeNo ratings yet

- Temperature Dependence of Stacking Fault Energy in Close-Packed Metals and AlloysDocument17 pagesTemperature Dependence of Stacking Fault Energy in Close-Packed Metals and AlloysFathia AlkelaeNo ratings yet

- Eth-31148-02 (Nitrogen Doped)Document160 pagesEth-31148-02 (Nitrogen Doped)Fathia AlkelaeNo ratings yet

- Control of Residual Oxygen The Process Atmosphere During Laser-Powder Bed Fusion Processing of Ti-6Al-4VDocument10 pagesControl of Residual Oxygen The Process Atmosphere During Laser-Powder Bed Fusion Processing of Ti-6Al-4VFathia AlkelaeNo ratings yet

- Tribological Characteristics of Nickel-Aluminium Bronze CuAl10Ni5Fe4 Against 30CrMnSiA Steel After The Prior Corrosion TreatmentDocument6 pagesTribological Characteristics of Nickel-Aluminium Bronze CuAl10Ni5Fe4 Against 30CrMnSiA Steel After The Prior Corrosion TreatmentFathia AlkelaeNo ratings yet

- Tribological and Mechanical Characterization of Nickel Aluminium Bronze (NAB) Manufactured by Laser Powder-Bed Fusion (L-PBF)Document10 pagesTribological and Mechanical Characterization of Nickel Aluminium Bronze (NAB) Manufactured by Laser Powder-Bed Fusion (L-PBF)Fathia AlkelaeNo ratings yet

- Four Point BendingDocument307 pagesFour Point BendingFathia AlkelaeNo ratings yet

- Prediction of DLC Friction Lifetime Based On A Local Archard Factor Density ApproachDocument17 pagesPrediction of DLC Friction Lifetime Based On A Local Archard Factor Density ApproachFathia AlkelaeNo ratings yet

- Bibc102, Metabolic Biochemistry: Gen-Sheng Feng Fall, 2010Document14 pagesBibc102, Metabolic Biochemistry: Gen-Sheng Feng Fall, 2010cool_trainerNo ratings yet

- Team Motivation FMGE Coaching Academy: Mock Test - 3Document23 pagesTeam Motivation FMGE Coaching Academy: Mock Test - 3abhishiktaNo ratings yet

- L&G Belts Cross RefDocument31 pagesL&G Belts Cross RefashielanieNo ratings yet

- Biosurfactants From YeastDocument18 pagesBiosurfactants From YeastoniatrdNo ratings yet

- Syllabus For BiochemistryDocument8 pagesSyllabus For BiochemistryJenny Lyn Nebres100% (1)

- Biochemical and Functional Properties ofDocument347 pagesBiochemical and Functional Properties ofValeria OlmedoNo ratings yet

- Preparatory Problems International Chemistry Olympiad 2013Document77 pagesPreparatory Problems International Chemistry Olympiad 2013RSLNo ratings yet

- Proteins and Amino AcidsDocument50 pagesProteins and Amino Acidsraddag100% (2)

- Protein Synthesis Paper Lab InstructionsDocument11 pagesProtein Synthesis Paper Lab Instructionsapi-292473508No ratings yet

- Ib Notes 1,2,3,4,5,6Document31 pagesIb Notes 1,2,3,4,5,6Kashish Doshi100% (2)

- Amino Acid CatabolismDocument24 pagesAmino Acid CatabolismAnonymous 0ha8TmNo ratings yet

- Lecture 1 - Molecular Genetics and Gene ExpressionDocument12 pagesLecture 1 - Molecular Genetics and Gene ExpressionChn ypNo ratings yet

- Chapter 23: Nucleotide Metabolism: MatchingDocument14 pagesChapter 23: Nucleotide Metabolism: MatchingAbe345123No ratings yet

- The Molecular Basis of InheritanceDocument35 pagesThe Molecular Basis of Inheritanceprehealthhelp80% (5)

- Ribosomes and Protein SynthesisDocument12 pagesRibosomes and Protein SynthesisSulfeekker AhamedNo ratings yet

- (Boschke F.L.) Medicinal ChemistryDocument157 pages(Boschke F.L.) Medicinal ChemistryJo ShuNo ratings yet

- DNA MCQsDocument5 pagesDNA MCQsfafa salahNo ratings yet

- Biology FSC Chapter 2Document15 pagesBiology FSC Chapter 2Diana PriyaNo ratings yet

- Role of Toxins in Pathogenesis: Pl. Path. 111 (Cr. Hrs. 3+1)Document26 pagesRole of Toxins in Pathogenesis: Pl. Path. 111 (Cr. Hrs. 3+1)Pravin KhaireNo ratings yet

- MODULE 4 Metabolism of Cabohydrate Fats and Proteins Biochem 2nd Sem 2020 2021 1Document19 pagesMODULE 4 Metabolism of Cabohydrate Fats and Proteins Biochem 2nd Sem 2020 2021 1Shaira BayubayNo ratings yet

- TranslationDocument1 pageTranslationGianne AbcedeNo ratings yet

- Biochemistry Final Review OutlinesDocument22 pagesBiochemistry Final Review Outlineslacey100% (1)

- 09 Chapter2 PDFDocument31 pages09 Chapter2 PDFRamNo ratings yet

- Mevalonic Acid PathwayDocument4 pagesMevalonic Acid PathwayChandra ReddyNo ratings yet

- Enzymes of Dna ReplicationDocument7 pagesEnzymes of Dna ReplicationSevdred CadelinaNo ratings yet

- TEAS 6 Science by KellyDocument22 pagesTEAS 6 Science by KellyLily Garcia100% (1)

- Ref 48 35. FernandesDocument10 pagesRef 48 35. FernandesJuan Jose Vega AlbaNo ratings yet