Professional Documents

Culture Documents

045 - Kaizen TKZ-ELG-CPD-0888

045 - Kaizen TKZ-ELG-CPD-0888

Uploaded by

Mithil MachhiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

045 - Kaizen TKZ-ELG-CPD-0888

045 - Kaizen TKZ-ELG-CPD-0888

Uploaded by

Mithil MachhiCopyright:

Available Formats

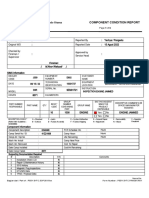

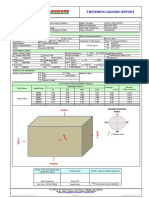

TPM Circle No : ELG-0286 TPM Pillar : QM Operation : Drilling & Tapping

KAIZEN

TPM Circle Name : QAIP02 Loss : Fixture and tool losses(Cost) Cell No : Helical-A Assembly

IDEA

GEAR DIVISION Department : QUALITY EP Result Area : Q Kaizen No : TKZ/ELG-CPD/0888 SHEET

Machine No : OTHERS Machine / Stage : Drilling Exact Location : Ganesh Engg MP Sheet : NO

KAIZEN THEME : KAIZEN IDEA : DIVISION

To Eliminate hole to hole variation in Motor Adaptor To developed dedicated jig for drilling Operation.

49

PROBLEM / PRESENT STATUS : COUNTERMEASURE :

Benchmark : 1

1 Hole is found shifted by 5 mm in motor adaptor Drilling jig developed for accurate drilling.

Drg.No 748-14-9117/B Target : 0

PHOTOGRAPH BEFORE CONDITION : PHOTOGRAPH AFTER CONDITION : Kaizen Start : 25/11/2021

Kaizen End : 25/12/2021

Team (L)RAJNIKANT MANUBHAI

Member : PRAJAPATI;RAJNIKANT M

PRAJAPATI;MAHESHKUMAR A

PUJARA;Krunal K Patel

BENEFITS :

1. Hole CD Variation eliminated.

2. improvement in OTD

3. Eliminate fitment issue at assembly.

COST

4. OF KAIZEN

Reduce : cost at

the Rework

1900

Assembly.

WHY WHY ANALYSIS : RESULT : KAIZEN SUSTENANCE :

What to do : 1. Periodic monitoring of Jig condition.

W1. Hole is found shifted by 5 mm 2. Periodic verification of components.

W2. Error in marked drill point Jig calibration plan to prepare & monitored by

How to do :

W3. Drill point taken on previously marked drill point which supplier.

was done with manual marking Horiz. Dep. Cmt :

Scope and plan for horizontal deployment :

ID MACHINE_NO TARGET_DATE RESP. STATUS

ROOT CAUSE : Registration No. & Registered

Drill point taken on previously marked drill point which was By :

done with manual marking Manager Sign :

You might also like

- M-Code List For Biglia SmartTurn SDocument3 pagesM-Code List For Biglia SmartTurn Scmgankl75% (4)

- ME417 Final Project PacketDocument40 pagesME417 Final Project PacketTAYYABA AMJAD L1F16MBAM0221No ratings yet

- Southbend Shaper V2 Parts ListDocument6 pagesSouthbend Shaper V2 Parts ListStephen HowardNo ratings yet

- 053 - Kaizen TKZ-ELG-CPD-0889Document1 page053 - Kaizen TKZ-ELG-CPD-0889Mithil MachhiNo ratings yet

- Daily Report Hydro 2 MaretDocument1 pageDaily Report Hydro 2 Maretdeny fajarNo ratings yet

- Material Safety Data Sheet FOR Co2 Recovery UnitDocument6 pagesMaterial Safety Data Sheet FOR Co2 Recovery Unitgudapati9No ratings yet

- B-PE-I-433-18-002-004-00 - Instrument Cable Schedule - Approved As NoteDocument3 pagesB-PE-I-433-18-002-004-00 - Instrument Cable Schedule - Approved As NoteMuhammad TeguhNo ratings yet

- Kaizen - Esp02 221B4 DamperDocument4 pagesKaizen - Esp02 221B4 DamperRakesh Kumar Singh (Phase 1B)No ratings yet

- Service Manual: HCD-V818Document92 pagesService Manual: HCD-V818Vitorio LogoNo ratings yet

- Name of Project:: 2 X 4.4Mw Rudi Khola HepDocument5 pagesName of Project:: 2 X 4.4Mw Rudi Khola HepapsNo ratings yet

- Adobe Scan 18 Jul 2023Document1 pageAdobe Scan 18 Jul 2023Anish Krishna AniNo ratings yet

- FA ReportDocument4 pagesFA ReportBudi ArtantoNo ratings yet

- D8R Abk D802Document6 pagesD8R Abk D802SMKN 6 SAMARINDA PANGESTUNo ratings yet

- Filter AsssemblyDocument2 pagesFilter AsssemblyKamalesh KumarNo ratings yet

- Thermography Report of Close Cooling Water Pump CDocument2 pagesThermography Report of Close Cooling Water Pump Csandro sitohangNo ratings yet

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanNo ratings yet

- TSR Sd22e Bd108Document3 pagesTSR Sd22e Bd108dwi supraptoNo ratings yet

- Boring Head DrawingsDocument7 pagesBoring Head DrawingsR WilkinsonNo ratings yet

- QAP With Covering Letter - 29112022Document4 pagesQAP With Covering Letter - 29112022PRASHANTNo ratings yet

- All Chevy Performance - October 2022 USADocument92 pagesAll Chevy Performance - October 2022 USAEmilio AlvarezNo ratings yet

- 09.06.23 - As CommisionedDocument16 pages09.06.23 - As CommisionedSourav SarkarNo ratings yet

- Sony HCDV-909-AV Service ManualDocument88 pagesSony HCDV-909-AV Service Manualvan nguyenNo ratings yet

- Ms-pl-p2-110-Re (Tower-2 Ground Floor Corbel & Nib Layout)Document2 pagesMs-pl-p2-110-Re (Tower-2 Ground Floor Corbel & Nib Layout)NitinNo ratings yet

- Entrance Door 4Document1 pageEntrance Door 4AYSON N. DELA CRUZNo ratings yet

- Installation, Operation & Maintenance Manual: Double Skin Packaged Air Conditioners 'PDS' SeriesDocument43 pagesInstallation, Operation & Maintenance Manual: Double Skin Packaged Air Conditioners 'PDS' SeriesSavad AlwyeNo ratings yet

- 81-03-0094-00ga General Assembly, X400-5D With FlangeDocument1 page81-03-0094-00ga General Assembly, X400-5D With FlangeMuthukumar RadhakrishnanNo ratings yet

- KG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Document5 pagesKG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Madheswaran DharmapuriNo ratings yet

- JSS Progress CANYCOM S25A BPF220273 UNIT 3Document6 pagesJSS Progress CANYCOM S25A BPF220273 UNIT 3Dera Fadhlih SupriyoNo ratings yet

- Drum Data Sheet: Ctci CorporationDocument4 pagesDrum Data Sheet: Ctci Corporationjdaig17No ratings yet

- Setup & Inprocess Inspection Report Twin AnchorDocument13 pagesSetup & Inprocess Inspection Report Twin AnchorMURALIDHRANo ratings yet

- Dfe-b00-Ele-dwg-sld-006 - Single Line Diagram For Process PCC Panel - 2a & 2b (Wet End)Document1 pageDfe-b00-Ele-dwg-sld-006 - Single Line Diagram For Process PCC Panel - 2a & 2b (Wet End)Electrical PCBL TeamNo ratings yet

- Switchyard FencingDocument1 pageSwitchyard FencingHarak DhamiNo ratings yet

- 320D T'LinksDocument1 page320D T'LinksMohammed KhalidNo ratings yet

- Quality RequirementsDocument26 pagesQuality RequirementsDilip PatilNo ratings yet

- 6 Sigma SD Shaft Dia. VariationDocument32 pages6 Sigma SD Shaft Dia. Variationsageershaikh100% (1)

- Deformer EliminationDocument4 pagesDeformer Eliminationvigneshbabu0809No ratings yet

- Bmm007-101.ext Model Z3PRTDocument1 pageBmm007-101.ext Model Z3PRTshashiranjan18021995No ratings yet

- Feeder Protection M1 - NGCP Side - Test ReportDocument2 pagesFeeder Protection M1 - NGCP Side - Test Reportjohncarloignacio45No ratings yet

- Tsr-Sd22e Bd106 TurrbocharrgeDocument2 pagesTsr-Sd22e Bd106 Turrbocharrgedwi supraptoNo ratings yet

- QSM11 Part PerformanceDocument8 pagesQSM11 Part PerformanceBac NguyenNo ratings yet

- Thermography Report of CIRCULATING WATER PUMP A #1Document2 pagesThermography Report of CIRCULATING WATER PUMP A #1sandrositohangNo ratings yet

- JSS Locomotive 1505 (D7) SENINDocument9 pagesJSS Locomotive 1505 (D7) SENINArul SahrulNo ratings yet

- QA Sheet Reinforce QuesterDocument10 pagesQA Sheet Reinforce QuesterLuqman HakimNo ratings yet

- A - Receiving R.1Document2 pagesA - Receiving R.1ugha victorNo ratings yet

- 327 50Mm Diameter Hole To Accept 48Mm O/D Standard Scaffold Tubing (Not Supplied)Document1 page327 50Mm Diameter Hole To Accept 48Mm O/D Standard Scaffold Tubing (Not Supplied)Gladstone LimaNo ratings yet

- Torque Plate Tightening Bolt-Model00000Document1 pageTorque Plate Tightening Bolt-Model00000Shoaib AkhtarNo ratings yet

- Component Condition Report DM007Document9 pagesComponent Condition Report DM007ahmat ramadaniNo ratings yet

- Feeder Protection M2 - NGCP Side - Test ReportDocument2 pagesFeeder Protection M2 - NGCP Side - Test Reportjohncarloignacio45No ratings yet

- Lv-168 Prozeal Infra Engineering Pvt. Ltd. Rev-01Document32 pagesLv-168 Prozeal Infra Engineering Pvt. Ltd. Rev-01Chaturbhai Hadiyal0% (1)

- Zapata BurdnyDocument1 pageZapata BurdnyjoseNo ratings yet

- PQCS Welding ProcessDocument22 pagesPQCS Welding Processazadsingh1No ratings yet

- Neo Logic Final Rev-3Document22 pagesNeo Logic Final Rev-3johari siraitNo ratings yet

- Datasheet For Gate Valves: ProjectDocument3 pagesDatasheet For Gate Valves: ProjectbecpavanNo ratings yet

- Va Tech Wabag Va Tech Wabag Va Tech Wabag Va Tech Wabag Reliance Industries LimitedDocument1 pageVa Tech Wabag Va Tech Wabag Va Tech Wabag Va Tech Wabag Reliance Industries LimitedRamKS80100% (1)

- TSR r220 9s Lambung 5 Replace Hose Oil Lub and Tooth BacketDocument3 pagesTSR r220 9s Lambung 5 Replace Hose Oil Lub and Tooth BacketkrisnaNo ratings yet

- CCR 980NG AbkDocument13 pagesCCR 980NG AbkSMKN 6 SAMARINDA PANGESTUNo ratings yet

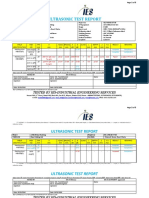

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- D9A&E2ADocument10 pagesD9A&E2Abagulrahul2023No ratings yet

- SealDocument3 pagesSealshashwatchaurasia83No ratings yet

- Sump Tank (New)Document1 pageSump Tank (New)RonniNo ratings yet

- ANZ-37MH Final Drilling ProgramDocument37 pagesANZ-37MH Final Drilling ProgramWilson OdiaNo ratings yet

- BSPP ChartDocument2 pagesBSPP ChartQC apollohxNo ratings yet

- MT2 University Question PaperDocument4 pagesMT2 University Question PaperKrishnan VelavanNo ratings yet

- MCMT QBDocument3 pagesMCMT QBKrishna MurthyNo ratings yet

- 1 52Document52 pages1 52jl_arvizoNo ratings yet

- Metric Tap Size Chart: Tap Size Diameter (In) Diameter (MM) Thread Count (TPI) Thread Pitch (MM) Tap Drill SizeDocument4 pagesMetric Tap Size Chart: Tap Size Diameter (In) Diameter (MM) Thread Count (TPI) Thread Pitch (MM) Tap Drill SizeherrysugarNo ratings yet

- Activity #9Document2 pagesActivity #9Mariella Alyzza InciongNo ratings yet

- Unit 5Document58 pagesUnit 5Palak NaikNo ratings yet

- Building Your Own CNC Router/milling Machine: InstructablesDocument16 pagesBuilding Your Own CNC Router/milling Machine: InstructablesSoma VargaNo ratings yet

- Machining Operations and Machine ToolsDocument64 pagesMachining Operations and Machine ToolsBlessing FajemirokunNo ratings yet

- UNC UNF BSW BSF Screw Thread ChartDocument4 pagesUNC UNF BSW BSF Screw Thread ChartDave Slope100% (2)

- Metal Removal ProcessesDocument45 pagesMetal Removal ProcessesWilliam Salazar100% (1)

- Crown - Esmeril Ch3301 - 115Document1 pageCrown - Esmeril Ch3301 - 115marco antonio talavera salazarNo ratings yet

- Lathe PDFDocument130 pagesLathe PDFNitin B maskeNo ratings yet

- Threads and Thread CuttingDocument21 pagesThreads and Thread CuttingravijecrcNo ratings yet

- Normas de Roscas y NormalizacionDocument1 pageNormas de Roscas y NormalizacionProyectos IngemetzaNo ratings yet

- Deaily Break Down (Jun-2018)Document54 pagesDeaily Break Down (Jun-2018)sandy webNo ratings yet

- 742 ML10 Screwcutting LatheDocument5 pages742 ML10 Screwcutting LatheSimon GuardNo ratings yet

- Vertical Turning and Boring MachineDocument5 pagesVertical Turning and Boring MachineShahbaz AlamNo ratings yet

- MAPAL CPMill Ball Track Milling Cutters enDocument8 pagesMAPAL CPMill Ball Track Milling Cutters enPlant Head PrasadNo ratings yet

- Setup Sheet Report: Mill DefaultDocument5 pagesSetup Sheet Report: Mill DefaultGandi SaputraNo ratings yet

- ME6402 Manufacturing Technology IIDocument10 pagesME6402 Manufacturing Technology IIprasanthprpNo ratings yet

- Hand Tools Vocabulary Esl Crossword Puzzle Worksheets For Kids PDFDocument4 pagesHand Tools Vocabulary Esl Crossword Puzzle Worksheets For Kids PDFEdvantic Applicant13100% (1)

- Ada 279290Document217 pagesAda 279290rei reiNo ratings yet

- จำหน่าย รับผลิต Broach โทร 081-9120884Document2 pagesจำหน่าย รับผลิต Broach โทร 081-9120884Anansitthichok MuangNo ratings yet

- Machine Tools and Automation Machine Tools Operations Mod-3Document20 pagesMachine Tools and Automation Machine Tools Operations Mod-3code makerNo ratings yet

- GAGESDocument156 pagesGAGESUNIISCRIBDNo ratings yet

- Module 1 Week 2-3, SMAW 10Document14 pagesModule 1 Week 2-3, SMAW 10Daryl TesoroNo ratings yet

- 3 BG-QA-FRM-03-13 Maintenance Machine HistroryDocument4 pages3 BG-QA-FRM-03-13 Maintenance Machine HistroryYousaf RichuNo ratings yet