Professional Documents

Culture Documents

053 - Kaizen TKZ-ELG-CPD-0889

053 - Kaizen TKZ-ELG-CPD-0889

Uploaded by

Mithil MachhiCopyright:

Available Formats

You might also like

- Bendi B3-30 AC Maintenance Manual F-560-0410 PDFDocument174 pagesBendi B3-30 AC Maintenance Manual F-560-0410 PDFChristian BedoyaNo ratings yet

- 045 - Kaizen TKZ-ELG-CPD-0888Document1 page045 - Kaizen TKZ-ELG-CPD-0888Mithil MachhiNo ratings yet

- Daily Report Hydro 2 MaretDocument1 pageDaily Report Hydro 2 Maretdeny fajarNo ratings yet

- Kaizen - Esp02 221B4 DamperDocument4 pagesKaizen - Esp02 221B4 DamperRakesh Kumar Singh (Phase 1B)No ratings yet

- Adobe Scan 18 Jul 2023Document1 pageAdobe Scan 18 Jul 2023Anish Krishna AniNo ratings yet

- Feeder Protection M1 - NGCP Side - Test ReportDocument2 pagesFeeder Protection M1 - NGCP Side - Test Reportjohncarloignacio45No ratings yet

- FA ReportDocument4 pagesFA ReportBudi ArtantoNo ratings yet

- Feeder Protection M2 - NGCP Side - Test ReportDocument2 pagesFeeder Protection M2 - NGCP Side - Test Reportjohncarloignacio45No ratings yet

- Feeder Protection M1 - BESS Side - Test ReportDocument2 pagesFeeder Protection M1 - BESS Side - Test Reportjohncarloignacio45No ratings yet

- Lv-168 Prozeal Infra Engineering Pvt. Ltd. Rev-01Document32 pagesLv-168 Prozeal Infra Engineering Pvt. Ltd. Rev-01Chaturbhai Hadiyal0% (1)

- Dimensional Inspection Report - Rev.01.Document2 pagesDimensional Inspection Report - Rev.01.GARIMA CASTINGS, JAIPURNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Drum Data Sheet: Ctci CorporationDocument4 pagesDrum Data Sheet: Ctci Corporationjdaig17No ratings yet

- The Sanmar Group: TCI Sanmar Chemicals, SAE Portsaid, Egypt ENGG Jan 2020 Review Review Date - 4-Feb-2020Document7 pagesThe Sanmar Group: TCI Sanmar Chemicals, SAE Portsaid, Egypt ENGG Jan 2020 Review Review Date - 4-Feb-2020Mosab AmmarNo ratings yet

- 5600 CFMDocument1 page5600 CFMmohammed rameesNo ratings yet

- Setup & Inprocess Inspection Report Twin AnchorDocument13 pagesSetup & Inprocess Inspection Report Twin AnchorMURALIDHRANo ratings yet

- 6 Sigma SD Shaft Dia. VariationDocument32 pages6 Sigma SD Shaft Dia. Variationsageershaikh100% (1)

- SR ElevatorDocument1 pageSR ElevatorAbdurachman100% (1)

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- Thermography Report of CIRCULATING WATER PUMP A #1Document2 pagesThermography Report of CIRCULATING WATER PUMP A #1sandrositohangNo ratings yet

- Traceability ReportDocument4 pagesTraceability ReportSalesNo ratings yet

- All Chevy Performance - October 2022 USADocument92 pagesAll Chevy Performance - October 2022 USAEmilio AlvarezNo ratings yet

- Filter AsssemblyDocument2 pagesFilter AsssemblyKamalesh KumarNo ratings yet

- Boxer PDFDocument5 pagesBoxer PDFmhNo ratings yet

- Collar Muffler MountDocument1 pageCollar Muffler MountPreetam KumarNo ratings yet

- SSL Asn Kiln D 20211122Document2 pagesSSL Asn Kiln D 20211122Prem KumarNo ratings yet

- JSS Progress CANYCOM S25A BPF220273 UNIT 3Document6 pagesJSS Progress CANYCOM S25A BPF220273 UNIT 3Dera Fadhlih SupriyoNo ratings yet

- MT ReportDocument1 pageMT ReportTotan KarNo ratings yet

- Thermography Report of Close Cooling Water Pump CDocument2 pagesThermography Report of Close Cooling Water Pump Csandro sitohangNo ratings yet

- D8R Abk D802Document6 pagesD8R Abk D802SMKN 6 SAMARINDA PANGESTUNo ratings yet

- VIGA18X86Document1 pageVIGA18X86proyectistanuevoNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Log Drilling Core: SNI 2436 - 2008 Mobile Power Plant and Fixed Gas Engine Power Plant PLTMG Nunukan 2 10MwDocument1 pageLog Drilling Core: SNI 2436 - 2008 Mobile Power Plant and Fixed Gas Engine Power Plant PLTMG Nunukan 2 10MwBambang SantosoNo ratings yet

- 080 Method Card 07.09.17Document3 pages080 Method Card 07.09.17sagar kashinath kodle50% (2)

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- 14 Work Sheet. T27.R0.2014.04.10 PDFDocument1 page14 Work Sheet. T27.R0.2014.04.10 PDFagus sugiantoNo ratings yet

- Civil Daily Report Fireproofing LTDCDocument1 pageCivil Daily Report Fireproofing LTDCfajargaluhwijaya09No ratings yet

- MTC3244 Ad BDocument1 pageMTC3244 Ad BLu Ad YunNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Gopal Adya 1Document1 pageGopal Adya 1gopal adya ariskaNo ratings yet

- Collar 9.5X10Document1 pageCollar 9.5X10Preetam KumarNo ratings yet

- Zapata BurdnyDocument1 pageZapata BurdnyjoseNo ratings yet

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- Interloop Satellite Stitching Unit: RecommendationDocument13 pagesInterloop Satellite Stitching Unit: RecommendationFraz AhmadNo ratings yet

- 04 DrawingDocument1 page04 DrawingAbm Faruk E MonjurNo ratings yet

- Scip2 TGXDocument6 pagesScip2 TGXKarthikeyan Ganesan100% (1)

- Annexure A - Preliminary DrawingDocument3 pagesAnnexure A - Preliminary Drawingmediaproject.icNo ratings yet

- Packing OptionsDocument3 pagesPacking Optionsclaudiogut123No ratings yet

- Quality AlertDocument3 pagesQuality AlertPreetam GiteNo ratings yet

- Talleres Mina: C2016, BUDGET2016 - Nov 16Document6 pagesTalleres Mina: C2016, BUDGET2016 - Nov 16Diego Cárdenas GallardoNo ratings yet

- DBCM 05 Mei 2021 Awal Shift IDocument5 pagesDBCM 05 Mei 2021 Awal Shift IHenny Komala Sari SibaraniNo ratings yet

- Fab Washer: Revision: Description: Date: ApprovedDocument1 pageFab Washer: Revision: Description: Date: ApprovedPoon Shoon ThimNo ratings yet

- D9A&E2ADocument10 pagesD9A&E2Abagulrahul2023No ratings yet

- OQC Inspection Sheet Pulley, Motor, CRDocument1 pageOQC Inspection Sheet Pulley, Motor, CRadi meliNo ratings yet

- Collar Muff ProtectorDocument1 pageCollar Muff ProtectorPreetam KumarNo ratings yet

- r2b p2 203 03 H HD 51062 - Rev.b - Data Sheet SRV PSV 61152 A B 1st Stage DischargeDocument17 pagesr2b p2 203 03 H HD 51062 - Rev.b - Data Sheet SRV PSV 61152 A B 1st Stage Dischargedavid perezNo ratings yet

- QA Sheet Reinforce QuesterDocument10 pagesQA Sheet Reinforce QuesterLuqman HakimNo ratings yet

- Material Safety Data Sheet FOR Co2 Recovery UnitDocument6 pagesMaterial Safety Data Sheet FOR Co2 Recovery Unitgudapati9No ratings yet

- Conveyor Chain-1Document8 pagesConveyor Chain-1Akim JoNo ratings yet

- Schedule Plan Installation Ongrid Solar Power Plant Kantor Divisi LRT Jabodebek - Bekasi TimurDocument1 pageSchedule Plan Installation Ongrid Solar Power Plant Kantor Divisi LRT Jabodebek - Bekasi TimurSAYA TAHUNo ratings yet

- "Design and Fabrication of Solar Vehicle ": A Project PresentationDocument33 pages"Design and Fabrication of Solar Vehicle ": A Project Presentationguru arya2100% (1)

- Toyota Hilux 2018 Overall EWD Vehicle Exterior Turn Signal and Hazard Warning Light (RHD)Document2 pagesToyota Hilux 2018 Overall EWD Vehicle Exterior Turn Signal and Hazard Warning Light (RHD)gabrielzinho43No ratings yet

- Eapp Position PaperDocument3 pagesEapp Position PaperShenisse OrnopiaNo ratings yet

- MS05 - MSE05: Hydraulic MotorsDocument36 pagesMS05 - MSE05: Hydraulic Motorsmuhammed atnNo ratings yet

- R.N.I.No - TELMUL/2016/73158.: The Telangana GazetteDocument6 pagesR.N.I.No - TELMUL/2016/73158.: The Telangana GazetteJakkula LavanyaNo ratings yet

- A Part of Normet CorporationDocument58 pagesA Part of Normet CorporationRodrigo MendizabalNo ratings yet

- 45.electrical Component LocationsDocument60 pages45.electrical Component LocationsKuba SwkNo ratings yet

- Jimmy Detailed Lesson PlanDocument10 pagesJimmy Detailed Lesson Planjecil perocho100% (4)

- HPV PorDocument2 pagesHPV PorChris ChrisNo ratings yet

- Cw-Sc185eph Cw-Sc245ephDocument5 pagesCw-Sc185eph Cw-Sc245ephPepz Rosauro Navarra0% (1)

- Hyundai Technical Training Step 2 Body Electrical 2009Document5 pagesHyundai Technical Training Step 2 Body Electrical 2009leroy100% (48)

- Lube Power LP2730 3 IOMDocument27 pagesLube Power LP2730 3 IOMJuan Carlos VenturaNo ratings yet

- Sop-Lab-Analitico-11: Page 1 of 2Document2 pagesSop-Lab-Analitico-11: Page 1 of 2basharat121No ratings yet

- Toyota Innova SurveyDocument13 pagesToyota Innova SurveyHarsh KbddhsjNo ratings yet

- Euromidi CC100 Tector 6 Diesel Euro IV-V EEVDocument2 pagesEuromidi CC100 Tector 6 Diesel Euro IV-V EEVHisham HamdiNo ratings yet

- Scrip Code Scrip NameDocument5 pagesScrip Code Scrip NamenitmemberNo ratings yet

- Yamaha Xc115-India CatalogueDocument50 pagesYamaha Xc115-India CatalogueAnonymous KoA00wXXD92% (12)

- 182-Point Inspection ChecklistDocument4 pages182-Point Inspection ChecklistAminur RahmanNo ratings yet

- Filtros FleetguardDocument15 pagesFiltros FleetguardFellipe LoboNo ratings yet

- D20S-5 - SB1109E17 - Spare Part ManualDocument888 pagesD20S-5 - SB1109E17 - Spare Part ManualFederico Jorge DiezNo ratings yet

- Eastman Industries - BoqDocument6 pagesEastman Industries - BoqcivilNo ratings yet

- Throttle Valve Screw-In Cartridge - Q 25 L/min - Q 25 L/min - P 350 BarDocument2 pagesThrottle Valve Screw-In Cartridge - Q 25 L/min - Q 25 L/min - P 350 BarDavidson GattoniNo ratings yet

- A Study On Consumers Perception TowardsDocument8 pagesA Study On Consumers Perception TowardsApurv JainNo ratings yet

- Tank Data: U. S. ArmyDocument484 pagesTank Data: U. S. ArmyTheo100% (1)

- FuelX Autotune RE INT CGTDocument35 pagesFuelX Autotune RE INT CGTGurdeep SinghNo ratings yet

- j20 Suzuki - JIII - 99500 - 64J00 - 01EDocument2 pagesj20 Suzuki - JIII - 99500 - 64J00 - 01EManuel RosuNo ratings yet

- Caleb's Path To Community Employment: Case Study For Specific Learning DisabilityDocument13 pagesCaleb's Path To Community Employment: Case Study For Specific Learning DisabilityAbigail TalaveraNo ratings yet

- Master Thesis Analysis and Specification of An AUTOSAR Based ECU in Compliance With ISO ... (PDFDrive)Document100 pagesMaster Thesis Analysis and Specification of An AUTOSAR Based ECU in Compliance With ISO ... (PDFDrive)Christoph KabekNo ratings yet

- Wiring Honda Freed - 1Document36 pagesWiring Honda Freed - 1Muh Klasin KalinegoroNo ratings yet

053 - Kaizen TKZ-ELG-CPD-0889

053 - Kaizen TKZ-ELG-CPD-0889

Uploaded by

Mithil MachhiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

053 - Kaizen TKZ-ELG-CPD-0889

053 - Kaizen TKZ-ELG-CPD-0889

Uploaded by

Mithil MachhiCopyright:

Available Formats

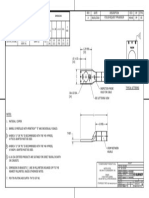

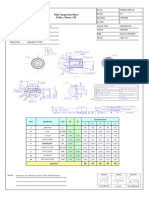

TPM Circle No : ELG-0286 TPM Pillar : QM Operation : Drilling & Tapping

KAIZEN

TPM Circle Name : QAIP02 Loss : Fixture and tool losses(Cost) Cell No : Helical-A Assembly

IDEA

GEAR DIVISION Department : QUALITY EP Result Area : Q Kaizen No : TKZ/ELG-CPD/0889 SHEET

Machine No : OTHERS Machine / Stage : Drilling Exact Location : Riya Industry MP Sheet : NO

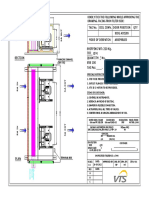

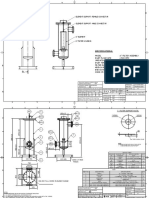

KAIZEN THEME : KAIZEN IDEA : DIVISION

To Eliminate variation in angular position of dipstick hole in gear To develop dedicated fixture for angular drilling operation.

49

case

PROBLEM / PRESENT STATUS : COUNTERMEASURE :

Benchmark : 2

Dipstick is fouled with wheel inside gear box. Fixture developed for accurate degree of dipstick hole.

Target : 0

PHOTOGRAPH BEFORE CONDITION : PHOTOGRAPH AFTER CONDITION : Kaizen Start : 20/12/2021

Kaizen End : 21/01/2022

Team (L)RAJNIKANT MANUBHAI

Member : PRAJAPATI;RAJNIKANT M

PRAJAPATI;MAHESHKUMAR A

PUJARA;Krunal K Patel

BENEFITS :

1. Hole degree Veriation eliminated.

2. improvent in OTD

3. Eliminate dipstick fouling issue at assembly.

COST

4. OF KAIZEN

Reduce :

the rectification

5000

cost at Assembly and improve

FTR. SUSTENANCE :

KAIZEN

WHY WHY ANALYSIS : RESULT :

What to do : 1. Periodic monitoring of Fixture condition.

W1. Dipstick is fouled with wheel inside gear box. 2. Periodic verification of gear case.

W2. Error during drilling in angular position. Fixture calibration plan to prepare & monitored by

How to do :

W3. Drill point taken with manual marking and angular set supplier.

up. Horiz. Dep. Cmt :

Scope and plan for horizontal deployment :

ID MACHINE_NO TARGET_DATE RESP. STATUS

ROOT CAUSE : Registration No. & Registered

Drill point taken with manual set up. By :

Manager Sign :

You might also like

- Bendi B3-30 AC Maintenance Manual F-560-0410 PDFDocument174 pagesBendi B3-30 AC Maintenance Manual F-560-0410 PDFChristian BedoyaNo ratings yet

- 045 - Kaizen TKZ-ELG-CPD-0888Document1 page045 - Kaizen TKZ-ELG-CPD-0888Mithil MachhiNo ratings yet

- Daily Report Hydro 2 MaretDocument1 pageDaily Report Hydro 2 Maretdeny fajarNo ratings yet

- Kaizen - Esp02 221B4 DamperDocument4 pagesKaizen - Esp02 221B4 DamperRakesh Kumar Singh (Phase 1B)No ratings yet

- Adobe Scan 18 Jul 2023Document1 pageAdobe Scan 18 Jul 2023Anish Krishna AniNo ratings yet

- Feeder Protection M1 - NGCP Side - Test ReportDocument2 pagesFeeder Protection M1 - NGCP Side - Test Reportjohncarloignacio45No ratings yet

- FA ReportDocument4 pagesFA ReportBudi ArtantoNo ratings yet

- Feeder Protection M2 - NGCP Side - Test ReportDocument2 pagesFeeder Protection M2 - NGCP Side - Test Reportjohncarloignacio45No ratings yet

- Feeder Protection M1 - BESS Side - Test ReportDocument2 pagesFeeder Protection M1 - BESS Side - Test Reportjohncarloignacio45No ratings yet

- Lv-168 Prozeal Infra Engineering Pvt. Ltd. Rev-01Document32 pagesLv-168 Prozeal Infra Engineering Pvt. Ltd. Rev-01Chaturbhai Hadiyal0% (1)

- Dimensional Inspection Report - Rev.01.Document2 pagesDimensional Inspection Report - Rev.01.GARIMA CASTINGS, JAIPURNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Drum Data Sheet: Ctci CorporationDocument4 pagesDrum Data Sheet: Ctci Corporationjdaig17No ratings yet

- The Sanmar Group: TCI Sanmar Chemicals, SAE Portsaid, Egypt ENGG Jan 2020 Review Review Date - 4-Feb-2020Document7 pagesThe Sanmar Group: TCI Sanmar Chemicals, SAE Portsaid, Egypt ENGG Jan 2020 Review Review Date - 4-Feb-2020Mosab AmmarNo ratings yet

- 5600 CFMDocument1 page5600 CFMmohammed rameesNo ratings yet

- Setup & Inprocess Inspection Report Twin AnchorDocument13 pagesSetup & Inprocess Inspection Report Twin AnchorMURALIDHRANo ratings yet

- 6 Sigma SD Shaft Dia. VariationDocument32 pages6 Sigma SD Shaft Dia. Variationsageershaikh100% (1)

- SR ElevatorDocument1 pageSR ElevatorAbdurachman100% (1)

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- Thermography Report of CIRCULATING WATER PUMP A #1Document2 pagesThermography Report of CIRCULATING WATER PUMP A #1sandrositohangNo ratings yet

- Traceability ReportDocument4 pagesTraceability ReportSalesNo ratings yet

- All Chevy Performance - October 2022 USADocument92 pagesAll Chevy Performance - October 2022 USAEmilio AlvarezNo ratings yet

- Filter AsssemblyDocument2 pagesFilter AsssemblyKamalesh KumarNo ratings yet

- Boxer PDFDocument5 pagesBoxer PDFmhNo ratings yet

- Collar Muffler MountDocument1 pageCollar Muffler MountPreetam KumarNo ratings yet

- SSL Asn Kiln D 20211122Document2 pagesSSL Asn Kiln D 20211122Prem KumarNo ratings yet

- JSS Progress CANYCOM S25A BPF220273 UNIT 3Document6 pagesJSS Progress CANYCOM S25A BPF220273 UNIT 3Dera Fadhlih SupriyoNo ratings yet

- MT ReportDocument1 pageMT ReportTotan KarNo ratings yet

- Thermography Report of Close Cooling Water Pump CDocument2 pagesThermography Report of Close Cooling Water Pump Csandro sitohangNo ratings yet

- D8R Abk D802Document6 pagesD8R Abk D802SMKN 6 SAMARINDA PANGESTUNo ratings yet

- VIGA18X86Document1 pageVIGA18X86proyectistanuevoNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Log Drilling Core: SNI 2436 - 2008 Mobile Power Plant and Fixed Gas Engine Power Plant PLTMG Nunukan 2 10MwDocument1 pageLog Drilling Core: SNI 2436 - 2008 Mobile Power Plant and Fixed Gas Engine Power Plant PLTMG Nunukan 2 10MwBambang SantosoNo ratings yet

- 080 Method Card 07.09.17Document3 pages080 Method Card 07.09.17sagar kashinath kodle50% (2)

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- 14 Work Sheet. T27.R0.2014.04.10 PDFDocument1 page14 Work Sheet. T27.R0.2014.04.10 PDFagus sugiantoNo ratings yet

- Civil Daily Report Fireproofing LTDCDocument1 pageCivil Daily Report Fireproofing LTDCfajargaluhwijaya09No ratings yet

- MTC3244 Ad BDocument1 pageMTC3244 Ad BLu Ad YunNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Gopal Adya 1Document1 pageGopal Adya 1gopal adya ariskaNo ratings yet

- Collar 9.5X10Document1 pageCollar 9.5X10Preetam KumarNo ratings yet

- Zapata BurdnyDocument1 pageZapata BurdnyjoseNo ratings yet

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- Interloop Satellite Stitching Unit: RecommendationDocument13 pagesInterloop Satellite Stitching Unit: RecommendationFraz AhmadNo ratings yet

- 04 DrawingDocument1 page04 DrawingAbm Faruk E MonjurNo ratings yet

- Scip2 TGXDocument6 pagesScip2 TGXKarthikeyan Ganesan100% (1)

- Annexure A - Preliminary DrawingDocument3 pagesAnnexure A - Preliminary Drawingmediaproject.icNo ratings yet

- Packing OptionsDocument3 pagesPacking Optionsclaudiogut123No ratings yet

- Quality AlertDocument3 pagesQuality AlertPreetam GiteNo ratings yet

- Talleres Mina: C2016, BUDGET2016 - Nov 16Document6 pagesTalleres Mina: C2016, BUDGET2016 - Nov 16Diego Cárdenas GallardoNo ratings yet

- DBCM 05 Mei 2021 Awal Shift IDocument5 pagesDBCM 05 Mei 2021 Awal Shift IHenny Komala Sari SibaraniNo ratings yet

- Fab Washer: Revision: Description: Date: ApprovedDocument1 pageFab Washer: Revision: Description: Date: ApprovedPoon Shoon ThimNo ratings yet

- D9A&E2ADocument10 pagesD9A&E2Abagulrahul2023No ratings yet

- OQC Inspection Sheet Pulley, Motor, CRDocument1 pageOQC Inspection Sheet Pulley, Motor, CRadi meliNo ratings yet

- Collar Muff ProtectorDocument1 pageCollar Muff ProtectorPreetam KumarNo ratings yet

- r2b p2 203 03 H HD 51062 - Rev.b - Data Sheet SRV PSV 61152 A B 1st Stage DischargeDocument17 pagesr2b p2 203 03 H HD 51062 - Rev.b - Data Sheet SRV PSV 61152 A B 1st Stage Dischargedavid perezNo ratings yet

- QA Sheet Reinforce QuesterDocument10 pagesQA Sheet Reinforce QuesterLuqman HakimNo ratings yet

- Material Safety Data Sheet FOR Co2 Recovery UnitDocument6 pagesMaterial Safety Data Sheet FOR Co2 Recovery Unitgudapati9No ratings yet

- Conveyor Chain-1Document8 pagesConveyor Chain-1Akim JoNo ratings yet

- Schedule Plan Installation Ongrid Solar Power Plant Kantor Divisi LRT Jabodebek - Bekasi TimurDocument1 pageSchedule Plan Installation Ongrid Solar Power Plant Kantor Divisi LRT Jabodebek - Bekasi TimurSAYA TAHUNo ratings yet

- "Design and Fabrication of Solar Vehicle ": A Project PresentationDocument33 pages"Design and Fabrication of Solar Vehicle ": A Project Presentationguru arya2100% (1)

- Toyota Hilux 2018 Overall EWD Vehicle Exterior Turn Signal and Hazard Warning Light (RHD)Document2 pagesToyota Hilux 2018 Overall EWD Vehicle Exterior Turn Signal and Hazard Warning Light (RHD)gabrielzinho43No ratings yet

- Eapp Position PaperDocument3 pagesEapp Position PaperShenisse OrnopiaNo ratings yet

- MS05 - MSE05: Hydraulic MotorsDocument36 pagesMS05 - MSE05: Hydraulic Motorsmuhammed atnNo ratings yet

- R.N.I.No - TELMUL/2016/73158.: The Telangana GazetteDocument6 pagesR.N.I.No - TELMUL/2016/73158.: The Telangana GazetteJakkula LavanyaNo ratings yet

- A Part of Normet CorporationDocument58 pagesA Part of Normet CorporationRodrigo MendizabalNo ratings yet

- 45.electrical Component LocationsDocument60 pages45.electrical Component LocationsKuba SwkNo ratings yet

- Jimmy Detailed Lesson PlanDocument10 pagesJimmy Detailed Lesson Planjecil perocho100% (4)

- HPV PorDocument2 pagesHPV PorChris ChrisNo ratings yet

- Cw-Sc185eph Cw-Sc245ephDocument5 pagesCw-Sc185eph Cw-Sc245ephPepz Rosauro Navarra0% (1)

- Hyundai Technical Training Step 2 Body Electrical 2009Document5 pagesHyundai Technical Training Step 2 Body Electrical 2009leroy100% (48)

- Lube Power LP2730 3 IOMDocument27 pagesLube Power LP2730 3 IOMJuan Carlos VenturaNo ratings yet

- Sop-Lab-Analitico-11: Page 1 of 2Document2 pagesSop-Lab-Analitico-11: Page 1 of 2basharat121No ratings yet

- Toyota Innova SurveyDocument13 pagesToyota Innova SurveyHarsh KbddhsjNo ratings yet

- Euromidi CC100 Tector 6 Diesel Euro IV-V EEVDocument2 pagesEuromidi CC100 Tector 6 Diesel Euro IV-V EEVHisham HamdiNo ratings yet

- Scrip Code Scrip NameDocument5 pagesScrip Code Scrip NamenitmemberNo ratings yet

- Yamaha Xc115-India CatalogueDocument50 pagesYamaha Xc115-India CatalogueAnonymous KoA00wXXD92% (12)

- 182-Point Inspection ChecklistDocument4 pages182-Point Inspection ChecklistAminur RahmanNo ratings yet

- Filtros FleetguardDocument15 pagesFiltros FleetguardFellipe LoboNo ratings yet

- D20S-5 - SB1109E17 - Spare Part ManualDocument888 pagesD20S-5 - SB1109E17 - Spare Part ManualFederico Jorge DiezNo ratings yet

- Eastman Industries - BoqDocument6 pagesEastman Industries - BoqcivilNo ratings yet

- Throttle Valve Screw-In Cartridge - Q 25 L/min - Q 25 L/min - P 350 BarDocument2 pagesThrottle Valve Screw-In Cartridge - Q 25 L/min - Q 25 L/min - P 350 BarDavidson GattoniNo ratings yet

- A Study On Consumers Perception TowardsDocument8 pagesA Study On Consumers Perception TowardsApurv JainNo ratings yet

- Tank Data: U. S. ArmyDocument484 pagesTank Data: U. S. ArmyTheo100% (1)

- FuelX Autotune RE INT CGTDocument35 pagesFuelX Autotune RE INT CGTGurdeep SinghNo ratings yet

- j20 Suzuki - JIII - 99500 - 64J00 - 01EDocument2 pagesj20 Suzuki - JIII - 99500 - 64J00 - 01EManuel RosuNo ratings yet

- Caleb's Path To Community Employment: Case Study For Specific Learning DisabilityDocument13 pagesCaleb's Path To Community Employment: Case Study For Specific Learning DisabilityAbigail TalaveraNo ratings yet

- Master Thesis Analysis and Specification of An AUTOSAR Based ECU in Compliance With ISO ... (PDFDrive)Document100 pagesMaster Thesis Analysis and Specification of An AUTOSAR Based ECU in Compliance With ISO ... (PDFDrive)Christoph KabekNo ratings yet

- Wiring Honda Freed - 1Document36 pagesWiring Honda Freed - 1Muh Klasin KalinegoroNo ratings yet