Professional Documents

Culture Documents

Formulation Development and Evaluation of Naproxensodium Tablets Usp

Formulation Development and Evaluation of Naproxensodium Tablets Usp

Uploaded by

zakarya wadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formulation Development and Evaluation of Naproxensodium Tablets Usp

Formulation Development and Evaluation of Naproxensodium Tablets Usp

Uploaded by

zakarya wadiCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/287617331

Formulation development and evaluation of naproxen sodium tablets USP

Article in International Journal of Drug Development and Research · January 2010

CITATIONS READS

5 8,045

5 authors, including:

Manivannan Rangasamy

EXCEL COLLEGE OF PHARMACY, NAMAKKAL , TN.

57 PUBLICATIONS 703 CITATIONS

SEE PROFILE

All content following this page was uploaded by Manivannan Rangasamy on 18 May 2016.

The user has requested enhancement of the downloaded file.

International Journal of Drug Development & Research

| Jan-March 2010 | Vol. 2 | Issue 1 |

ISSN 0975-9344

Available online http://www.ijddr.com

©2010 IJDDR

Original Research Manuscript

FORMULATION DEVELOPMENT AND EVALUATION OF NAPROXEN

SODIUM TABLETS USP

*Rangasamy Manivannan, Kugalur Ganesan Parthiban, Sanaullah Shaik,

Balasubramaniam Senthilkumar and Natesan Senthilkumar

Department of Pharmaceutics, JKK Munirajah Medical Research Foundation, College of Pharmacy,

Namakkal (DT) – 638 183, Tamilnadu, India.

ABSTRACT

The objective of the present study is to develop a pharmaceutically stable and robust formulation of

Naproxen sodium tablets USP 220mg comparable with innovator. In the present study we are reducing the

excipients there by we can reduce the cost of the dosage form. The tablets of Naproxen sodium USP 220mg were

successfully prepared by using wet granulation technique. Several trial formulations i.e., from F1-F10 have

been taken to optimize and develop a robust formulation. The prepared tablets were evaluated for weight

variation, hardness, thickness, friability, % drug content, disintegration time and in vitro drug release.

Formulation F10 showed a drug release of 103.5% in 60mins which is faster than the innovator product. The

stability studies, shown that the formulation F10, F11 and F12 were stable enough at 400C / 75% RH for a

period of 3 months. Therefore it can be concluded that the formulation F10 (Naproxen sodium tablets USP

220mg) is robust and stable.

Key Words: Naproxen sodium, Maize starch, Microcrystalline cellulose, In-Vitro drug release.

Introduction:

Tablet delivery systems can range from

simple immediate release formulations to complex

extended or modified release dosage forms [1]. More

than 50% of drug delivery systems available in the

market are oral drug delivery systems[2]. Accuracy

of dose is maintained since tablet is a unit solid

dosage form. Structure 1: Chemical Structure of Naproxen

Sodium

Naproxen is a non-steroidal anti-inflammatory drug

(NSAID), with analgesic and antipyretic properties.

Naproxen sodium is an odourless crystalline

Corresponding author: powder, white to creamy in color. It is soluble in

Rangasamy Manivannan methanol and water. The molecular weight of

Assistant Professor, Department of Pharmaceutics Naproxen Sodium is 252.24 and it melts at 105oC.

JKK Munirajah Medical Research Foundation, Naproxen itself is rapidly and completely absorbed

College of Pharmacy, Namakkal (DT). from the GI tract with an in vivo bioavailability of

Email: manivannan_biotech@yahoo.co.in 95%. Naproxen is extensively metabolized to 6-0-

Mobile: 09976139446 desmethyl naproxen and both parent and metabolites

Int.J.Drug Dev. & Res., Jan-March 2010, 2(1):47-53

Rangasamy Manivannan et al: Development And Evaluation Of Naprox En Sodium

Tablets USP

do not induce metabolizing enzymes. Naproxen has were not found during Formulation F1 & F2. Better

a volume of distribution of 0.16 L/kg. At therapeutic granules were found during Formulation F3 but DT

levels, naproxen is greater than 99% albumin- was not matching with innovator. During

bound. The elimination half-life of Naproxen is formulation F4, F5, F6, F7, F8, F9 & F10 maize

approximately 15 hours. Most of the drug is starch was replaced by micro crystalline cellulose.

excreted in the urine, primarily as unchanged Load Naproxen sodium into RMG along with

naproxen (less than 1%), 6-0-desmethyl naproxen diluent (micro crystalline cellulose, pregelatinized

(less than 1%) and their glucuronide or other maize starch, sodium starch glycolate) and mixed

conjugates (66-92%). A small amount (< 5%) of the for 5 min at slow mixer speed[4]. Dissolve the PVP

drug is excreted in the feces. K-30 in purified hot water. Add binder into RMG

Naproxen sodium tablets are indicated for the while mixing at slow mixer speed.

treatment of Rheumatoid arthritis, Osteoarthritis, Start the fluidized bed processor (Palm Glatt,

Ankylosing spondylitis, Tendinitis, Bursitis, Acute Mumbai) in manual mode & set process parameters

gout[3]. as given below. Dry the wet granules. Sift the dried

granules through # 18 mesh. Load the sifted

Materials and Methods: granules into Octagonal blender (Saan, Mumbai).

Naproxen Sodium, Maize Starch and Stearic acid (Lubricant) is added into blender by

Pregelatinized Maize Starch are obtained as gift sifting it in 40 mesh and blended for 5 min at 8 rpm.

samples from Aurobindo pharma Limited, Compress the blend into tablets weight of 300.0 mg.

Hyderabad. Micro crystalline cellulose, sodium Coat the tablets to get 2.5 % buildup by using 15%

starch glycolate, polyvinyl pyrrolidone K-30 (PVP), aquarius BP 17066 coating solution. During

stearic acid and aquarius BP 17066 were purchased formulation F4 & F5 better granules were found but

from local vendor. Other materials used were of disintegration time is not matching with reference

analytical grade. sample. During Formulation F6, F7, F8 & F9

disintegration time was satisfactory but percentage

Experimental work: drug release was lower than that of innovator

sample. Granules produced during Formulation F10

Preparation Naproxen Sodium Tablets USP: have good flow property as the disintegration time

Naproxen sodium tablets containing 220 and dissolution profile were matching with

mg were prepared by wet granulation technique and innovator sample. Two reproducibility batches (F11

formulae used in the study are shown in table 1. & F12) of Formulation F10 were taken. Physical

During formulation F1, F2 & F3 load Naproxen properties of the granules are similar to that of F10

sodium into rapid mixer granulator (RMG) (Sainath and the dissolution profiles as well as the chemical

Boilers & Pneumatics, Hyderabad) along with properties of the tablets are same as that of F10.

diluent (Maize starch, pregelatinized maize starch,

sodium starch glycolate) and mixed for 5 min at Comparative data of various formulations:

[4]

slow mixer speed . Dissolve the PVP K-30 in A batch size of 3333 tabs was planned for

Purified hot water. Add binder into RMG while each formulation and the quantity for each

mixing at slow mixer speed. Add extra water till formulation was expressed in grams.

required consistency of mass is obtained. Granules

Int.J.Drug Dev. & Res., Jan-March 2010, 2(1):47-53 48

Rangasamy Manivannan et al: Development And Evaluation Of Naprox En Sodium

Tablets USP

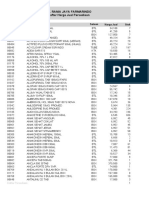

Table 1: Shows various Formulations of Naproxen Sodium Tablets USP

Formulations

Ingredients (gms/batch)

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

Naproxen Sodium 733 733 733 733 733 733 733 733 733 733

Maize starch 206 204 214 _ 112 117 109 89 69 79

Pregelatinized maize starch 36 32 20 20 20 _ _ _ _ _

Microcrystalline cellulose _ _ _ 212 100 115 110 130 150 140

Sodium starch glycolate 12 16 20 20 20 20 20 20 20 20

PVP K-30 5 7 5 7 7 7 20 20 20 20

Stearic acid 8 8 8 8 8 8 8 8 8 8

Evaluation of powder blend: The simplest way measurement of free

Determination of bulk density and tapped flow property of powder is compressibility, an

density indication of ease with which a material can be

Bulk Density: induced to flow is given by % compressibility,

Apparent bulk density (B.D) was which is calculated as follows:

determined by placing presieved drug excipients C = [(T.D-B.D) / T.D] x 100

blend into a graduated cylinder and measuring the Where T.D and B.D are bulk density and

initial volume (Vo) weight of powder (W). The bulk tap density respectively.

density was calculated using the formula.

Bulk Density (B.D) = W / Vo Hausner’s ratio:

Hausner’s ratio is an index of ease of

Tapped Density: powder flow; it calculated as follows:

The measuring cylinder containing known Hausner’s ratio = T.D / B.D

mass of blend was tapped for a fixed number of Where T.D and B.D are bulk density and

taps. The minimum volume (Vf) occupied in the tap density respectively.

cylinder and the weight of powder (W) was

measured. The tapped density was calculated using Evaluation of tablets:

the formula. All the tablets were evaluated for different

Tapped Density (T.D) = W / Vf parameters like hardness, thickness, friability, drug

content, disintegration time and in-vitro drug

Angle of repose: release.

Angle of repose (a) was determined by

using funnel method. The blend was poured through Hardness:

a funnel that can be raised vertically until a For each formulation hardness was tested

maximum cone height (h) was obtained. The radius using the Fizer hardness tester (Cadmach, India) [1, 2]

of the heap (r) was measured and angle of repose

was calculated. Friability:

-1

a = tan (h/r) Twenty tablets were weighed and placed in

Roche friabilator (Electrolab, Mumbai) and

Compressibility index: apparatus was rotated at 25 rpm for 4 min. After

Int.J.Drug Dev. & Res., Jan-March 2010, 2(1):47-53 49

Rangasamy Manivannan et al: Development And Evaluation Of Naprox En Sodium

Tablets USP

revolution tablets were dusted and weighed [1, 2]. The of rotation of paddle was set at 50 rpm. At a

friability is given by the formula: predetermined time interval of 5, 10, 15, 30, 45 &

F = [1- Wo / W] x 100 60 min, 5 ml samples were withdrawn and filtered

Where, through Whatman filter paper. Absorption of

Wo = weight of the tablets before the test, solution was checked by UV spectrophotometer at

W = weight of the tablets after the test. 272 nm and % drug release was calculated [10, 11].

Drug content: Stability Studies:

Two tablets were powdered and the blend Stability studies are an integral part of the

equivalent to 220 mg of naproxen was weighed and drug development program & are one of the most

dissolved in suitable quantity of distilled water. The important areas in the registration of pharma

solution was filtered, suitably diluted and drug products [11]

content was analyzed spectrophotometrically at 272

nm. Each sample was analyzed in triplicate [8]. Characterization of Innovator Product:

FD&C Blue #2, Hypromellose, Magnesium

Disintegration time: stearate, Micro crystalline cellulose, Povidone, Poly

The disintegration apparatus consist of ethylene glycol, Pregelatinised maize starch, Maize

basket of six tubes with a base of metal sieve. This Starch, Sodium Starch glycolate, Stearic acid.

assembly is suspended using a hanger with a

mechanism of vertical motion at affixed speed of Physicochemical Evaluation of Innovator

product:

28-30 cycles/ minutes. The assembly moves in the

Marketed tablets are Blue Colored, Oval

vertical motion in the distilled water maintained at

shaped and biconvex film coated tablet, with an

37o+0.5oC. The time required for disintegration of

average weight of 300 mg, strength of 220 mg

tablet is recorded and should meet the required time

having a thickness of 4.50 - 5.00 mm, hardness of

specification [9].

5.0 - 12.0 kg and disintegration time of 12.30 min.

In vitro drug release:

In vitro Dissolution data of Innovator:

The in vitro drug release of naproxen was

determined by using USP Dissolution Testing Time (Min) 5 10 15 30 45 60

Apparatus II (Paddle type) (Electrolab, Mumbai). % Drug

37.9 69.6 86.9 100.8 101.6 102.8

Release

The dissolution test performed using 900 ml of

distilled water maintained at 37o+0.5oC. The speed

Results and Discussion

Table 2: Evaluation of Powder Blend

Formulations

Parameters

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

Bulk density 1.224 + 1.132+ 0.711+ 0.651+ 0.475+ 0.462+ 0.445+ 0.438+ 0.422+ 0.413+

(gm/cm3) 0.04 0.02 0.003 0.004 0.003 0.002 0.002 0.004 0.005 0.002

Tapped 1.321+ 1.265+ 0.654+ 0.546+ 0.457+ 0.465+ 0.453+ 0.455+ 0.436+ 0.421+

density(gm/cm3) 0.02 0.04 0.03 0.05 0.06 0.02 0.04 0.03 0.002 0.003

Angle of repose 36.45 34.12 27.26 25.12 26.32 23.14 21.25 23.45 21.25 20.12

% compressibility 31.45 30.12 28.62 18.65 16.25 15.45 13.95 12.45 10.36 9.65

Hausner’s ratio 1.625 1.542 1.334 1.125 1.064 1.122 1.056 1.078 1.045 1.006

Int.J.Drug Dev. & Res., Jan-March 2010, 2(1):47-53 50

Rangasamy Manivannan et al: Development And Evaluation Of Naprox En Sodium

Tablets USP

Table 3: Evaluation of Naproxen sodium Tablets USP

FORMULATIONS

TEST

F3 F4 F5 F6 F7 F8 F9 F10 F11 F12

% Weight variation

0.76+0.15 0.84+0.14 0.65+0.12 0.73+0.21 0.82+0.13 0.61+0.2 0.89+0.16 0.75+0.15 0.63+0.14 0.61+0.11

(+ 5%)

Hardness (Kg) 8-9 9-10 8-10 8-10 10-11 9-11 9-10 8-10 8-10 9-10

Friability -%w/w 0.41+0.03 0.16 0.14 0.15 0.4 0.21 0.18 0.20 0.19 0.18

% Drug content 99.1 99.1 99.3 99.5 99.4 99.3 99.6 99.7 99.4 99.6

Disintegration time

11.15 10.53 8.58 9.01 8.34 8.51 8.47 8.54 8.53 8.57

(min)

% Drug

75.3 88.5 90.12 91.5 94.5 96.4 98.5 103.5 103.2 103.5

release (after 60 min)

Fig 1: Comparative In Vitro Dissolution Study of Formulations F10, F11, F12 with Innovator Product.

120

100

Percentage Drug Release

80

60

40

20

0

0 10 20 30 40 50 60 70

Time (Min)

Innovator Product Formulation 10 Formulation 11 Formulation 12

Discussion: Stability Studies:

The assay of Naproxen Sodium in all trials Naproxen sodium tablets USP 220mg were

lies within the limit and complies with the evaluated for accelerated stability studies at

specifications. The film coating process was also 40ºc/75% RH conditions. The stability study for 3

found to be smooth with no processing problems. months shows that the formulation is stable enough

There is not much variation in the release of drug at 400C/75%RH

from the core as well as coated tablets indicating

that the coating of tablets to obtain a 2.5% weight Summary And Conclusion

gain is found to be sufficient to coat the tablets. Summary:

Therefore formulation F11 and F12 are planned for The preformulation study of Naproxen

stability study. Sodium complies with specifications. Several trials

(F1-F10) have been taken to optimize and develop a

Int.J.Drug Dev. & Res., Jan-March 2010, 2(1):47-53 51

Rangasamy Manivannan et al: Development And Evaluation Of Naprox En Sodium

Tablets USP

robust formulation. Various processing problems References:

were encountered during the formulation 1) Lachman L, Herbert AL, Joseph LK. The Theory

development and these were overcome with proper and Practice of Industrial Pharmacy. Bombay,

optimization of composition of formulation Varghese Publishing House, 1990, pp 293-294.

2) Ansel HC, Popovich NG, Allen LV.

ingredients and processing conditions. The coating

Pharmaceutical Dosage Forms and Drug

process of the tablets was optimized with a good

Delivery System. New Delhi, B.I Waverly Pvt.

release of drug from the coated tablets. The coated

Ltd., 2005, pp 189-194, 235-236.

tablets were evaluated for the physical as well as 3) Laurence LB, John S L, Keith LP, Naproxen,

chemical attributes and were found to be Goodman and Gilman. The Pharmacological

satisfactory in comparison to the market sample. In- Basis of therapeutics. New Delhi, McGraw-Hill,

vitro drug release profile of formulation F10 in 2005, pp 700.

purified water was found to be 103.5% in 60 min, 4) Piera Di Martino et al; Physico-chemical and

which is faster than reference product. Two technological properties of sodium Naproxen

granules prepared in a high-shear mixer-

reproducibility batches F11 & F12 were taken. In

granulator; J Pharm Sci 2008; 97: 5263-5273.

vitro drug release profile of F11 & F12 in purified

5) Young-soo Kim et al; Solubility and prediction of

water was found to be 103.2% & 103.5%

the heat of solution of sodium naproxen in

respectively in 60 mins, which is faster than aqueous solutions, J Pharm Sci 2005; 94: 1941-

reference product. Formulations F10, F11, F12 were 1948.

taken and were charged for stability studies at 6) Brahmankar DM, Sunil BJ, Biopharmaceutics and

accelerated condition. Pharmacokinetics-a treatise. Delhi, Vallabh

Prakashan, 1995, pp 25 & 40.

7) Herbert AL, Leon L. Pharmaceutical Dosage

Conclusion:

Forms: Tablets. Vol I, Newyork, pp 416-417.

The assay of Naproxen Sodium in all trials

8) Indian pharmacopoeia. Vol. 2. New Delhi:

lies within the limit and complies with the

Controller of Publication; 1996, pp 555-556.

specifications. In vitro drug release profile of

9) Milind PW, Chetan PY, Santosh UZ, Paresh IK,

formulation F10 in purified water was found to be Ganesh HM. Formulation and evaluation of fast

103.5% in 60 min, which is faster than reference dispersible tablets of aceclofenac using different

product. The stability study for 3 months shows that superdisintegrants, Int J Pharm & Pharm Sci

0

the formulation is stable enough at 40 C/75%RH. 2010; 10: 154-157.

So it can be concluded that the Naproxen sodium 10) Deelip D, Omkar J, Ashish P, Jatin P, Amol J.

tablets USP 220mg formulation is robust and stable. Formulation and evaluation of Buccoadhesive

bilayer tablet of propranolol hydrochloride, Int J

Pharm & Pharm Sci 2009; 1: 206-212.

Acknowledgment:

11) Dalia AA. In Vitro and in Vivo Evaluation of

We authors are very thankful to Dr.

Transdermal Absorption of Naproxen Sodium.

J.K.K.Munirajah, M.Tech (Bolton)., D.Litt., Aus J Basic and Appl Sci 2009; 3: 2154-2165.

Chairman, J.K.K.M Group of Institutions, for his 12) The United State Pharmacopoeia 30/NF 25, Asian

kind encouragement and support during the research edition, the official compendia of standard United

work. States Pharmacopoeial Convection Inc. Rockville

2007: pp 277.

********************************************

Int.J.Drug Dev. & Res., Jan-March 2010, 2(1):47-53 52

Rangasamy Manivannan et al: Development And Evaluation Of Naprox En Sodium

Tablets USP

Author Information: Dr Rangasamy

Manivannan is working as Assistant

Professor, Department of Pharmaceutics

JKK Munirajah Medical Research

Foundation, College of Pharmacy,

Namakkal (DT).

Article History:--------------------------------

Date of Submission: 22-01-10

Date of Acceptance: 05-03-10

Conflict of Interest: NIL

Source of support: NONE

Int.J.Drug Dev. & Res., Jan-March 2010, 2(1):47-53 53

View publication stats

You might also like

- Geopolymer Concrete PPT-KVRDocument24 pagesGeopolymer Concrete PPT-KVRBindu Srirangam100% (3)

- 0604-14-01 Report - International Paint Coating System-May 12 2014 PDFDocument88 pages0604-14-01 Report - International Paint Coating System-May 12 2014 PDFMBastawy100% (1)

- Formulaiton and Pharmacokinetic Evaluation of Naproxen Sodium Modified Release TabletDocument8 pagesFormulaiton and Pharmacokinetic Evaluation of Naproxen Sodium Modified Release TabletiajpsNo ratings yet

- Formulation and Evaluation of Levodropropizine LozengesDocument14 pagesFormulation and Evaluation of Levodropropizine LozengesFitria MokodompitNo ratings yet

- Optimization and Formulation of Orodispersible Tablets ofDocument7 pagesOptimization and Formulation of Orodispersible Tablets ofUmar AliNo ratings yet

- Bisoprolol Fumarate Optizorb Dispersible Tablet PDFDocument16 pagesBisoprolol Fumarate Optizorb Dispersible Tablet PDFmailtorubal2573No ratings yet

- Protocol For Dissertation Work - NITROFURANTOIN 26-10-2018Document20 pagesProtocol For Dissertation Work - NITROFURANTOIN 26-10-2018dasarathramNo ratings yet

- Formulation and Design of Taste Masked Quetiapine Fumarate Orally Fast Disintegrating Tablets by Sublimation MethodDocument16 pagesFormulation and Design of Taste Masked Quetiapine Fumarate Orally Fast Disintegrating Tablets by Sublimation MethodJuan IgnacioNo ratings yet

- Formulation and Evaluation of Enteric CoatedDocument13 pagesFormulation and Evaluation of Enteric Coatedvanvu buiNo ratings yet

- Solubility Enhancement of Poorly Aqueous Soluble Furosemide Using Peg-4000 by Solid DispersionDocument9 pagesSolubility Enhancement of Poorly Aqueous Soluble Furosemide Using Peg-4000 by Solid Dispersionnha.99No ratings yet

- 727 1784 1 PBDocument10 pages727 1784 1 PBRajasekharNo ratings yet

- Article WJPR 1400475907Document13 pagesArticle WJPR 1400475907miserable1995No ratings yet

- FORMULATION AND EVALUATION OF MICONAZOLE NITRATE LOADED NANOSPONGES FOR VAGINAL DRUG DELIVERY P.Suresh Kumar, N.Hematheerthani J.Vijaya Ratna and V.SaikishorDocument10 pagesFORMULATION AND EVALUATION OF MICONAZOLE NITRATE LOADED NANOSPONGES FOR VAGINAL DRUG DELIVERY P.Suresh Kumar, N.Hematheerthani J.Vijaya Ratna and V.SaikishoriajpsNo ratings yet

- Pioglitazone NaopaticlesDocument11 pagesPioglitazone NaopaticlesAtiq Ur-RahmanNo ratings yet

- 41 RJPT 14 6 2021Document6 pages41 RJPT 14 6 2021Rizki Uhud NasofiNo ratings yet

- Formulation and Evaluation of Nanoemulsion For Solubility Enhancement of KetoconazoleDocument14 pagesFormulation and Evaluation of Nanoemulsion For Solubility Enhancement of KetoconazoledgdNo ratings yet

- Design and Evaluation of Spherical Agglomerated Crystals Loaded Fast Disolving Tablets For Enhancing The Solubilityof Mefenamic AcidDocument7 pagesDesign and Evaluation of Spherical Agglomerated Crystals Loaded Fast Disolving Tablets For Enhancing The Solubilityof Mefenamic AcidBaru Chandrasekhar RaoNo ratings yet

- 18.rajiv Kumar Parminder Nain Jaspreet Kaur Vipin Saini and Varinder SoniDocument11 pages18.rajiv Kumar Parminder Nain Jaspreet Kaur Vipin Saini and Varinder Sonidesi imastutiNo ratings yet

- 42 Development and Evaluation of Naproxen Sodium 250 MG Effervescent Tablets PDFDocument6 pages42 Development and Evaluation of Naproxen Sodium 250 MG Effervescent Tablets PDFIyad Naeem MuhammadNo ratings yet

- Dissolution Enhancement and Formulation of Film CoDocument12 pagesDissolution Enhancement and Formulation of Film CobimaNo ratings yet

- 124 1009 1 PBDocument4 pages124 1009 1 PBSherly KristiNo ratings yet

- Jurnal CarbamazepinDocument9 pagesJurnal CarbamazepinRosamaria Yuni UtamiNo ratings yet

- 8cf3 PDFDocument9 pages8cf3 PDFnelisaNo ratings yet

- Article 7Document12 pagesArticle 7Dang Chi CongNo ratings yet

- Nystatinniosomes PDFDocument7 pagesNystatinniosomes PDFEufrasia Willis PakadangNo ratings yet

- Pharma Ceu TicDocument33 pagesPharma Ceu TicPankaj SharmaNo ratings yet

- JURNAL PEDIATRI 19-Vol.-3-Issue-1-Jan.-2012-RA-963-Paper-19Document3 pagesJURNAL PEDIATRI 19-Vol.-3-Issue-1-Jan.-2012-RA-963-Paper-19AnditapitalokaNo ratings yet

- Fabrication, Characterization and Pharmacological Activity of Usnic Acid Loaded NanoparticlesDocument9 pagesFabrication, Characterization and Pharmacological Activity of Usnic Acid Loaded Nanoparticlesdesma elitaNo ratings yet

- Formulation and Evaluation of Immediate Release Tablet of LevonorgestrelDocument9 pagesFormulation and Evaluation of Immediate Release Tablet of LevonorgestrelNatasya AyuNo ratings yet

- Formulation and In-Vitro Characterisation of Sustained Releasemetronidazole Cocoa Butter SuppositoriesDocument7 pagesFormulation and In-Vitro Characterisation of Sustained Releasemetronidazole Cocoa Butter SuppositoriesRowaidaNo ratings yet

- 4.nag NifedipinebuccalRamreddy Dec 2012Document16 pages4.nag NifedipinebuccalRamreddy Dec 2012Siddhesh KharmateNo ratings yet

- Kumar Vol1 Pag 33 41Document10 pagesKumar Vol1 Pag 33 41Sampath KumarNo ratings yet

- 3199 PDFDocument8 pages3199 PDFAnonymous TjrM0BXkZNo ratings yet

- Formulation and in Vitro Assessment of Eudragit L 100 and Eudragit S 100 Based Naproxen MicrospheresDocument9 pagesFormulation and in Vitro Assessment of Eudragit L 100 and Eudragit S 100 Based Naproxen MicrospheresAsifa ShabbirNo ratings yet

- Monte LukastDocument6 pagesMonte LukastPham XuanNo ratings yet

- Formulation and Evaluation of Itraconazole Opthalmic in Situ GelsDocument8 pagesFormulation and Evaluation of Itraconazole Opthalmic in Situ GelsiajpsNo ratings yet

- Formulation, Development and Evalution of An Immediate Release Tablet of MethotrexateDocument22 pagesFormulation, Development and Evalution of An Immediate Release Tablet of MethotrexateDarlianaMelloSouzaNo ratings yet

- Formulation and Evaluation of Orodispersible Tablets Ofdonepezil HydrochlorideDocument7 pagesFormulation and Evaluation of Orodispersible Tablets Ofdonepezil HydrochlorideDr. P.V.Kamala KumariNo ratings yet

- Formulation Development and Evaluation of Immediate Release Tablets Containing Antihypertensive Agent Amlodipine Besylate and ValsartanDocument8 pagesFormulation Development and Evaluation of Immediate Release Tablets Containing Antihypertensive Agent Amlodipine Besylate and ValsartanDược K45 Trần Dũng TâmNo ratings yet

- Effect of Tablet Processing and Formulation FactorDocument13 pagesEffect of Tablet Processing and Formulation FactorMaria Carmen Rivera PorrasNo ratings yet

- 34923-Article Text-161954-1-10-20190717Document9 pages34923-Article Text-161954-1-10-20190717Aziza Anggi MaiyantiNo ratings yet

- Article WJPR 1530615743Document13 pagesArticle WJPR 1530615743nelisaNo ratings yet

- A Review On Medicated Lozenges: Volume 8, Issue 2, 396-412. Review Article ISSN 2277 - 7105Document17 pagesA Review On Medicated Lozenges: Volume 8, Issue 2, 396-412. Review Article ISSN 2277 - 7105mary grace trinidadNo ratings yet

- Vol. 2, Issue 6, June 2014, PharmaTutor, Paper-20Document7 pagesVol. 2, Issue 6, June 2014, PharmaTutor, Paper-20Viri MarquezNo ratings yet

- Na DastinibDocument20 pagesNa DastinibPradheep SNo ratings yet

- KT Hình Cầu Của ItraconazoleDocument11 pagesKT Hình Cầu Của ItraconazoleDương TrungNo ratings yet

- Formulation, Development and Evaluation of Oral Reconstitutable Dry SyrupDocument10 pagesFormulation, Development and Evaluation of Oral Reconstitutable Dry SyrupdhilahNo ratings yet

- Dokumen PDFDocument8 pagesDokumen PDFnadia julisaNo ratings yet

- Formulation and Evaluation of Aspirin Delayed ReleDocument4 pagesFormulation and Evaluation of Aspirin Delayed RelePutri Febriana WidyaningtyasNo ratings yet

- PlantagoovataDocument8 pagesPlantagoovataAli RizieqNo ratings yet

- Full TextDocument7 pagesFull TexttuayuNo ratings yet

- Can Makjong (Scaphium Macropodum) Powder Formed Gel in Effervescent Blend?Document3 pagesCan Makjong (Scaphium Macropodum) Powder Formed Gel in Effervescent Blend?KuntoNo ratings yet

- Article WJPR 1496227877Document26 pagesArticle WJPR 1496227877DrAmit VermaNo ratings yet

- Formulation Development and Optimization of Taste Masked Generic Fast Dissolving ZincDocument7 pagesFormulation Development and Optimization of Taste Masked Generic Fast Dissolving ZincmulazimhNo ratings yet

- Formulation and In-Vitro Characterization of Risperidone Nanosuspensions For The Enhancement of Drug Release RateDocument16 pagesFormulation and In-Vitro Characterization of Risperidone Nanosuspensions For The Enhancement of Drug Release RateSiva PrasadNo ratings yet

- Formulation and Evaluation of Vilazodone Sublingual Tablets by Using Lyophilization TechniqueDocument9 pagesFormulation and Evaluation of Vilazodone Sublingual Tablets by Using Lyophilization Techniquealamia pharmNo ratings yet

- FORMULATION AND IN-VITRO EVALUATION OF ZOLMITRIPTAN ORO-DISPERSIBLE TABLETS Arigela Bharathi, Vemugunta Ramakrishna, Baratam Anupama, Chukkapalli ManishaDocument9 pagesFORMULATION AND IN-VITRO EVALUATION OF ZOLMITRIPTAN ORO-DISPERSIBLE TABLETS Arigela Bharathi, Vemugunta Ramakrishna, Baratam Anupama, Chukkapalli ManishaiajpsNo ratings yet

- Formulation and Evaluation of Mouth Dissolving Tablets of OxcarbazepineDocument12 pagesFormulation and Evaluation of Mouth Dissolving Tablets of OxcarbazepineTyas Apa TyasNo ratings yet

- A3 Eraga Et Al PublishedDocument6 pagesA3 Eraga Et Al PublishedNovilkadwiNo ratings yet

- Once-Daily Sustained-Release Matrix Tablets of Metoprolol Tartrate: Formulation and In-Vitro EvaluationDocument5 pagesOnce-Daily Sustained-Release Matrix Tablets of Metoprolol Tartrate: Formulation and In-Vitro EvaluationAryanto DedyNo ratings yet

- Preparation and Characterization of Nanogel Drug Delivery System Containing Clotrimazole An Anti-Fungal Drug"Document10 pagesPreparation and Characterization of Nanogel Drug Delivery System Containing Clotrimazole An Anti-Fungal Drug"Fibie LionaNo ratings yet

- Taste Masking of Oral Pharmaceutics A ReviewDocument9 pagesTaste Masking of Oral Pharmaceutics A Reviewzakarya wadiNo ratings yet

- Interview Industry-Insights Overcoming Challenges of Taste MaskingDocument2 pagesInterview Industry-Insights Overcoming Challenges of Taste Maskingzakarya wadiNo ratings yet

- Prac - Medecinal Pharmacy 1Document5 pagesPrac - Medecinal Pharmacy 1zakarya wadiNo ratings yet

- Prac - Medecinal Chemistry 5Document3 pagesPrac - Medecinal Chemistry 5zakarya wadiNo ratings yet

- Flexpro Whitepaper Guide To A Successful Drug Development Technology Transfer 1Document12 pagesFlexpro Whitepaper Guide To A Successful Drug Development Technology Transfer 1zakarya wadiNo ratings yet

- CH New Horizon Public School: Practice Worksheet (October - 2023)Document4 pagesCH New Horizon Public School: Practice Worksheet (October - 2023)Vasudhara yadavNo ratings yet

- Biosafety, Facilities and Design of A Molecular Biology LaboratoryDocument6 pagesBiosafety, Facilities and Design of A Molecular Biology LaboratoryMichal VillanuevaNo ratings yet

- Eral Directorate of Health Affairs - Najran - Ksa - Email: Labsnj@ Moh - Gov.Sa Material Safety Data Sheet (MSDS)Document10 pagesEral Directorate of Health Affairs - Najran - Ksa - Email: Labsnj@ Moh - Gov.Sa Material Safety Data Sheet (MSDS)Saifeldein ElimamNo ratings yet

- 1st & 2nd Year Mbbs Teacher Report-22Document3 pages1st & 2nd Year Mbbs Teacher Report-22DR AbidNo ratings yet

- H2O BookDocument137 pagesH2O BookSwaminathan ThayumanavanNo ratings yet

- Comb Shaped SEBS Based Anion Exchange Membranes With Obviou - 2022 - ElectrochimDocument12 pagesComb Shaped SEBS Based Anion Exchange Membranes With Obviou - 2022 - ElectrochimLeyla UNo ratings yet

- 2IIT1920 (IIT Camp) (Advanced) C (U1) WS01 (Periodic Properties - Chemical Bonding) (NC Sir) Q + SolnDocument10 pages2IIT1920 (IIT Camp) (Advanced) C (U1) WS01 (Periodic Properties - Chemical Bonding) (NC Sir) Q + SolnSooryaNo ratings yet

- English Module 1.5: What I KnowDocument7 pagesEnglish Module 1.5: What I KnowJak Amammo Nagan KoNo ratings yet

- Grade 10 - Life Science - November Paper 2-1 - MemoDocument5 pagesGrade 10 - Life Science - November Paper 2-1 - MemoJustinCase1991No ratings yet

- D ThyroxineDocument5 pagesD ThyroxinedebasishmannaNo ratings yet

- Planer Vs Non Planer DefectsDocument2 pagesPlaner Vs Non Planer DefectsSavad Alwye75% (8)

- Inorganica Chimica ActaDocument10 pagesInorganica Chimica ActaNikhil BhoumikNo ratings yet

- Silicone Compatibility TestDocument2 pagesSilicone Compatibility TestDyeing DyeingNo ratings yet

- Compressed Air System: by Raj PrabhakarDocument21 pagesCompressed Air System: by Raj PrabhakarNabilBouabanaNo ratings yet

- Pt. Rania Jaya Farmarindo Daftar Harga Jual PersediaanDocument22 pagesPt. Rania Jaya Farmarindo Daftar Harga Jual PersediaanWulan FitriNo ratings yet

- Sanitary Installation Works: Chapter - S-1Document74 pagesSanitary Installation Works: Chapter - S-1Ravindu RansaraNo ratings yet

- Celex 02019R1021-20230610 en TXTDocument40 pagesCelex 02019R1021-20230610 en TXTdasfNo ratings yet

- 5107 FL en Profi-Tipp Co2Document8 pages5107 FL en Profi-Tipp Co2Bung Ma'rufNo ratings yet

- 2-21 - Mohamed S2.0-S1658361221000378-MainDocument11 pages2-21 - Mohamed S2.0-S1658361221000378-Maindwlat.mostafaNo ratings yet

- Chapter 9Document9 pagesChapter 9mysthicriousNo ratings yet

- Chapter 6Document39 pagesChapter 6A kNo ratings yet

- JETIR2106217Document7 pagesJETIR2106217Ananjana cNo ratings yet

- Characterization Studies Waste Plastic Oil and Its BlendsDocument12 pagesCharacterization Studies Waste Plastic Oil and Its BlendsPieyah ChomelNo ratings yet

- Bio PP 1Document20 pagesBio PP 1Hamza AnwarNo ratings yet

- Bastion Exterior UV Stabilised WPU MembraneDocument8 pagesBastion Exterior UV Stabilised WPU MembraneGuruNo ratings yet

- ASTM D910 Aviation Gasoline PDFDocument8 pagesASTM D910 Aviation Gasoline PDFJesse KrebsNo ratings yet

- L4 Elements and CompoundsDocument13 pagesL4 Elements and CompoundsQueenie EstrabilloNo ratings yet

- 2 Factors Affect. Lime SlakingDocument4 pages2 Factors Affect. Lime SlakingWilder Atalaya ChavezNo ratings yet