Professional Documents

Culture Documents

PWHT Table For ASME Material-Sec VIII

PWHT Table For ASME Material-Sec VIII

Uploaded by

abhinavOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PWHT Table For ASME Material-Sec VIII

PWHT Table For ASME Material-Sec VIII

Uploaded by

abhinavCopyright:

Available Formats

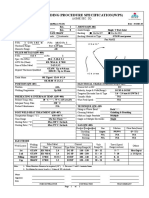

PWHT CYCLE TIME AS PER ASME CODES FOR ASME MATERIALS

P # & Material PWHT

ASME Sec VIII , Div 1

Sr # P# Gr # Grade Temperature Min Ref: Table UCS - Heating rate Thickness Limits Ref: Table UCS - Governing Thickness for

Soaking time Ref: Table UCS -56 Cooling rate Ref: UCS -56 (d) (5) Preheat Temperature

56 Ref : UCS -56 (d) (2) 56 PWHT(Socket Welding)

1 SA 36 ,SA 53 ,SA 106 Gr B

2 SA234 WPB, SA 283 GR A

1 1) 595˚C (1100˚F) Above 425˚C , the rate shall not Above 425˚C , the rate shall not 1) For Nominal Thickness above

3 SA 333 Gr 6, sa 350 Gr Lf1 1) Up to 2" Thickness, 1Hr /Inch (

-For Gr 1,2 & 3. more than 222˚C / Hr divided by more than 280˚C / Hr divided by 1.5" ( 38.0 mm) & For Thickness Sahll not be less than 0˚C.If

25.0 mm), But Min 15 Minutes.

maximum Thickness of Shell or maximum Thickness of Shell or from 1.25" (32.0 mm) to 1.5" surface temperature goes below

4 1 SA420 WPL6, SA 516 GR 60 2) For 2" to 5" Thickness 2 Hr Plus

Header (in Inches), But Any case Header (in Inches) & Not Less (38.0MM) if Preheat is 0˚C , then to be preheated to

15 Minnutes for each additional

5 SA 105, SA 216 WCB,SA 234 WPC not exceed 222˚C / Hr & Not Less than 56˚C /Hr. From 425˚C , Cool maintained at 95˚C during Minimum of 15˚C ( UW -30)

of 25.00 MM over 2" Thickness.

than 56˚C /Hr. in Still Air. Welding.Note C of table UCS-56

6 2 A 350 GR LF2,SA 516 GR 70

2) For Gr # 4 Not Applicable

7 SA 671 GR CC 70 CD 70

8 A 204 GR A, SA209 GR T1B

1) For Gr # 3 , Not Mandatory

1) Up to 2" Thickness, 1Hr /Inch (

9 1 SA 213 T2,SA 234 WP1, SA 335 P1

25.0 mm), But Min 15 Minutes. Above 425˚C , the rate shall not more Above 425˚C , the rate shall not more Sahll not be less than 0˚C.If

than 222˚C / Hr divided by maximum than 280˚C / Hr divided by maximum 2) For Gr # 1 ,2 Thickness ≤ 16 mm,

10 SA 356 GR 2, SA 691 CM-65 595˚C ( 1100˚F) -For Gr 1,2 & surface temperature goes below

3 Thickness of Shell or Header (in Thickness of Shell or Header (in unless PQR Thickness ≥ Production

3. Inches), But Any case not exceed Inches) & Not Less than 56˚C /Hr. Weld Nominal Thickness, Not 0˚C , then to be preheated to

11 A 182 GR F2, GR F1 , SA 204 GR C required. Minimum of 15˚C ( UW -30)

222˚C / HR & Not Less than 56˚C /Hr. From 425˚C , Cool in Still Air.

2

12 SA 336 GR F1 3) For Other Conditions , Refer Code.

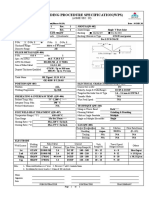

13 A 182 FL12, CL.1,2

1) Up to 2" Thickness, 1Hr /Inch ( 25.0

14 A 213 T11 / T 12 mm), But Min 15 Minutes.

1) Not Mandatory for D ≤ 100.0 MM ,

1 T ≤ 16.0 MM , Max C = 0.15% &

15 A 234 WP11 / 12 Cl.1,SA 335 P11 Above 425˚C , the rate shall not more Above 425˚C , the rate shall not more Preheat maintained at 120˚C

Sahll not be less than 0˚C.If

than 222˚C / Hr divided by maximum than 280˚C / Hr divided by maximum

2) Over 2"(50mm) to 5" ( 125mm) = 1Hr surface temperature goes below

16 4 A 335 P12 ,SA 336 GR F12/F11 650˚C ( 1200˚F) -For Gr 1,2 /Inch

Thickness of Shell or Header (in Thickness of Shell or Header (in

Inches), But Any case not exceed Inches) & Not Less than 56˚C /Hr.

0˚C , then to be preheated to

17 2 A 333 GR 4 222˚C / HR & Not Less than 56˚C /Hr. From 425˚C , Cool in Still Air. Minimum of 15˚C ( UW -30)

2) Others Refer UCS -56 of Sec VIII ,

18 A 148 90 -60 Div -1

3

19 A 668 Cl.kb, ka, kc

20 SA 182 F22, Cl.1 , Cl.3, F21

21 SA 213 T21 & T 22, SA 217 GR WC9

22 SA 234 WP22, Cl.1,

1) Up to 2" Thickness, 1Hr

23 5A 1 A 335 GR P21 & 22 /Inch ( 25.0 mm), But Min 15

Minutes.

24 A 336 F22 Cl.1 & Cl.3, SA 336 F21 CL.1

25 SA 369 FP21 & 22, SA 369 FP21 & 22

675˚C ( 1250˚F)

26 A 691 2.25 CR, Cl.1 & 2

Above 425˚C , the rate shall

27 A 182 F5a , F5 & F9, SA 234 EP5 & WP9 Above 425˚C , the rate shall

not more than 222˚C / Hr

not more than 280˚C / Hr Sahll not be less than 0˚C.If

28 A 213 T5c, T5, T5b &T 9 divided by maximum Thickness Refer UCS -56 Page # 164 of

divided by maximum Thickness surface temperature goes below

of Shell or Header (in Inches), ASME Sec VIII, Div -1 - 2007 ,

of Shell or Header (in Inches) 0˚C , then to be preheated to

29 1 A 335 GR P5, 5b & 5c , P9 But Any case not exceed 222˚C 209b Addenda.

& Not Less than 56˚C /Hr. Minimum of 15˚C ( UW -30)

/ HR & Not Less than 56˚C

30 A 336 F5, F5a & F9 ,369 GR FP5 &FP9 2) Over 2"(50mm) to 5" ( From 425˚C , Cool in Still Air.

5B /Hr.

31 SA 387 5 Cl.1 & 2 , SA 691 5 CR, Cl.1 & 2 125mm) = 1Hr /Inch

32 A 213 T91

33 2 A 217 GR C12A Not Given

34 A 356 GR 12A

35 A 182 F 3V, F3 VCb,F22V

3) Over 5" Thickness , 5hrs +15

35 5C 1 A 336 F3VCb , F3V & F22V 650˚C ( 1200˚F) -For Gr 1,2 Minutes for Each Additional inch Over

2"(50 mm).

37 A 508 22 Cl.3 & 3V ,SA 542 22 Cl3 & 3V

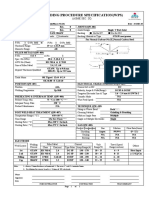

38 SA-182 F6a Cl 1,2,3 & 4, F6b

39 6 1,2 & 3 SA217 CA15,SA240 Type 410, 429 Not Given in Code NA NA NA NA NA NA

40 SA268 Type 410, SA 336 F6,SA 351 CA15

41 SA182 F430,SA 240 Type 405,409,410S

7 1&2 Not Given in Code NA NA NA NA NA NA

42 SA240 S44400,SA268 Type 439

43 A 182 FR , SA 203 Gr A,B, SA 234 WPR

Sahll not be less than 0˚C.If

44 A 333 GR 7 & GR 9, SA 334 GR 7 & 9 Refer UCS -56 Page # 166 of

1hr Minimum, Plus 15 Minutes surface temperature goes below

9A 1 595˚C ( 1100˚F) Above 425˚C , the rate shall not Above 425˚C , the rate shall not ASME Sec VIII, Div -1 - 2007 ,

/Inch Over 1"(25.0 mm) 0˚C , then to be preheated to

45 A 350 GR LF5, Cl 1&.2 , SA 350 GR LF9 more than 222˚C / Hr divided by more than 280˚C / Hr divided by 209b Addenda. Minimum of 15˚C ( UW -30)

maximum Thickness of Shell or maximum Thickness of Shell or

46 SA 714 Gr v, Tp.E , Gr V

Header (in Inches), But Any case Header (in Inches) & Not Less

47 A 203 Gr D , Gr. E & F not exceed 222˚C / HR & Not Less than 56˚C /Hr. From 425˚C , Cool

Sahll not be less than 0˚C.If

than 56˚C /Hr. in Still Air. Refer UCS -56 Page # 167 of

1hr Minimum, Plus 15 Minutes surface temperature goes below

48 9B 1 A 333 GR 3 , SA 334 GR 3 595˚C ( 1100˚F) ASME Sec VIII, Div -1 - 2007 ,

/Inch Over 1"(25.0 mm) 0˚C , then to be preheated to

209b Addenda.

49 A 350GR LF3 , SA 765 III Minimum of 15˚C ( UW -30)

50 SA 479 S32550

10 1 Not Given NA NA NA NA NA NA

51 SA 815 S 32760

52 Alloy S31803

53 10H 1 Alloy S32550 Not Given NA NA NA NA NA NA

54 Alloy S32750

55 SA 240 XM-33,27,SA268 TP446

10 I 1 Not Given NA NA NA NA NA NA

56 SA479 XM-27,SA 268 & 731 XM-27,33

57 SA 182 F91,A217 CA12A,SA234WP91 1) Up to 5" Thickness, 1 Hr/Inch (

2.0 Min / MM) , 30 Mints Sahll not be less than 0˚C.If

minimum . surface temperature goes below

58 15 E 1 SA336 F91,SA369F91,A356 12A 720°C Same as P # 9A Same as P # 9A ALL Thickness

2) For above 5" Thickness, 5hr 0˚C , then to be preheated to

Plus 15 Mints for each additional Minimum of 15˚C ( UW -30)

59 A691 91,EN10222-2 X10CrMoVNb9-1 Inch.

Note

1 The above table is prepared based on ASME Code edition 2010 addenda 2011a

1 of 1

You might also like

- MTS Vocab 2023Document9 pagesMTS Vocab 2023Rahul Chauhan100% (1)

- Toray Btcy-1: Description FeaturesDocument6 pagesToray Btcy-1: Description FeaturesAkhil HebbarNo ratings yet

- PWHT Table For ASME Material-Sec VIIIDocument1 pagePWHT Table For ASME Material-Sec VIIIabhinavNo ratings yet

- PWHT Table For ASME Material-Sec VIIIDocument1 pagePWHT Table For ASME Material-Sec VIIIsabir.ashrafme12No ratings yet

- HT Chart For ASME Material-Sec IDocument1 pageHT Chart For ASME Material-Sec IMurugananthamParamasivamNo ratings yet

- HT Chart For ASME Material-B31.3 PDFDocument1 pageHT Chart For ASME Material-B31.3 PDFMurugananthamParamasivamNo ratings yet

- HT Chart For ASME Material-B31.3Document1 pageHT Chart For ASME Material-B31.3MurugananthamParamasivamNo ratings yet

- PWHT Table For ASME Material B31 3 1714980924Document1 pagePWHT Table For ASME Material B31 3 17149809248n7ngyh6c2No ratings yet

- 3496445985Document2 pages3496445985yosep gomezNo ratings yet

- V-1401 Level - 3 AnalysisDocument3 pagesV-1401 Level - 3 AnalysisVipin NairNo ratings yet

- Heat Treatment - ShortDocument18 pagesHeat Treatment - ShortKartik AhalawatNo ratings yet

- Gac 244Document2 pagesGac 244mohamad mostafaviNo ratings yet

- TenCate BT250E-6 DatasheetDocument4 pagesTenCate BT250E-6 DatasheetGregory A KressNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Abs 70Document2 pagesAbs 70mohamad mostafaviNo ratings yet

- SM CatalogDocument20 pagesSM CatalognamnamqweNo ratings yet

- Timetal: Ti - 1 0 V-2 F e - 3 A LDocument2 pagesTimetal: Ti - 1 0 V-2 F e - 3 A LBüyüleyici GözlerNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Gac 250Document2 pagesGac 250mohamad mostafaviNo ratings yet

- Abs 250Document2 pagesAbs 250mohamad mostafaviNo ratings yet

- Abs 60Document2 pagesAbs 60mohamad mostafaviNo ratings yet

- Abs-72 MDocument2 pagesAbs-72 Mmohamad mostafaviNo ratings yet

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Jis C3771Document2 pagesJis C3771bkprodhNo ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- Gac 265Document2 pagesGac 265mohamad mostafaviNo ratings yet

- Job No. Item No: Doc. No. Tag No. Client Fine Filter Skid FD-38063A/B Bharat Heavy Electricals LimitedDocument3 pagesJob No. Item No: Doc. No. Tag No. Client Fine Filter Skid FD-38063A/B Bharat Heavy Electricals LimitedgauravNo ratings yet

- Abs-Hfa 70Document2 pagesAbs-Hfa 70mohamad mostafaviNo ratings yet

- 31.3 PWHT RequirementDocument2 pages31.3 PWHT RequirementEIL NDTNo ratings yet

- Abs 80Document2 pagesAbs 80mohamad mostafaviNo ratings yet

- Bandas - Alliance2009Document435 pagesBandas - Alliance2009Nelson Gabriel Gallo C.No ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- Abs 30Document2 pagesAbs 30mohamad mostafaviNo ratings yet

- Welding Processes Welding KnowledgeDocument85 pagesWelding Processes Welding KnowledgeIshtiaqNo ratings yet

- Abs 38Document2 pagesAbs 38mohamad mostafaviNo ratings yet

- Cpme Tharmal Desing DataDocument3 pagesCpme Tharmal Desing DataNaam Ka KyaNo ratings yet

- Abs 40Document2 pagesAbs 40mohamad mostafaviNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- Nap-Gard 7-2500 PDFDocument2 pagesNap-Gard 7-2500 PDFPietro ViganNo ratings yet

- Datasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1Document13 pagesDatasheet Sandvik 2rk65 en v2019!06!19 14 - 54 Version 1mauferesNo ratings yet

- Propriedades ABSDocument1 pagePropriedades ABSengmecanica07022013No ratings yet

- Tall Height (4.3mm and 5.0mm) and Surface Mount TypeDocument3 pagesTall Height (4.3mm and 5.0mm) and Surface Mount TypeshyhuNo ratings yet

- Heat Exchanger - Preliminary Data SheetDocument4 pagesHeat Exchanger - Preliminary Data SheetgksakthiNo ratings yet

- Datasheet-Sandvik-Saf-31803-En-V2018-07-20 11 - 04 Version 1Document9 pagesDatasheet-Sandvik-Saf-31803-En-V2018-07-20 11 - 04 Version 1Gonzalo AlarciaNo ratings yet

- 5370 N Pag8Document11 pages5370 N Pag8payoseNo ratings yet

- Technical Delivery Condition (TDC) : Exhibit 3 - 2 Rev. 0 Dtd. 12.12.2014Document3 pagesTechnical Delivery Condition (TDC) : Exhibit 3 - 2 Rev. 0 Dtd. 12.12.2014shazanNo ratings yet

- Nap-Gard 7-2514 PDFDocument2 pagesNap-Gard 7-2514 PDFPietro ViganNo ratings yet

- Abs 75Document2 pagesAbs 75mohamad mostafaviNo ratings yet

- Technical Specification Sheet: Sr. No Project: Division: Doc. No: 3.1 IdentityDocument16 pagesTechnical Specification Sheet: Sr. No Project: Division: Doc. No: 3.1 IdentityRishabh VermaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Ie 101Document14 pagesIe 101raiNo ratings yet

- Shielded Power Inductors - MOS6020Document2 pagesShielded Power Inductors - MOS6020mauricio alfonsoNo ratings yet

- P.No. Group N AWS No. Class Filler No (F. No.) A. No. Si No. Material Grade Filler Metal SFA NoDocument3 pagesP.No. Group N AWS No. Class Filler No (F. No.) A. No. Si No. Material Grade Filler Metal SFA NoSitaram JhaNo ratings yet

- Regulador Presion de CondDocument8 pagesRegulador Presion de CondEduardoNo ratings yet

- Fbe Dual Rock - Tds 7-2610Document3 pagesFbe Dual Rock - Tds 7-2610Jair PadillaNo ratings yet

- The SQUID Handbook: Fundamentals and Technology of SQUIDs and SQUID SystemsFrom EverandThe SQUID Handbook: Fundamentals and Technology of SQUIDs and SQUID SystemsNo ratings yet

- Unit 4Document8 pagesUnit 4lolybarreiroNo ratings yet

- Yfm70Ry Yfm70Ry Yfm70Ry: (1S3R) (1S3V) (1S3L)Document76 pagesYfm70Ry Yfm70Ry Yfm70Ry: (1S3R) (1S3V) (1S3L)Ventas CaliNo ratings yet

- The Sounds of EnglishDocument58 pagesThe Sounds of EnglishSara Albina0% (1)

- STB60NF10 STB60NF10-1 - STP60NF10: N-Channel 100V - 0.019 - 80A - TO-220 - D Pak - I PAK Stripfet™ Ii Power MosfetDocument15 pagesSTB60NF10 STB60NF10-1 - STP60NF10: N-Channel 100V - 0.019 - 80A - TO-220 - D Pak - I PAK Stripfet™ Ii Power MosfetAnonymous C6Vaod9No ratings yet

- Openmind 3 Unit 1 Video Worksheet PDFDocument2 pagesOpenmind 3 Unit 1 Video Worksheet PDFMisael GonzalezNo ratings yet

- PSS2020 345Document11 pagesPSS2020 345Fergus BurnsNo ratings yet

- PART 1: Overview of Retail Marketing TrendsDocument64 pagesPART 1: Overview of Retail Marketing TrendsRavichandran Ramanujan100% (2)

- Goin Where The Wind BlowsDocument2 pagesGoin Where The Wind BlowsIcaro BispoNo ratings yet

- Petitioner vs. vs. Respondents Primo O. Orellan Jose M. KimpoDocument5 pagesPetitioner vs. vs. Respondents Primo O. Orellan Jose M. Kimpogenel marquezNo ratings yet

- Sop QubDocument2 pagesSop QubAMRUD GAMINGNo ratings yet

- Carl Zeiss Jena Apo TessarDocument28 pagesCarl Zeiss Jena Apo TessarElla Antonella0% (1)

- Publishing Free Sample Content Review Only Copied or Sold.: Our WorldDocument8 pagesPublishing Free Sample Content Review Only Copied or Sold.: Our WorldcinemaNo ratings yet

- Preventive Actions of Police: A Project Proposal Made byDocument23 pagesPreventive Actions of Police: A Project Proposal Made bynupur jhodNo ratings yet

- BIG-IP CGNAT ImplementationsDocument208 pagesBIG-IP CGNAT ImplementationsThiago CabralNo ratings yet

- Project Mobilization Plan-NarrativeDocument25 pagesProject Mobilization Plan-NarrativeJoey Marasigan100% (1)

- SYNOPSISDocument25 pagesSYNOPSISpriyankaNo ratings yet

- Chetan Mitra Updated CV DecDocument4 pagesChetan Mitra Updated CV Decchetan mitraNo ratings yet

- Cobb 500Document16 pagesCobb 500scribeascrapNo ratings yet

- OfficerDocument8 pagesOfficerdesliNo ratings yet

- Schunk, 2001. Self-Regulation Through Goal SettingDocument4 pagesSchunk, 2001. Self-Regulation Through Goal SettingNani Maciel100% (1)

- AXOLOTL (Tugas Kelompok Bsi)Document5 pagesAXOLOTL (Tugas Kelompok Bsi)Ardina Citra NimanNo ratings yet

- Adverb of Affirmation and Negation Worksheet 3Document6 pagesAdverb of Affirmation and Negation Worksheet 3MARIZ BALBANo ratings yet

- 2.2.9 Practice - Complete Your Assignment (Practice)Document5 pages2.2.9 Practice - Complete Your Assignment (Practice)johnnyhockey91No ratings yet

- Countdown - DC Database - FandomDocument9 pagesCountdown - DC Database - FandomJTKirk61No ratings yet

- What Is Radionics - Nick FranksDocument3 pagesWhat Is Radionics - Nick Franksambertje12100% (1)

- Ug Cse Co With SyllabusDocument173 pagesUg Cse Co With Syllabuscsetiet csetietNo ratings yet

- BEGC-105 Ignouassignmentguru - Com DEC21Document2 pagesBEGC-105 Ignouassignmentguru - Com DEC21Fawkes RavneetNo ratings yet

- WP 1997 - 16 Catherine Marquette-07112007 - 1Document19 pagesWP 1997 - 16 Catherine Marquette-07112007 - 1k1l2d3No ratings yet

- Ratio Analysis ProjectDocument63 pagesRatio Analysis ProjectYalluraj HukkeriNo ratings yet