Professional Documents

Culture Documents

26-000-2-02-00001 FL 581574-1-R01-Model

26-000-2-02-00001 FL 581574-1-R01-Model

Uploaded by

MartinAlexisGonzálezVidalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

26-000-2-02-00001 FL 581574-1-R01-Model

26-000-2-02-00001 FL 581574-1-R01-Model

Uploaded by

MartinAlexisGonzálezVidalCopyright:

Available Formats

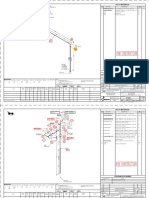

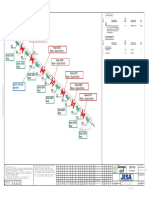

BILL OF MATERIAL

FABRICATION MATERIALS

CONT. ON

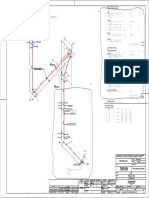

581573 PT ITEM CODE L-CODE QTY COMPONENT DESCRIPTION N.S. WEIGHT

E 139184862 NO (INS)

N 112513175

PIPE

EL +28064

1 PIPL020B1340 L-7809 6.1M PIPE SMLS BE SCH 40 B36.10 ASTM A-333 GR.6 3 68.06

FITTINGS

3"NS

2 TEBL210F315061506 L-8259 2 EQUAL TEE BW SCH 40/40 B16.9 ASTM A-420 Gr.WPL6 3x3 6.80

640

3 EREL210F315061406 L-8256 2 ECC. REDUCER BW SCH 40/40 B16.9 ASTM A-420 Gr.WPL6 3x2 2.26

4 SOKL300LB01512 L-7906 1 SOCKOLET 3000# SW MSS-SP-97 ASTM A-350 Gr.LF2 3x1 0.27

5 SOKL300LB01511 L-7906 1 SOCKOLET 3000# SW MSS-SP-97 ASTM A-350 Gr.LF2 3 x 3/4 0.15

<1> 1 6 90LL210F3340 L-6642 4 90º ELBOW LR BW SCH 40 B16.9 ASTM A-420 Gr.WPL6 3 8.16

7 NTOL020E1110323 L-9261 2 NIPPLE PE/TE SCH 160 75MM B36.10 ASTM A-333 GR.6 3/4 0.46

E 139184862

8 CATL300KBK3/4 L-7902 2 CAP 3000# THF B16.11 ASTM A-350 Gr.LF2 3/4 0.28

N 112513175

EL +27424 FLANGES

9 WNFL300R35340 L-7981 6 WN FLANGE 300# RF SCH 40 B16.5 ASTM A-350 Gr.LF2 3 40.74

6 10 WNFL300R35240 L-7981 2 WN FLANGE 300# RF SCH 40 B16.5 ASTM A-350 Gr.LF2 2 8.16

EL +27424

TOTAL FABRICATION WEIGHT 135.34

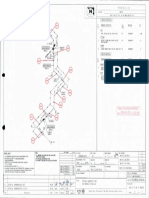

<2> 1

ERECTION MATERIALS

PT ITEM CODE L-CODE QTY COMPONENT DESCRIPTION N.S. WEIGHT

6 NO (INS)

6 0

15 GASKETS

E 139183302 11 SPWQ400R3EA3 L-1528 6 SPIRAL WOUND GASKET 4mm 300# RF B16.20 AISI 316 WITH 3 1.14

N 112513175 GRAPHITE

EL +27424 12 SPWQ400R3EA2 L-1528 2 SPIRAL WOUND GASKET 4mm 300# RF B16.20 AISI 316 WITH 2 0.22

GRAPHITE

BOLTS

414

CONT. ON

581588 13 SB2R055G3/441/4+S3 48 4.1/4 L. PERNOS +2T(+S3) ASTM A-320 Gr.L7 3/4 20.16

E 139183302 VALVES / IN-LINE ITEMS

N 112513240

4

EL +27010 14 A43L-7865 L-7865 1 GLOBE VALVE 300# RF Trim Nº16 ASTM A-352 Gr.LCC 3 58.00

3"x1"NS EL +27010 15 G43L-7863 L-7863 2 GATE VALVE 300# RF Trim Nº10 ASTM A-352 Gr.LCC 3 96.00

16 V63_4L-9944 L-9944 2 VALVOLET 800# SW Trim Nº10 ASTM A-350 Gr.LF2 3/4 7.80

65 INSTRUMENTS

17 1 CONTROL VALVE 300# RF (26FV58101) 26-FV-58101 2 65.00

<3> 1

232

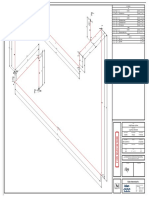

SUPPORTS

18 S-13-0-8600 2 U-BOLT - GL TYPE Galvanised 3 1.66

2 19 - 1 SIMPLE SUPPORT 3 0.00

3"x3"NS

TOTAL ERECTION WEIGHT 249.98

EL +26778

TOTAL WEIGHT 385.32

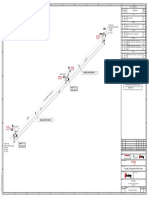

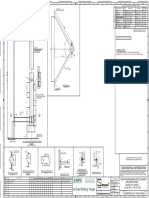

<4 CUT PIPE LENGTH

>1 F9 G11 B13

14 PIECE CUT N.S. REMARKS PIECE CUT N.S. REMARKS

568

45 33

<7> 1 3 NO LENGTH (INS) NO LENGTH (INS)

<1> 525 3 <2> 1332 3

<3> 446 3 <4> 288 3

<5> 1126 3 <6> 953 3

EL +26210 F9 G11 B13 <7> 403 3 <8> 100 3

<9> 400 3 <10> 455 3

15

EL +25923 F9 G11 B13 S18

283 14 PR581574S002

ORI = D

317 Prep.: VGON Nº Processo: MM2B

<8> 1

Status: APC Data: 04/05/2024 Rev.01

E 139183302

294

N 112513175 Dimensional: Assinatura:

EL +25625 F9 G11 B13 <5

>1

13 Antes Soldadura ___/___/_____

20

6 225 5

EL +25625 Após Soldadura ( VT ) ___/___/_____

3"x3/4"NS

6 Visual Test ___/___/_____

3"x3/4"NS 17

26-FV-58101 * Assinalar desvios nos desenhos (“+ n” ou “- n”).

41 <9> 1 E 139183302 Autocontrolo (visual) registado na folha de produção do soldador no campo

4

S18

N 112511077 das observações. (Autocontrolo OK)

F10 G12 EL +26778

PR581574S001

325

ORI = D 16 7

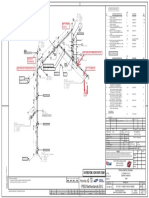

8 25

9

25 F9 G11 B13

9

E 139183302 325 NOTE:

N 112512761 <10> 1

43

1067

EL +25300 4 ISOMETRIC DRAWING MODIFIED FOR GENERAL UNIT ADJUSTMENTS.

26

8

F10 G12 283

7 EL +25711

<6> 1

21 16

7 5 86

3

3"x2"NS 3

15MM OFFSET 3"x2"NS 2

15MM OFFSET 16

3"x3"NS

15

E 139183302 85 PIPE MATERIAL DESIGN TEMP. > 400ºC SHOP MATERIAL

WEIGHTS

N 112511967 8

EL +25300 3"NS BOLT TIGHTENING (ED-L-01.00)

CARBON STEEL FIELD MATERIAL

EL +25711

X TORQUE CONTROL

ALLOY STEEL

CONT. ON

S19 E 139183302 HYDRAULICTENSIONER

TOTAL

DRG 2 STAINLESS STEEL

PR581574S003 N 112510991

EL +25625 OTHERS

NOTES: 1.- FOR TECHNICAL DETAILS SEE LINE LIST.

2.- FOR VENT, DRAIN OR INSTRUMENT CONNECTION DETAILS SEE PE-L-0100.29, 30 AND 31.

F9 G11 B13 HEAT TREATMENT 3.- PAINTING ACCORDING TO ED-B-06.00.

4.- WHEN DESIGN TEMP > 400º C, DO NOT USE CALCIUM OXIDE-BASED GREASES FOR BOLT TIGHTENING.

PAINTING SCHEME (3)

1 CONTRACTOR: PROJECT:

4001008

PIPING CLASS

C42 FILE:

26-000-2-02-00001 FL 581574-1-R01.dwg

STRESS CALC. N TITLE MM2B CLIENT / COMPLEX

26PR581590

1 GENERAL REVIEW 16.02.24 EMM JRG AMS JRG GRC PLZ

P&ID

26-000-1-01-00001 FL52B

ISOMETRIC DRAWING: REPSOL POLíMEROS, S.A.

0 APC ALBA PROJECT 14.12.23 EMM JRG AMS JRG GRC PLZ

LINE LIST

COMPLEJO INDUSTRIAL SINES

PIPE LAYOUT DRW

26-000-1-05-00010

LINE: 3"-581574-C42 ANNEX SPEC DRAWING NUMBER REV.

REV. DESCRIPTION DATE DRW. BY STRESS/SUPP. INSTR. M.T.O. CHECKED BY CLIENT APPR.

26-058-2-01-00001 26 C42 26-000-2-02-00001 FL 581574

PAGE 1 OF 4

1

c REPSOL S.A. MADRID - LAST UPGRADE 2004 - 2020 COMPUTARIZED DRAWING (HANDWRITING STRICTLY FORBIDDEN) FILE NUMBER HD-L-0100.02H1.DGN REV.05 DATE JUNY-2020 DRAWN CHECKED APROVED NUMBER HD-L-0100.02 SHEET 1 OF 1

E.B.P. C.A.B. T.P.M.

You might also like

- Virtual Verde Release Plan Emails: Email 1Document4 pagesVirtual Verde Release Plan Emails: Email 1Violet StarNo ratings yet

- Eriez Metal DetectorsDocument48 pagesEriez Metal DetectorspapathsheilaNo ratings yet

- Axens Technip India Ltd. Mumbai, India.: Bill of MaterialDocument9 pagesAxens Technip India Ltd. Mumbai, India.: Bill of MaterialSiddhu DudwadkarNo ratings yet

- Tupi BV: Cosco (Dalian)Document3 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- HS372221 26 Pip Iso 0168 0000 1 - Rm01aDocument1 pageHS372221 26 Pip Iso 0168 0000 1 - Rm01aibrahim qasimovNo ratings yet

- Appendix IDocument6 pagesAppendix IkarthickmectrNo ratings yet

- Tal Wsa PNG Iso 1P020807 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1P020807 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- Fabrication Materials: Saudi Arabian Oil CompanyDocument8 pagesFabrication Materials: Saudi Arabian Oil CompanyD7mey XNo ratings yet

- 4103 TOYO20 92DJ 1300 027 - Rev 1 - Sht001Document5 pages4103 TOYO20 92DJ 1300 027 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- Tupi BV: Cosco (Dalian)Document3 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Notes: M-CB-767101-A-0865 00 004Document1 pageNotes: M-CB-767101-A-0865 00 004Hesi KusumaNo ratings yet

- Bill of Materials: 331U15-OWS-002-02-1Document1 pageBill of Materials: 331U15-OWS-002-02-1PT Bumi Liputan PusakaNo ratings yet

- 20GHB20-BR001-03 Rev0 0001 240426 141615Document2 pages20GHB20-BR001-03 Rev0 0001 240426 141615philippeballina2810No ratings yet

- 4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Document2 pages4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- J3b-Am-05-D-44010-2 - Ro Building. 05-SP-010Document1 pageJ3b-Am-05-D-44010-2 - Ro Building. 05-SP-010Nauman TahirNo ratings yet

- Pages From AMDP01LP2100 Rev01 CommentsDocument1 pagePages From AMDP01LP2100 Rev01 CommentsOkas PaskalNo ratings yet

- SA04C2-03-WP-D-43003-01-1: 3. FJ - Field Joint 4. SJ - Shop JointDocument1 pageSA04C2-03-WP-D-43003-01-1: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

- 01 E02STB007-W146693-03-0 - BC - Stress UpdateDocument1 page01 E02STB007-W146693-03-0 - BC - Stress Update86tejas100% (1)

- Piping Isometric - 6Document1 pagePiping Isometric - 6CosminMarianNo ratings yet

- PipelineDocument9 pagesPipelineRhoteram VikkuNo ratings yet

- Bill of Materials: See Iso 10-P-1202 SHT 02Document2 pagesBill of Materials: See Iso 10-P-1202 SHT 02Junaid AdnanNo ratings yet

- Tal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Document1 pageTal Wsa PNG Iso 1PGW063402 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- J3b-Am-05-D-44011-2 - Ro Building. 05-SP-011Document1 pageJ3b-Am-05-D-44011-2 - Ro Building. 05-SP-011Nauman TahirNo ratings yet

- Tupi BV: Cosco (Dalian)Document1 pageTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- J3BGDF02BR005 01 01Document1 pageJ3BGDF02BR005 01 01saleem naheedNo ratings yet

- FL3B-474-P-2634 AsbuiltDocument1 pageFL3B-474-P-2634 AsbuiltAlbet MulyonoNo ratings yet

- 0127 R8B 03 WP 311 01Document1 page0127 R8B 03 WP 311 01ABDERRAZZAKNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- 12lba52br002 Rev0Document1 page12lba52br002 Rev0ruralashishNo ratings yet

- Piping Isometric - 7Document1 pagePiping Isometric - 7CosminMarianNo ratings yet

- 0127 R8B 05 WP 311 01Document1 page0127 R8B 05 WP 311 01ABDERRAZZAKNo ratings yet

- 172 I1909e 000 46 DW 0107Document1 page172 I1909e 000 46 DW 0107Jose Carlos Moraga LópezNo ratings yet

- Shuqaiq 3 Independent Water Project: Ro Building T7 GDF03-001Document1 pageShuqaiq 3 Independent Water Project: Ro Building T7 GDF03-001ABAID ULLAHNo ratings yet

- Tupi BV: Cosco (Dalian)Document5 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- U22 Valve List 2 - April 2024 (3 Units)Document3 pagesU22 Valve List 2 - April 2024 (3 Units)Mohd Effiezool YaserNo ratings yet

- SA04C2-03-WP-D-42201-01-3: Shuqaiq 3 Independent Water ProjectDocument1 pageSA04C2-03-WP-D-42201-01-3: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- Punj Lloyd: 4 See Iso ACC-5100-00015-01 5100PSV 2602Document1 pagePunj Lloyd: 4 See Iso ACC-5100-00015-01 5100PSV 2602Saptarshi MandalNo ratings yet

- General Arrangement Drawing For Slug Catcher Rev.c IfaDocument1 pageGeneral Arrangement Drawing For Slug Catcher Rev.c IfaMe RahmanNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- 100 A 32421PE-2 - Layout1Document1 page100 A 32421PE-2 - Layout1Frederique VerhulstNo ratings yet

- SA04C2-03-WP-D-42008-01-5: 3. FJ - Field Joint 4. SJ - Shop JointDocument4 pagesSA04C2-03-WP-D-42008-01-5: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

- 0127 R8B 06 WP 311 01Document1 page0127 R8B 06 WP 311 01ABDERRAZZAKNo ratings yet

- XLP Pre L15 WL15P43Document2 pagesXLP Pre L15 WL15P43Aria NickbakhtNo ratings yet

- South Refineries Company: Basrah Refinery Upgrading Project ProjectDocument5 pagesSouth Refineries Company: Basrah Refinery Upgrading Project ProjectBasem AlsaftliNo ratings yet

- Material List - Fabrication: - / - A1ZA-1 2 PMDocument2 pagesMaterial List - Fabrication: - / - A1ZA-1 2 PMMallela Sampath KumarNo ratings yet

- P4059zor 62 22 1 T1001 018 002 - ADocument1 pageP4059zor 62 22 1 T1001 018 002 - Ashravan.office11No ratings yet

- 066504u58271 001 001-BDocument1 page066504u58271 001 001-BDINESH VNo ratings yet

- SF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsDocument2 pagesSF4-A-100-450-100-6-SC G0-6-CS: Bill of MaterialsSENTHILNo ratings yet

- 1/1 P055AZOR-05P00-1353-51 A A-2: 3c 248 HV 10 Shop ASME B31.3Document1 page1/1 P055AZOR-05P00-1353-51 A A-2: 3c 248 HV 10 Shop ASME B31.3Deshwa SaravananNo ratings yet

- FL3B-474-P-2603 As BuiltDocument1 pageFL3B-474-P-2603 As BuiltAlbet MulyonoNo ratings yet

- TR-DM-MI-0218: Issued For ConstructionDocument2 pagesTR-DM-MI-0218: Issued For ConstructionMarcellino YohanesNo ratings yet

- J3b-Am-05-D-44028-0 - Supports Ro Building 05-SP-028Document1 pageJ3b-Am-05-D-44028-0 - Supports Ro Building 05-SP-028Nauman TahirNo ratings yet

- Issued For Construction Modular Isometrics: Remove TrunnionDocument1 pageIssued For Construction Modular Isometrics: Remove Trunnion86tejasNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- Tupi BV: Cosco (Dalian)Document4 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Ifc - Issued For Construction: AngloamericanDocument1 pageIfc - Issued For Construction: AngloamericanLuis Fernando GONZALES HUMIRENo ratings yet

- Piping Isometric - 10Document1 pagePiping Isometric - 10CosminMarianNo ratings yet

- Detail "A" Detail "B" Detail "C": Susunan Butterfly Valve Ø300 Bendungan SermoDocument1 pageDetail "A" Detail "B" Detail "C": Susunan Butterfly Valve Ø300 Bendungan SermosilviNo ratings yet

- XvssyYwnahw 788911123Document1 pageXvssyYwnahw 788911123Ahmed Ayman AhmedNo ratings yet

- Shuqaiq 3 Independent Water Project: Ro Building T4 GDT01-007Document1 pageShuqaiq 3 Independent Water Project: Ro Building T4 GDT01-007ABAID ULLAHNo ratings yet

- Proposal Drawing: Customer ApprovalDocument1 pageProposal Drawing: Customer Approvalphantuan080213No ratings yet

- Activity Exemplar - Job Search Project PlanDocument7 pagesActivity Exemplar - Job Search Project PlanMartinAlexisGonzálezVidalNo ratings yet

- How To Create A Work Breakdown Structure and Why You ShouldDocument12 pagesHow To Create A Work Breakdown Structure and Why You ShouldMartinAlexisGonzálezVidalNo ratings yet

- Activity Template - Job Search Project PlanDocument7 pagesActivity Template - Job Search Project PlanMartinAlexisGonzálezVidalNo ratings yet

- Activity Exemplar - Emails For The Release PlanDocument4 pagesActivity Exemplar - Emails For The Release PlanMartinAlexisGonzálezVidal100% (1)

- Week 2Document53 pagesWeek 2MartinAlexisGonzálezVidalNo ratings yet

- Activity Template - Project PlanDocument49 pagesActivity Template - Project PlanMartinAlexisGonzálezVidalNo ratings yet

- MAGV - Refine Time EstimatesDocument56 pagesMAGV - Refine Time EstimatesMartinAlexisGonzálezVidalNo ratings yet

- Week 2 - Historical Project PlanDocument8 pagesWeek 2 - Historical Project PlanMartinAlexisGonzálezVidalNo ratings yet

- 13.specification Steam and Condensate SystemDocument2 pages13.specification Steam and Condensate SystemV U P RaoNo ratings yet

- 16 To 17-Class PDFDocument44 pages16 To 17-Class PDFVikaas SagerNo ratings yet

- H 06Document53 pagesH 06Ricardo MendesNo ratings yet

- Building Materials Final Solution After Cor.Document64 pagesBuilding Materials Final Solution After Cor.TarunNo ratings yet

- En 253Document78 pagesEn 253Dragan PilipovićNo ratings yet

- Econ Bimetal Thermometers Brass InsertDocument1 pageEcon Bimetal Thermometers Brass InsertChristianGuerreroNo ratings yet

- FORD WSS-M2P190-A1 Paint SpecificationDocument8 pagesFORD WSS-M2P190-A1 Paint SpecificationJuanPeriquitanNo ratings yet

- Jyothish Kumar Took Sulphur Powder On A Spatula and Heated It. HeDocument9 pagesJyothish Kumar Took Sulphur Powder On A Spatula and Heated It. HeSharan SiuuNo ratings yet

- 2.4 M Ku-Band Dual Optics RXTX Antenna System: One Company. A World of SolutionsDocument2 pages2.4 M Ku-Band Dual Optics RXTX Antenna System: One Company. A World of SolutionsTateszNo ratings yet

- Cooling Water TreatmentDocument115 pagesCooling Water TreatmentMuhammad Abdullah100% (1)

- Lin PaperDocument7 pagesLin PaperEmreNo ratings yet

- Chemicals Zetag DATA Burst 1400 - 0410Document2 pagesChemicals Zetag DATA Burst 1400 - 0410PromagEnviro.comNo ratings yet

- 7A-LoadClassandServFactors AGMA PDFDocument8 pages7A-LoadClassandServFactors AGMA PDFJairo Andrés FANo ratings yet

- Weedeater Manual BV1650-BV1800Document9 pagesWeedeater Manual BV1650-BV1800SpirockNo ratings yet

- Whirlpool FFD 9469E Manual de UtilizareDocument4 pagesWhirlpool FFD 9469E Manual de Utilizaregigi13bvrNo ratings yet

- Fillet Weld Strength Calculation Example For Welded Connection Subjected To BendingDocument6 pagesFillet Weld Strength Calculation Example For Welded Connection Subjected To Bendingchetanmale0% (1)

- E Book - Complete Guide of Polycarbonate Fabrication - ExceliteDocument49 pagesE Book - Complete Guide of Polycarbonate Fabrication - ExcelitecpcdbrNo ratings yet

- Molecular Sieve MSDSDocument4 pagesMolecular Sieve MSDSRajesh GalgalikarNo ratings yet

- A4Romold Domestic Grease Trap PDFDocument1 pageA4Romold Domestic Grease Trap PDFmohammudpNo ratings yet

- Catalogo Deublin ST141 USDocument12 pagesCatalogo Deublin ST141 USAndréStefenonNo ratings yet

- Guidance Notes On Current Procedures On Supervision of Soil Nailing WorksDocument10 pagesGuidance Notes On Current Procedures On Supervision of Soil Nailing WorksTanNo ratings yet

- Special Turbo TrainingDocument90 pagesSpecial Turbo TrainingAmit Kaushal100% (6)

- Mastercrete 1000 TdsDocument2 pagesMastercrete 1000 Tdsaruncg2No ratings yet

- Ingress Protection - IP Ratings - Fans & MotorsDocument6 pagesIngress Protection - IP Ratings - Fans & MotorsAmirmasoudNo ratings yet

- 06 VD Mee-Welding of Super Duplex Stainless SteelsDocument12 pages06 VD Mee-Welding of Super Duplex Stainless SteelsKareem AbdelazizNo ratings yet

- 3 System Process Outline - SLP R2Document56 pages3 System Process Outline - SLP R2Pirun Sirimangkalo100% (1)

- SRRB Does Not YieldDocument2 pagesSRRB Does Not YieldAldrin Abestano Jr.No ratings yet

- Metal Conversion ChartDocument8 pagesMetal Conversion ChartChuan SwtsNo ratings yet

- Illustrated Code Catastrophes - Sections 410.30 (B), 500.5 (A) & 514Document2 pagesIllustrated Code Catastrophes - Sections 410.30 (B), 500.5 (A) & 514rajuanthatiNo ratings yet