Professional Documents

Culture Documents

Pending Observation Points - Radiator (72 R 40 0000)

Pending Observation Points - Radiator (72 R 40 0000)

Uploaded by

Prabhakaran CHNQuality0 ratings0% found this document useful (0 votes)

3 views1 pageOriginal Title

Pending Observation points - Radiator (72 R 40 0000)

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

3 views1 pagePending Observation Points - Radiator (72 R 40 0000)

Pending Observation Points - Radiator (72 R 40 0000)

Uploaded by

Prabhakaran CHNQualityCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 1

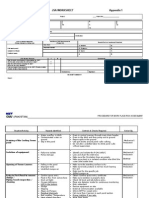

PART NO Welding points - Radiator Assembly (72 R 40 0000) Date: 25.05.

2024 Shift: B

SL No Category Constraints PPAP Status / Next actions Target date Responsibility Status Pics

1. 10nos Helicoil to be added at In-house. 1. Yacub

1 Child Part RAD Top Holding Boss Helicoil not there. 2. Remaining Boss move to Supplier Rework Warehouse. 2. Velmurugan

3. Supplier end Rework to be done. 3.

1. 10nos to be done at In-house - Completed. 1. Yacub

2 Child Part Outlet Pipe Step Rework 2. Remaining Pipes move to Supplier Rework Warehouse. 2. Velmurugan

3. Supplier end Rework to be done. 3.

Outlet Pipe Bottom Piece welding Template not

Welding

3 Fixture

available currently. Required welding template Deva

With NPD Support manually welded temporarily.

1. Step provision to be given in Child Parts

4 Child Part Inlet Pipe with Extrusion Tank manually holded in ( Or) 1. Yacub

hands and Welded. 2. Deva

2. Fixture control to be given.

Outlet Pipe with Step and Bottom Piece roatate after

5 Child Part setting in Extrusion Tank profile.

Required separate Sub-Assy Fixture for LH and RH

Welding Tank welding.

6 Fixture Deva

Currently Interchangeable welding fixture is used.

7 LOI Out of 59 Specifications, 16 Specifications found NOT

OK.

Spacer for Radiator hits on the Core Tube Sheet and

8 Child Part Long bar during setting in RAD and After Welding also. Yacub

You might also like

- Well Intervention IntroductionDocument43 pagesWell Intervention Introductionmissaoui100% (4)

- Sample Structural Investigation ReportDocument16 pagesSample Structural Investigation Reportmr. one100% (1)

- Project Scope of WorkDocument20 pagesProject Scope of WorkAbu Muhammed KhwajaNo ratings yet

- Brochure Control Upgrades Shafer en 84314Document4 pagesBrochure Control Upgrades Shafer en 84314josecordova2014No ratings yet

- Summary Defect List EPSB JULYDocument7 pagesSummary Defect List EPSB JULYMohamad SyafiqNo ratings yet

- Summary Defect List EPSBDocument4 pagesSummary Defect List EPSBMohamad SyafiqNo ratings yet

- Qurayyah Combined Cycle Power Plant: GSU 5 Transformer Bushing FailureDocument19 pagesQurayyah Combined Cycle Power Plant: GSU 5 Transformer Bushing FailureAli Al HanabiNo ratings yet

- Five Ess C'measures & Progress ReportDocument24 pagesFive Ess C'measures & Progress ReportLaxmikant JoshiNo ratings yet

- Pending Works List 25-1-2017Document3 pagesPending Works List 25-1-2017Yaser MajeedNo ratings yet

- CGL - Instruction & Maintenance Manual Voltage TransformerDocument18 pagesCGL - Instruction & Maintenance Manual Voltage TransformerHari Krishna.MNo ratings yet

- Five Ess Auto Part: C' Measure OnDocument11 pagesFive Ess Auto Part: C' Measure OnLaxmikant JoshiNo ratings yet

- Problema de Clampeo Gleason 20088Document18 pagesProblema de Clampeo Gleason 20088nestorNo ratings yet

- Poka YokeDocument8 pagesPoka YokeRohit TripathiNo ratings yet

- 112 K K Murty Retrofitting of 420 KV Bushing IIDocument10 pages112 K K Murty Retrofitting of 420 KV Bushing IIchandraippa2No ratings yet

- 05.learning by Failures A Transformer Case StudyDocument11 pages05.learning by Failures A Transformer Case StudyvikashNo ratings yet

- SOP 032 - QC Hoist Wire Rope Replacement - V 2.0Document6 pagesSOP 032 - QC Hoist Wire Rope Replacement - V 2.0ncthanhck0% (1)

- Did You Know?: Valve Position Errors Can Cause Serious IncidentsDocument1 pageDid You Know?: Valve Position Errors Can Cause Serious IncidentsSantosh KumarJayantiNo ratings yet

- Shut Down Job Schedule Jan 2023Document1 pageShut Down Job Schedule Jan 2023CaripahNo ratings yet

- Weekly Status 131222Document3 pagesWeekly Status 131222Vedatma BhoyrooNo ratings yet

- 240129.updated Defect List Incomplete Work UpdateDocument1 page240129.updated Defect List Incomplete Work UpdatesmedfacNo ratings yet

- MV Capacitor - 5.0Document15 pagesMV Capacitor - 5.0AhsanNo ratings yet

- Field JB's Specification (FF.17001) ORIGNALDocument2 pagesField JB's Specification (FF.17001) ORIGNALreliableplacementNo ratings yet

- BS7671 2008Document11 pagesBS7671 2008Vijai Prasath100% (1)

- Important Instructions To Examiners:: (Autonomous)Document21 pagesImportant Instructions To Examiners:: (Autonomous)Vrishin PatilNo ratings yet

- D Padding Survey Water Injection Pump and Condenser Turbine No # 1 Condenser Turbine No # 1 and Condenser No # 2 and Condenser Turbine No # 2Document4 pagesD Padding Survey Water Injection Pump and Condenser Turbine No # 1 Condenser Turbine No # 1 and Condenser No # 2 and Condenser Turbine No # 2Gunarso NarsoNo ratings yet

- Inspected Padding Survey Water Injection Pump and Condenser Turbine No # 1 Condenser Turbine No # 1 and Condenser No # 2 and Condenser Turbine No # 2Document4 pagesInspected Padding Survey Water Injection Pump and Condenser Turbine No # 1 Condenser Turbine No # 1 and Condenser No # 2 and Condenser Turbine No # 2Gunarso NarsoNo ratings yet

- IFC Closure Approval ReportDocument12 pagesIFC Closure Approval ReportAjayNo ratings yet

- HSE Observation Report: S. No Location Issues Photograph Action Required / Recommendations Rectification Close Out PhotoDocument2 pagesHSE Observation Report: S. No Location Issues Photograph Action Required / Recommendations Rectification Close Out Photofaisal nadeemNo ratings yet

- Finepix S5700/ S700: Digital CameraDocument134 pagesFinepix S5700/ S700: Digital CameraIzaias AlexandreNo ratings yet

- TAC IR3 E&I Report 23062021Document3 pagesTAC IR3 E&I Report 23062021demetri-kcNo ratings yet

- 220 KV Gss NadbaiDocument55 pages220 KV Gss NadbaiNimisha Goyal100% (2)

- Jsa Worksheet Appendix 1: A-2401 Cooling Tower Pond CleaningDocument4 pagesJsa Worksheet Appendix 1: A-2401 Cooling Tower Pond CleaningAmmadRehmanNo ratings yet

- Surface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedDocument22 pagesSurface Driller Equipment Paper NO. 1.: All Questions Require Only ONE Answer Unless Otherwise StatedandrzemaNo ratings yet

- Spark Star-83 BKR Non-TripDocument1 pageSpark Star-83 BKR Non-Tripbpatel3785No ratings yet

- 8.11-14.11 Weekly Work Report-Nashaat Dhyaa QAQC DepartmentDocument4 pages8.11-14.11 Weekly Work Report-Nashaat Dhyaa QAQC DepartmentNashaat DhyaaNo ratings yet

- Umbilical DescriptionDocument10 pagesUmbilical DescriptionIkhuosho AbodeNo ratings yet

- Instructional Model of Basic Rankine Cycle: User'S ManualDocument4 pagesInstructional Model of Basic Rankine Cycle: User'S ManualJoseph DavidNo ratings yet

- 10-05-24-Nizam Sagar Site Work Progress ReportDocument3 pages10-05-24-Nizam Sagar Site Work Progress Reportnizamsagar tsgencoNo ratings yet

- Base Plate and Anchor Rod DesignDocument2 pagesBase Plate and Anchor Rod DesignKannan MurugesanNo ratings yet

- CAAB Findings (Need To Solve Before Commissioning)Document1 pageCAAB Findings (Need To Solve Before Commissioning)Mehedi HasanNo ratings yet

- Case StudiesDocument32 pagesCase StudiesSE Electrical100% (2)

- Daily Activity Report July 29Document2 pagesDaily Activity Report July 29Zohaib AlamNo ratings yet

- Jha JiggingDocument4 pagesJha Jiggingsyed aquibNo ratings yet

- Summary Report-220 KV Akal-Rajasthan-2019-20Document1 pageSummary Report-220 KV Akal-Rajasthan-2019-20ddhruvalpNo ratings yet

- Liebert Air Cooled Fintube Condensers User Manual 00Document76 pagesLiebert Air Cooled Fintube Condensers User Manual 00Heriberto Esquivel ValverdeNo ratings yet

- DS-212200-FM200 CLEAN AGENT EXTINGUISHING SYSTEM - RiskDocument1 pageDS-212200-FM200 CLEAN AGENT EXTINGUISHING SYSTEM - RiskLi LiuNo ratings yet

- Fault, Protection and Failure Indications in PSE Soft StarterDocument5 pagesFault, Protection and Failure Indications in PSE Soft StartermichaelNo ratings yet

- Kobelco Issues and ActionsDocument10 pagesKobelco Issues and Actionssonawaneyogesh694No ratings yet

- Up To 1Document4 pagesUp To 1Gunarso NarsoNo ratings yet

- Engineering and Maintenance DeptDocument2 pagesEngineering and Maintenance Deptjherson gravidesNo ratings yet

- Assembly Instructions For Cable Gland: 121 Industrial General PurposeDocument2 pagesAssembly Instructions For Cable Gland: 121 Industrial General PurposerhomadonaNo ratings yet

- Tower Manufacturing ProcessDocument30 pagesTower Manufacturing Processmechajay2002No ratings yet

- English (GB) Installation and Operating Instructions: 2. ApplicationsDocument1 pageEnglish (GB) Installation and Operating Instructions: 2. Applicationsselmir_9No ratings yet

- Joint Inspection of SOGR Prior To NI 1Document3 pagesJoint Inspection of SOGR Prior To NI 1Siva Rama KrishnaNo ratings yet

- Monthly Report - Jan 2023Document2 pagesMonthly Report - Jan 2023Pravin BoteNo ratings yet

- Circuit Breaker LTB D 72.5 - 170 KV FSA Spring Operating MechanismsDocument8 pagesCircuit Breaker LTB D 72.5 - 170 KV FSA Spring Operating MechanismsjaimeNo ratings yet

- 2 - Completion Pressure Control Equipment - Well Control For Well Intervention - 6619932 - 01Document94 pages2 - Completion Pressure Control Equipment - Well Control For Well Intervention - 6619932 - 01Carlos A.No ratings yet

- HANDBOOK QTB-JOB DP016901-rev.01Document27 pagesHANDBOOK QTB-JOB DP016901-rev.01engmkhalaf1977No ratings yet

- Ocean Cable Engineering Handbook Vol3 Compiled by Ian S. CooteDocument88 pagesOcean Cable Engineering Handbook Vol3 Compiled by Ian S. Cootemannydesousa52No ratings yet

- SW V2 1 1250 Service ManualDocument15 pagesSW V2 1 1250 Service ManualChristian Hidalgo NochesNo ratings yet

- Kenwood TS-440 Repair - OZ1BXMDocument9 pagesKenwood TS-440 Repair - OZ1BXMRui Slva100% (1)

- 06 IC 480 0000 - PFDDocument2 pages06 IC 480 0000 - PFDPrabhakaran CHNQualityNo ratings yet

- 06 IC 580 0000 - PFDDocument2 pages06 IC 580 0000 - PFDPrabhakaran CHNQualityNo ratings yet

- 21 IC 81 0000 - PFDDocument2 pages21 IC 81 0000 - PFDPrabhakaran CHNQualityNo ratings yet

- 06 IC 436 0000 - PFDDocument2 pages06 IC 436 0000 - PFDPrabhakaran CHNQualityNo ratings yet

- 06 IC 529 0000 - PFDDocument2 pages06 IC 529 0000 - PFDPrabhakaran CHNQualityNo ratings yet

- 19 03 2024 10 RicDocument1 page19 03 2024 10 RicPrabhakaran CHNQualityNo ratings yet

- 06 R 435 Bow Rod Trail ES To ES ReportDocument4 pages06 R 435 Bow Rod Trail ES To ES ReportPrabhakaran CHNQualityNo ratings yet

- 27 RIC 11 Major Dimensions ReportDocument4 pages27 RIC 11 Major Dimensions ReportPrabhakaran CHNQualityNo ratings yet

- 28 02 2024 05 RicDocument1 page28 02 2024 05 RicPrabhakaran CHNQualityNo ratings yet

- 28 02 2024 05 RicDocument1 page28 02 2024 05 RicPrabhakaran CHNQualityNo ratings yet

- Software TestingDocument27 pagesSoftware TestingFrank Vijay100% (1)

- ANG en Construction Business 23022006Document94 pagesANG en Construction Business 23022006Cris NeculaNo ratings yet

- PPT5 UiPath Forward Roadmap v17.5 V06Document35 pagesPPT5 UiPath Forward Roadmap v17.5 V06wonkographerNo ratings yet

- Project Report On Inventory MnagementDocument109 pagesProject Report On Inventory MnagementLavkeshhNo ratings yet

- Chromo LithographyDocument6 pagesChromo LithographyPaula ZorziNo ratings yet

- 2021 Corporate Aircraft Product Support SurveyDocument1 page2021 Corporate Aircraft Product Support SurveyCamila TeixeiraNo ratings yet

- Nippon Valve Actuator PDF L120 LMENBR1200-02Document16 pagesNippon Valve Actuator PDF L120 LMENBR1200-02Yasser BadrNo ratings yet

- Active DatabasesDocument22 pagesActive Databasesradhikakumaran3No ratings yet

- Airforce Bro enDocument11 pagesAirforce Bro enTungust SiberianNo ratings yet

- 1 Piping CostingDocument33 pages1 Piping Costingamoldhole97% (35)

- APTA Peer Review ReportDocument26 pagesAPTA Peer Review ReportHonolulu Star-Advertiser100% (1)

- Drone Final ProjectDocument6 pagesDrone Final Projectapi-383760519100% (1)

- Design of Masonry According To EC6Document5 pagesDesign of Masonry According To EC6murid1985No ratings yet

- IR NishaDocument41 pagesIR NishabpharmbaNo ratings yet

- EAI Architecture Vodafone IndiaDocument11 pagesEAI Architecture Vodafone IndiaacetaleleNo ratings yet

- GM Brazil - Service Parts Business - CeDocument16 pagesGM Brazil - Service Parts Business - CeGrant Marco MarianoNo ratings yet

- CMJU-Common Fee Structure (W.e.f. 01 March, 2012) : Sl. No. Course University Fee (Per Year)Document3 pagesCMJU-Common Fee Structure (W.e.f. 01 March, 2012) : Sl. No. Course University Fee (Per Year)souvik5000No ratings yet

- Super High Power Poly Perc ModuleDocument2 pagesSuper High Power Poly Perc ModuleTu Nguyen Thi CamNo ratings yet

- To Illustrate or Clarify Your Application Data ATTACHMENTDocument22 pagesTo Illustrate or Clarify Your Application Data ATTACHMENTAd ElouNo ratings yet

- Big Data 101 Module 4 Video 1Document2 pagesBig Data 101 Module 4 Video 1Dipak NandeshwarNo ratings yet

- NH CE Reman Engines Application GuideDocument8 pagesNH CE Reman Engines Application GuideFernando Garcia CortesNo ratings yet

- Kay Bouvet Engineering Pvt. LTD Central Inspection: Academy of Welding & Consultancy ServicesDocument7 pagesKay Bouvet Engineering Pvt. LTD Central Inspection: Academy of Welding & Consultancy ServicessatnamNo ratings yet

- XML, Web Service and SOADocument10 pagesXML, Web Service and SOAParthaSarathiSamantaNo ratings yet

- Vishwakarma Institute of TechnologyDocument42 pagesVishwakarma Institute of TechnologyAnkush RatnaparkheNo ratings yet

- Enterprise SystemsDocument30 pagesEnterprise SystemsAbhi SinghNo ratings yet

- Estimation ECM416Document12 pagesEstimation ECM416Darwish WahabNo ratings yet

- Worldcal StrategyDocument95 pagesWorldcal StrategyPakassignmentNo ratings yet

- Monitor ProDocument148 pagesMonitor Prodanipgc88No ratings yet

- World One: This PDF Was Downloaded From The Skyscraper Center On 2016/06/10 UTCDocument2 pagesWorld One: This PDF Was Downloaded From The Skyscraper Center On 2016/06/10 UTCDaniel AmosNo ratings yet