Professional Documents

Culture Documents

Masonry Units

Masonry Units

Uploaded by

gwakojackson64Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Masonry Units

Masonry Units

Uploaded by

gwakojackson64Copyright:

Available Formats

PRODUCE MASONRY UNITS

UNIT CODE: CON/OS/BUT/CR/03/6

UNIT DESCRIPTION

This unit describes the competences required to manufacture masonry units. It involves

producing masonry bricks, preparing concrete and clay products and dressing building

stones

ELEMENTS AND PERFORMANCE CRITERIA

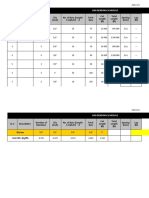

ELEMENT PERFORMANCE CRITERIA

(Bold and italicized terms are elaborated in the Range)

1. Produce masonry 1.1. Bricks moulds are prepared as per client specification

bricks 1.2. Brick earth /clay is prepared as per building code

1.3. Bricks are moulded depending on the prescribed size and

customer specifications.

1.4. Bricks are dried as per the building codes

1.5. Bricks are baked/fired as per baking procedures

2. Prepare concrete 2.1Concrete moulds are prepared as per the customer

products specifications.

2.2 concrete constituents are gathered as per concrete mix design

2.3Concrete constituent are batched as per batching methods

2.4 Concrete ingredients are mixed as per ASTM standards

2.5 Concrete mix is placed in moulds as per placing convections

2.6 Concrete is cured as per laid down procedures

2.7 Moulds are dismantled and stored as per laid down

procedures.

3. Dress building 3.1 Building stones are acquired as per prescribed size and

stones quality.

3.2 Stones surfaces are dressed as per the method and type of

dressing.

4. Prepare clay 4.1 Clay products are produced as per manufactures

products guidelines/specification.

4.2 Clay products are tested as per manufactures standards.

4.3 Clay products are packaged according to type, size, shape,

quantity and environmental requirements.

© TVET CDACC 2018 79

RANGE

Variable Range

May include but is not limited to:

1. Building code 1.1 BS 8110

2. Prescribed size 225x102.5x65mm

3. Baking procedure 3.1 Dehydration

3.2 oxidation

3.3 Vitrification

3.4 Burning

3.5 Cooling

4. Concrete constituents 4.1 Fine Aggregates

4.2 Coarse Aggregates

4.3 Cement

4.4 Water

4.5 Admixtures

5. batching methods 5.1 batching by weight

5.2 batching by volume

6. Method of stone dressing 6.1 Manual dressing

6.2 Mechanical dressing

7. Type of stone finish 7.1 Combed finish

7.2 Punched finish

7.3 Tooled finish

7.4 Bush finish

8. Clay products 8.1 Tiles

8.2 Bricks

8.3 Cills

8.4 Ventilators

REQUIRED KNOWLEDGE

Concrete and motar mix ratios

Soil testing

Curing

strength of materials

use of building tools and equipnment

concerete aggregate

Basic arithmetics

Batching

packaging

© TVET CDACC 2018 80

SKILLS

moulding

concrete mixer operation

dressing

Batching

Measuring

Modelling

EVIDENCE GUIDE

This provides advice on assessment and must be read in conjunction with the

performance criteria, required skills and knowledge and range.

1. Critical Aspects of Assessment requires evidence that the candidate:

Competency 1.1 Prepared brick moulds.

1.2 Moulded bricks

1.3 Dried bricks

1.4 Burned bricks

1.5 Prepared concrete moulds

1.6 Mixed concrete constituents

1.7 Placed concrete mix

1.8 Cured concrete

1.9 Dismantled and stored concrete moulds

1.10 Dressed stones

1.11 Prepared clay

1.12 Produced clay products

1.13 Packaged clay products

2. Resource Implications 2.1 ASTM document

2.2 Desktop PCs

2.3 Printer/plotting device

2.4 Calculator

2.5 Calibration tools

2.6 Internet

2.7 Operations Manuals

2.8 Concrete and clay moulds

2.9 Water

2.10 Stone blocks

2.11 Wheel barrows

2.12 Building tools and equipment

© TVET CDACC 2018 81

2.13 Qualified trainers

3. Methods of Competency may be assessed through:

Assessment 5.1 Written Test

5.2 Demonstration

5.3 Practical assignment

5.4 Interview/Oral Questioning

6. Context of Competency may be assessed in an off and on the job setting

Assessment

7. Guidance information Holistic assessment with other units relevant to the building

for assessment sector, workplace and job role is recommended.

© TVET CDACC 2018 82

You might also like

- Ractice Test: (Answers P. 246)Document14 pagesRactice Test: (Answers P. 246)Vo Sunny100% (2)

- The Chronology of Palladio's Villa RotondaDocument13 pagesThe Chronology of Palladio's Villa Rotondaweareyoung5833100% (1)

- Natural Stone Finishes: CONQUAS Enhancement SeriesDocument43 pagesNatural Stone Finishes: CONQUAS Enhancement SeriesFirdaus Pasro RadziNo ratings yet

- GRZ Pavement Design Guide & STDs PDFDocument43 pagesGRZ Pavement Design Guide & STDs PDFyouou HaaNo ratings yet

- FCE345 Highway MaterialsDocument43 pagesFCE345 Highway Materialsjava nameNo ratings yet

- Specs Civil Works For 132kV SubstationsDocument87 pagesSpecs Civil Works For 132kV SubstationsUthaya Siva100% (6)

- Stone Cladding Eng CamposinhosDocument177 pagesStone Cladding Eng Camposinhos700spymaster007100% (3)

- GCC Hand BookDocument260 pagesGCC Hand Booksujeeth100% (1)

- Abdurafiu Abdullahi Olalekan ProjectDocument63 pagesAbdurafiu Abdullahi Olalekan ProjectAbdulrafiuNo ratings yet

- Glo Sika Concrete HandbookDocument280 pagesGlo Sika Concrete Handbookdhan singh100% (1)

- Sika Concrete HandbookDocument151 pagesSika Concrete HandbookDes Vlietstra100% (1)

- Sika Concrete Handbook 2013Document262 pagesSika Concrete Handbook 2013Csillag Janos100% (1)

- Masonry UnitsDocument9 pagesMasonry Unitsdennismaina700No ratings yet

- Section 13 Part 2 Mortar and GroutDocument6 pagesSection 13 Part 2 Mortar and GroutRotsapNayrbNo ratings yet

- S4P2Document6 pagesS4P2snieroshNo ratings yet

- Civil Engineering MaterialDocument366 pagesCivil Engineering MaterialKhan BibiNo ratings yet

- adede4c4-925a-4db1-a4a8-dfe1f6a55712Document625 pagesadede4c4-925a-4db1-a4a8-dfe1f6a55712karan aroraNo ratings yet

- Full ThesisDocument119 pagesFull ThesisShifat Hossain KhanNo ratings yet

- Sika Sprayed Concrete Handbook IndexDocument2 pagesSika Sprayed Concrete Handbook IndexbunkunNo ratings yet

- Field Engineering Longland 1983Document242 pagesField Engineering Longland 1983asprinoNo ratings yet

- Guide Specifications For Plant Precast Concrete ProductsDocument18 pagesGuide Specifications For Plant Precast Concrete Productswalidtkh78No ratings yet

- Building Construction Materials and Techniques P Purushothama Raj Full ChapterDocument67 pagesBuilding Construction Materials and Techniques P Purushothama Raj Full Chapterdenise.sweeney729100% (6)

- Self-Compacting ConcreteDocument68 pagesSelf-Compacting ConcreteMisgun SamuelNo ratings yet

- Acknowledgement For, Major LastDocument8 pagesAcknowledgement For, Major LastPalla ManikantaNo ratings yet

- Building MaterialsDocument3 pagesBuilding Materialssakshinagargoje2007No ratings yet

- Specs Course Project - FINAL UPDATEDocument60 pagesSpecs Course Project - FINAL UPDATEDania Abu RamadanNo ratings yet

- ल्याव टेक्निसियन स्विकृतDocument5 pagesल्याव टेक्निसियन स्विकृतHaider ImamNo ratings yet

- IC Workshop Materials 09 - Construction WorkshopDocument81 pagesIC Workshop Materials 09 - Construction WorkshoptrndemNo ratings yet

- Finish Masonry WorksDocument9 pagesFinish Masonry Worksdannieycandiey44No ratings yet

- 624 1834RICp2dedDocument7 pages624 1834RICp2dedscriptd_ozd3nNo ratings yet

- Basic Civil Engineering PDFDocument348 pagesBasic Civil Engineering PDFDeependra100% (1)

- 2696 Technical-SpecificationsDocument168 pages2696 Technical-SpecificationsRajesh KumarNo ratings yet

- ANNEX I TS 001 R0 Technical Specifications DikonversiDocument67 pagesANNEX I TS 001 R0 Technical Specifications DikonversiGerry Dwi PutraNo ratings yet

- MortarsTechnicalGuide OnlineDocument148 pagesMortarsTechnicalGuide Onlineseii.chenNo ratings yet

- Coating Reference Handbook CORP 20160421 PDFDocument147 pagesCoating Reference Handbook CORP 20160421 PDFnnuek100% (2)

- Composite Counter-Weight Application in Washing Machine: Institute of Science and TechnologyDocument115 pagesComposite Counter-Weight Application in Washing Machine: Institute of Science and TechnologyHassanNo ratings yet

- Masonry Design and Detailing Sixth Edition 6th Edition Ebook PDFDocument61 pagesMasonry Design and Detailing Sixth Edition 6th Edition Ebook PDFkaryn.corman836100% (47)

- UffghDocument25 pagesUffghArchNo ratings yet

- Updated Study Guide PDFDocument44 pagesUpdated Study Guide PDFrendaninNo ratings yet

- Introduction To Industrial Minerals-Springer Netherlands (1995)Document287 pagesIntroduction To Industrial Minerals-Springer Netherlands (1995)Kathleen SuanzoNo ratings yet

- AdamDocument219 pagesAdamMohan KumarNo ratings yet

- Straw-Construction-in-the-UK - Technical-Guide - February-2022 InglesDocument80 pagesStraw-Construction-in-the-UK - Technical-Guide - February-2022 InglesclaudioquijadaNo ratings yet

- BS5628-2 1995 Structural Use of Reinforced & Prestressed MasDocument58 pagesBS5628-2 1995 Structural Use of Reinforced & Prestressed MasGan Chin PhangNo ratings yet

- UFGS 04 20 00 Unit MasonryDocument70 pagesUFGS 04 20 00 Unit MasonryPetrit AhmetiNo ratings yet

- Annexure e SpecificationsDocument147 pagesAnnexure e Specificationsajjbarnard85No ratings yet

- Brick Water TanksDocument76 pagesBrick Water TanksAnonymous iTzCnM100% (2)

- SRCS 2-6 Zanatski Radovi (120512-Eng-Koncna) PDFDocument44 pagesSRCS 2-6 Zanatski Radovi (120512-Eng-Koncna) PDFMaркo ДеурићNo ratings yet

- Civl284 Lecture Notes 2015Document150 pagesCivl284 Lecture Notes 2015Debendra Dev KhanalNo ratings yet

- Design Alternative SteelDocument86 pagesDesign Alternative SteelViet Hung NguyenNo ratings yet

- 2408-Unit MasonryDocument3 pages2408-Unit MasonryRyanNo ratings yet

- Full Download PDF of (Ebook PDF) Materials For Civil and Construction Engineers 4th Edition All ChapterDocument43 pagesFull Download PDF of (Ebook PDF) Materials For Civil and Construction Engineers 4th Edition All Chapterdvjtalaja100% (5)

- Detailed SpecificationDocument129 pagesDetailed SpecificationChethan GowdaNo ratings yet

- Slag CementDocument185 pagesSlag CementMIL RAB100% (1)

- 4.1 Concrete Technology L T P 3 - 2 Rationale: //Hameed/Official/Syllabuspdf/Civil-4Sem PDFDocument27 pages4.1 Concrete Technology L T P 3 - 2 Rationale: //Hameed/Official/Syllabuspdf/Civil-4Sem PDFمحمدNo ratings yet

- Course Outline Construction MaterialsDocument2 pagesCourse Outline Construction MaterialsOsman Abdala OsmanNo ratings yet

- Book - Sprayed Concrete - enDocument294 pagesBook - Sprayed Concrete - enBenjamin Musa ダNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- The Effects of Silica Nanoparticles in Toughened Epoxy Resins and Fiber-Reinforced CompositesFrom EverandThe Effects of Silica Nanoparticles in Toughened Epoxy Resins and Fiber-Reinforced CompositesNo ratings yet

- Fundamentals of Materials Engineering - A Basic GuideFrom EverandFundamentals of Materials Engineering - A Basic GuideNo ratings yet

- Unit 7 Metal Sawing: StructureDocument9 pagesUnit 7 Metal Sawing: StructureRavi KumarNo ratings yet

- DAS Complete System - With S6 ThicknessDocument47 pagesDAS Complete System - With S6 ThicknessJun Rong FooNo ratings yet

- ConsbeamDocument4 pagesConsbeamtraisimdoNo ratings yet

- POSTMODERN, 253s '12Document270 pagesPOSTMODERN, 253s '12Raluca Gîlcă100% (1)

- Egd GR 11 Nov 2017 p1 MemoDocument9 pagesEgd GR 11 Nov 2017 p1 MemoLevi JohnsonNo ratings yet

- Site Planning and Space ProgramDocument65 pagesSite Planning and Space ProgramJerzy Mae GloriosoNo ratings yet

- Electrical DesignDocument1 pageElectrical DesignTrikam PatelNo ratings yet

- Recommendations For Marking Power Facilities: With The Use of 3M ™ EMS Electronic MarkersDocument12 pagesRecommendations For Marking Power Facilities: With The Use of 3M ™ EMS Electronic MarkersHassan Zakaria100% (1)

- TF MasterEmaco S488 PDFDocument5 pagesTF MasterEmaco S488 PDFMd. Shahadat HossainNo ratings yet

- Bop Overhead LintecDocument4 pagesBop Overhead Linteca.msNo ratings yet

- Bridge CASE STUDYDocument7 pagesBridge CASE STUDYF. Sarfarazi0% (1)

- Construction Planning 2019 MemoDocument6 pagesConstruction Planning 2019 MemoNtokozo JiyanaNo ratings yet

- Overall Project - Detail Progress Tracking Sheet - JHP - Updated - 19-Aug-21 - PMDocument59 pagesOverall Project - Detail Progress Tracking Sheet - JHP - Updated - 19-Aug-21 - PMMRadwanNo ratings yet

- Batcher Wall Foundation (Inner Partition)Document1 pageBatcher Wall Foundation (Inner Partition)Moinul Alam ShihabNo ratings yet

- Project Planner Scheduler CVDocument3 pagesProject Planner Scheduler CVbhaisahabjdNo ratings yet

- 4 ODS-OCS Phase-IV PDFDocument551 pages4 ODS-OCS Phase-IV PDFravi raghav100% (1)

- Senior Site Civil Engineer Hatem Mamdouh CVDocument3 pagesSenior Site Civil Engineer Hatem Mamdouh CVhatem mamdouhNo ratings yet

- Example 22 Worked Examples2Document30 pagesExample 22 Worked Examples2Refisa Jiru100% (4)

- Ultra-High Performance Concrete UHPC - Fundamentals, Design, Examples PDF (Free - 201 Pages)Document2 pagesUltra-High Performance Concrete UHPC - Fundamentals, Design, Examples PDF (Free - 201 Pages)Kamal PriyanNo ratings yet

- Tunnel Engineering Solved ProblemsDocument12 pagesTunnel Engineering Solved Problemsniladri.civil.iitkgpNo ratings yet

- Jig Maker's Toolkit: Stock Up On This Ti Me-Saving Collecti On of Important IngredientsDocument6 pagesJig Maker's Toolkit: Stock Up On This Ti Me-Saving Collecti On of Important IngredientsJd Diaz100% (1)

- G7 Selected Layer G9 Subgrade The Following Results Were Calculated With Elsym5: Foseg4 1.3' V G7Document2 pagesG7 Selected Layer G9 Subgrade The Following Results Were Calculated With Elsym5: Foseg4 1.3' V G7Paulo GomesNo ratings yet

- Risk Involved in Construction Works.Document10 pagesRisk Involved in Construction Works.Shaibal AhmedNo ratings yet

- Embankment Construction MethodologyDocument16 pagesEmbankment Construction MethodologyTinwin HtutNo ratings yet

- Experimental Study On Redmud Based Geopolymer Concrete With Fly Ash & Ggbs in Ambient Temperature CuringDocument4 pagesExperimental Study On Redmud Based Geopolymer Concrete With Fly Ash & Ggbs in Ambient Temperature CuringIsrael VenkatNo ratings yet

- (Vol B), 2021 Guidance For Class Notations, 2021Document132 pages(Vol B), 2021 Guidance For Class Notations, 2021M. Rifky RNo ratings yet

- Bar Bending Schedule Format (BBS)Document4 pagesBar Bending Schedule Format (BBS)MartinusNo ratings yet