Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

0 viewsWriting Uii - Lopez Mejia Jorge Eduardo - 1322415034

Writing Uii - Lopez Mejia Jorge Eduardo - 1322415034

Uploaded by

Jorgegjgnghnhgn

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Surface Grinding ReportDocument12 pagesSurface Grinding ReportNur Muhammad Fitri67% (21)

- MACHININGDocument10 pagesMACHININGDrSomnath BhattacharyaNo ratings yet

- Material Removal ProcessesDocument138 pagesMaterial Removal ProcessesM. Raza100% (1)

- Reid 618hr Ins Man Part ListDocument20 pagesReid 618hr Ins Man Part ListzuhzuhzuhNo ratings yet

- Portable Grinder Operating ProceduresDocument2 pagesPortable Grinder Operating ProceduresSammie Williams100% (1)

- Elements of Technology: - Grinding Machines (Grinder)Document14 pagesElements of Technology: - Grinding Machines (Grinder)SushantNo ratings yet

- Grinding and Grinding MachineDocument64 pagesGrinding and Grinding MachinePranav RamakrishnanNo ratings yet

- Grinding MachineDocument15 pagesGrinding MachineKeeru BossNo ratings yet

- Working With Grinding MachineDocument16 pagesWorking With Grinding MachineAirlangga GoonersNo ratings yet

- Unit IV - Abrasive Process and Broaching PDFDocument80 pagesUnit IV - Abrasive Process and Broaching PDFKanda SamyNo ratings yet

- U 4 Surface Finishing Process PDFDocument37 pagesU 4 Surface Finishing Process PDFSubhadip MaliNo ratings yet

- Grinding Machine: Grinding Machine, Often Shortened To G Rinder, Is Any of VariousDocument16 pagesGrinding Machine: Grinding Machine, Often Shortened To G Rinder, Is Any of VariousMudassar AkhtarNo ratings yet

- U-4 Surface Finishing ProcessDocument38 pagesU-4 Surface Finishing Processapi-271354682100% (1)

- Lecture8-Common Machine Equipment and Cutting ToolsDocument36 pagesLecture8-Common Machine Equipment and Cutting ToolsKamal SurenNo ratings yet

- Cipet Bhubaneswar FombDocument15 pagesCipet Bhubaneswar Fombcipet imphalNo ratings yet

- Module II - GrindingDocument73 pagesModule II - GrindingHARI KRISHNANNo ratings yet

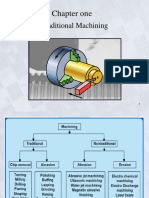

- Machining MechAnalysis CHPT 1Document98 pagesMachining MechAnalysis CHPT 1Brahim MouchaneNo ratings yet

- GrindingDocument105 pagesGrindingPrashant Rao Meshram100% (1)

- V Module GrindingDocument61 pagesV Module GrindingsajinirajithNo ratings yet

- Presentation On GrindingDocument36 pagesPresentation On GrindingPragyan Agrawal100% (3)

- Finishing Operations Lec 4Document27 pagesFinishing Operations Lec 4AnnieMalik100% (1)

- Grinding and Grinding OperationsDocument14 pagesGrinding and Grinding OperationsRitik Pothare0% (2)

- Yeni Microsoft PowerPoint Sunusu - KopyaDocument56 pagesYeni Microsoft PowerPoint Sunusu - KopyaMustafa Bilge AydoğduNo ratings yet

- Unit 1Document106 pagesUnit 1anandNo ratings yet

- Surface Grinding ReportDocument12 pagesSurface Grinding Reportyowiskie100% (1)

- Grinding MachineDocument38 pagesGrinding MachineFaisal MaqsoodNo ratings yet

- Machining: Workshop Practice ME-105Document20 pagesMachining: Workshop Practice ME-105Mazahir habibNo ratings yet

- Machine Tools and Machining 2Document38 pagesMachine Tools and Machining 2Faisal Maqsood100% (1)

- Grinding OperationsDocument25 pagesGrinding OperationsSundaram Jegatheesan100% (2)

- Metarial Removal Cutting and Surface Finish OperationsDocument86 pagesMetarial Removal Cutting and Surface Finish OperationsengrumerranaNo ratings yet

- Finishing 1Document17 pagesFinishing 1YátêndråRäwâtNo ratings yet

- Chapter 21-Theory of Metal MachiningDocument50 pagesChapter 21-Theory of Metal MachiningFaizanNo ratings yet

- SurfacefinishingproDocument38 pagesSurfacefinishingproraviraj20082No ratings yet

- Subtractive Process SM3009Document64 pagesSubtractive Process SM3009Kritik JoshiNo ratings yet

- Lathe PresentationDocument37 pagesLathe Presentationsamurai7_77No ratings yet

- Class 18Document51 pagesClass 18Rajesh ShahNo ratings yet

- Manufacturing Systems and Service Operations: Manufacturing Process Metal Forming Process Metal Removal ProcessDocument51 pagesManufacturing Systems and Service Operations: Manufacturing Process Metal Forming Process Metal Removal Processabhinav_bitspilani8991No ratings yet

- Unit I - Theory of Metal CuttingDocument111 pagesUnit I - Theory of Metal CuttingSaravana KumarNo ratings yet

- IntroductionDocument106 pagesIntroductionMahalingam SundaradasNo ratings yet

- Sharpening - Reconditioning of ToolsDocument6 pagesSharpening - Reconditioning of ToolsMeer UmarNo ratings yet

- Grinding MachineDocument54 pagesGrinding Machineravi upadhyay100% (5)

- Fixture Design: Introduction To Jigs and FixturesDocument10 pagesFixture Design: Introduction To Jigs and Fixturespankajpn100% (1)

- Machining of MetalsDocument23 pagesMachining of MetalsFiq IskandarNo ratings yet

- Abrasive Machining and Finishing Operations: MAE 250 LDocument70 pagesAbrasive Machining and Finishing Operations: MAE 250 LBody NassifNo ratings yet

- Types of Cutting ToolsDocument23 pagesTypes of Cutting Toolsbabu_mm2001No ratings yet

- Ch3.4 Grinding and OthersDocument33 pagesCh3.4 Grinding and OthersAdugna KasimNo ratings yet

- Manufacturing Technology: Unit - IvDocument37 pagesManufacturing Technology: Unit - IvramadanNo ratings yet

- A Presentation OnDocument14 pagesA Presentation OnAbhishek KalraNo ratings yet

- Chap. 1Document49 pagesChap. 1Fabinus BinusNo ratings yet

- MachiningDocument16 pagesMachiningShaheer SuhaibNo ratings yet

- Machining of MetalsDocument22 pagesMachining of MetalsFiq IskandarNo ratings yet

- Unit - Iv: Manufacturing TechnologyDocument39 pagesUnit - Iv: Manufacturing TechnologyAniket KharpateNo ratings yet

- Class 4 Tooling in Grinding ProcessDocument20 pagesClass 4 Tooling in Grinding Processsanukumar2382No ratings yet

- Single Point Cutting ToolDocument22 pagesSingle Point Cutting ToolJerin CyriacNo ratings yet

- Machining ProcessesDocument44 pagesMachining Processesregassa rajiNo ratings yet

- MillingDocument46 pagesMillingHumberto Angulo100% (1)

- Machining ShopDocument16 pagesMachining ShopOsii CNo ratings yet

- Machining Operation: - Turning - Drilling - Miling - Press Work - BorringDocument19 pagesMachining Operation: - Turning - Drilling - Miling - Press Work - BorringMiAzNo ratings yet

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingFrom EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingRating: 5 out of 5 stars5/5 (2)

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Grinding Overview: Machinist Grinder Interview Questions and AnswersFrom EverandGrinding Overview: Machinist Grinder Interview Questions and AnswersNo ratings yet

- Sharpening Woodturning ToolsDocument4 pagesSharpening Woodturning ToolsPierre799esNo ratings yet

- Grinder Checklist2Document3 pagesGrinder Checklist2jovyNo ratings yet

- Safety Alert - Grinder WheelDocument3 pagesSafety Alert - Grinder WheelsarojNo ratings yet

- Electrode Consumption PDFDocument1 pageElectrode Consumption PDFharold_bhieNo ratings yet

- Bench Grinder PDFDocument2 pagesBench Grinder PDFcityofdarwingisNo ratings yet

- Abrasive WheelsDocument21 pagesAbrasive Wheelssirelkhatim123No ratings yet

- Bosch Production Air Tools PDFDocument144 pagesBosch Production Air Tools PDFRAUL RODRIGUEZ VEGANo ratings yet

- MFT - II Lab ManualDocument33 pagesMFT - II Lab ManualMohan Prasad.M0% (1)

- Standard Manual Machine Guard en Tryb ZgodnosciDocument31 pagesStandard Manual Machine Guard en Tryb Zgodnoscicomputacion100% (1)

- VM2050C 2150C Conical Seat Globe Valve Machine BrochureDocument6 pagesVM2050C 2150C Conical Seat Globe Valve Machine BrochureMoises CunhaNo ratings yet

- Roller, Vibrator, Floats, Hand ToolsDocument24 pagesRoller, Vibrator, Floats, Hand ToolsAditi BazajNo ratings yet

- Shop Supplies SectionDocument194 pagesShop Supplies SectionHenryMonteagudoParedesNo ratings yet

- Bench Grinder: DO NOT Use This Machine Unless A Teacher Has InstructedDocument2 pagesBench Grinder: DO NOT Use This Machine Unless A Teacher Has InstructedNabil Qayyum Roslee100% (1)

- GnaDocument29 pagesGnamohit_kanyanNo ratings yet

- Grinding Machine: Navigation Search List of References External Links ImproveDocument13 pagesGrinding Machine: Navigation Search List of References External Links ImprovePruthviKashiNo ratings yet

- Effect of Grinding Parameters On Grinding Wheel PerformanceDocument18 pagesEffect of Grinding Parameters On Grinding Wheel PerformancePallav0% (1)

- 6029 Advanced Machine Tool LabDocument18 pages6029 Advanced Machine Tool LabSarath T.RNo ratings yet

- Study of Grinding MachinesDocument16 pagesStudy of Grinding MachinesRethish BalakrishnanNo ratings yet

- Me 8462-Mt-Ii Lab Manual PDFDocument39 pagesMe 8462-Mt-Ii Lab Manual PDFNagamani Rajesh50% (2)

- Catalog Accesorii Productie Wilson Tool Xtra 2017Document44 pagesCatalog Accesorii Productie Wilson Tool Xtra 2017SM TECH SRLNo ratings yet

- Grinding Machine: Grinding Machine, Often Shortened To G Rinder, Is Any of VariousDocument16 pagesGrinding Machine: Grinding Machine, Often Shortened To G Rinder, Is Any of VariousMudassar AkhtarNo ratings yet

- Maurya Motors AssignmentDocument21 pagesMaurya Motors Assignmentshubham kumar mehtaNo ratings yet

- RivetDocument15 pagesRivetEllyYanaNo ratings yet

- Bajrangi Project ReportDocument46 pagesBajrangi Project ReportAmodTKvideosNo ratings yet

- 2.me 8462-Mt-II Lab ManualDocument48 pages2.me 8462-Mt-II Lab ManualMURALI KRISHNAN RNo ratings yet

- Grinding PDFDocument1 pageGrinding PDFAfzaal FiazNo ratings yet

- Grinding MachineDocument15 pagesGrinding MachineTan Jun Zhe0% (1)

Writing Uii - Lopez Mejia Jorge Eduardo - 1322415034

Writing Uii - Lopez Mejia Jorge Eduardo - 1322415034

Uploaded by

Jorge0 ratings0% found this document useful (0 votes)

0 views3 pagesgjgnghnhgn

Original Title

WRITING UII_LOPEZ MEJIA JORGE EDUARDO_1322415034

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentgjgnghnhgn

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

0 views3 pagesWriting Uii - Lopez Mejia Jorge Eduardo - 1322415034

Writing Uii - Lopez Mejia Jorge Eduardo - 1322415034

Uploaded by

Jorgegjgnghnhgn

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

TECHNICAL GLOSSARY ON THE DESIGN OF A

GRINDING MACHINE

This technical glossary related to a grinding machine would include specific terms and concepts

used in the opera�on and func�oning of a grinding machine.

• Grinding Machine: The machine used to remove material from a

workpiece by abrasion, usually with a grinding wheel.

• Grinding wheel: The cu�ng tool that rotates in a grinding

machine and is used to remove material from the

workpiece.

• Workpiece: The piece of material that is placed in the

grinding machine to be ground or honed.

• Contact area: The part of the grinding wheel that comes

into contact with the workpiece during the grinding

process.

• Tolerance: The varia�on allowed in the dimensions of the

workpiece a�er grinding.

• Dimensional tolerance: The allowable difference

between the specified dimensions and the

actual dimensions of the workpiece a�er the

grinding process.

• Feed: The speed at which the grinding wheel moves

toward the workpiece during the grinding process.

• Cu�ng Speed: The peripheral speed of the grinding

wheel, which influences the material removal rate

and surface quality of the workpiece.

• Coolant: A liquid or oil used to cool and lubricate the

contact area between the grinding wheel and the

workpiece during grinding.

• Dressing: The process of condi�oning the grinding

wheel to maintain its shape and effec�veness by

removing worn material or irregulari�es.

• Diamond wheel: A grinding wheel that uses diamond

par�cles as an abrasive material, used for grinding

hard materials.

• Aluminum oxide wheel: A grinding wheel that

uses aluminum oxide par�cles as the abrasive

material, suitable for grinding so� materials and

some metals.

• Ground surface: The surface of the workpiece

a�er the grinding process, which generally has

high precision and surface finish.

• Grinding Stone: A device used to hold the

grinding wheel in a specific shape and to

remove buildups of unwanted material.

• Chip Hopper: A device that collects and

disposes of metal chips or debris generated

during the grinding process.

• CAD Design: Using computer-aided design (CAD)

so�ware to create detailed plans and 3D models of

the grinding machine.

• Valida�on and tes�ng: The phase in which it is

verified that the grinding machine meets all

specifica�ons and requirements before being put into

opera�on.

You might also like

- Surface Grinding ReportDocument12 pagesSurface Grinding ReportNur Muhammad Fitri67% (21)

- MACHININGDocument10 pagesMACHININGDrSomnath BhattacharyaNo ratings yet

- Material Removal ProcessesDocument138 pagesMaterial Removal ProcessesM. Raza100% (1)

- Reid 618hr Ins Man Part ListDocument20 pagesReid 618hr Ins Man Part ListzuhzuhzuhNo ratings yet

- Portable Grinder Operating ProceduresDocument2 pagesPortable Grinder Operating ProceduresSammie Williams100% (1)

- Elements of Technology: - Grinding Machines (Grinder)Document14 pagesElements of Technology: - Grinding Machines (Grinder)SushantNo ratings yet

- Grinding and Grinding MachineDocument64 pagesGrinding and Grinding MachinePranav RamakrishnanNo ratings yet

- Grinding MachineDocument15 pagesGrinding MachineKeeru BossNo ratings yet

- Working With Grinding MachineDocument16 pagesWorking With Grinding MachineAirlangga GoonersNo ratings yet

- Unit IV - Abrasive Process and Broaching PDFDocument80 pagesUnit IV - Abrasive Process and Broaching PDFKanda SamyNo ratings yet

- U 4 Surface Finishing Process PDFDocument37 pagesU 4 Surface Finishing Process PDFSubhadip MaliNo ratings yet

- Grinding Machine: Grinding Machine, Often Shortened To G Rinder, Is Any of VariousDocument16 pagesGrinding Machine: Grinding Machine, Often Shortened To G Rinder, Is Any of VariousMudassar AkhtarNo ratings yet

- U-4 Surface Finishing ProcessDocument38 pagesU-4 Surface Finishing Processapi-271354682100% (1)

- Lecture8-Common Machine Equipment and Cutting ToolsDocument36 pagesLecture8-Common Machine Equipment and Cutting ToolsKamal SurenNo ratings yet

- Cipet Bhubaneswar FombDocument15 pagesCipet Bhubaneswar Fombcipet imphalNo ratings yet

- Module II - GrindingDocument73 pagesModule II - GrindingHARI KRISHNANNo ratings yet

- Machining MechAnalysis CHPT 1Document98 pagesMachining MechAnalysis CHPT 1Brahim MouchaneNo ratings yet

- GrindingDocument105 pagesGrindingPrashant Rao Meshram100% (1)

- V Module GrindingDocument61 pagesV Module GrindingsajinirajithNo ratings yet

- Presentation On GrindingDocument36 pagesPresentation On GrindingPragyan Agrawal100% (3)

- Finishing Operations Lec 4Document27 pagesFinishing Operations Lec 4AnnieMalik100% (1)

- Grinding and Grinding OperationsDocument14 pagesGrinding and Grinding OperationsRitik Pothare0% (2)

- Yeni Microsoft PowerPoint Sunusu - KopyaDocument56 pagesYeni Microsoft PowerPoint Sunusu - KopyaMustafa Bilge AydoğduNo ratings yet

- Unit 1Document106 pagesUnit 1anandNo ratings yet

- Surface Grinding ReportDocument12 pagesSurface Grinding Reportyowiskie100% (1)

- Grinding MachineDocument38 pagesGrinding MachineFaisal MaqsoodNo ratings yet

- Machining: Workshop Practice ME-105Document20 pagesMachining: Workshop Practice ME-105Mazahir habibNo ratings yet

- Machine Tools and Machining 2Document38 pagesMachine Tools and Machining 2Faisal Maqsood100% (1)

- Grinding OperationsDocument25 pagesGrinding OperationsSundaram Jegatheesan100% (2)

- Metarial Removal Cutting and Surface Finish OperationsDocument86 pagesMetarial Removal Cutting and Surface Finish OperationsengrumerranaNo ratings yet

- Finishing 1Document17 pagesFinishing 1YátêndråRäwâtNo ratings yet

- Chapter 21-Theory of Metal MachiningDocument50 pagesChapter 21-Theory of Metal MachiningFaizanNo ratings yet

- SurfacefinishingproDocument38 pagesSurfacefinishingproraviraj20082No ratings yet

- Subtractive Process SM3009Document64 pagesSubtractive Process SM3009Kritik JoshiNo ratings yet

- Lathe PresentationDocument37 pagesLathe Presentationsamurai7_77No ratings yet

- Class 18Document51 pagesClass 18Rajesh ShahNo ratings yet

- Manufacturing Systems and Service Operations: Manufacturing Process Metal Forming Process Metal Removal ProcessDocument51 pagesManufacturing Systems and Service Operations: Manufacturing Process Metal Forming Process Metal Removal Processabhinav_bitspilani8991No ratings yet

- Unit I - Theory of Metal CuttingDocument111 pagesUnit I - Theory of Metal CuttingSaravana KumarNo ratings yet

- IntroductionDocument106 pagesIntroductionMahalingam SundaradasNo ratings yet

- Sharpening - Reconditioning of ToolsDocument6 pagesSharpening - Reconditioning of ToolsMeer UmarNo ratings yet

- Grinding MachineDocument54 pagesGrinding Machineravi upadhyay100% (5)

- Fixture Design: Introduction To Jigs and FixturesDocument10 pagesFixture Design: Introduction To Jigs and Fixturespankajpn100% (1)

- Machining of MetalsDocument23 pagesMachining of MetalsFiq IskandarNo ratings yet

- Abrasive Machining and Finishing Operations: MAE 250 LDocument70 pagesAbrasive Machining and Finishing Operations: MAE 250 LBody NassifNo ratings yet

- Types of Cutting ToolsDocument23 pagesTypes of Cutting Toolsbabu_mm2001No ratings yet

- Ch3.4 Grinding and OthersDocument33 pagesCh3.4 Grinding and OthersAdugna KasimNo ratings yet

- Manufacturing Technology: Unit - IvDocument37 pagesManufacturing Technology: Unit - IvramadanNo ratings yet

- A Presentation OnDocument14 pagesA Presentation OnAbhishek KalraNo ratings yet

- Chap. 1Document49 pagesChap. 1Fabinus BinusNo ratings yet

- MachiningDocument16 pagesMachiningShaheer SuhaibNo ratings yet

- Machining of MetalsDocument22 pagesMachining of MetalsFiq IskandarNo ratings yet

- Unit - Iv: Manufacturing TechnologyDocument39 pagesUnit - Iv: Manufacturing TechnologyAniket KharpateNo ratings yet

- Class 4 Tooling in Grinding ProcessDocument20 pagesClass 4 Tooling in Grinding Processsanukumar2382No ratings yet

- Single Point Cutting ToolDocument22 pagesSingle Point Cutting ToolJerin CyriacNo ratings yet

- Machining ProcessesDocument44 pagesMachining Processesregassa rajiNo ratings yet

- MillingDocument46 pagesMillingHumberto Angulo100% (1)

- Machining ShopDocument16 pagesMachining ShopOsii CNo ratings yet

- Machining Operation: - Turning - Drilling - Miling - Press Work - BorringDocument19 pagesMachining Operation: - Turning - Drilling - Miling - Press Work - BorringMiAzNo ratings yet

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingFrom EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingRating: 5 out of 5 stars5/5 (2)

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.From EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.No ratings yet

- Grinding Overview: Machinist Grinder Interview Questions and AnswersFrom EverandGrinding Overview: Machinist Grinder Interview Questions and AnswersNo ratings yet

- Sharpening Woodturning ToolsDocument4 pagesSharpening Woodturning ToolsPierre799esNo ratings yet

- Grinder Checklist2Document3 pagesGrinder Checklist2jovyNo ratings yet

- Safety Alert - Grinder WheelDocument3 pagesSafety Alert - Grinder WheelsarojNo ratings yet

- Electrode Consumption PDFDocument1 pageElectrode Consumption PDFharold_bhieNo ratings yet

- Bench Grinder PDFDocument2 pagesBench Grinder PDFcityofdarwingisNo ratings yet

- Abrasive WheelsDocument21 pagesAbrasive Wheelssirelkhatim123No ratings yet

- Bosch Production Air Tools PDFDocument144 pagesBosch Production Air Tools PDFRAUL RODRIGUEZ VEGANo ratings yet

- MFT - II Lab ManualDocument33 pagesMFT - II Lab ManualMohan Prasad.M0% (1)

- Standard Manual Machine Guard en Tryb ZgodnosciDocument31 pagesStandard Manual Machine Guard en Tryb Zgodnoscicomputacion100% (1)

- VM2050C 2150C Conical Seat Globe Valve Machine BrochureDocument6 pagesVM2050C 2150C Conical Seat Globe Valve Machine BrochureMoises CunhaNo ratings yet

- Roller, Vibrator, Floats, Hand ToolsDocument24 pagesRoller, Vibrator, Floats, Hand ToolsAditi BazajNo ratings yet

- Shop Supplies SectionDocument194 pagesShop Supplies SectionHenryMonteagudoParedesNo ratings yet

- Bench Grinder: DO NOT Use This Machine Unless A Teacher Has InstructedDocument2 pagesBench Grinder: DO NOT Use This Machine Unless A Teacher Has InstructedNabil Qayyum Roslee100% (1)

- GnaDocument29 pagesGnamohit_kanyanNo ratings yet

- Grinding Machine: Navigation Search List of References External Links ImproveDocument13 pagesGrinding Machine: Navigation Search List of References External Links ImprovePruthviKashiNo ratings yet

- Effect of Grinding Parameters On Grinding Wheel PerformanceDocument18 pagesEffect of Grinding Parameters On Grinding Wheel PerformancePallav0% (1)

- 6029 Advanced Machine Tool LabDocument18 pages6029 Advanced Machine Tool LabSarath T.RNo ratings yet

- Study of Grinding MachinesDocument16 pagesStudy of Grinding MachinesRethish BalakrishnanNo ratings yet

- Me 8462-Mt-Ii Lab Manual PDFDocument39 pagesMe 8462-Mt-Ii Lab Manual PDFNagamani Rajesh50% (2)

- Catalog Accesorii Productie Wilson Tool Xtra 2017Document44 pagesCatalog Accesorii Productie Wilson Tool Xtra 2017SM TECH SRLNo ratings yet

- Grinding Machine: Grinding Machine, Often Shortened To G Rinder, Is Any of VariousDocument16 pagesGrinding Machine: Grinding Machine, Often Shortened To G Rinder, Is Any of VariousMudassar AkhtarNo ratings yet

- Maurya Motors AssignmentDocument21 pagesMaurya Motors Assignmentshubham kumar mehtaNo ratings yet

- RivetDocument15 pagesRivetEllyYanaNo ratings yet

- Bajrangi Project ReportDocument46 pagesBajrangi Project ReportAmodTKvideosNo ratings yet

- 2.me 8462-Mt-II Lab ManualDocument48 pages2.me 8462-Mt-II Lab ManualMURALI KRISHNAN RNo ratings yet

- Grinding PDFDocument1 pageGrinding PDFAfzaal FiazNo ratings yet

- Grinding MachineDocument15 pagesGrinding MachineTan Jun Zhe0% (1)