Professional Documents

Culture Documents

SP 62 2014 Library

SP 62 2014 Library

Uploaded by

shivakumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SP 62 2014 Library

SP 62 2014 Library

Uploaded by

shivakumarCopyright:

Available Formats

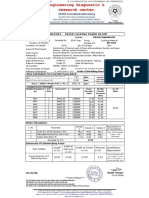

VEMENTS FOR RURAL ROADS AS PER IRC:SP 62-2013.

Case 1 Only wheel load stress : Case 2 Temperature and wheel load stresses without fatigue: Case 3 fatigue analysis

considering load and temperature

Case 1: design traffic is <50cvpd Case 2 : traffic is in between 50 to 150 cvpd Case 3 traffic is >150 cvpd

Case 1 /2/3 Enter the Data

3 Tyre (1- single/2 - dual) 2 Transverse joint spacing,m 3.25

(without temperature-1/ with temperature

Temperatureand

2/with temparature Zone (1 to analysis-3)

fatigue 6) 3 Spacing of wheels Sd (mm) 310 Ratio of L/l NO NEED TO CALC TEMP STRESS

Modulus of the subgrade reaction, k MPa/m 50 wheel load, P kN 50 Co-efficient of thermal expansion 0.00001

Elastic modulus of concrete E, MPa 30000 Tyre pressure, q MPa 0.8 Correction factor C

Poisson Ratio of the concrete, µ 0.15 Radius of contact, a (mm) 180.5648174 Design life of pavement, yrs 20

Temperature differntial, ∆T oC

19.8 Trial thickness, h m 0.22 Rate of increase of traffic 0.05

Modulus of rupture of concrete, fcr 4.22 No. of commercial vehicels per day 409 Truck with 50kN Wheel load,% 10

RESULTS FOR ONLY WHEEL LOAD CONSIDERATIONd RESULTS FOR WHEEL LOAD AND TEMPARATURE STRESS

Case 1 Case 2

Radius of relative stiffness, l m 859.0734955 temparature stress at edge, Mpa

Stress developed, σ, Mpa SAFE Wheel load Stresses at edge, Mpa

Design is Total stresses, σ, Mpa

Design is

RESULTS FOR FATIGUE ANALYSIS

Case 3

Design No.of vehicles for fatigue analysis 493625.0958

Stresses due to wheel load,σ, Mpa 2.335645213

Ratio of L/l 3.783145467

Correction factor C 0.3996620594

stresses due to temparature,σ, Mpa 0.7944842113

negative stress due to nonlinear temparature diffrential,σ, Mpa 0.5058823529

Total stress for Fatigue calculation,σ, Mpa 2.624247071

stress ratio 0.6218594955

Allowable repetititons 312175.394

Design is Unsafe

Cummulative fatigue damage 1.581242805

You might also like

- Design of Concrete Pavements For Rural Roads As Per Irc:Sp 62-2013Document3 pagesDesign of Concrete Pavements For Rural Roads As Per Irc:Sp 62-2013bnkadia60% (5)

- Design of Concrete Pavement Name of The WorkDocument10 pagesDesign of Concrete Pavement Name of The WorkDurga Rama Swamy KalvakolanuNo ratings yet

- Buried PipeDocument11 pagesBuried PipeAKKI KUMARNo ratings yet

- Sparks, C.P., The Influence of Tension, Pressure and Weight On Pipe and Riser Deformations and Stresses PDFDocument12 pagesSparks, C.P., The Influence of Tension, Pressure and Weight On Pipe and Riser Deformations and Stresses PDFNguyen Thanh BinhNo ratings yet

- IRC - SP 62-Dsign SheetDocument1 pageIRC - SP 62-Dsign SheetRajat BaghelNo ratings yet

- DesignDocument2 pagesDesignEdison SinghNo ratings yet

- 150 MM Thick PanelDocument1 page150 MM Thick PanelTECHNOCONS CONST.No ratings yet

- Design of Cement Concrete Pavement: 1 Design Data Design Traffic Case Case-3Document3 pagesDesign of Cement Concrete Pavement: 1 Design Data Design Traffic Case Case-3Satish BhairanattiNo ratings yet

- Creep Calculation by Colin Bayliss & Brain HardyDocument1 pageCreep Calculation by Colin Bayliss & Brain HardyVenkatasubramanian Iyer100% (1)

- Technical Data UD062/00: PrimcoDocument3 pagesTechnical Data UD062/00: PrimcoMirceaNo ratings yet

- HoneycombDocument1 pageHoneycombBudi SimatupangNo ratings yet

- Composites Data SheetDocument2 pagesComposites Data SheetAndreaSaavedraNo ratings yet

- 4 - Spur GearsDocument8 pages4 - Spur GearsAnil YildizNo ratings yet

- Omega Consultancy Services: A Govt. Regd. Test HouseDocument1 pageOmega Consultancy Services: A Govt. Regd. Test HouseSanjoy RoyNo ratings yet

- 202-Report On Lashing CalculationDocument6 pages202-Report On Lashing CalculationJg bzNo ratings yet

- Exercise 01Document9 pagesExercise 01Srimonta RoyNo ratings yet

- Triaxial Lab ResultsDocument2 pagesTriaxial Lab ResultsCharles Warren GoNo ratings yet

- Direct Shear StudentsDocument3 pagesDirect Shear StudentsDamian AlexanderNo ratings yet

- Sample Report Design MixDocument6 pagesSample Report Design MixShuvro ChakravortyNo ratings yet

- Rigid Pavement Design As Per IRC 58 2011 BUC and TDC AnalysisDocument3 pagesRigid Pavement Design As Per IRC 58 2011 BUC and TDC Analysisarvind sharmaNo ratings yet

- Evaluation and Optimization of Tensile Strength Responses of Copper at Sub Zero Temperatures Using Taguchi Robust Design and Machine LearningDocument17 pagesEvaluation and Optimization of Tensile Strength Responses of Copper at Sub Zero Temperatures Using Taguchi Robust Design and Machine LearningsandeepNo ratings yet

- Memoria de Calculo Actual 1339460 - 0Document20 pagesMemoria de Calculo Actual 1339460 - 0JAVIER ANTONIO PEREZ ALVARADONo ratings yet

- Ellipsoidal Head ASME CalculationDocument22 pagesEllipsoidal Head ASME CalculationPABLO MATEONo ratings yet

- Screeing Method Fea FatigueDocument34 pagesScreeing Method Fea FatigueGokul Amarnath0% (1)

- CC Road Design PalasaDocument18 pagesCC Road Design PalasaManikantaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9Document1 pageAspen Exchanger Design and Rating Shell & Tube V9MAYANK AGRAWALNo ratings yet

- Key Information: Analysis Type StatusDocument4 pagesKey Information: Analysis Type StatusMayank SinghNo ratings yet

- Comparation For Stresses Values Obtained by Finite Element Analyis (Ansys) and by Strain-Gage MethodDocument22 pagesComparation For Stresses Values Obtained by Finite Element Analyis (Ansys) and by Strain-Gage MethodCarlos BorgesNo ratings yet

- File: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Document14 pagesFile: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Camila Florencia ScarlatoNo ratings yet

- Project: TLD Shed, IOCL Motihari Design of Cement Concrete Pavements For Low Volume Roads As Per Irc:Sp:62-2014Document2 pagesProject: TLD Shed, IOCL Motihari Design of Cement Concrete Pavements For Low Volume Roads As Per Irc:Sp:62-2014Ashish SorathiyaNo ratings yet

- A. Design StipulationsDocument3 pagesA. Design StipulationsAnyam RambabuNo ratings yet

- Result:: Data Sheet For Mechanical PropertiesDocument1 pageResult:: Data Sheet For Mechanical Propertiesনৈঃশব্দের শব্দNo ratings yet

- Bending Stress CalculationsDocument4 pagesBending Stress Calculationsschaali100% (5)

- Anexo 1 - Resultados Ensayos Geomembrana - TRIDocument9 pagesAnexo 1 - Resultados Ensayos Geomembrana - TRIVictor Junior Guadalupe AguilarNo ratings yet

- Technical Data SL199/01: PrimcoDocument3 pagesTechnical Data SL199/01: PrimcoMirceaNo ratings yet

- Fundamentals FatigueDocument13 pagesFundamentals Fatiguelemuel mabilinNo ratings yet

- 18me52 Dme 1 Febarch 2022Document22 pages18me52 Dme 1 Febarch 2022Thirumal K SNo ratings yet

- ASICON2011 Paper - PaikDocument4 pagesASICON2011 Paper - Paikwei zhen LeongNo ratings yet

- SC13003-C9001-Q03-0009-2 - ITP Main Cooling Water MotorDocument4 pagesSC13003-C9001-Q03-0009-2 - ITP Main Cooling Water MotorDwi Mulyanti DwimulyantishopNo ratings yet

- 01 1MVA Transformer Test Results First Farmers L247979CDocument5 pages01 1MVA Transformer Test Results First Farmers L247979CMario GabunilasNo ratings yet

- 13 Ub DN 6676 (C)Document74 pages13 Ub DN 6676 (C)HemanthNo ratings yet

- IJATES Journal PaperDocument9 pagesIJATES Journal PaperAJIT SHINDENo ratings yet

- Rigid PavementDocument3 pagesRigid PavementPrabhakar LadNo ratings yet

- Plastic Deformation in Tensile Testing: Renewable Energy Equipment DesignDocument17 pagesPlastic Deformation in Tensile Testing: Renewable Energy Equipment DesignNoman AhmedNo ratings yet

- Comparison in Deformation and Fracture Behavior of Magnesium During Equal Channel Angular Pressing by Experimental and Numerical MethodsDocument4 pagesComparison in Deformation and Fracture Behavior of Magnesium During Equal Channel Angular Pressing by Experimental and Numerical Methodskamel touilebNo ratings yet

- Motor Rating DataDocument7 pagesMotor Rating DataamatrusliNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V8.8Document3 pagesAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoNo ratings yet

- Deck Cross Beam - 25 - 5 - 2022Document14 pagesDeck Cross Beam - 25 - 5 - 2022thazinNo ratings yet

- Design Calculation of Packing Support PlateDocument3 pagesDesign Calculation of Packing Support PlatevikeshkharvaNo ratings yet

- SOM Lab ManualDocument39 pagesSOM Lab ManualdineshvaricomNo ratings yet

- Title: Tensile TestDocument5 pagesTitle: Tensile TestAbdulrahmanNo ratings yet

- Introduction To: Nonlinear Cracked Section AnalysisDocument17 pagesIntroduction To: Nonlinear Cracked Section AnalysisCSEC Uganda Ltd.No ratings yet

- Earthing Calculation For NGR PANEL: Sr. No. Description DataDocument4 pagesEarthing Calculation For NGR PANEL: Sr. No. Description Datanaran19794735No ratings yet

- Piezo Material Properties Data Sheet 20201112Document1 pagePiezo Material Properties Data Sheet 20201112Trương Anh DuyNo ratings yet

- Test Report-Inter Locking Paver BlockDocument9 pagesTest Report-Inter Locking Paver Blockudit shahNo ratings yet

- Amp 2021-07Document9 pagesAmp 2021-07Renata OsunaNo ratings yet

- Element Topping Concrete: A I y y y Z Z Z e e E' BDocument6 pagesElement Topping Concrete: A I y y y Z Z Z e e E' BAistė VaitkuvienėNo ratings yet

- Effective Stress Triaxial Compression: Consolidated UndrainedDocument2 pagesEffective Stress Triaxial Compression: Consolidated UndrainedgomesNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Airflow Around An Ahmed Body ProjectDocument5 pagesAirflow Around An Ahmed Body ProjectSagar MehtaNo ratings yet

- Comptes Rendus Physique: L'équation de LangevinDocument13 pagesComptes Rendus Physique: L'équation de LangevinFrancisco José Juárez MoleroNo ratings yet

- Solid FrictionDocument9 pagesSolid FrictionJungun HwangNo ratings yet

- Comprehensive Exam-Fluid EngineeringDocument3 pagesComprehensive Exam-Fluid EngineeringSarvjeet Singh (P20ME014)No ratings yet

- Static/dynamic Aluminium AlloysDocument11 pagesStatic/dynamic Aluminium AlloysGonzalo AnzaldoNo ratings yet

- Diamond Tunnel Training 1 1520975582Document67 pagesDiamond Tunnel Training 1 1520975582Juan Miguel Gómez PalaciánNo ratings yet

- MODULE 3 (Force and Motion)Document19 pagesMODULE 3 (Force and Motion)André SanchezNo ratings yet

- 3 Periodical Examination in Science Vii: La Paz National High SchoolDocument3 pages3 Periodical Examination in Science Vii: La Paz National High SchoolFactura NeilNo ratings yet

- Gr11 Physical Sciences P1 (ENG) NOV Question PaperDocument14 pagesGr11 Physical Sciences P1 (ENG) NOV Question Paperora mashaNo ratings yet

- 1 Electrostatics: Practice 1.1 (p.20)Document11 pages1 Electrostatics: Practice 1.1 (p.20)Jerry ChanNo ratings yet

- Influence LineDocument7 pagesInfluence Lineaduyekirkosu1scribdNo ratings yet

- Assignment 2 2015 AAiTDocument5 pagesAssignment 2 2015 AAiTMISKIR TADESSENo ratings yet

- The Bell-Delaware MethodDocument12 pagesThe Bell-Delaware MethodPradyumna DhamangaonkarNo ratings yet

- 03 - Chapter 4Document12 pages03 - Chapter 4Sahiel HaripersadNo ratings yet

- Tutorial 07 SolutionsDocument11 pagesTutorial 07 SolutionshadaNo ratings yet

- Spec-25% GF PTFEDocument1 pageSpec-25% GF PTFEwawanNo ratings yet

- Chapter 3-BreakDocument37 pagesChapter 3-Breakkibromgidey12No ratings yet

- The Causes of Shear Cracking in Prestressed Concrete Box Girder BridgesDocument10 pagesThe Causes of Shear Cracking in Prestressed Concrete Box Girder BridgesVipin Kumar ParasharNo ratings yet

- MOE Test Result of Acc ConcreteDocument4 pagesMOE Test Result of Acc ConcreteSabyasachi BangalNo ratings yet

- ColumnsDocument16 pagesColumnsrohiniNo ratings yet

- Revolving Field TheoryDocument1 pageRevolving Field TheorySudipto PramanikNo ratings yet

- $4$$/HYHO3K/VLFV: PLQXWHVDocument22 pages$4$$/HYHO3K/VLFV: PLQXWHVbruh070724No ratings yet

- Constructal Design For Heat ConductionDocument214 pagesConstructal Design For Heat ConductionEmanuelEstradaNo ratings yet

- Ipe 300Document2 pagesIpe 300FTC OFF SHORENo ratings yet

- 01 - PPT - Basics of SeismicsDocument63 pages01 - PPT - Basics of SeismicsRishi RanjanNo ratings yet

- Dynamics 17-92 17-93 SolutionDocument3 pagesDynamics 17-92 17-93 Solutionpearldrummer992No ratings yet

- Pipe Fea Using AnsysDocument14 pagesPipe Fea Using AnsysjamilNo ratings yet

- Pinca T-Meet 314la Mee31me Lab 1 Finals Summative Exam (01dec2021)Document4 pagesPinca T-Meet 314la Mee31me Lab 1 Finals Summative Exam (01dec2021)Voonz PincaNo ratings yet

- Poster PresentationDocument1 pagePoster PresentationKarli KingNo ratings yet