Professional Documents

Culture Documents

HFY-Checklist-5-1-2 - Pipeline - Fitup

HFY-Checklist-5-1-2 - Pipeline - Fitup

Uploaded by

khaledinspectaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HFY-Checklist-5-1-2 - Pipeline - Fitup

HFY-Checklist-5-1-2 - Pipeline - Fitup

Uploaded by

khaledinspectaCopyright:

Available Formats

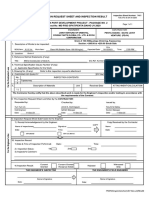

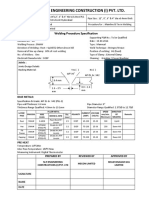

Inspection Checklist

Pipeline Fitup

Document # : HFY-Checklist-5-1-2

Report # PRID #: Project Name: Contractor :

RFI # :

Inspection Time Start: Finish: Inspection Date:

Dwg # / Line # : Area/Location :

Spec Reference : HFY-GEN-PPL-SPC-0016

Inspector's Checklist

Inspector's Observation

Sr # Description of Activity (Write N/A if Not Applicable)

(Record the Data)

Verify the approval of all the Documents (e.g. IFC, Drawing, Procedures,

1 Qualifications of Welding/NDE Personnels etc.)

¨ Acc

¨ Rej

2 Verify all the Pipes are Materials are inspected and approved .

¨ Acc

Before Fit-up: ¨ Rej

Verify the pipes/Fittings/Flanges are cleaned at least 25mm at both side of the

Weld joint .

3 Pipes are internally cleaned.

Beveling done on the Pipes are as per approved WPS.

¨ Acc ¨ Rej

After Fit-up :

Ensire Joint Preparation is made as per the WPS and ASME 31.4 or 31.8 (As

applicable)

Ensure the Joint Number is marked.

Internal misalignment at the prepared joint shal not exceed 10% of the wall

thickness and not more than 1.6mm whichever is smaller.

4 If the misallignment exceed morethan 1.6mm (Due to dimensional variation) ¨ Acc

trimmed 1:4 ratio. ¨ Rej

Distance between 2 Circumferential Joints atleast 2 times of Pipe diameter or

200 mm (Whichever is greater).

Note : Checklist is not all inclusive and must not relieve Contractor of its obligation to Contract requirements

(Specifications, Codes and Standards, Equipment Manufacturer's recommendations). Where relevant or

applicable, other activities can be added to the checklist.

Contrator PMC

Name

Date

Signature

760105401.xlsx 1 OF 1

You might also like

- ITP - Installation of Fiber Optic CablesDocument5 pagesITP - Installation of Fiber Optic CablesVasilica Barbarasa60% (5)

- Inspection and Test Plan: Installation of Fire Alarm SystemDocument3 pagesInspection and Test Plan: Installation of Fire Alarm SystemBinu Sulochanan100% (4)

- Itp Installation of Fiber Optic CablesDocument4 pagesItp Installation of Fiber Optic Cablesqasim078100% (2)

- Inspection and Test PlanDocument10 pagesInspection and Test PlanixoteeNo ratings yet

- ITP For False Ceiling Works of BuildingsDocument4 pagesITP For False Ceiling Works of BuildingsYay B. Gico0% (1)

- Design of Sludge Drying BedsDocument14 pagesDesign of Sludge Drying BedsAafaque Hussain100% (1)

- Pedal Operated Grinding MachineDocument48 pagesPedal Operated Grinding Machinealgoju lokesh67% (3)

- Polypropylene Process TechnologyDocument1 pagePolypropylene Process TechnologyAntonio MendesNo ratings yet

- HFY Checklist 5 1 1 Pipeline Material ReceivingDocument1 pageHFY Checklist 5 1 1 Pipeline Material ReceivingkhaledinspectaNo ratings yet

- Ventsand DrainsDocument1 pageVentsand DrainsGabriel MistreanuNo ratings yet

- Blowers Fans Supply Verification ITPDocument7 pagesBlowers Fans Supply Verification ITPgauravamberkarNo ratings yet

- Qic-Qsp-Uni-Tdr-Itp-0418 (3) Rev001Document1 pageQic-Qsp-Uni-Tdr-Itp-0418 (3) Rev001Ragab EisaNo ratings yet

- Subcon ItpDocument6 pagesSubcon ItpManu MohanNo ratings yet

- CHK PH 0002Document4 pagesCHK PH 0002jvfcvNo ratings yet

- SBG1-00-0K-1-CLD-0008-A ITP For Thermal Control Actuator Installation PDFDocument6 pagesSBG1-00-0K-1-CLD-0008-A ITP For Thermal Control Actuator Installation PDFsalamlinNo ratings yet

- Work Inspection Request: Contract Number: MDC/2471374 - 2 Wir Reference: Revision: 00 Date & Time of InspectionDocument10 pagesWork Inspection Request: Contract Number: MDC/2471374 - 2 Wir Reference: Revision: 00 Date & Time of Inspectionamith_kmNo ratings yet

- Fat ProcedureDocument50 pagesFat ProcedureDin AizuNo ratings yet

- Grounding Installation Inspection and Test Plan ITPDocument2 pagesGrounding Installation Inspection and Test Plan ITPtristan guarinoNo ratings yet

- Qic-Qsp-Uni-Tdr-Itp-0407 (3) Rev001Document1 pageQic-Qsp-Uni-Tdr-Itp-0407 (3) Rev001Ragab EisaNo ratings yet

- Qa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Document3 pagesQa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Ali Haider100% (1)

- CHK PH 0001Document6 pagesCHK PH 0001jvfcvNo ratings yet

- N5012-CS-PCP-0010-02 - InclinometerDocument13 pagesN5012-CS-PCP-0010-02 - Inclinometerdiego ahumadaNo ratings yet

- Qic QSP Uni TDR Itp 0403 (3) Rev001Document1 pageQic QSP Uni TDR Itp 0403 (3) Rev001Ragab EisaNo ratings yet

- Inspection and Test Plan For Above Ground FRP Piping Fabrication & Erection at FieldDocument3 pagesInspection and Test Plan For Above Ground FRP Piping Fabrication & Erection at FieldGohel100% (1)

- N5012-CS-PCP-0012-02 - StandpipesDocument17 pagesN5012-CS-PCP-0012-02 - Standpipesdiego ahumadaNo ratings yet

- Method Statement: Consolidated Contractors Company & Teyseer Contracting Company J.VDocument10 pagesMethod Statement: Consolidated Contractors Company & Teyseer Contracting Company J.Vrvsreddy1972No ratings yet

- AozayDocument11 pagesAozayheryfiononanapierrette01No ratings yet

- 4.1i Inspection &test PlanDocument8 pages4.1i Inspection &test PlanISAACNo ratings yet

- ITP For Structural Cabling System Testing and CommissioningDocument1 pageITP For Structural Cabling System Testing and CommissioningRommel Espinosa ParasNo ratings yet

- Distribution PanelDocument5 pagesDistribution PanelSourav RanaNo ratings yet

- Inspection & Test Plan: Area/LocationDocument2 pagesInspection & Test Plan: Area/LocationRoshan ThomasNo ratings yet

- 4172-GENON-1-25-0019 - Rev 1Document16 pages4172-GENON-1-25-0019 - Rev 1Rajesh SinghNo ratings yet

- ITP - Field Application of Heat Shrink SleeveDocument6 pagesITP - Field Application of Heat Shrink SleeveVasilica BArbarasaNo ratings yet

- Comments Resolution Sheet (CRS)Document31 pagesComments Resolution Sheet (CRS)SrinivasNo ratings yet

- 1.SRO-QPITP - Mechanical WorksDocument2 pages1.SRO-QPITP - Mechanical Worksachusanachu100% (1)

- 25045-A1000-18-ITP-E-006r004 - ITP For Installation of Building Wires and CablesDocument12 pages25045-A1000-18-ITP-E-006r004 - ITP For Installation of Building Wires and CablesmsmkhanNo ratings yet

- FFA Checklist & ITP Air OutletsDocument7 pagesFFA Checklist & ITP Air OutletsWaqar KhanNo ratings yet

- Inspection Test Plan ITP Painting WorksDocument4 pagesInspection Test Plan ITP Painting WorksMichael AntipuestoNo ratings yet

- N0579-TJN-ET-SI0001 - R02 ITP For Grounding InstallationDocument12 pagesN0579-TJN-ET-SI0001 - R02 ITP For Grounding InstallationAbat SayekeyevNo ratings yet

- Itp For Painting WorksDocument28 pagesItp For Painting WorksAhmed saberNo ratings yet

- SF.690I.Test and Commissioning File IndexDocument7 pagesSF.690I.Test and Commissioning File IndexLiberty MunyatiNo ratings yet

- Request For Inspection (Rfi) : Project TitleDocument3 pagesRequest For Inspection (Rfi) : Project TitleehteshamNo ratings yet

- 4020-001A-VD-004 Rev 1 - Inspection & Test Plan (ITP) - Code1Document5 pages4020-001A-VD-004 Rev 1 - Inspection & Test Plan (ITP) - Code1BUDI HARIANTONo ratings yet

- ITP For CCTV System Testing & CommissioningDocument1 pageITP For CCTV System Testing & CommissioningTamer EidNo ratings yet

- N0579-TJN-ET-SI0008 - R02 ITP For AIS InstallationDocument7 pagesN0579-TJN-ET-SI0008 - R02 ITP For AIS InstallationAbat SayekeyevNo ratings yet

- Application of Proprietary Cementitious Fireproofing Minimum Requirement ITP Template - Rev 001Document6 pagesApplication of Proprietary Cementitious Fireproofing Minimum Requirement ITP Template - Rev 001Adam FarhanNo ratings yet

- Method Statement For Duct InstallationDocument7 pagesMethod Statement For Duct InstallationShaikh MateenNo ratings yet

- M Storm Drainage System IC M SDS 00Document2 pagesM Storm Drainage System IC M SDS 00achusanachuNo ratings yet

- Electrostatic Precipitator Installation: Field Inspection & Test Plan (F-Itp) : 1: 16-Feb-10Document40 pagesElectrostatic Precipitator Installation: Field Inspection & Test Plan (F-Itp) : 1: 16-Feb-10Alif Rahmat FebriantoNo ratings yet

- Static: M I W IDocument6 pagesStatic: M I W IHamdanNo ratings yet

- SD05wi1 Structural Inspection WorkpackDocument22 pagesSD05wi1 Structural Inspection WorkpackidrisNo ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- Tank Erection Itp Org ChartDocument34 pagesTank Erection Itp Org Chartvasantha kumar100% (1)

- ITP - Erection Instalation and Testing of HDPE Piping - UGDocument10 pagesITP - Erection Instalation and Testing of HDPE Piping - UGVasilica BArbarasaNo ratings yet

- Pre Start-Up Test Certificate Pipework Distribution System Form FM-05 NoDocument1 pagePre Start-Up Test Certificate Pipework Distribution System Form FM-05 NoKhaled FatnassiNo ratings yet

- Outotec: Danem Engineering Works WLL Doha - QatarDocument4 pagesOutotec: Danem Engineering Works WLL Doha - QatarRejoy babyNo ratings yet

- ITP - Concrete WorksDocument17 pagesITP - Concrete WorksVasilica BArbarasa100% (2)

- MD1-0-T-030-05-00069 - ITP For Rotating Equipment InstallationDocument9 pagesMD1-0-T-030-05-00069 - ITP For Rotating Equipment InstallationTran Khuynh100% (1)

- ITP ErectionDocument3 pagesITP Erectionjanpaul2481No ratings yet

- (Itp For Cast Insitu Foundation) 4172-Genon-1!25!0002-ADocument45 pages(Itp For Cast Insitu Foundation) 4172-Genon-1!25!0002-ARajesh SinghNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and Auditors with CD ROMFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and Auditors with CD ROMNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- DLL - Tle 6 - Q4 - W2Document5 pagesDLL - Tle 6 - Q4 - W2Marween QuiambaoNo ratings yet

- Novares Marocco: FrigelDocument15 pagesNovares Marocco: FrigelHarmouche MedNo ratings yet

- 9883511790ENUWADocument8 pages9883511790ENUWAhalexNo ratings yet

- Welding WireDocument20 pagesWelding WirefoxmancementNo ratings yet

- SMAW 9 - Q1 - W6 - Mod6Document18 pagesSMAW 9 - Q1 - W6 - Mod6Romeo Dela RosaNo ratings yet

- Electric-Fusion-Welded Steel Pipe For Atmospheric and Lower TemperaturesDocument7 pagesElectric-Fusion-Welded Steel Pipe For Atmospheric and Lower Temperaturesrgi178No ratings yet

- Scotch-Weld: Cyanoacrylate Adhesive PR100Document3 pagesScotch-Weld: Cyanoacrylate Adhesive PR100Marco AurélioNo ratings yet

- BoltsDocument14 pagesBoltsBelalNorNo ratings yet

- Proposed WPS For API 5LDocument1 pageProposed WPS For API 5LMecon HyderabadNo ratings yet

- WPS Casing Sea Water PumpDocument10 pagesWPS Casing Sea Water PumpdethamrnNo ratings yet

- Sheet 5Q Manufacturing Processes 1Document1 pageSheet 5Q Manufacturing Processes 1Ahmed Rabie Abd ElazeemNo ratings yet

- Experiment No. 3: To Perform Turning Operation On LatheDocument3 pagesExperiment No. 3: To Perform Turning Operation On LatheHasnain AshrafNo ratings yet

- Trellex Hose Flanges GasketsDocument6 pagesTrellex Hose Flanges GasketsHassan ShirivandNo ratings yet

- DWD Accessories 09Document4 pagesDWD Accessories 09Mario Allesina JuniorNo ratings yet

- Schaublin 22 Catalogue 1990 (English)Document28 pagesSchaublin 22 Catalogue 1990 (English)...No ratings yet

- Different Forms of Corrosion - Intergranular Corrosion - Weld DecayDocument2 pagesDifferent Forms of Corrosion - Intergranular Corrosion - Weld DecayHarry NuryantoNo ratings yet

- Long Test in SmawDocument4 pagesLong Test in SmawTeacher Ronel SDO NavotasNo ratings yet

- Principles of SolidificationDocument49 pagesPrinciples of SolidificationAmr AsaadNo ratings yet

- Job Safety Analysis Worksheet: JGC Penthouse Extension BLDGDocument2 pagesJob Safety Analysis Worksheet: JGC Penthouse Extension BLDGCherry BetonioNo ratings yet

- Post Installed Anchors General Notes CAN-032013Document2 pagesPost Installed Anchors General Notes CAN-032013Zuhair AliNo ratings yet

- Replace LD-002H Air Filtration With Elegoo FilterDocument4 pagesReplace LD-002H Air Filtration With Elegoo FilterInflux 3DNo ratings yet

- 660.501 A01 Standard Clean (Class SC) Inspection and Acceptance RequirementsDocument3 pages660.501 A01 Standard Clean (Class SC) Inspection and Acceptance Requirementspuwarin najaNo ratings yet

- WPS PQR As Per IsDocument3 pagesWPS PQR As Per Istarun kaushalNo ratings yet

- Core Acceptance - Injection PumpDocument9 pagesCore Acceptance - Injection PumpGersonNo ratings yet

- Copy of Potential (FMEA) (Original)Document52 pagesCopy of Potential (FMEA) (Original)arunpandey1686No ratings yet

- Prianka Binte Zaman Assistant Professor Dept. of IPE, BUETDocument17 pagesPrianka Binte Zaman Assistant Professor Dept. of IPE, BUETKibria Prangon100% (1)

- Thread-Cutting Tools and ProceduresDocument31 pagesThread-Cutting Tools and ProcedureszaidoNo ratings yet