Professional Documents

Culture Documents

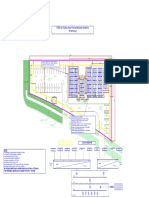

Sa Ami 000 Hdai 370102 - 1 - General Notes Concrete Works

Sa Ami 000 Hdai 370102 - 1 - General Notes Concrete Works

Uploaded by

mohamed esmailOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sa Ami 000 Hdai 370102 - 1 - General Notes Concrete Works

Sa Ami 000 Hdai 370102 - 1 - General Notes Concrete Works

Uploaded by

mohamed esmailCopyright:

Available Formats

GENERAL NOTES

CONCRETE WORKS 10. CONCRETE PROTECTION (fy = 420MPa)

10.1. ALL REINFORCED CONCRETE SURFACES IN DIRECT CONTACT WITH EARTH SHALL BE COATED BAR BAR NUMBER

f'c COATING

(MPa) LOCA-

WITH MINIMUM TWO COATS OF COAL TAR OR BITUMEN COATING THAT CONFORMS TO AMIES-H-003. TYPE

TION 10 12 14 16 18 20 22 25 28 32

MATERIAL

- COATING SYSTEM-3 OR BASF MASTERSEAL550 IS ACCEPTABLE FOR NORMAL BURIED CONDITION.

I 580 690 810 920 1040 1420 1570 1780 1990 2280

- COATING SYSTEM-1B SHALL BE USED FOR ABOVE GROUND CONCRETE EXPOSED TO THE AIR.

1. CEMENT TOP

II 440 530 620 710 800 1090 1200 1360 1530 1740

1.1. EXPOSURE CLASS FOR AMIRAL PKG4 PLANT IN ACCORDANCE WITH GEOTECHNICAL REPORT 10.2. PROTECTION OF CONCRETE SURFACE IN ABOVE GROUND AREAS SHALL BE PERFORMED WITH

35

TO BE AS FOLLOWS; (TBD) ADEQUATE MATERIALS IN ACCORDANCE WITH AMIES-H-003. IN PARTICULAR ONLY FIRST 3M FROM I 510 610 710 820 920 1260 1380 1570 1760 2010

GRADE OF CAST IN SITU COLUMNS SHALL BE COATED ACCORDING TO AMIES-H-003. OTHER

ABOVE GROUNDWATER LEVEL : SULFATE EXPOSURE CLASS : S2 II 340 410 480 550 610 840 920 1050 1170 1340

CHLORIDE EXPOSURE CLASS : C2 10.3. ALL GROUT EXPOSED TO WEATHER OR IN ACID AREA SHALL BE PROTECTED IN ACCORDANCE

WITH AMIES-H-003.

BELOW GROUNDWATER LEVEL : SULFATE EXPOSURE CLASS : S1 2) DEVELOPMENT LENGTH IN COMPRESSION (Ldc)

CHLORIDE EXPOSURE CLASS : C1 10.4. A PLASTICIZED SHEET VAPOR BARRIER IN ACCORDANCE WITH ASTM E1745, CLASS A, MINIMUM OF Ldc SHALL NOT BE LESS THAN 200mm

0.25MM (10MILS) IN THICKNESS, SHALL BE PLACED BENEATH SLABS ON GRADE. OUTDOOR SIDEWALKS (fy = 420MPa)

1.2. ASTM C150 PORTLAND CEMENT TYPES AND REINFORCING STEEL ARE SELECTED

ARE EXEMPTED FROM THIS REQUIREMENT. RE-BAR

IN ACCORDANCE WITH TABLE 1 OF AMIES-Q-001, AS FOLLOWS : D10 D12 D14 D16 D18 D20 D22 D25 D28 D32

f'c

10.5. A PLASTICIZED SHEET VAPOR BARRIER SHALL BE PLACED BELOW AND AROUND THE SIDES OF

GROUND CEMENT CONCRETE THAT IS PLACED DIRECTLY INTO EXCAVATION WITHOUT THE USE OF FORMWORK, 35 200 220 260 290 330 370 400 460 510 580

STRUCTURE TYPE REBAR

LEVEL TYPE WHERE COAL-TAR OR BITUMEN COATING CANNOT BE APPLIED.

I+POZZOLAN 3) TENSILE DEVELOPMENT LENGTH OF STANDARD HOOK (Ldh)

ABOVE GROUND /SLAG UNCOATED

Ldh SHALL NOT BE LESS THAN 8db NOR LESS THAN 150mm

(fy = 420MPa)

STRUCTURAL CONCRETE,

WATER RETAINING BELOW GROUND I+POZZOLAN ECR* RE-BAR

(IN SOIL) /SLAG ABOVE GRADE COATING D10 D12 D14 D16 D18 D20 D22 D25 D28 D32

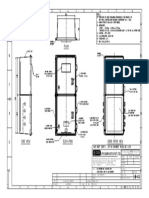

MIN. FDN EL. +100.300 f'c

STRUCTURES

ELEVATION

BELOW GROUND I+POZZOLAN ECR* 35 210 250 290 330 370 410 450 520 580 660

(IN WATER) /SLAG ISOLATED JOINT

GRADE LEVEL

* ECR : EPOXY COATED REBAR C. SPLICE LENGTH OF REINFORCEMENT

R.C. PAVING U/G COATING

SHALL BE EXTENDED UP TO 300MM LAP SPLICES SHALL BE AS REQUIRED FOR CLASS A OR B SPLICE, BUT NOT LESS

1.3. ALL CONCRETE SHALL BE READY-MIXED PORTLAND CEMENT CONCRETE (SEE AMIMS-Q-9097) AND PLASTICIZED SHEET ABOVE GRADE LEVEL THAN 300mm, WHERE ;

CONCRETE WORKS SHALL BE IN ACCORDANCE WITH AMIES-Q-001, AMIES-Q-005 AND ACI 318M-14. (THK MIN. 0.25)

LEAN CONCRETE

50

50 CLASS A SPLICE 1.0 Ld

2. CONCRETE OR PLASTICIZED SHEET CLASS B SPLICE 1.3 Ld

(THK 0.15, FOR PRECAST ONLY)

THE MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT 28 DAYS (ASTM C39) SHALL WHERE Ld IS THE TENSILE DEVELOPMENT LENGTH.

BE AS FOLLOWS. LAP SPLICES OF DEFORMED BAR AND DEFORMED WIRE IN TENSION SHALL BE

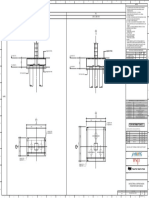

10.6. MINIMUM CONCRETE COVER CLASS B SPLICES EXCEPT THAT CLASS A SPLICES ARE ALLOWED WHEN:

A. STRUCTURAL CAST-IN PLACE CONCRETE --------------------------------------------------------- f'c = 35MPa

B. WATER RETAINING STRUCTURE ----------------------------------------------------------------------- f'c = 35MPa A. CONCRETE CAST AGAINST OR PERMANENTLY EXPOSED TO EARTH - THE AREA OF REINFORCEMENT PROVIDED IS AT LEAST TWICE THAT REQUIRED BY

C. CONCRETE PAVEMENT ------------------------------------------------------------------------------------ f'c = 30MPa (INCLUDING FOUNDATIONS OVER A SUB-SLAB) ------------------------------------------------ 75 MM ANALYSIS OVER THE ENTIRE LENGTH OF THE SPLICE.

D. FIRE PROOFING ---------------------------------------------------------------------------------------------- f'c = 30MPa

B. FORMED CONCRETE EXPOSED TO EARTH OR WEATHER - ONE-HALF OR LESS OF THE TOTAL REINFORCEMENT IS SPLICED WITHIN THE

E. LEAN CONCRETE --------------------------------------------------------------------------------------------- f'c = 14MPa

SUPPORTING PROCESS EQUIPMENT --------------------------------------------------------------- 75 MM REQUIRED LAP LENGTH.

F. PRECAST & PRESTRESSED ------------------------------------------------------------------------------- f'c = 35MPa

BUILDINGS, WALKWAY PLATFORMS, STAIRS, AC PADS ------------------------------------- 50 MM - LAP SPLICES SHALL BE STAGGERED FOR CLASS A SPLICES.

3. AGGREGATES C. CONCRETE NOT EXPOSED TO WEATHER NOR IN CONTACT WITH GROUND

(WHICH CAN BE INSPECTED FROM ALL SIDES): 1) LAP SPLICE LENGTH IN TENSION, Ls ( ) : FACTOR

AGGREGATES SHALL CONFORM TO THE REQUIREMENT OF ASTM C33 AS MODIFIED BY AMIMS-Q-9088.

BEAMS, COLUMNS AND TENSION TIES ------------------------------------------------------------- 50 MM

CLASS

BAR COA- BAR NUMBER

4. WATER SLABS, WALLS, JOISTS ---------------------------------------------------------------------------------- 25 MM f'c

(MPa) LOCA- TING

4.1. WATER TO BE USED IN MIXING CONCRETE SHALL CONFORM TO AMIMS-Q-9097. D. CONCRETE EXPOSED TO SEA WATER, RAW WATER OR SEWAGE ------------------- 75 MM TION TYPE 10 12 14 16 18 20 22 25 28 32

SEC 5.4.

E. BETWEEN REINFORCEMENT AND ANCHOR FLANGE/PIPE WITHIN A I 580 690 810 920 1040 1420 1570 1780 1990 2280

4.2. WATER FOR CURING SHALL CONFORM TO AMIES-Q-001, SEC 8.18. PIPELINE ANCHOR BLOCKS ---------------------------------------------------------------------------- 100 MM (1.0)

II 440 530 620 710 800 1090 1200 1360 1530 1740

F. CONCRETE SLAB OVER 50MM SUB SLAB ------------------------------------------------------- 50 MM TOP

5. ADMIXTURES : AS PER AMIMS-Q-9097. I 760 900 1060 1200 1360 1850 2050 2320 2590 2970

B

G. SIDEWALKS, WALKWAYS, ETC. --------------------------------------------------------------------- 50 MM

(1.3)

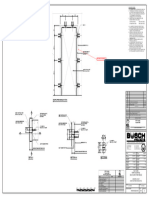

6. WATERSTOP : AS PER ACI 350.5, PVC WATERSTOP, W=MIN 150MM II 580 690 810 930 1040 1420 1560 1770 1990 2270

35

7. GROUT

CONCRETE CONSTRUCTION A I 510 610 710 820 920 1260 1380 1570 1760 2010

(1.0)

7.1. CEMENT BASED GROUT SHALL BE IN ACCORDANCE WITH AMIES-Q-010 AND HAVE MINIMUM 1. ALL FOUNDATIONS SHALL BE PLACED ON 50mm THICK LEAN CONCRETE AS SHOWN ON II 340 410 480 550 610 840 920 1050 1170 1340

OTHER

COMPRESSIVE STRENGTH OF 40 MPa. INDIVIDUAL DRAWINGS.

B I 670 800 930 1070 1200 1640 1800 2050 2290 2620

7.2. EPOXY GROUT FOR MACHINERY SUPPORT SHALL BE IN ACCORDANCE WITH AMIES-Q-011 AND 2. JOINT (1.3)

II 450 540 630 720 800 1100 1200 1370 1530 1750

HAVE MINIMUM COMPRESSIVE STRENGTH OF 80 MPa.

2.1. JOINT FILLER STRIPS FOR EXPANSION JOINTS SHALL CONFORM TO ASTM D1751 OR ASTM D1752.

7.3. GROUT MAY BE PLACED BY EITHER POURING OR PUMPING. AFTER ADEQUATE CURING, TYPE SHALL BE AS NOTED ON THE DESIGN DRAWINGS.

2) LAP SPLICE LENGTH IN COMPRESSION (Lsc) HDAI-370201 GENERAL NOTES STEEL WORKS

THE PERIMETER EDGES SHALL BE STEEL TROWELLED TO A NEAT 45° EXTERNAL CHAMFER. (fy = 420MPa)

2.2. JOINTS NOT SPECIFIED ON THE DESIGN DRAWINGS, SHALL BE IN ACCORDANCE WITH ACI 301-10

7.4. ALL FOUNDATIONS SUPPORTING STEEL STRUCTURES OR EQUIPMENT SHALL HAVE MINIMUM 25MM SECTION 2.2.2.5, 5.1.2.3A, 5.2.2.1 AND 5.3.2.6. RE-BAR HDAI-370101 GENERAL NOTES CIVIL WORKS

f'c D10 D12 D14 D16 D18 D20 D22 D25 D28 D32

THK AND NO MORE THAN 50MM THK OF NON SHRINK CEMENTITIOUS GROUT, BETWEEN BASE PLATE Drawing No DESCRIPTION

2.3. PAVING OR SLAB CONSTRUCTION JOINTS NOT SPECIFIED ON THE DRAWINGS SHALL BE LOCATED

AND TOP OF FOUNDATION. 35 300 360 420 480 540 600 660 750 840 960

AT COLUMN CENTERLINES AND AT INTERMEDIATE INTERVALS.

REFERENCE DRAWINGS

8. REINFORCING STEEL 2.4. WHERE FOUNDATIONS PROTRUDE THROUGH THE PAVING, 12mm DIAMETER REINFORCING BARS,

4. ALL EXPOSED EDGES AND CORNER OF CONCRETE ABOVE GRADE LEVEL SHALL HAVE

800mm LONG, SHALL BE PLACED DIAGONALLY IN THE PAVING AT ALL INTERIOR CORNERS.

8.1. REINFORCING STEEL BARS SHALL CONFORM TO ASTM A615/A615M GRADE 60 HIGH TENSILE, 20MM x 20MM CHAMFERS.

DEFORMED STEEL, WHOSE MINIMUM YIELD STRENGTH IS 420MPa.

3. REINFORCING STEEL

5. BACKFILLING AND COMPACTION

8.2. COATING FOR REINFORCING STEEL

3.1. PLACING REINFORCING BAR

- FUSION BONDED EPOXY COATED STEEL BARS IN ACCORDANCE WITH AMIMS-H-9016 SHALL 5.1. BACKFILLING AND COMPACTION SHALL BE IN ACCORDANCE WITH AMIES-A-114 AS WELL AS

REINFORCING BARS SHALL BE HANDLED AND STORED IN ACCORDANCE WITH ACI 318 AS PER 1 IFC 12-OCT-2023 ISSUE FOR CONSTRUCTION Y.B. LEE D.K. KIM Y.B.IM

BE APPLIED FOR STRUCTURAL CONCRETE, PRECAST/PRESTRESSED CONCRETE, THE RECOMMENDATIONS OF THE FINAL GEOTECHNICAL INVESTIGATION.

CLAUSE 7.2.8 IN AMIES-Q-001.

WATER RETAINING STRUCTURES LOCATED BELOW GROUND WATER LEVEL. 0 IFR 07-SEP-2023 ISSUE FOR REVIEW Y.B. LEE D.K. KIM Y.B.IM

5.2. FILL OR BACKFILL PLACED BENEATH FOOTINGS SHALL BE COMPACTED TO AT LEAST 95% OF

- UNCOATED REINFORCING STEEL BARS CAN BE APPLIED FOR OTHER TYPES OF CONCRETE 3.2. FABRICATION TOLERANCE SHALL CONFORM TO ACI 117.

THE MAXIMUM MODIFIED PROCTOR DENSITY AS DETERMINED BY ASTM D1557. Issued Reviewed Approved

STRUCTURES. Rev. Step Rev. Date Revision Description

3.3. DEVELOPMENT AND SPLICES OF REINFORCEMENT by by by

8.3. WELDED WIRE REINFORCEMENT SHALL BE PLAIN WIRE IN ACCORDANCE WITH ASTM A1064/A1064M. 5.3. FOR COHESIONLESS FREE DRAIN SOILS, 85% RELATIVE DENSITY AS DETERMINED BY ASTM D4253

ROLLS OF WELDED REINFORCEMENT SHALL NOT BE USED. A. COATING FACTORS ARE CLASSIFIED AS BELOWS. AND ASTM D4254 SHALL BE USED.

AMIRAL

8.4. GALVANIZED WELDED WIRE FABRIC SHALL BE CONFORM TO ASTM A1060/A1060M. - TYPE I : EPOXY COATED REINFORCEMENT 5.4. FOR FOUNDATION STATIC LOADS OVER 320 kPa AND FOUNDATIONS FOR VIBRATING OR HEAVY

- TYPE II : UNCOATED REINFORCEMENT MACHINERY AS DEFINED IN AMIES-Q-007, AND FOR CONCRETE PAVEMENT SUBGRADES, FILL PROJECT

9. EMBEDDED MATERIAL SHALL BE COMPACTED TO 85% RELATIVE DENSITY FOR COHESIONLESS SOILS OR 95%

B. DEVELOPMENT LENGTH OF REINFORCEMENT This document is the property of AMIRAL and shall not be disclosed to third parties or reproduced without permission of the owner.

OF THE MAXIMUM DENSITY AS DETERMINED BY ASTM D1557 FOR COHESIVE MATERIALS.

ALL EMBEDDED STEEL ITEMS SUCH AS SUPPORTING ANGLES, SLIDE PLATES, UNISTRUT, This document has been generated by an Electronic Document Management System. When printed it is considered as a for information

1) DEVELOPMENT LENGTH IN TENSION, Ld only copy. The controlled copy is the screen version and it is the holder's responsibility that he/she holds the latest valid version.

STEEL PLATES, ETC. WHICH ARE ATTACHED TO THE FORMWORK AND CAST

THIS LENGTH SHALL NOT BE LESS THAN 300mm 6. TOLERANCES

AT THE CONCRETE SURFACE SHALL BE HOT-DIP GALVANIZED IN ACCORDANCE WITH

AMIES-H-001 AND ASTM A123. 6.1. FOUNDATION HORIZONTAL POSITION --------------------------------------------------------------------------- ±25MM GENERAL NOTES

6.2. FOUNDATION VERTICAL POSITION --------------------------------------------------------------------- -10MM / +20MM CONCRETE WORKS

6.3. PRE-EMBEDDED ANCHOR BOLTS

- HEIGHT ---------------------------------------------------------------------------------------------------------------- 0MM / +5MM Doc Type: STD Discipline: CIV Phase: DE Class: 2 System / Subsystem: NA Equipment Type: NA

- POSITION : FOR ANCHOR BOLT DIAMETER < 20 MM -------------------------------------------------------- ±1MM Contractor Site

Document - Reference:

-

FOR ANCHOR BOLT DIAMETER ≥ 20 MM ---------------------------------------------------------- ±2MM Number :

Company Rev: Scale: Format: Sheet:

- SKEW ----------------------------------------------------------------------------------------------------------- 3MM PER METER Document SA-AMI-000-HDAI-370102

ID : 1 N.T.S A1 001

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF AMIRAL. NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT OF AMIRAL.

You might also like

- Preservation Proceedure (SAMPLE)Document29 pagesPreservation Proceedure (SAMPLE)Hasann Maawia100% (1)

- (PDF) Dwonload Dr. John Chung S New SAT Math: New SAT Math Designed To Get A Perfect Score Full OnlineDocument1 page(PDF) Dwonload Dr. John Chung S New SAT Math: New SAT Math Designed To Get A Perfect Score Full OnlineDoraNo ratings yet

- Introduction To Spectroscopy Pavia 4th Solutions ManualDocument5 pagesIntroduction To Spectroscopy Pavia 4th Solutions Manualسیاہ پوش100% (1)

- AB 036090 001 Joints For Cement Lined Pipe PDFDocument1 pageAB 036090 001 Joints For Cement Lined Pipe PDFfdfazfzNo ratings yet

- Master Drain Drawing From 406 To 512 (Yet To Submit)Document1 pageMaster Drain Drawing From 406 To 512 (Yet To Submit)Anal BiswasNo ratings yet

- C01ADocument1 pageC01AGyayak BhutaNo ratings yet

- 7-65-0404 Rev 4Document1 page7-65-0404 Rev 4rajanjisri2259No ratings yet

- p92-4440 Harness - Chassis Load CNTR CumminsDocument4 pagesp92-4440 Harness - Chassis Load CNTR CumminsDiego Lira100% (1)

- B-H110978004V00 Fa Miscellaneous DetailsDocument1 pageB-H110978004V00 Fa Miscellaneous DetailsAnonymous X3PnFL6No ratings yet

- Notes:-: Structural ConsultantsDocument1 pageNotes:-: Structural ConsultantsHarbhajan SinghNo ratings yet

- Gambar Listrik CilacapDocument10 pagesGambar Listrik CilacapDanang RizkiNo ratings yet

- SRD - 111 - S CWDT 01 02.05.2022Document1 pageSRD - 111 - S CWDT 01 02.05.2022Nishant KarthikeyanNo ratings yet

- P02O274001V - DH Bulk Plant (Gate #15) - Gatehouse - Electrical One Line DiagramDocument1 pageP02O274001V - DH Bulk Plant (Gate #15) - Gatehouse - Electrical One Line DiagramShahed HussainNo ratings yet

- P01O274001V - DH Airport Fuel Tank Farm Gate21GH - Electrical One Line DiagramDocument1 pageP01O274001V - DH Airport Fuel Tank Farm Gate21GH - Electrical One Line DiagramShahed HussainNo ratings yet

- Bato-Cogon Pertcpm (Final)Document1 pageBato-Cogon Pertcpm (Final)MANNY CARAJAYNo ratings yet

- B-8453-CL023 - ASSEMBLY-ModelDocument1 pageB-8453-CL023 - ASSEMBLY-ModelsanusiibrahimNo ratings yet

- Samsung+max909 910 916 929 930 932 (P) 936 938 939 940 941 PDFDocument7 pagesSamsung+max909 910 916 929 930 932 (P) 936 938 939 940 941 PDFSergioNo ratings yet

- Detail A': A B C YDocument1 pageDetail A': A B C Ydan PioquintoNo ratings yet

- Eave Detail @Lean-To Gable End Closure DetailDocument1 pageEave Detail @Lean-To Gable End Closure DetailLUUVANDONG48XFNo ratings yet

- STR-051 Shoring Sections & Details MR. QADHEEBDocument1 pageSTR-051 Shoring Sections & Details MR. QADHEEBamr abdalhNo ratings yet

- B 8453 Cl025 Assembly ModelDocument1 pageB 8453 Cl025 Assembly ModelsanusiibrahimNo ratings yet

- Pre Cast SignedDocument1 pagePre Cast SignedcivilceejiNo ratings yet

- ACM-TSC-VS-MF-GFC-DWG-ST-2001 - Rev 1Document1 pageACM-TSC-VS-MF-GFC-DWG-ST-2001 - Rev 1Aecom IndiaNo ratings yet

- JB0001218985 - After Construction Map - MARKUP - ASBUILTDocument5 pagesJB0001218985 - After Construction Map - MARKUP - ASBUILTJorge Matamoros TingoNo ratings yet

- Finalized Drawings StrutureDocument23 pagesFinalized Drawings StrutureSalin ShresthaNo ratings yet

- SMC Meter Box 810X350X230 Mm-Polycarbonate Sheet R01Document1 pageSMC Meter Box 810X350X230 Mm-Polycarbonate Sheet R01LavanyaNo ratings yet

- Damp Proof Course - Riya ShomeDocument1 pageDamp Proof Course - Riya ShomeSam WilliamNo ratings yet

- Notes:-: Reinforcement Detail Bar ShapeDocument8 pagesNotes:-: Reinforcement Detail Bar ShapeDushyant JadaunNo ratings yet

- Saudi Arabian Oil Company: VA-291301 001 P 0A2 K11 RestrictedDocument1 pageSaudi Arabian Oil Company: VA-291301 001 P 0A2 K11 Restrictedsaleem naheedNo ratings yet

- Meadows Plot LimitsDocument1 pageMeadows Plot LimitsBilal JavaidNo ratings yet

- Ab Elec B126 106Document1 pageAb Elec B126 106arainzada807No ratings yet

- Ns2-Vk02-P0ucb-171651 - CHS Electrical & Control Building - Column Re-Bar Schedul - Fi-2Document1 pageNs2-Vk02-P0ucb-171651 - CHS Electrical & Control Building - Column Re-Bar Schedul - Fi-2Doan Ngoc DucNo ratings yet

- Proposed Shopping Complex in Chandur Municipality.: Column & Footing (2/2) Reinforcement DetailsDocument1 pageProposed Shopping Complex in Chandur Municipality.: Column & Footing (2/2) Reinforcement Detailsaasifmusthafa.shaikNo ratings yet

- Madhavaram radiance-GA-REV-1Document1 pageMadhavaram radiance-GA-REV-1suhailNo ratings yet

- GDC Layout Updated 14.06.2023Document1 pageGDC Layout Updated 14.06.2023PradneshNo ratings yet

- Samsung MAX-910 Service ManualDocument59 pagesSamsung MAX-910 Service ManualJasmine VaaltynNo ratings yet

- Start Fuel Station Page 2Document1 pageStart Fuel Station Page 2EDGARDO JR. DIGALNo ratings yet

- LM Tower - FDN - DWG - Pgcil - 271023Document1 pageLM Tower - FDN - DWG - Pgcil - 271023SECURE STRUCTURENo ratings yet

- UNit Transformer GA DrawingDocument3 pagesUNit Transformer GA DrawingdineshNo ratings yet

- Hdpe 81aDocument1 pageHdpe 81aAli RaheemNo ratings yet

- Second & Upto Terrace Floor LVL (+9.45m.) Top of Grade Slab Both Ways 150 Thk. GRADE SLAB Level Match With Existing Site LVLDocument1 pageSecond & Upto Terrace Floor LVL (+9.45m.) Top of Grade Slab Both Ways 150 Thk. GRADE SLAB Level Match With Existing Site LVLSarvang PandyaNo ratings yet

- Ci TP 01 11 001Document1 pageCi TP 01 11 001harihfclNo ratings yet

- Arnes Fusibles BateriaDocument1 pageArnes Fusibles Bateriajohn guzmanNo ratings yet

- TSL AcmvDocument11 pagesTSL AcmvTrần ChâuNo ratings yet

- Sp3 MB A WPF Det - Typ 007 (Roof)Document1 pageSp3 MB A WPF Det - Typ 007 (Roof)Renaldo BunaidiNo ratings yet

- Ajv DPW 10 525 CL DWG 0695 03 R03Document1 pageAjv DPW 10 525 CL DWG 0695 03 R03sivagnanamNo ratings yet

- SH 1Document1 pageSH 1sbjamdadeNo ratings yet

- Close 20-100 Full WDDocument13 pagesClose 20-100 Full WDNurSyuhada ANo ratings yet

- Construction Drawing: All Installation Detail That Not Stated in This Drawing Are Complies With Specifications DetailDocument1 pageConstruction Drawing: All Installation Detail That Not Stated in This Drawing Are Complies With Specifications DetailrajavelNo ratings yet

- J-DMS: Project HarmonyDocument1 pageJ-DMS: Project HarmonyMary DenizeNo ratings yet

- p92-4441 Harness - Chassis Load CNTR MXDocument4 pagesp92-4441 Harness - Chassis Load CNTR MXDiego Lira100% (1)

- ANNEX C. Storey BLK Classroom Structural and Architectural DrawingsDocument6 pagesANNEX C. Storey BLK Classroom Structural and Architectural DrawingsLaki ENNo ratings yet

- 5000 Key P 7013-9020262o0p020200000 3 Section Aa: - 5500 - Carriagewy Gtheawse Oned. Only Ton Esons SeloedDocument2 pages5000 Key P 7013-9020262o0p020200000 3 Section Aa: - 5500 - Carriagewy Gtheawse Oned. Only Ton Esons SeloedAkemi HarutoNo ratings yet

- VBQ 748 Thimmaiah House Binder 230209Document9 pagesVBQ 748 Thimmaiah House Binder 230209shivumtechNo ratings yet

- Ns2-Vk02-P0ucb-171650 - CHS Electrical & Control Building - Foundation Re-Bar Schedule - Fi-2Document1 pageNs2-Vk02-P0ucb-171650 - CHS Electrical & Control Building - Foundation Re-Bar Schedule - Fi-2Doan Ngoc DucNo ratings yet

- Single Dead End, Terminal Pole, Dead End Riser Pole: Saudi Arabian Oil CompanyDocument1 pageSingle Dead End, Terminal Pole, Dead End Riser Pole: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- Service Installation Pole Mount (Shown) : Notes: Grounding SystemDocument1 pageService Installation Pole Mount (Shown) : Notes: Grounding SystemEnrique Hdez. E.No ratings yet

- Harn - Allison 4th Gen Ext P92-3017 - 01: DWG SizeDocument1 pageHarn - Allison 4th Gen Ext P92-3017 - 01: DWG SizeMohanad MHPSNo ratings yet

- North: OB-1 OB-2 OB-1a OB-1bDocument1 pageNorth: OB-1 OB-2 OB-1a OB-1bDareen BaredNo ratings yet

- ARC-MSMI-SDW-AR-30003-Mess Hall SectionDocument1 pageARC-MSMI-SDW-AR-30003-Mess Hall SectionmsmetalstabukNo ratings yet

- 66 SCD 0014 ADocument1 page66 SCD 0014 AMbalekelwa MpembeNo ratings yet

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Affidavit of DesistanceDocument4 pagesAffidavit of DesistanceRaymond RainMan DizonNo ratings yet

- Coping Strategies, Optimism, and Life SatisfactionDocument12 pagesCoping Strategies, Optimism, and Life SatisfactionNurulAtiqahAbRajiNo ratings yet

- "The Pedestrian" By: Rey BradburyDocument7 pages"The Pedestrian" By: Rey BradburyGabBragatNo ratings yet

- Bolt Length TableDocument16 pagesBolt Length TablePrasanta Kumar BeheraNo ratings yet

- PGM List R1 - 05.04.2018Document58 pagesPGM List R1 - 05.04.2018Shubham Shinde100% (1)

- TextsDocument10 pagesTextsapi-446884620No ratings yet

- Math in Focus 3B WorksheetDocument6 pagesMath in Focus 3B WorksheetBobbili PooliNo ratings yet

- Coin FlipDocument10 pagesCoin Flip林丽莹No ratings yet

- T7350 Installation InstructionsDocument12 pagesT7350 Installation InstructionsAmy ThompsonNo ratings yet

- The Word Wall: Chants and Cheers ActivitiesDocument5 pagesThe Word Wall: Chants and Cheers Activitieseva.bensonNo ratings yet

- En PL Da220c5300 5 (8) 080104 JDocument36 pagesEn PL Da220c5300 5 (8) 080104 Jluisleao1982No ratings yet

- Ferrari On FroomeDocument2 pagesFerrari On FroomeRaceRadioNo ratings yet

- 536805502401 (1)Document30 pages536805502401 (1)kedarkNo ratings yet

- Requirements Analysis - SPMDocument11 pagesRequirements Analysis - SPMantonyNo ratings yet

- Pinelands National ReserveDocument2 pagesPinelands National ReservesallyNo ratings yet

- The Alexander Technique and Flute PlayingDocument7 pagesThe Alexander Technique and Flute PlayingCarlos Andres CarpizoNo ratings yet

- CH 11Document91 pagesCH 11Putri AsmeliaNo ratings yet

- CirclesDocument54 pagesCirclestrishaNo ratings yet

- Sodium Sulfite: Product Safety SummaryDocument5 pagesSodium Sulfite: Product Safety SummaryMannar1No ratings yet

- CirclesDocument15 pagesCirclesJustine ReanNo ratings yet

- 12 Architecture & Methodology ENDocument36 pages12 Architecture & Methodology ENYash BhatnagarNo ratings yet

- Lifting Plan - PDF - Crane (Machine) - Mechanical EngineeringDocument25 pagesLifting Plan - PDF - Crane (Machine) - Mechanical EngineeringAdonis CaraanNo ratings yet

- Rose Water OintmentDocument1 pageRose Water OintmentThomas Niccolo Filamor ReyesNo ratings yet

- Individual Career Plan: DIRECTIONS: Answer The Following Questions in Paragraph Form (3-4 Sentences) Per QuestionDocument2 pagesIndividual Career Plan: DIRECTIONS: Answer The Following Questions in Paragraph Form (3-4 Sentences) Per Questionapi-583039598No ratings yet

- Clinical Laboratory of San Bernardino, IncDocument40 pagesClinical Laboratory of San Bernardino, Inckharberson1613No ratings yet

- AN1184 Application Note: Bu808Dfi in The Horizontal Deflection StageDocument13 pagesAN1184 Application Note: Bu808Dfi in The Horizontal Deflection StagetrmnmyNo ratings yet

- Breathing TowelDocument8 pagesBreathing TowelIqbal Sodiq MaltaNo ratings yet