Professional Documents

Culture Documents

7.5T X 10.5M Span Dgeot Crane

7.5T X 10.5M Span Dgeot Crane

Uploaded by

Vinod Kumar0 ratings0% found this document useful (0 votes)

11 views69 pages7.5T X 10.5M SPAN DGEOT CRANE

Original Title

7.5T X 10.5M SPAN DGEOT CRANE

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document7.5T X 10.5M SPAN DGEOT CRANE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

11 views69 pages7.5T X 10.5M Span Dgeot Crane

7.5T X 10.5M Span Dgeot Crane

Uploaded by

Vinod Kumar7.5T X 10.5M SPAN DGEOT CRANE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 69

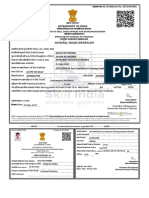

EDDYCRANES ENGINEERS PVT. LTD.

FINAL DOCUMENTS

FOR 7.5T x 10.5M SPAN DGEOT CRANE

INDEX

Page 1/1

CLIENT: VEDANTA ALUMINA LTD.- LANJIGARH

PROJECT: 1.4MMTPA ALUMINA REFINERY LAJIGARH

VAL P.O. NO, : VALILANJ/ C & H/45 dt. 14/02/2005

EL JOB NO.: 6369

EDDYCRANES WORK ORDER NO.: 0505E

EDDYCRANES CRANE SR. NO.: 05/0547

7.5Tx10.5M. SPAN EOT CRANE

SR,NO. JORG. NO. [REVISION DESCRIPTION REMARK

oi Jososeo1) 2 |G.A.FOR7.STx 10.5M SPAN DGEOT CRANE

02 Jos0sE-08] 0 |CRAB ASSEMBLY

03 |osose-o9] 0 |LTDRIVE ASSEMBLY

04 josose-o7) 0 {DATASHEET

05 |0505£.02) 0 — |STRUCTURAL CALCULATIONS

06 |0s05€-03] 1 — |MOTOR SELECTION CALCULATIONS

07 }05056-04] 0 — |BRAKE SELECTION CALCULATIONS

os | 5056-50] 2 [WIRING DIAGRAM

09 | 505 E51 2 |CABLE SCHEDULE

40 | 5056-83] 2 |PUSHBUTTONGA

41 | s05E-60) 2 — |SINGLE LINE DIAGRAM

2 | — 0 [MOTOR DATA SHEET

3 | — — _|TEST CERTIFICATES

4

MANUAL FOR EOT CRANE

SHEET : 1

CLIENT: VEDANTA ALUMINA LTD.

CONSULTANT: ENGINEERS INDIA LTD.

PROJECT: 1.4 MMTPA ALUMINA REFINERY,

LANJIGARH, ORISSA.

EIL JOB NO.: 6369

[contRouten copy

I ——————— FIRST ANGLE [SCALE [DRAWN [Abhijit

SEs So) - eeeee

Hes — APPROVED |

ENGINEERS PVT. LTD. [AU DIMENSIONS ARE IN MM. | DATE. 28/05/2005

>

CAUTION

THIS DRAWING 1S THE

PROPERTY OF M/s.

EDDYCRANES ENGINEERS

PVT. LID. PUNE 411019

AND SHALL NOT SE USED

WITHOUT THEIR EXPRESS.

WRITTEN PERMISSION

IN ANY FORM,

TITLE:

DATA SHEET FOR 7.5x10.5M/7.5Tx8.5M

SPAN EOT CRANE

Doc Ni

0505E/F-07

REVISION

0

DOCUMENT No.

Sars saeee RISA ito DATA SHEET 6368.00-HH4.D8-4900, Rev. 0

eae age 16

DATA SHEET

FOR

EOT CRANES

0 weonaets issueo WHPR BEE ie VR

Pa i

A 0112-2008 ISSUED WITH Har ani.

‘Approved by |

Re Date Purpose oe

‘Copyright El. — Al ighis reserved

mot Wo, ER 1644-1824 Rew 1

ceenee Dar. Na! 6505 E/e~ ove

SSH TET GB ENGINEERS eee DOCUMENT No.

segneis ORDA Uti DATASHEET ¢999.00-1H-08.4900 Rov.0

Page 20f0

Project : Alumina Refinery, Lanjigarh ++ Giient Stetite Industies

Job No.: 6369 Item EOT Cranes

Vendor: Eddycrane Engineers Quantiy 7: 30

4.0 PURCHASER'S REQUIREMENTS

141 Location : Comp. fw.

42° Quantity

1.3. Main Hoist capacity, Metric Tons

14 Span, mi

1.5. Type of cranc (Single girder/Déuble girder)

4.7- Class of duty (as por IS 807 2.3177)

1.8 Height of it (Main hoist), m

1.8" . Gperating speeds (loaded)

2)Main hoist (MH) mimi,

b)Bridge travel (LT), main,

JTrolley travel (CT), mémin.

4} Creep for hoist, m/min

1.10 Acceleration om sq. see

2) Cross travel

b) Long travel

4.44 Bay length (rm)

412 Location (Indoor/Outdoor)

1.43. Max bridgé-defiections

4.44 Type of controt (eabin/Pendant)

7 <= Indoors

Noto ekceed Spanito0d— fe

Pendant push buttoi type’moving independent of cra.”

along the full length of Bridge on a éeparaté os

track.

10 6 8

Eddy cranes Engineers’ Pe Ud tune

KEC/ BeL/ ALSToM/ Ca A

As Fe ected SpeclPeations,

SATL 5c

steno desig oaty Finds [raco/ ews abl

EE laren. tasnatia] Senodoya ~xgins

oe wae Mya ede

2900 4 $000

ae

BA00 /

1800 4 1800

3300 Ye 3500

(36 Yo \20

12936 ZL 620

GOO Y 6080

7s00 J Hoo

6400 7 6000

Pale Weided ex type

620X240

Tw

Is, 2062.

12.00 / 900

‘ConyrgnT ETC AT aghtevaeerved

cute. rece nes ve

Sthe. Q6CSC/E et hy

©

Sailer’, iINEERS,

eae AMATO

DOCUMENT No.

DATA SHEET 6369-00-HH-DS-4800 Rev. 0

TCS OME pope

. 2) Type of construction Fabsicated frm steel plates

b) Material Es t206u

c) Width 5 Mine SO mm.

@) Length Fer Fu lengty of Span,

€) Location On the Gide “of diving girder,

1) Handrail Provided

g) Matiress material chequered piaté,

i) Raits oliey bridge

a) Typeandsize Flat bottom : 30 thy%d, fires sa, cre kg/m)

©) Length Bow RAN trowel oF eteyy Ry Pull ay lenaty

<} Material

8), Buffer treme type Ban ateel

€) Fixing details a

ivy Wnt Bates wotey BOS gs

8 Nobo one SEES cance

lumber : i. fn

3) ; pres

3) Diameter 40/45 vm

vy) Bearings for whee! axles peer bridge

a) Type and make Ant Friction, Riley Beadiay - aa

b) Ske 22208 x) [st ena EP ORSINMT/ DTH copy

c) Number E Too Mos. per cibeel!

¢) Material Beading stect

©) Lubrication Grease.

f) Type of dust sealing Bearing euclag caved 5

vi) Wheels folloy bridge

a) Type Downe “Png eal

>) Size Gm i

@)_ Number per end carriage ee {sown

@) Hardiness No. (BHN) "400-850

e) Material CSS Mats

1) Diameter JG 7 b2e0mm

g) Whee! base 1300 mr 3660 mm

vil) Butfers trolley bridge

a) Type of construction Fabricated Copying Loaded)

b) Location On rte y On End Carmiog &

) Materist speog s

d) Number : fH Fout

©) Type of stops to engage the buffers End stoppais

vil) Rail Sweep trolley 1 oridge

2) Type of construction b Fabateoted | :

) Location an frlley y 00 end camiage,

©) Material re 11060,

x) End Truck :

) 2) Type Fabricated fry stect plates / sentions ‘

b) Size is a7oxL4o

©) Number Wo

d) Material 3 600

©) Weight kg

a length ALoo

242 Operators Cabinet

i) Cab. Perticulars 2

2). Type of construction

b) size 2

©) Fan type, size and make

dd) ttumination

ii) Operator's Seat

a) Type of seat

b) Location

iil) Warning Gong

a) Type and make

b) Location

Format No. BIL 104-1804 Rew. 7

Cop EAH eave

PAdwcre res Dee te. A505 Fire B/pa

{

eSiGtere, DOCUMENT No

s@urfelgies DATA SHEET 6366-00-HH-D5-4900 Rev. 0

See Page 5 of 6

iv) Ledder from cab to Bridge +

2) Fiting : ee

b) Type of material .

v) Control Panel

2) Location

5) Location of emergency switches

243 Pendant : le

Type {Radic Renate Cntul/Mobileintepecent of-nlley 0 seule

Furnish list of Controls/buttons ‘Holst Lowen, pri i pits, fi

244 Bridge Div Machinery and Trolley orive aChineny cong MA ae EE pee SNE geo

2) Type of Bridge Drive Unit t EDrreet clive teeough melo 7 beake “and .

b) Type of Foley Divo Unit 1 ateduction a anche

©) Material a

} eal 5 PAS perv cl. G00 § 3.0% of ETL

i) Shafts ecifieor e. 6-4g— S

iil) Other components 1 seeifeetin we. 6-42-0000 .

@) Lubricant Particulars 2 ol /Grease

@), Guards and Enclosures provided as necesseny, 2

ae Anifeiction Rolled bearas /stP/PAG/ REE A/ama/za-rA/i Remy

i) size 6 alesign

i) umber eee eer

248 Hoisting Mechanism Main hoist

j) Materials ee

2) Gear As per ch No. Ger of ETL Speejficotioy

6) Shat : No. 6~4@~ Ooor ,

©) Drums ASTI A 106 Grade @,

d) Sheaves : Cast S+eel

ii) Winding Drum Type & Size (da x length) F320 mm x 1050 ny

ii) Ratio of winding drums (diameter to wire rope}: wining

iv) Bearing : .

2) Type and make ‘Anifieien Reor beasies KEt/ene/ssee abe /ama/ia/ sama

ize :

6) Number PAs pe¥ design

¥) Hoist Rope

2) Type Revie Ruve Cove of pest plough steel

b) DiameteriNo. of strands tAnn/oxage

oc}. Number of fats : >

6) Safe capacity tonnesisq.cm 18 Tig

24.6 Particulars of Hook Block Main Hoist i

a) Type of Hook Point Nok ity shank type,

b) Material of Hooke Fotged Steel

©) Type and size of hearing at hook support iq — S120

0) Safety latches provided Sec st

247 Controls ¢ :

a) Hoisting i seas

i) Type of control Radio Remere CGwbre) | Frm Arortniaghy motile pendant 22

il) Number of speeds : Toso

>) Lowering i

Type of contol Radio Reamsbe Conbel ym -Rartateeagh mibie ferent A.A

i) Number of speeds : Tee eee

©) Bridge Travet 7 a} From Rey maeibe pendant He

@ Trokytoa fadie Roscste (abn! : ae fs

@) Creep speed : A

i) Anrangetment during lowering —Tineugh VV FE pyive

i) Arrangement during hoisting Tag VVVE Drive.

248 Limit Switen Long Travel | Trolley travel

2) TypelMake lever female ewer ty6e /€ Ineg [ons

8) Construction Fav ced

} Number one 5

tone tm ent cornioge on Rheufjirder’

©) Voliage and current rating ’isv ae.

Formal No, EIL 1647-1024

7 ang Ei AAG TRCN

Feldyrranes Dee Wee cec ¢ tc

8a gy paneer

249

+ 2.4.40

2.4.11

2412

2.4.13

2.4.44

2415

2.4.16

INDIA LIMITED.

iil) Hoist fait switen

DATA SHEET

DOCUMENT No.

6269-D0-HH-DS-4900 Rev. 0

Page 6016

a) Over hoist limit switch type/make: Rolery Limit sestich 7 Clmag / SHS

b) imit switch construction: Fate cout €e}

3 tit switch locaton On End Can

©} Unéerloeing it swith ypetmate: Relay limit Santee 7 Etay /equg

©) Under lowering lint swt constuction Fate ca ee

4) Under lowering mit switch location: tn end cacdoge.

9) Back up limit switch type/makefconstruction:

umination fitting on bridge

i) Number

i) Type

i) Portable hand lamp with wiring

Grrovity ec. ltmtt suatich

Fours

260 Wat, HOV lamps,

iv) Supply of transformers end ather Vue, Ao watts,

accessories as necessary Pao ted

i) Runway Rail ay oy

Type Flot bo m Pe Material 4

Sue: los Mes/ud (0 Ke/rs) Manufocurer : Rall Stee!

All fitings (including fish plates & bolls) and fixtures O/ S ATL

fy Runway Rail end stops: -

Type: Spying buffer type Number 4

Material: Soca, Leet Construction + Patreicad ecf,

toters wing steet, arigo tava Pov rotey tovel

1) Number ane

i) Type Sq,tage

it) Manufacturer

iv) Volage, phase, frequency Ber (FECL cal / ALE tom

vy) kw ‘F 45° Bo Ha

{) Temp. rise over 50° ambient Ody

vi) insulation cas =

Vil) Type of enclosure

ix). Rated speed (pm) faeae

b) Heist Motors Mom hoist

i) Number one.

‘Type by ge

i) Menutecturer BEL / ALSTOM Kee /caL. :

iv) Voltage, phase, frequency AIS, 3 Phase, So tte ,

vy) KW SE

vi) Temp. rise aver 50°C ambient

‘ip Insulation cass 7

YW Type ol ose ee

1) Degree of protection

Brakes ud

) Trolley rtoge

2) Type and number EMT /

b) Mateisize eee

€) Braking capacty offulloadtonue : yey 2/SNF~ ERT (oe

4) Designed distance for complete Witty (*% ef Speed

stopping from full speed, mm

Fioist Machinery Brake

a) Type, number

b) Make/Size

ii)

Main hoist

ERNTA+ DCEM/]

2 Elmg/Ens / ENT+dCEM —160

) Braking capacity as % y

of full load torque 200%.

Gear boxes Ratio Type Rating SF.

a) oT Verticat 1. AS pee sean

Be herent ay & 1514000

e edzan’

3) AH ees ,

Load indication sign on Crane Bridge

Extent end type of Paicting on equipment:

Before shipment (as per specs.)

‘Shop tests conform to requirement of specification

Format No, EI 1041-1824 Rew. 7

a

TAL wame plate painted “orth Crove Capacity

As poy specificetens,

Yes

Copyright EL Alright reserved

dyrrnnes a NA! OEE /e—At/ PA

EDDYCRANES ENGINEERS PVT. LTD. Page 1/4

GIRDER SELECTION CALCULATIONS FOR

7.5Tx10.5M. SPAN CLASS II(M5), INDOOR DUTY EOT CRANE

CLIENT: VEDANTA ALUMINA LTD DOC NO: 0505E-02

PROJECT: 1.4 MMTPA ALUMINA REFINERY, LANJIGARH, ORISSA REV:0

Double plate box type girders , welded construction is adopted

1 a8 shown below

‘The selected box section has

the following properties

8

be = 61695.7 em J

Zxxtop = 1940.12 em’3 Teer

woos 10363.49 ems

wy = 863.62 m3 «620

‘ Ara = 1128 em"2

yy 9.59 em

Wy = 76.64

Wo = 30.63 =

kK 0

Vr <= 300 The above ratios are within the limits

m= 60

(As per C1.7.3.283 , IS: 807 )

‘The drive girder , which is loaded more than idler girder , is designed

for the Ioading and the same section is used for the idler girder also,

Weight of girder 31.177

[Weight of platform*LT Shafting :1.39T

Span - 1050 em

Weight of LT machinory - 0387

Weight of platform+LT Shafting(if present) 13s T

Weight of girder with sail - 1.1? Tmax, each

Weight of electricals 0sT

Weight of Cebin NA

Bending moment duc to LT machinery wt= BM1 (Single Drive)

a 0.35 x 1050/4

- glia Lem

(Plann Shafts ~ POD ~ (Mason Wes Spon“)

lass em

Page 214

Bending Moment due to Self W., = BM3 = (Self Wtx Span /8)

- 153.563 Tem

Bending Moment duc to Wt. of Flectricals = BM¢ = (Electricals Wex 3 m x (Span - 3m)/Span) )

= 107.143 Tem

Bending Moment due to Cabin We = BMS @ (Cabin Wtx I m x ((Span ~ ImySpan) )

- 0 Term

Hence, total Dead load BM = MD = BMI+BM2+BM34EM4+BMS

- 529.769 Tem

Load to be lifted = 18T

Weight of crab including hook block and wirerope 347

Impact factor as per IS 807 13

Load under impact = 9957

Total live load with impact . 13.15 T

‘Total live load without impact = 109T

CT whee! load of laden trolley with impact - 3.288 T

CT wheel load of laden trolley without impact = 2.728 T

‘ML: Max, Bending moment due to live load with impact

MI = (CT wheel foad with impact x (Span - 1/2 xCrab wheel base)? }/2 x Span

= 1519.095 Tem

M2: Max. Bending moment due to live load without impact :

M2 = (CT wheel load without impact x (Span - 1/2 xCrab wheel base? )/2 x Span

= 1258.982 Tem

‘The combined bending moment stress is calculated by the following two

combinations ,and the greater value must be less than the permissible

bending stress .

Case (1) Sum of maximum stress due to {1} Dead load

(2} Live load with impect

Case (2) Sum of maximum stress due to {1} Dead load

{2} Live load without impact

{3} Lateral force

Case (1) Maximum Bending suess on top = (MD/Zex top) + (MUZxx top

- 1.0561 Tent?

Maximum Bending stress on bottom = (oD /Zx bot +. (MI/Z3x bot

- 1.0561 Ten?

Case (2) Max. Bending stress. on top = x top) + (M2/Zse« top) + (HEEx (MD*M2VZwy)

= 1.0255 ‘emé

rom = (MZ bat)

Z 1.0255 Tem?

Page 3/4

Allowable Stresses

(As per IS 890 C1. 6.2.4) ey

(1) Compressive Siress : Feb = kI(X +12. ) x (€2/el)

Effective Girder lea 0.7 x 1050

= 735 cm

Radius of gyration about Y axis in em ryy = 9.59

Hence, slendemess ratio, Uryy = 76.64

Since the ends of compression flanges are restrained against lateral

bending by provision of bearing stifners provided at the ends

(As per I8:800 C1. 6.6)

‘Y as defined in 18:800 = (26.5 x 10°S) ((Wryy)2)

= 451.164 MPa

: YxEle1 (LT 205s

[20 (yD) T

DIT as defined in 18:800

795

Hence, X

= 461.527

As flanges are not curtailed, the ratio of total area of both flanges at the

point of least bending moment to the corresponding arca atthe point of greatest

bending moment is 1

KI as defined in IS:800 : 1

w - lyy of compression flange

Iyy of (Compression flange + tension flange)

7 Fe 921.6

Si6 + 921.6

- Os

12 as defined in 18:800 °

col as defined in 18:800 = 318

2 as defined in 18:800 318

Critical stress as per 1S:800 in Mpa = Feb =I * (X+12"Y) * (e2/c1)

= 461.53

Permissible compression stress (ky/em)

she = 0.66xFebxfy «10.194

(eran | fan

1306.79 keen?

Page 44

Allowable stress = duty factors. sbe

= 1241451 kgm

‘Max. induced stress 1056.1 kgfem?

Induced compressive stress (1056.1 kg/cm) is less than allowable stress (1241.451 kg/em®)

(U) Tensile Stress

Allowable bending stress in tension

(As per Cl. 6.2.1 of IS:800)

= fyx 066

fy = 250 MPa = 2550 ke/em?

0.6 x 2550x 0.95

Allowable tension stress

1598.9 kyem"2

‘Max. induced stress 1056.1 kg/em?

Induced stress in tension (1056.1 kg/cm) is less than allowable stress (1598.85 kg/en)

OK from stress consideration

JER DEFLECTION CALCULATION

As per 1S:807,Clause 7.4.1, the deflection of girder is found by

considering crab + SWL (without impact) placed at the center of the

span.

Deflection inimim= _pa( 38°2- da")

24BLix

~ 0.9921 em

9.921 mam

where,

p= CT Wheel load without impact = 2.725T

Sis Span = 1050 em

E = Young's Modulus = 2.1x 10% kg per em"2.

B is CT Wheel base = 130 em

By2 = 460

Te = 61695.7 em

Allowable deflection = ‘Span/1000

= 10.5 mm

‘Actual deflection (9.921) is less than allowable deflection (10.5)

OK from deflection consideration

EDDYCRANES ENGINEERS PVT. LTD.” Page 1/3

MOTOR SELECTION CALCULATIONS FOR

7.5Tx10.5M. SPAN CLASS II(MS), INDOOR DUTY EOT CRANE

CLIENT: VEDANTA ALUMINA LTD DOC NO: 0505E-03

PROJECT: 1.4 MMTPA ALUMINA REFINERY, LANJIGARH, ORISSA REV: 1

)) MAIN HOIST:

KW= Mv Gv Caf x 1

612E Camb

Where

M= Mass of rated load on the hook plus

weight of the hook block and the wire rope in tonnes (7.5+0.15)

Specified hoisting speed in M/min,

service factor for vertical motion depending on type of motor

Duty factor as defined in 7.4.3,

Combined efficiency of gears and sheaves

Camb = Dearating factor of ambient tomp. as per table 208

kw R2xO.67K1.5 x 1

6.12%0.848 095

23m

SELECTED MOTOR

TYPE — SQCAGE Kw 3.7 (6.0 HP)

CDF 40% POLES 6

ary, 4 NO. MAKE BBLIKECICGLALSTOM

oA FRAME SIZE 112M

NOTE

1, Motor HP calculation conforms to 1S 3177.

2, Gears efficiency : (0.95) ‘n

where 0.95 = effcieney per stage

and n number of stages = 3

3, Sheaves effiecency : (0.99) * ( (FI2)-1 )

where 0.99 : efficiency per sheave

F umber of fais = 4

Page 2/3

ll) CROSS TRAVEL:

KW= MVS Caf x(F+ 11004)

eii7T 981 E

M = Mass of trolley plus mass of max. rated load in tonnes(3.4*7.5)

\V= Specified free running speed t/min.

S = Service factor

Caf = Duty factor as defined in 7.4.3

T= Torque factor

F = Overall friction factor

a= Acceleration as given

E = Mechanical efficiency of gearing

KW = 10.9x10x1.06x1.25_x (8+ _1100x7)

6117x168 281%0.902

KW= 0.24

SELECTED MOTOR

TYPE SQCAGE KW 0.37 (0.5 HP)

COF 40% POLES 6

ary. 1NO. MAKE BBLIKECICGLIALSTOM

Za FRAME SIZE 77

NOTE

1, Motor HP calcualation conforms to IS 3177.

2. Gears efficiency : (0.95) *n

where 0.95 : efficiency per stage

and a number of stages = 2

I) LONG TRAVEL:

Kw= MVSCat x(F* __ 1100 a)

6ti7T 981 E

M = Mass of crane plus mass of max. rated load in tonnes (8.9+7.5)

V = Specified free running speed M/min.

S = Service factor

Cat = Duty factor as defined in 7.4.3

Torque factor

F = Overall friction factor

Acceleration as given

Mechanical efficiency of gearing

KW 16.4x20x1x1.25 x (8+ _1100x9)

erirxt.6 381x0.902

Kw= 08

SELECTED MOTOR

TYPE — SQCAGE KW

COF 40% POLES

ary. 1NO. MAKE

Ls FRAME SIZE

NOTE

1. Motor HP calcvalation conforms to IS 3177.

2. Gears efficiency : (0.95) ‘n

where 0.95 : efficiency per stage

Page 3/3

4.4 (4.5 HP)

8

BBLIKECICGLIALSTOM

901,

and number of stages = 2

EDDYCRANES ENGINEERS PVT. LTD. Page 1/2

BRAKE SELECTION CALCULATIONS FOR

7.STx10.5M. SPAN CLASS IK(M5), INDOOR DUTY EOT CRANE

CLIENT: VEDANTA ALUMINA LTD. DOC NO: 0505-04

PROJECT: 1.4 MMTPA ALUMINA REFINERY, LANJIGARH, ORISSA REV:0

HOIST:

KW x 975

RATED RPM OF MOTOR

BRAKING TORQUE REQUIRED

3at_ x 975 3.16

360

FINAL BRAKING TORQUE 200% OF ABOVE VALUE

= 3.16 x 2

= 6.32 KG-M

SELECTED BRAKE

TYPE EHT+DCEM

KGM 2917.6

ary 441 NO

MAKE E'MAG/SNS

OM. 160 MM

4) CROSS TRAVEL:

BRAKING TORQUE REQUIRED

FINAL BRAKING TORQUE

SELECTED BRAKE

TYPE

KGM

ary

MAKE

DIA.

ll) LONG TRAVEL:

BRAKING TORQUE REQUIRED

FINAL BRAKING TORQUE

‘SELECTED BRAKE

TYPE

KG-M

ary

MAKE

DIA.

:EHT

6

4 NO

: E'MAG/SNS

100 MM

EMT

6

4NO.

E'MAG/SNS

100 MM

Page 2/2

KW x 975

[RATED RPI OF MOTOR

0.24 x 975 = 0.24

PEE Seo

130% OF ABOVE VALUE

0.24 x 13

031 KGM

KW x 975

TED RPM OF MOTOR

og x 975 = 0.81

30

130% OF ABOVE VALUE

0.81 x 13

1.05 KG-M

CLIENT: VENANTA ALUMINA LTD

PROJECT: 1.4 MM TPA ALUMINA REFINERY

LANJIGARH, ORISSA.

FIRST ANGLE] SCALE [DRAWN [35

nS | 0 | - este —

=r APPROVED| @ELE

ENGINEERS PVT. LTD. [ACL DIMENSIONS ARE IN M.M.|DATE 14/08/05

CAUTION

THIS DRAWING IS THE

PROPERTY OF M/s.

EDDYCRANES ENGINEERS

PVT. LTD. PUNE 411019

AND SHALL NOT BE USED

WITHOUT THEIR EXPRESS

WRITTEN PERMISSION

IN_ANY FORM,

TITLE:

WIRING DIA OF 7.5Tx10.5m SPAN

EOT CRANE

DRAWING NO:

O505E-50

DOCUMENT NO:

DGN-FR-O3,

5

Rev-0 dt-01/03/0:

SH.NO,

1/6

REV

02

AS BUILT|

“CLIENT: VEDANTA ALUMINA LTD wey. SUEETNO:2016

"TITLE: OOM & WIRING DIAGRAM, "

FORTS EOT CRANE sour

DRG. RO 0805 1-50

PROTECTIVE PANEL.

BQUIENEN THCRTTONS

Sah Fi Ua EAE as Sap ST

THE RS OAT

PSR WSIS OR

Ta Ceaser STA TOV Sana

Fas Tag TK

Fa DOA RTE

TC FE FRE TOA TA TST

aT Tre IST

Fray SV ALTO Secondy Do TOV,

ial Terao BOOVR

Taig AV, oO, SeenON

pa RTO

Brgy Sap Eat

Tab Tipe Masvcon lsd ORTOVAT.

Saha pe Rab Bare RTO AC

Taig Fare Wi m

aI ag ETF RTN

‘ORTOFF LT Cant se Cara apo

TST

FLT CONTR ATR OAT TODS

BELT pa

‘ia eve Rely TOV

RT OTEATIOVET

MAIN WOIsT

TST CAGES

WH COPIOOS I

eee Ba

Ta RS TSE TT

REX, Shee Nada

RG. NO: 0808 E89 0

Fae Cee RATT TE, TTR

SSSI

RRS ITI Sena

“is TITER om

Tee REA TL [Sama

RAC SE ROA THE SSO Ieee

TS TT TER eRe

1b TBS [pean

To BOER BRC brome

cross TRAVERSE

THREES CE OTN TRS TE

‘Ceci TERT eit

Tine ag BOR TOR ise Oa

[pa aby Ree SOOTALTTOVAL

end aay, TST

TREE, STAY SSSA RT,

LONG TRAVEL,

aa a TT

oir TSAATOV ea

TRC Fae Tag A, TOR TSE

a ae BY RR ATL TOA

mye

TT TY, Te way TT SAI.

$0/£0/10-18 o~

AN3WC90q] :0N ONIMWEG

TANVd FAILDILOYd 4O “VIG ON!

“OMLNOD

¥BMOd 9 3L0N

HOO doHs ty

(no)opxpsutug —_|

978 “ON

a3Ms OL

SI¥INOD GA

‘OY ME~/+ HOS

%O1-/+'AS Lp 'ude

ONINOONI

aA u 2

al

st

a

to

a

I

y

TaN YZ 9 23

tea} 1

IA

pes 'Y

ro

Ache

aA’

S44

9/S 133s

on

liaina sv nz

$0/£0/t0-1P_ 0-A8y ined 1 zsh

zo [9/5 g0-u4-nod| OS~3SOSO) crise auvag "14300 —

“nzu__|isaus| _:0N _LNaHN90G} *ON ONiMYea] —_IO¥INOD ye, OEE HEL

STVNINSBL (nojopxpswwg:z

AINDUID _YaMOd

“LORISIOH 40 “VI ONIMIM ‘UU

UaMOd @ ALON

BOLON “19 nei=ecr

apxpyinon han

Fi

ise

aavaa 13 pug

(nojopepswug:Z:

sie—s18)

"yee awzT

3HOHO 9a

Zi-szb

gor G4} ~

$ ezi-zet

lol!

J arse |

El>oxo Bee

yg [[Jres—zon

601-201

one an

sos-rog.

izt-6LL

g- beg

soe- 108

(nojopxpsunigz

9/9°0N

L33HS OL

>

S/W HS NOUS

zinuuad 9

laine sv

$0/20/L0-1P O~Aey

zo [9/9 $0-us-Noa] OS—3SOSO) syns:

‘nay |LaaHs SON _LN3NN90G| ON ONIMWYa] —TO¥NOD gt

SINR

“LINDYID TONLNOD “L°1/1'9 YaNOd Bt LON

2 YMOd “1'1 4O “Vid ONIIM

nun]

ort

Bs

or ow

CI

Zar tor zor toe

bor, zor, woe zoe

[=

aod TOUINOD

310n3y

lay 48

i

L@ TARY

a AS

HE

———Bsni

9/7ON L33HS NOUS

NOLO “11

Ley}

ayaa LH3

(na)opxosumg'2

Sir-elp

@

ziv-o1y

oer

60r—Zor

ZOO -\--\--\_ LO4

90¥-vor

irl

ah

(no) opxosuuig'2

goer

c0r- tor

F

9/s'ON

1S3HS HOUS

CABLE SCHEDULE

SRNO.|CABLETAGNO | CABLE SIZE FESTOON / FLEX. CABLE DESCRIPTION

1 eN-imiiaxa ‘6mm 6q x 4¢ Panel to M.H.Motor 1m1

02 [PNALSTI2.5xa 2.5mm sq X2o/4¢_| Panel to M.H, Limit switch 1181

03 JPN-1L82/2.5x4 | 25mmsqX2cl4c | PaneltoMH. Limit switch 1182

04 | PN1S1/2.5x4 2.5mm sq X40 Panel fo M.HOIST. E.H.T Brake 181

05 PN-1S2/2.5X4 2.5mm sq X 4c/2c Panel to M.HOIST. DCEM Brake 1S2

06 | PN-3m1/2.5x4 2.5mm sq X 4c Panel to C.T.Motor 3m1

o7 PN 3LS1/2.5x4 2.5mm sq X 2c/4c_ Panel to C.T. Limit switch 3L1

08 | PN-SLS22.6x4 2.5mm sqX2el4c_ | Panel to ©.T. Limit switch 3182

09 PN-3S1/2.5X4 2.5mm sq X 4c Panel to C.T.motor E.H.T. Brake 3S1

10 [PN-4mi/2.5x4 4mm sq X 46 Panel to L.T.Motor 4mt |

1 PN-4LS1/2.5X4 2.5mm sq X 2c/4c Panel to L.T. Limit switch 4LS1

12 PN-481/2.5X4 2.5mm sq X 4c. Panel to L.T.motor E.H.T. in Brake 484 |

13 [REC-PN-t.6x16 | 25mmsqX 16 | Receiver to Panel |

14 |pneus.u25xa | 2.5mmsqX 40 Panel to Underbridge light L1,L2,L3,L4.

15 [DSL-PN/6x4 6mm sq X 4¢ DSL to Panel |

16 | SFU St-DSLI6x4 | 6mm sq X 4c Switch fuse unit 1 to DSL

NOTE

All Power & Control cables will be 1100Volts Flexible Multicore Cables with

Annealed Bare copper conductor, PVC insulated as per IS:694-1990

MAKE OF CABLE : POLYCAB/FINOLEX

CLIENT: VEDANTA ALUMINA LTD

PROJECT: 1.4 MM TPA ALUMINA

LANJIGARH, ORISSA.

REFINERY

FIRST ANGLE

SCALE [ORAWN [Ai

[CHECKED [5

EMO GERAN=5I

—

[APPROVED] @E2E

ENGINEERS PVT. LTD.

ALL DIMENSIONS ARE IN WiM,| DATE.

(03708705

‘CAUTION

THIS ORAWING 1S THE

PROPERTY OF N/s.

EDDYCRANES. ENGINEERS

PYT. UD. PUNE 411019

TITLE:

CABLE SCHEDULE FOR 7.5Tx10.Sm

SPAN EOT CRANE

AND SHALL NOT BE USED

WITHOUT THEIR_EXPRESS

WRITTEN PERMISSION

IN-ANY FORM.

DRAWING NO:]

O505E~51

DOCUMENT NO: [HNO] REV

DGN-FR-03

Rev-0 at~01/03/05

02

1/1 Jas BUILT]

CABLE ENTRY 3/4 INCH

GLAND _HOLE

$

nit

INDICATING LAMP _|

(RED)110V.

on

|| EMERGENCY STOP (RED)

Hie

‘STAY PUT TYPE

LOKABLE STOP(RED)

wT

ba

START PUSH BUTTON

(GREEN)

EOR LIGHT(RED

BELL P.B.(YELLOW)

oO

270

STAY PUT ‘TYP!

DOWN P.B.(BLACK)

UP P.B.(YELLOW)

LEFT P.B.(YELLOW)

©

RIGHT P.B.(BLACK)

Oo

FORWARD P.B.(YELLOW)

Oo

rTP ere

REVERSE P.B.(BLACK)

TITLE:

PUSH BUTTON G.A.FOR

7.5T EOT CRANE

DRAWING NO: SH:1/1

0505 E-53 REV:02

AS BUILT

Kina _s¥|

zo. | ‘Vt

Aga fON'HS|

$0/£0/10-1P o-n0u

£0-¥4-NOG

09-300

ON IN3WNO0G|‘ON ONIMVEG

ANVYO LOZ N¥dS

MgOLXlS*£ YO4 “WIG 3NI1 FIONIS

uy

"Hos ANY NI

NOISSIMMTS NALIN,

SS3UEX3 “WISHL LNOHLIN,

35M 38 LON TWHS oNY

Blobly aNna “alt “ind

SHARMIONG S3NveOAGC

“S/N 40 As3ao¥d

SHL ‘S| ONUAVAG SiHE

NOUNS,

50/80/71

SIWGTAA Wr SY SNOISNaMG Te

‘3730 (GIN

(Oud

O39

=

furl 03

ov] NMVIG)

sivos _|Fiony isa

bene inais

et vamos va

(Cayos)wolon 17 ((99°0S)4OLON “19.

oe

7 Lever

fey q) 10g

waa W300 7 AH HUM

(ooes)aolon Won am YO

‘eon:

aun

‘rao0z

‘ ek | i.

eta

t

4

g™

loose

weazore

ounnoo 310n2e

]

“aos

oui /nsty

sdansns-/+ 2H 08

De O1-/+ Agi “4a

iat shoes

i

& cr

5 (a Pio yn py Nenana sedis be wats ype Yastin MATS POST MOTOR

29 [2 | wanseesvy ley 24 ne Biase TUE Eesquneyiny Sle al

Sa [iia sel te (Spe SOKA GLO

aan : Diuefetieinany AoE

ee Coomectinn -DELE 7

#3 A a “enyp-sise"o at

#9 [| cates 2) We Tye + PVG Plex

ge ack bert IDA ‘onling TEE

a Inaladon clase Chace Est amp Bie Lia Ce

Fé fae rac ze Sraup cal “ome Clas _aNUA

an expkeion oie candied ED oan Sev

se ‘Technical particulars from equipment manufacturer

22 [| eaunginew Sh soe 2.2% with VWe

isi wow sted {Sok

ge [1a _| speoan wot ama NDE 4

Ve 3 [a Te dainty [3-

pb [as Lear, wt Includisgleceludiog Apdehicgm? O° 40

ae 3

12a —apddnce >

i seadeoual Genaes

#2 fanaa EDDY Agues

a

ae ‘Technical particulars from motor manufacturer

2s fy [ae i BuARMT isles Ft

ers 5 ta

2S [oa | eeumedosignnionmenning.__12. sénting Po"

28 [oe [ems 20, TulULaad Taomed mtn A 2 Gio

28 [os | soning nenue se Saf fallin 2S oI

Be EulLand wt

2S bor | tected sntar. 220

Be esl dase ar pl a py

os od fe eT uh trot DIRECT LON

eB a GV Zo % se 1008Y (one) 1 0

tL Locked soto seth stand imeCalAs Mont 206M 1G | 10 rosy 16 |S snc

Sal ree ee ae 020 536 : :

Puen fictoet 0siimad aE wait Ob

: ef ttaicor oe MOE pa BiG Stood SEL

ie spaces fd fos 140s

33 [uote ne ste _nasrng Type DEO G

Be Lat | ype otto GLERSE

2s Le foht of matnet 4, = ee VOTE

2 # [2 Loom [ERD Type Cano Re Legs SE EEE Ha DOD

8

# Mailer

5 “eile

By 1-2.

38 [0 | 06-04-2005 |resueo wit Pn Be TAN TAS

33 [a [20-11-2008 |issuco wire ar SG a

= 8 [rev | cate PURPOSE BY gb CHECKED | arengveo

lrojcet: ALY FINE ONT vata sue|r ne

ENGINEERS INDIA LIMITED Be: Sl novspnd eS of ve eee tne

NEW. DELS apnea 3} 6369-16-F0.1N0-4000 1

Pastane sor crane Lc SED Sater

Rane

toa

+ PVE PLEX,

ing TERE

spate st Spon).

iz ‘Tyghmical particulars from equipment manufacturer

12_| Rating at 50°C! Oo.

x Shaft Jowllow st end of 219.4 | 3

14 ur v7 coos NDE Boo

en reaeserenee fate © GLG]0- lh

16_| swe? af equipeaeat nelidingleriuding typhebbent | O-08 Ly

cae te wens

as_| vali GOWLED.

wafacny CRANES

‘Technical particulars from motor. manufacturer +

31] vamteen BARAT - BITLEE: eal

7 aad Oa. Mo afgelae

BS [asl eame designati ent Moussng Oy

2 | ce | patos speed Oe Eu Land Toxguet veg} O° 450.

Fear Sol full asd sacquen 1G

Be Eni tosd Zp

= [a0 Tracts A5

Ba 20 | poe hiewed fe sod. Bork Digecvon

SS ian ling at FO) 1-9 9. LODO. 6074 1:0

= Pf Lack sith stand dine otarior sp Ages 2O|D wate AGB ce

wo | wry poke oat 2. 8

a | Power 6 100 aad, 2B ws 0.55

tinny at ‘aia Aloe ina SO

mel Span ee

2 [ao | menting pein DE 2.0 Bearing Typrlon WE 252

EE La | ype ares CRctse

ae le Jghtaf. Es

eile 7 pb Type Canopy Reged for Oud "Cher Regd AND aST

Se

oe 2 0.

decree coer nae ee We NS

23 [a Tast-200¢ [issueo waren S 7

Ee | REV DATE PURPOSE BY, CHECKED: APPROVED

ENGINEERS worn Lawreo fA ERNE gece OTA SHEERHO. | Rey

nao a ere ogee F casesouongse [1

Tonayes © Ce

eo

Fortine

: “pane Sane

were

sliuim vokage Mytur

7 ESIGN DATA

: 5s 3a la gp or moreR

c Vinee TREE a a

(

Maal BTN Ree,

( bienttoma est “ramp ctete

aliases « Ae* 4A wut A nes pve PUES

c | et : opt IP ing. TEEC

: osultian cl Ciseo Ef with Famp Bisel Chace

ra sash BE 7 “Temp Claes NUL

( 11 | type of explaion petedon U6 Apglicblecardatds- ETL Spee_ 651-0004 2

Tocnical particulars from equipment manufacturer

2 |i [maining GF Soec ONT at

¢ B [4a] spat toute at cod of Oe [ro

5 [aa sitenvation of equipement Coney NDE. 2.

C 8 [us ne sara 196/205, x

°/$.8 [Last ee of equipmen tnkidiogeschuding Dystclign® 0 - OO8S

c ~ Ly Thos va fee) NA

Sf [ie ing type CERRED

183 Lao LT eantnesses. EDDY ARAN ES

zi

Clee ‘Technical particulars fro’ motor mamifacturer

7 B= (1 [em BuARAT -BIGLEE

OES fe Teor ata :

gs Brame desigeatios a y BS

2 [os un toad ane 4. EalLLoad Taoqiet ntgy (63 Teg

‘ <6 b ll load nag

ee Ealltond 42

22 [a2 Practna 18

B2 aoe fi ere

Be R Lic oandciingead BOTH? OIRECTIO

ey aLans LS ge is sone La.

38 [ar [recut meni saad ington aise 22] ia ae

c [EE “WAC af motae: Ye nt Os0th

£8 [ss | pucrteoea meted as aa 0-5.

‘ 7 [ag | etna at 10g oad SEL Et toad_EL

é pace woe nie —

OV 2's [40 | pessing eypelan DE: 20 Resting Tylon NDE QOS

Be [a ape atta Rew

‘ BE sight.

eile pi a conn (por BEQD ~INDEAR]|

2s

a

3 I 0 22.

$3 |e _[esoxzocs |ssueo win en Be | Ne NS

83 [a [a91t-2008 fissueo wire nar SG =

2 {rev | oATe PURPOSE BY cueckeo | APPROVED

= 1

cts ‘

ENGINEERS INDIA LiMiTED [pei : Mate AT Me teeta sueervo. | Rey

( NEW DELHI iad eor spas Fipy Cee soHoes00 |

BRA 2 fur RQ OL ‘Shoet tof 1]

a pene ANE

; Te

EDDYCRANES ENGINEERS P. LTD

INDEX ert

CLIENT — : VEDANTA ALUMINA LIMITED,

CR CAP 7ST X 10.5M SPAN DGEOT CRANE

CRSRNO :05/5a7

PO NO : VAUILANJIC&HI45 DT 19.02.2005

PROJECT : 1.4 MMTPA ALUMINA REFINERY, LANJIGARH

SRNO DESCRIPTION CERTIFICATE SOURCE PAGENO

OF ITEM No.

1 CRANE TEST REPORT osisa7 sDOY 13

2 RAW MATERIAL TEST REPORT x7942, 7941 elcaac. 48

3 CHEM, TEST REPORT FOR 637,638 wie 67

WHEELS

4 MOTORS TEST CERTIFICATES BBL Bat 20

5 BRAKES TEST CERTIFICATE EMM evn tia

6 CONTROL PANEL T ECICPIOSOSEIO® epoy 14

7 WIRE ROPE To 120060901 USHA MARTIN 15

@- HOOK TC BEcI21C]200s-B COCK WORKER, 16

9 HARONESS TEST REPORT FOR 1506, 1010 JVOT.NUTECK 17.21

GEARS AND PINION

10 RADIOGRAPHIC TEST REPORT FOR RTISISIEDIONS SONAL 2

GIRDER JOINTS .

11. SRREPORTFOR ROPE DRUM 1200 FERROTHERIA, + 23-24

Rez

DDYCRANES.

CRANE TESTING REPORT

EDDYCRANES ENGINEERS PVT. LTD.

A) GENERAL

2)P.0.NO. VALILANJIC&HI4S dt 19.02.05,

3)Class M5 Duly7.5T x 110.5M§

5} Approved QAP No: 0505 Rev 0

6) EL Job No: 6369

CRANE Ni 05/547

4) Client's Name VEDANTA ALUMINA LIMITED

Project : {.aMi{TPA ALUMINA REFINERY, LANJIGARH

‘SPAN DG EOT Crane conforming to IS : 3177, 807

4) Approved G.A. Drawing No. O505E-01 REV 1

DATE : 04.08.2005

B) 0B IONS

Specified Observed

7) Span 70500 mm 10502/70503mm

2) Diagonal 11166 mm 11168/11166mm

3) Head room 1850 mm Max. 4565mm

4) End clearances 1) 200mm Max 145mm

2) 200mm fviax 445mm

5) Hook approach +jMH 900 mm Max. a6sis6smm

2)AH NA NA

6)Height of Lift 1) MH 8500 mm 500mm,

7) L.T. Wheel Centre Distance 3600 mm 3599/3600mm

8) C.T. Wheel Gauge 2100mm 2105/2100/2099mm

9) CT. Rail size 30Lbs/yd 30Lbs/yd

10) Overall width 4300mm 4090mm+Buffer

11) Overall Length 10900mm Max 40792mm

"2) Main Hoist speed 2.0m/min 2.05mimin

13) Main Hoist Micro speed 0.2m/min <16m/min

14) C.T. speed 40m/min 9.9m/min

15) L.T. speed{ ON NO LOAD) 20mimin 22m/min

16) Deflection on Full Load 44.66mm 6.0mm

Ne Kp.

w

INSPECTION OF COMPONENTS

1) BRAKES :

1. Main Hoist Brake : Dia 160mm EHT, EMM Make Sr No 4894/4

2. Main Hoist Brake : Dia 160mm DCEM, EMM Make Sr No 36197

3. Cross Travel Brake : Dia 100mm EHT, Emm Make, Sr No V4917/1

4. Long Travel Brake : Dia 100mm EHT, Emm Make Sr No V5016/2,

2) LIMIT SWITCHES :

4. Main Hoist : |) Two way rotory Geared Type Sr no 36375

il) Gravity Type limit switch Sr no 4983/3

2. Cross Travel : Two Way lever type limit switch Sr no 36202/3 & 4735/6

3) MOTORS :

[Motion Type KW__[Sr Nos. Revimin] Rating

fain Hoist Sq | 37/88 |k5512687 920 | 84 40%

ross Travel sq | ora |n2s20104 | 800 | sa 40%

[tong Travel sq_|_ see _|k5514579 95_| 84 40%

4) GEAR BOXES :

MOTION TYPE RATIO

MH HR4070 28:1

UT HR 250 26.9:1

ct VR 250

5) HOOK:

4. Hook Sr No.for MH SF 74 (For 7.57)

6) WIRE ROPE :

4.Wire Rope dia. for MH & 14MM

7) REMARK :

io

ee

FOR EDDYCR, Customers Inspection Representative

EDDYCRANES ENGINEERS P. LTO.

LOAD TEST REPORT

DATE 04.08,2008

CLIENT : VEDANTA ALUMINA LIMITED

CONSULTANT : ENGINEERS INDIA LTD/ KPG.

CR CAP: 7.5T X 10.5M SPAN DGEOT CRANE

CR SR NO : 05/547

PONO — : VALILANJIC&H/45 dt 19.02.2005

Approved G.A. Drawing No. 0505E-01 Rev 1

Approved QAP No: 0505 Rev 0

A__ Full Load Test (On 7.5 Tonne )

S.No. [Motion Speed Required|Observed [Full load

mi min.wsy [mimin_~|Amps.

7 [Mit Main Homing | 20mimia Zosmimin | 7.118.183 | ot

2 | Main Lowering | 2.0m/min 22mimin | 8.718.888 | 9.1

3 |MH Micro-Hoisting | O.2m/min | 0.19imtmin | 5.616.063 | 9.4

4 |i Micro-Lowering] 0.2mmin | 0.2im/min | 2.713.010 | 94

5 [cTMain-Let | 10.0m/min 9.9mimin | 4.4.22 | 1.43

6 |c7Main-Right | 40.0m/enin g9mimin|_ton2n2 | 1.43

B LT NOLOADCURRENTS- Forward .319.413.9 42

Reverse — 3.913.373.8 42

C Deflection Test

Girder Allowable] Observed

Drive Girder 11.65 mm 6mm

Idler Girder 1.65 mm mm

D Permanent Set

(Girder [Allowabte

Drive Gider NT

Idler Girder NIL

E Overload Test : 125% of SWL for MH and CT

Performance observed : Salisfactory

ate

ELCA

QUALITY SYSTEMS & CALIBRATIONS.PVT. LTD.

S. Ho. 23272, Pune-Wasik oad, “Opp. Rupee Co-op, bank LUG., Ohesarl, Pune - 411 039.

“el, : 2712 91°94, 271250 24 Fax: 27126420 E-fal ealabeGin.ch nel Wed + wwerAestelee.com

: x 7942

Dated: 18/60/26

Page aol:

= 1999 of, 8 (Fe 4108 By

and the résults are as be

$ 1603 ef 1995

ss(ma). Area (mm?) Gauge Lenimm)

203.75 208

iding Load

Pinal Length

G.t.g

Elong

Fracture

BEND

Test Date

width/Dia

40.00

Result of BEND TEST

Acceptal

chemicat se etree

Test Date EEF AS71995

{Standard Values

cx 0.14 0.22 max an £0.78 4.50 max

Sik 0.026 0.40 8% 0.015 0.088 max

PH 0.032 0.065 max

it of the tested as

qunt of TS 2962 ~1999 cr.Bire 410W B)

Physical & Chemical

above meets with the

Checked by : For ELCA QUALITY SYSTEMS & CALIBRATIONS PVT

gol NL

vo “ast

oy

rey

ELLA

QUALITY SYSTEMS & CALIBKATIONS, PVT. LTD.

5. No. 292/2, Punt-Nasik Ros6e Opp. Rupee Co-op. Bank Lid., Bhosari, Pune ~ #11 039.

Tol: 27128194, 2712 90.24 Fax: 7712 6430 Esl: elcaleos@Imethnat Wed | wrwwz.tostetea.cor

(re 410% B)

Its are as below

I8 1608 af 1995

kness(mm) Area (mm*) Gauge Len{am)

148,75 69.00

7.00

i Sear ues as per std Specn.

Yield Stress (N/mm*).e 2

WTS ‘x fmm ) Zr

long. on 5.6SSareayie 2

Practure ee

BEND (PLATES)!

Date + 15/06/20

Width/Dia Thickness,

20-99 5957

Chemical ade

Test Date : 15/06/2008.

Standard: Valves.

of 198s

Result of BEND TEST

Acceptable

ct o.18 0.22 max

Sit 0.038 9.40 max

PR 0.031 02045 max

ple material tested as

above meets with the re: I 1999 Gr.BIFe 410W B}

Checked by

YT ELCA QUALITY SYSTEMS & CALIBRATIONS PVT.

LED py pete

Ginley B Lad Cam] e A :

(Authorised Signatory:

Sr Bice Oununy sive

SOL PISO OOD

{

0.17 “LAd SONIDYOS WIGNI NUZLS3M 0)

vo

'$.193430 JOVsUNS ANY WOW 33Ys ONAOS TINALYIN Suet.

NIN] NI [Ni

covet] ee'om | pyres

loads NOUONCO

ud aaSTNWYON

Leet] ov'ry | se'sz “hoz Need

EY A ETE SES POuEA | NAG

} wvalw6s| sx | sin _|-ony L se__|ssaup.ey) weunes, 1

puepuels ecueidesoy” [S31 STISNEL 36U16.04 vee

puepueis un

0 300 | ss00 | Geo | 000

so'0 : 7 oso | oso

leo ozo'o | ozoo | ovo | iso

iv oA WT 3 a wi 2 zc

{ (9%) uonisoduios jeaiweus ca

+ Obb xX oz, azeuos NIE 9881 200

oF OL X06 | pzgoz ‘suUNgSO, as9NO4 yNVIE £881 -d0

GoNTAB Bas ‘oNeaH | ePSENT ToRBUOS. wondaasea ONO}

cas SO0z/SOPT=__siea 829/90°S0 "ON ueeUO” SF7POIGE : B10 $8 LOT PEISTWTIOS: ‘tn Joni;

“GLY INd SUBENIONS SENVUO ADCS 5

ALVOISILUEO UsaL

b SON oBeq 920 LLb = eung ‘NeSoUS OO zr

Soozisorr) : 91eq ANWdHOD 2008 OS! ea

9e8! NOL ~ G11 LAd ~ *NIOUOS VIGNI NYSLS3m i AR

GEOL PEISOMLOTOD.

g7

: ‘S1O480 ZOVIUNS ANY WOYd 354 GNNOS WivaLvA_: wewr 4

i NW] NW [ NIN

OO'eL | Se'Oy by el

i }93d$} IQNOD

i ut G3SIW.HON

vb'eL) 2e'sh LL “OLL NVdL :

| gaia panty ea POU 7

wveleoal sx [| sin fs] Lf sen ywewyee:

prepueis soueydeooy| (L831 STISN2. (r)isal ovat s6u:5v04 29H

piepuels inl

se0 ‘$50°0 $500 06'0 o8'0 WANK

soo : : ovo | oso | won

| v0 OLo'o Poo 20 @s'0 WnLoy

= v - ow iN 35 is s J oH S| sews

46) uonisedwon jeonwoug

a30u04

a Or x oz | AMAL | seuHsso a39¥04 oNVIa $691 400

OND, aig ‘ONeeH| USTED ToHpUGS sea ‘evag 7

, ‘S00z/SO/Pr ?__sieq’ 828/80-90 ‘ON welleun So/PO/EZ : 8120 $B 120TH ISTWN/ OS: ol! sepic

GL LAd S¥3aNION3 SSNVUD Adds sm |

BLWOlSILYAO LS3L

b ON ebeg 920 bbb - ound 'vesoug ‘O'O NW 'z-¢

so0z/sorr) aed ANWdINOD 2006 OS! =

fees ONL - GLTLAd ~ NIDYOS VIGNI NYA1S3M at

BHARAT BULEE LTD.

Rouiine Test Cettificaie of 3 Phase,

B® onae

Bijlee Limited

FORM No.: MK2/T TAF.

THANE BELAPUR ROAD, KALWE, THANE-400601,

CRANE DUTY INDUCTION MOTOR

This is to certify that the motor bearing the below mentioned

machine number has been tested in confirmity with {S-325-1996

at vther relevent standards and has satisfactorily passed all

. 4 routine test mentioned therein.

Machine No.

Client

Frame: 90L

Prot. 1P55

Conn. : STAR

Amps. 4.20

Bn% =: 74

Mo Load Test :

Vols: 415

Locked Rotor Test

Volts

Windi

450

ing Resistance :

Tag No. :

Reduced Voltage running up test in both directions : 0.«. at 249 Volts.

5514579

‘Type Reference

KW: 45 Volts

Freq SOHZ 475% RPM

Rating : 84.40% Ins,

PF. : a7 Amb.

Const.

Amps. 3 Watts

Amps. 4 Waits

W.O.No.

S.0.No.

MCO9L6S3_ Encl

4.42 ohms per phase

Bearing No.DE ; 620272

NOE

: TEFC

2 415 V4 46%

2 895

Or

io

1 45C

: B3

2 330

: 850

Insulation resistance (befor and after H.V. Test) : > 30Meg.ohms.

HN.

Speci

Testat 2 KV fort min, 0K.

ial Remarks : 180 STHR

2199.09

Vompurer Ge

Nope A

fares Venmunie

& Bharat Bijlee Limited

FORM No. MiC2/TTIF/03

HARAT BULEELTD., THANE BSLAPUR ROAD, KALWE, THANE 490601,

(‘outine Test Certificate of 3 Phase,

his ts to certify thet the motor bearing the below mentioned

( ‘aching number has been tested in confirmity with 1S-325-1996

ad other relevant standards and has satisfactorily passed all

ve test mentioned therein,

CRANE DUTY INDUCTION MOTORS,

chine No. Wi 2620104 W.O.No.

( tient S.0.No,

vame 74 ‘Type Reference MCO71033 Encl. : TEFC

co: PSB KM: ost Volts : 4154 10.0%

ona Star Freq 50,00 + 5% RPM: 800

nps. 143° Rating: 84-40% ins. 0: OF

1% 500 0 PF : 0.72 Amb. : 48°C

Const. : 83

2 Load Test :

Solis: 445 Amps. 43 Watts + 190

eked Rotor Test

(ots 1100 Amps. = are Watts : 90

inding Resistance : 27 ohms per phase

ig No. : BeaingNo. — : 620222 631

620222 63

2duced Voltage running up test in both directions : 0.K. et 240 Volts,

sulation resistance (befor and after HV. Test) : > 30 Meg.ohims.

v. Testat 2 KV for4 min. 10K,

ectal Remarks : 300 STAR,

BHR * 285 > LiMITED,

aie 201)

See AME “G00 bon,

p68 7 06

i

z eRe7 Fane « So198

ko 160 mm ia De, Elect:

© Magnetic Rrake type “IPR

Panel Tyne RPNLS,

S 720/hour. Braking Tor

#7460 Kaa

(A) Operations tested and foundescsseee ok

ny

= ok

que testyvarried and found.

ngud

Registance above 50 Maga Ohms...ok

Ls 2400 Volts for 2 Minwte ... Ol

stromag Methods Date s

ANE ENGINES

Hustor Gpereted breke

ars

14) Operations te:

Sand found.

sarried and found. .

Resistance above 30 tag,

kiromag Metheds pe

wi btaw

Dhan

nanos B. CHaupMaRT

2008 Volts for 4 Minute

king Torque: 6.08 Kga

© JEG me die thruster Opereted

Yoleaue + 445 vor

3 Phase 58 Ose

eiloue tested sid omer... ok

Um Torque

carvied and found...... ok

wd

Silence abuve BO Megs Ghaw..ob

1 RUGS Volts for i Minute 2.2. Ok

2irer vas

WAN AY

7 EDDYCRANES ENGINEERS PVT. LTD.

TEST CERTIFICATE

T.CNO.:EC 1 CP 1 O508E / 01

bare: 2007-2005

PRooucr Control Panet Fr 7.5 Tx 10.5 Mt span DGEOT Crane Se No, 05/547

cuENT Vedanta Alumina, Lejgerh

PROJECT 1.4 MTPA ALUMINA REFINERY

JOB DETALS ‘Supply Voltage - 415

: Tests conoucTED

‘A INSULATION RESISTANCE TEST

( Insulation esistaneo is measured with meager.

(Belore HV. Test) _ (Aftor LV. Test)

( Value in Mega-ohms "Value in Maga-ohme

1) Between Phase to Phate > 200 ohms > 200 Mohme

2) Between Phase to Earth 2 200 Meolims > 200 Mohne.

8, HIGH VOLTAGE TEST. 1.5 KV for 60sec.

1) Between Phase ta Phase Witrsioos

2) Between Phase to Earth Witnstoce

CC, GENERAL OBSERVATIONS

Instuments used ) Mogger Se. No2270/6, 500 VDC.

‘ £2). V. Tester Sr. No, HVTASS,

BOM wih make, ratings & soquonce of eperatons ae per aperaved wring diagram checked &

found 0,

lnsposton Engineer.

Ol

Le AE a os

v

iartin Limited

& Wie Rope: Bieision)

Toteabwos «B35, 16%, Sane

D091 aot) 335 52 21/407

PV eI) 296 59737168

CERTIFICATE OF TEST

Certificate Number

customer

Order Ref

Works Order Nunber

Reel Nunber

Manufacturer

8

applied Standard

‘ominal Diameter of rope

Construction

Strand Construction

Tensile Grade of Steel W:

ize Finish

bength of Rope

Hess/Unit Length (Aporx

ication

rom*Breaking Force

Prestretching

Measured Dia. off-

vaterial Grade

‘Type of Core/Lay Direction

‘ension

Measured Lay Off-tension

F/QP-2-17/33R Rev:1

H 200603/2 Date: 16-07-2004

BOMBAY BRANCH (USHA MARTIN LTD.)

+ U/SPL/599 Date:26-05-2004

903907/ 19 Date :28-05-2004

200609/1 Date of Test :16-07-2004

USHA MARTIN LIMTTED, INDIA

FECIFICATION

18-2266/2002 (Marked)

14 wy,

6x36.

142787-7-1

1960 N/mm

Ungalvanised

(Preformed)

ire

Jute / RHO

+ 1000.00 Mer

} 9.726 Ko/tite

AL 18-3

127.0 iat

Wa

RESULTS OF TEST & EXAMINATTON

14.2900 mm

92.0000 ian

133.3 kW

Measured Breaking Force

We certify that the moti

Properties of the product

BIS certification marks

against each reel/coil.

erial described above conforms to

as tested in accordance with STI contained in

-Licence no. CM/L-0176239 are as indicated

oe eee

Signature of 1 eee \

Competent Parson Usha Martin Led, Ie

- Ranchi ft

Yiewe rer

FRIRERNER BOYS

ath

AueR VERE oy y

vende dat

FORM ¥

DOCK WORKLRS ( SAPETY, HEAL TH WEL Kanter apc ATIONS 79

. See epsiatets 7 nd Sazzyj

Covet ot als Peete fxr wonor danse ne

c DS: CRT ntr DEE ste 20

/ arama oer

cnte

Penden

jietectaa

ee, [etl

. a @ [oy 6

| shoo 4c #8nngnesal di wih a

3610)

ate per

1 Name & address of wnafecter oF soppiers MuS. Sar eta Sogings

Mumb

Wel Jest & exumnnauon cenfinre

Aha feak sane ped

les eeminon |

amend ade of puis sar ice, assert Betat Eagineering Coe

“igany or fim or teeing estsishtsnt SAGAR/D-3212 5, Sector 29,

Prting the test ang curate Vashi, Navt Mune 400-702

Tel. 808850 ten: 208870

‘ (9 Same tian fhe Compete prs :

pavic nite monte sonpan he eae cup Kana Gayen

: ‘Simatic epee

| | cerufy that on the 29 soy oF July 2008,

mination thoseed the sa:4 g

above gear was tested in the manaer set forth overleaf that the

EC eat Load wilt ngsay os defOematnn ana ho t

ip —

wi

nat

ebtsictnns

nena

snide set ee

A PRECISION HEAT TREATMENT HOUSE

Plot No, 243, ' Block, M..0.C-, Bhosari, Pune - 411 026 Ph. 4114929, 27470904 Fax : 27119907

§ JYOT! HEAT TREAT INDUSTRIES

a

Quality Assurance Certificate No. 4886

HEAT NO. DATE: as [ee (7

CUSTOMER Mis, :

Cddiconrs Erainin Ot el:

e

AppRESsS: {It led, WDC, QURDC.NO.: R013,

Uknduanad + CUSTOMER D.C.NO.: 27g

pate: 2allos

QUANTITY: Long 1 Noy

COMPONENT: Qo0 @ wal > P.O.NO:—

aod sual

L Yeo of Guar cabal SPECIFICATION

"RENO: HARONESS SURFACE 250 | 360 2 UN

He CORE —

PROCESS CASE DEPTH —

ordering de Caragoung [MATERIAL Cus] Gee 19 95>

Qrest Resutt

HARDNESS CASE DEPTH

SURFACE 2b |26 KR | CORE — =

HARDNESS TRAVERSE

DEPTH (mm) I L

RONESS \

WHR )

SPECIAL TESTS

REMARKS

ow

APPROVED BY.

}

L

L

§ JYOTI HEAT TREAT INDUSTRIES

ae

— A PRECISION HEAT TREATMENT HOUSE

ort Plot No. 243, ‘J’ Blook, M.LD.C,, Bhosati, Pune - 411 028 Ph. 4114929, 27470904 Fax : 27419907

TU

Quality Assurance Certificate No.

HEAT NO. : DATE: 27] Sos

CUSTOMERS: EAMG aoien Ena fet el

ADDRESS : OURDE.NO.: YL q

CUSTOMER D.C. NO. -Joq

DATE: als

QUANTITY: UY flog

SONPONENT: 140 RoOWL’ ype asheal |PONO! —

SPECIFICATION

\ ARTO. : HARDNESS SURFACE $0 ~ 200 BHNY

CORE —~

PROCESS CASEDEPTH —

Wedentys 4 Tanaganing 2 [MATERIAL Cos Nate

2 Gest ResuLr

HARDNESS CASE DEPTH

SURFACE 275/300 84) CORE =

HARDNESS TRAVERSE

DEPTH (mm {

RONESS \

AV/ARC)

SPECIAL TESTS

REMARKS a + ey

o“e- fafhed Wey

APPROVED BY, RERORTED BY

ti

ye i

iwi —

NU-TECK ENGG.CO.PVT.LTD

PUNE - 411 026

HARDNESS TEST REPORT

Project : Eddycranes Engineers Inspection Date :_ 18/06/2005)

W.O. No: N 5045.4

]Gearbox Size : 4010 HNG({) Ratio: 228: 1 Qty : 2 nos.

P.O. No : Ord - 505/A /B/ C Date : 7/04/05

Item Final Size Material) Hardness Hardness Actual

Required 4 2 3

P181|6 45 x529L EN -24 | 266-300 BHN| 269 | 272

G1 _|@ 183 x 53 thk C-45 | 220-250 BHN| 222 224

P282|@ 48 x 2791 EN-19 | 266-300 BHN| 269 | 269

G2_|@ 270 x 63 thk. C-45 | 220-250 BHN| 228 | 222

P282|9 88x 279L EN-9 | 266-300BHN | 269 |_272

G2_|@ 438 x 103 thk. EN-8 | 220-250BHN| 231 | 229

for Nu-Teck Engg.Co.Pvt.Ltd.

>

SP Rawan

2¢

NU-TECK ENGG.CO.PVT.LTD

PUNE - 411 026

HARDNESS TEST REPORT

¢ Project ; Eddycranes Engineers Inspection Date : 18/06/2005

W.O. No : N 5045-8

' [Gearbox Size: 250 VEL Ratio: 48:1 Qty : 2 nos.

; P.O. No : Ord - 505/A 18 /C Date : 7/04/05

Item Final Size Material] Hardness Hardness Actual

Required AEE Heo eegs

P181|@ 33 x 405L EN-9 | 266-300BHN| 269 | 271

Gi _|@ 181% 33 thk C-45 | 220-250BHN| 221 | 222

‘ P282|@ 61 x 172L EN-9 | 266-300BHN| 263 | 269

( G2 _|@ 267 x 33 thk. C-45 | 220-250 BHN| 222 | 224

for Nu-Teck Engg.Co.Pvt.Ltd.

el .

‘SP Rawan

NU-TECK ENGG.CO.PVT.LTD

PUNE - 441 026

HARDNESS TEST REPORT

Project : Eddycranes Engineers

Inspection Date : 18/06/2005:

W.O. No : N 5045-4

Gearbox Size ; 250 HNP

Ratio: 26.9:1

Qty :_2 nos.

P.O. No : Ord - 505/A /B JC

Date: 7/04/05

Item Final Size Material} Hardness Hardness Actual

Required 4 rts:

Pist|o4t x405L EN-24 | 268-300 BHN| 269 | 272

G1_|@ 173 x43 thk C-45 | 220-250BHN| 224 | 222

P282|@ 61 x 175 EN-9 | 266-300BHN| 269 | 269

G2_|@ 258 x 53 thk. EN-9 | 220-250 BHN| 222 | 224

for Nu-Teck Engg.Co.Pvt.Ltd.

4

SP Rawan

c a RADIOGRAPHIC EXAMINATION REPORT.

‘ Report No: RenSISY EC/006

NON DESTRUCTIVE TESTING

— eee Date 14007105

* OFFICE : KRUSHNA’,, SNO. 17/3, LANE NO. 5,

MADHUBAN, SANGVI, PUNE-411027 Page: Page tof

“LABORATORY : MANE MANGAL, 8-103, Ph: (0) 27148329, 56510514

SARASWATI NAGAR,NEAR SIDDHARTH MOTORS

- (®) 27280047 , 27280020

KASARWADI, PUNE: 41 1034 Fax: (020) 27145329

ws BODY ceanes Enea PTLD Erol omeenirt

JobiJoint Ident. | ED-605-C— GIRDER PLATE WELD JOINT

( Sous (F402 Tay Thickness [68 "ait [ Radiograpiy E-TOOR BORE

cP sansa a 27 fcr [7 1 | pine | A500 i

Ht Exposure Time | 719 Lead. Ot mm Welding SMAW

“soo¢niny | season | end taing| ver |

© erDaiminson [an wa | Hage 17 va i

© 4 6 Singleor | SWSY a t+

Rect

| TBECH istanbanaECt| rin oar tee= | vse Te ese |

Sr.No | _Radlagrph No Firat Exposure ti m2 | Remats

¢ 1 rut ‘AB| Salistactory I

¢ lo | 2 AS) Satisfactory

ct set F Peo] Same | |

gi Setetctoy |

a | Setstactoy” : I

{ € Bt AB) Satisfactory |

yey x

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ut Ascent Traction ElevatorsDocument20 pagesUt Ascent Traction ElevatorsVinod KumarNo ratings yet

- 5T X 16.0M Span Dgeot CraneDocument75 pages5T X 16.0M Span Dgeot CraneVinod KumarNo ratings yet

- 7-13-0003 Rev 5Document3 pages7-13-0003 Rev 5Vinod KumarNo ratings yet

- 10T X 13M Span Dgeot CraneDocument52 pages10T X 13M Span Dgeot CraneVinod KumarNo ratings yet

- 7.5T X 8.5M Span Dgeot CraneDocument69 pages7.5T X 8.5M Span Dgeot CraneVinod KumarNo ratings yet

- NCVTCTSCertificateAnnual R180821013523Document1 pageNCVTCTSCertificateAnnual R180821013523Vinod KumarNo ratings yet

- Marksheet R180821013523 2Document1 pageMarksheet R180821013523 2Vinod KumarNo ratings yet

- InsuranceDocument3 pagesInsuranceVinod KumarNo ratings yet

- FOS000022740396Document1 pageFOS000022740396Vinod KumarNo ratings yet

- XCT110 Load ChartDocument26 pagesXCT110 Load ChartVinod KumarNo ratings yet

- Anchor Bolt-ModelDocument1 pageAnchor Bolt-ModelVinod KumarNo ratings yet

- Data Spring DesignDocument7 pagesData Spring DesignVinod KumarNo ratings yet