Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewsLaptop Flex-Pages-2

Laptop Flex-Pages-2

Uploaded by

ghost2humanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- EUV LithographyDocument26 pagesEUV LithographyGabriel DonovanNo ratings yet

- LCD Panel Fabrication ProcessDocument1 pageLCD Panel Fabrication Processghost2humanNo ratings yet

- Background LCD Panel FabricationDocument1 pageBackground LCD Panel Fabricationghost2humanNo ratings yet

- Lecture 18 Optical Inspection PrincipleDocument36 pagesLecture 18 Optical Inspection Principletl xNo ratings yet

- Tecnologia LCD BDocument24 pagesTecnologia LCD BJuan Lujan SalasNo ratings yet

- Recent Trends in Retardation FilmsDocument10 pagesRecent Trends in Retardation FilmsJeevan JalliNo ratings yet

- PhotolithographyDocument37 pagesPhotolithographyuwjin0622No ratings yet

- Section 2: Printed Circuit Board (PCB) Terminology, Materials & ManufactureDocument19 pagesSection 2: Printed Circuit Board (PCB) Terminology, Materials & Manufactureyash kushwahaNo ratings yet

- A6 Chapter 3 FinalDocument35 pagesA6 Chapter 3 FinalHam YasNo ratings yet

- Lg-Pdp-Training Plasma TV AlapokDocument67 pagesLg-Pdp-Training Plasma TV AlapokHamedKoneNo ratings yet

- Mse 09Document37 pagesMse 09Rahul ReddyNo ratings yet

- Liquid Crystal Display - TLTDocument28 pagesLiquid Crystal Display - TLTastriddastariiNo ratings yet

- Analog and Digital VLSI Design: Lecture 6: Manufacturing ProcessDocument37 pagesAnalog and Digital VLSI Design: Lecture 6: Manufacturing ProcessYash GuptaNo ratings yet

- "Front Drive" Display Structure For Color Electronic Paper Using Fully Transparent Amorphous Oxide TFT ArrayDocument7 pages"Front Drive" Display Structure For Color Electronic Paper Using Fully Transparent Amorphous Oxide TFT ArrayRajesh AgarwalNo ratings yet

- Deca Tec FO WLPDocument14 pagesDeca Tec FO WLPAhSangCheeSangNo ratings yet

- 95 2 Semiconductor PDFDocument27 pages95 2 Semiconductor PDFsumitzz4737No ratings yet

- LG 2006 LCD TV Training ManualDocument60 pagesLG 2006 LCD TV Training ManualAnil BpsNo ratings yet

- TMP 9422-0202FIN05 (2) 767527349 PDFDocument3 pagesTMP 9422-0202FIN05 (2) 767527349 PDFAnonymous oyUAtpKNo ratings yet

- LITHOGRAPHYlecs PDFDocument10 pagesLITHOGRAPHYlecs PDFNorhan AshrafNo ratings yet

- Chapter 5. Overview of The Manufacturing ProcessDocument10 pagesChapter 5. Overview of The Manufacturing ProcessVAHID KHALILINo ratings yet

- Chap 5 TFT Technology 整合 (含摻雜微影蝕刻)Document101 pagesChap 5 TFT Technology 整合 (含摻雜微影蝕刻)劉昱岑No ratings yet

- Scheme of D.C. Sputtering: StartDocument8 pagesScheme of D.C. Sputtering: StartJawahar DasNo ratings yet

- Specification For Painting Appendix-1 Coating System On Metallic SurfacesDocument18 pagesSpecification For Painting Appendix-1 Coating System On Metallic SurfacesLy Thanh HaNo ratings yet

- Toaz - Info Silicon Vlsi Technology Fundamentals Practice and Modeling PRDocument43 pagesToaz - Info Silicon Vlsi Technology Fundamentals Practice and Modeling PRNikita MadaviNo ratings yet

- Lecture 42Document18 pagesLecture 42Nathan KemboNo ratings yet

- PCB Manufacturing Process PDFDocument21 pagesPCB Manufacturing Process PDFAnima RahdriyaNo ratings yet

- ch1 (20231004)Document32 pagesch1 (20231004)jane8773No ratings yet

- IC Fabrication Technology - L3 - FinDocument23 pagesIC Fabrication Technology - L3 - FinPublicityNo ratings yet

- V Grubsky-3D Backscatter X-RayDocument30 pagesV Grubsky-3D Backscatter X-Rayugo_rossiNo ratings yet

- Micro and Smart SystemsDocument22 pagesMicro and Smart SystemsGopinath ChakrabortyNo ratings yet

- Lithography: Overview of Process StepsDocument46 pagesLithography: Overview of Process StepsPrakharNo ratings yet

- Charles Bishop - C.a.bishop Consulting LTDDocument24 pagesCharles Bishop - C.a.bishop Consulting LTDchipulinoNo ratings yet

- Lab Course Projects PDFDocument1 pageLab Course Projects PDFingenieria softwareNo ratings yet

- Introduction To Microfabrication: PHYS 534 (Fall 2008)Document34 pagesIntroduction To Microfabrication: PHYS 534 (Fall 2008)LydiaNo ratings yet

- Chapter 3 Fabrication of Cmos Integrated Circuits Jin Fu Li Department of Electrical Engineering National Central University Jhongli TaiwanDocument37 pagesChapter 3 Fabrication of Cmos Integrated Circuits Jin Fu Li Department of Electrical Engineering National Central University Jhongli TaiwanYusra AmeenNo ratings yet

- 20080701-061-LCD Lithography Process & EquipmentDocument49 pages20080701-061-LCD Lithography Process & Equipmentengineeringhandbook100% (5)

- Taining Manual PL42D5 PL42P5Document58 pagesTaining Manual PL42D5 PL42P5Adriano QuintanilhaNo ratings yet

- Exposure Light Source: - High-Pressure Mercury Lamp - Excimer Laser - Short Wavelength - High Intensity - StableDocument47 pagesExposure Light Source: - High-Pressure Mercury Lamp - Excimer Laser - Short Wavelength - High Intensity - StableMuhammad Muzammil SaleemNo ratings yet

- Introduction To Mems EA C415: Dr. N.N. SharmaDocument14 pagesIntroduction To Mems EA C415: Dr. N.N. SharmaArjit GoswamiNo ratings yet

- PCB - Fault DetectionDocument8 pagesPCB - Fault DetectionDinti SaiNo ratings yet

- LCD-TFT Tech Info and SpecsDocument45 pagesLCD-TFT Tech Info and SpecsVương AnhNo ratings yet

- Pentacene TFT Driven AM OLED DisplaysDocument3 pagesPentacene TFT Driven AM OLED DisplayskanchankonwarNo ratings yet

- 6mm Superlite 70 40t Clear +16as+6mm ClearDocument1 page6mm Superlite 70 40t Clear +16as+6mm ClearNav JavNo ratings yet

- 6mm Superlite 70 40t Clear +16as+6mm ClearDocument1 page6mm Superlite 70 40t Clear +16as+6mm ClearNav JavNo ratings yet

- Add-Vision PE Summitt 2010Document18 pagesAdd-Vision PE Summitt 2010Devin MacKenzieNo ratings yet

- 1.john Lau - ASM-CSIA - Recent Advances in PackagingDocument148 pages1.john Lau - ASM-CSIA - Recent Advances in Packagingyang100% (1)

- Proceedings of Spie: Laser Annealing of LTPSDocument10 pagesProceedings of Spie: Laser Annealing of LTPSzidan ojaNo ratings yet

- 01 Mon - Jun23 Trouble Shooting - Panel (Compatibility Mode)Document51 pages01 Mon - Jun23 Trouble Shooting - Panel (Compatibility Mode)بوند بوندNo ratings yet

- Reflectivity Study of The 2-D Macroporous Silicon Photonic CrystalsDocument23 pagesReflectivity Study of The 2-D Macroporous Silicon Photonic CrystalsJosep Ferre-BorrullNo ratings yet

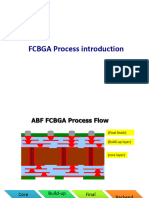

- FCBGA带Core基板制造工艺流程 FCBGAProcessflowDocument18 pagesFCBGA带Core基板制造工艺流程 FCBGAProcessflowhhaiddaoNo ratings yet

- EE235 - Paper1 - DarsenDocument19 pagesEE235 - Paper1 - DarsenYusman AlrizkyNo ratings yet

- Trouble Shooting - Panel 20140612043059324Document51 pagesTrouble Shooting - Panel 20140612043059324Mohamed SalahNo ratings yet

- 9787-48370 Performance Assessment of DR SystemsDocument11 pages9787-48370 Performance Assessment of DR SystemsJames BondNo ratings yet

- ICAPE - Flex & Rigid-Flex PCB Spec Template Ver 1.2Document24 pagesICAPE - Flex & Rigid-Flex PCB Spec Template Ver 1.2digicromNo ratings yet

- OLEDDocument10 pagesOLEDGyurmoooNo ratings yet

- Recent Advances in Display Technologies: Dr. K. R. Sarma Adviser Technology Samtel GroupDocument43 pagesRecent Advances in Display Technologies: Dr. K. R. Sarma Adviser Technology Samtel Groupyadvendra2011No ratings yet

- Dewada 2021 Mater. Res. Express 8 122001Document25 pagesDewada 2021 Mater. Res. Express 8 122001AynamawNo ratings yet

- A MAIC Approach To TFT-LCD Panel Quality Improvement: Microelectronics Reliability July 2006Document11 pagesA MAIC Approach To TFT-LCD Panel Quality Improvement: Microelectronics Reliability July 2006NG JIA QIANNo ratings yet

- Digital Color Management: Encoding SolutionsFrom EverandDigital Color Management: Encoding SolutionsRating: 5 out of 5 stars5/5 (1)

- Photoalignment of Liquid Crystalline Materials: Physics and ApplicationsFrom EverandPhotoalignment of Liquid Crystalline Materials: Physics and ApplicationsNo ratings yet

- Scored Edge Strength: 4-Point-Bending Test Make Samples With ChangingDocument1 pageScored Edge Strength: 4-Point-Bending Test Make Samples With Changingghost2humanNo ratings yet

- Clamshell Test, Out Put of The Test: Display Technologies Corning Restricted Corning Technology CenterDocument1 pageClamshell Test, Out Put of The Test: Display Technologies Corning Restricted Corning Technology Centerghost2humanNo ratings yet

- Scoring Damage: Score Track by Standard Wheel Score Track by Penett® WheelDocument1 pageScoring Damage: Score Track by Standard Wheel Score Track by Penett® Wheelghost2humanNo ratings yet

- Laptop Flex-Pages-9Document2 pagesLaptop Flex-Pages-9ghost2humanNo ratings yet

- Surface Defect, Case 2Document1 pageSurface Defect, Case 2ghost2humanNo ratings yet

- Tsbrcrit 19V063 0843Document7 pagesTsbrcrit 19V063 0843ghost2humanNo ratings yet

- Cat Adoption Questionnaire: Name: Address: City: Postal Code: Telephone: CellDocument2 pagesCat Adoption Questionnaire: Name: Address: City: Postal Code: Telephone: Cellghost2humanNo ratings yet

- Engineers Act 1Document13 pagesEngineers Act 1ghost2humanNo ratings yet

- 2023 English Catalog Full CompleteDocument91 pages2023 English Catalog Full Completeghost2humanNo ratings yet

- PRS ScheduleDocument1 pagePRS Scheduleghost2humanNo ratings yet

- APSC 279 Materials Properties Lab Required Reading For Each Lab 2012-13Document2 pagesAPSC 279 Materials Properties Lab Required Reading For Each Lab 2012-13ghost2humanNo ratings yet

- NPPE Candidate GuideDocument16 pagesNPPE Candidate Guideghost2humanNo ratings yet

- Q1 Lesson 1 - Introduction To Computer & Its CharacteristicsDocument23 pagesQ1 Lesson 1 - Introduction To Computer & Its CharacteristicsAlyssaNo ratings yet

- STE Grade 10 Electronics Q1 Module 6Document21 pagesSTE Grade 10 Electronics Q1 Module 6harry timbol100% (1)

- (Teikoku Rotary Gurdian) : Bearing Wearing Monitor For Teikoku Canned Motor PumpDocument18 pages(Teikoku Rotary Gurdian) : Bearing Wearing Monitor For Teikoku Canned Motor Pumpneliomedina01No ratings yet

- Foundation of Information and Communication Technology Facilitator: DR Igwe Joseph SundayDocument15 pagesFoundation of Information and Communication Technology Facilitator: DR Igwe Joseph SundayFrancis OmongaNo ratings yet

- 1 Darlington Pair AmplifierDocument2 pages1 Darlington Pair AmplifierSheikh Noor MohammadNo ratings yet

- What Effect Does Direct Coupling Have On A Two Stage BJT AmplifierDocument63 pagesWhat Effect Does Direct Coupling Have On A Two Stage BJT Amplifierzraider50% (2)

- 772484EN-7+Pocket+Doppler+IFU SR2Document58 pages772484EN-7+Pocket+Doppler+IFU SR2Nattawut ZuesatNo ratings yet

- EMEC F FA Series Instruction Manual R1 11 03Document28 pagesEMEC F FA Series Instruction Manual R1 11 03antonio vukeNo ratings yet

- Tableau de Commande PCC1.2Document6 pagesTableau de Commande PCC1.2thainarimeNo ratings yet

- TC909A and B, TC910N and R, TC941A: Eclipse™ Series Intelligent ModulesDocument2 pagesTC909A and B, TC910N and R, TC941A: Eclipse™ Series Intelligent ModulessureshNo ratings yet

- Construction of SRMDocument5 pagesConstruction of SRMdhanusiya balamuruganNo ratings yet

- TransducersDocument24 pagesTransducersSania NowshinNo ratings yet

- LTC6810 1 6810 2Document86 pagesLTC6810 1 6810 2jonathan.hodaNo ratings yet

- Exercise Sheet 1: Buck-Converter (Step-Down Converter)Document10 pagesExercise Sheet 1: Buck-Converter (Step-Down Converter)Fury NightNo ratings yet

- ESL-429 & 449 Smoke DetectorsDocument6 pagesESL-429 & 449 Smoke DetectorsBenjamin DoverNo ratings yet

- Analysis of Commutation in DC MachinesDocument57 pagesAnalysis of Commutation in DC Machinesagnostic07No ratings yet

- Unit-1 ACADocument86 pagesUnit-1 ACArestin069No ratings yet

- History of MicroelectronicsDocument60 pagesHistory of MicroelectronicsRalph Laurence G VisayaNo ratings yet

- Led Eco Floodlight 100 W 6500 K Gray: Product DatasheetDocument3 pagesLed Eco Floodlight 100 W 6500 K Gray: Product Datasheetfirman pahrizalNo ratings yet

- Solar Cell Losses and Design: Arno SmetsDocument17 pagesSolar Cell Losses and Design: Arno SmetsGianmarco PeñaNo ratings yet

- Expected Floor Puzzle Reasoning Questions For Bank MainsDocument51 pagesExpected Floor Puzzle Reasoning Questions For Bank MainsShobhit MohtaNo ratings yet

- HI 98509 (Checktemp®1) : Instruction ManualDocument2 pagesHI 98509 (Checktemp®1) : Instruction ManualJhonatan Alexander Soto RodriguezNo ratings yet

- Czns 4 PDocument14 pagesCzns 4 PВасилий ВасильченкоNo ratings yet

- Model: Rotation: Clockwise Air Ow Outlet: Air Out Over Struts 1: Average Values in Free AirDocument2 pagesModel: Rotation: Clockwise Air Ow Outlet: Air Out Over Struts 1: Average Values in Free Airboubker2bessaiNo ratings yet

- Was-1923 CKT&PCBDocument4 pagesWas-1923 CKT&PCBReginaldo souza santosNo ratings yet

- Rac03 K PDFDocument6 pagesRac03 K PDFSimon AmplemanNo ratings yet

- EC503 Partha ChakrabortyDocument8 pagesEC503 Partha ChakrabortyPartha ChakrabortyNo ratings yet

- Cordless Impact Wrench: Instruction ManualDocument12 pagesCordless Impact Wrench: Instruction ManualCésar PérezNo ratings yet

- Danotherm WirewoundPowerResistorsDocument4 pagesDanotherm WirewoundPowerResistorsAsderaNo ratings yet

- A Novel Bridge-Type Hybrid Saturated Core Fault Current Limiter Based On Permanent MagnetsDocument4 pagesA Novel Bridge-Type Hybrid Saturated Core Fault Current Limiter Based On Permanent MagnetsGul Ahmad LudinNo ratings yet

Laptop Flex-Pages-2

Laptop Flex-Pages-2

Uploaded by

ghost2human0 ratings0% found this document useful (0 votes)

1 views2 pagesOriginal Title

laptop flex-pages-2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views2 pagesLaptop Flex-Pages-2

Laptop Flex-Pages-2

Uploaded by

ghost2humanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

Background

LCD Panel fabrication

• Liquid Crystal Displays (LCD) panel is structured that Liquid

Crystal is sandwiched by two glass substrates with

– Thin Film Transistor (TFT)

– Color filter (CF) Polarizer

Black matrix Glass substrate for CF

Color dye Liquid crystals

R, G, and B

Glass substrate for TFT

Polarizer

Pixel

Transistor electrode

Sharp homepage, “Sharp High Technology/ LCD World/ Chapter 2/ 1-1, Principle of LCD Technology”, Copyright (1999).

Display Technologies Corning Restricted Corning Technology Center 3

Deposition

Cleaning

LCD panel fabrication process Photo Resist Coating

Exposure

Gate Metal by PEP

Developing

a-Si by PEP Black matrix by PEP Etching

ITO by PEP Red printing Photo Resist Stripping

Inspection

Insulator PEP Green printing

1 Photo Engraving Process cycle

Source/drain by PEP Blue printing

Passivation by PEP ITO by PEP

Alignment film

Spacer dispersion TAB bonding

Cell separation Back-light mount

Sealing material Alignment film

LC filling Print Circuit Board

Sealing Polarizer film Bending TAB

Array test Lighting test

Y. Suzuki, “Special Report, Color TFT LCD production processes, LCD Module

recent topics”, Electronic Engineering, Vol. 35, No. 8, pp73-79, (1993)

Display Technologies Corning Restricted Corning Technology Center 4

You might also like

- EUV LithographyDocument26 pagesEUV LithographyGabriel DonovanNo ratings yet

- LCD Panel Fabrication ProcessDocument1 pageLCD Panel Fabrication Processghost2humanNo ratings yet

- Background LCD Panel FabricationDocument1 pageBackground LCD Panel Fabricationghost2humanNo ratings yet

- Lecture 18 Optical Inspection PrincipleDocument36 pagesLecture 18 Optical Inspection Principletl xNo ratings yet

- Tecnologia LCD BDocument24 pagesTecnologia LCD BJuan Lujan SalasNo ratings yet

- Recent Trends in Retardation FilmsDocument10 pagesRecent Trends in Retardation FilmsJeevan JalliNo ratings yet

- PhotolithographyDocument37 pagesPhotolithographyuwjin0622No ratings yet

- Section 2: Printed Circuit Board (PCB) Terminology, Materials & ManufactureDocument19 pagesSection 2: Printed Circuit Board (PCB) Terminology, Materials & Manufactureyash kushwahaNo ratings yet

- A6 Chapter 3 FinalDocument35 pagesA6 Chapter 3 FinalHam YasNo ratings yet

- Lg-Pdp-Training Plasma TV AlapokDocument67 pagesLg-Pdp-Training Plasma TV AlapokHamedKoneNo ratings yet

- Mse 09Document37 pagesMse 09Rahul ReddyNo ratings yet

- Liquid Crystal Display - TLTDocument28 pagesLiquid Crystal Display - TLTastriddastariiNo ratings yet

- Analog and Digital VLSI Design: Lecture 6: Manufacturing ProcessDocument37 pagesAnalog and Digital VLSI Design: Lecture 6: Manufacturing ProcessYash GuptaNo ratings yet

- "Front Drive" Display Structure For Color Electronic Paper Using Fully Transparent Amorphous Oxide TFT ArrayDocument7 pages"Front Drive" Display Structure For Color Electronic Paper Using Fully Transparent Amorphous Oxide TFT ArrayRajesh AgarwalNo ratings yet

- Deca Tec FO WLPDocument14 pagesDeca Tec FO WLPAhSangCheeSangNo ratings yet

- 95 2 Semiconductor PDFDocument27 pages95 2 Semiconductor PDFsumitzz4737No ratings yet

- LG 2006 LCD TV Training ManualDocument60 pagesLG 2006 LCD TV Training ManualAnil BpsNo ratings yet

- TMP 9422-0202FIN05 (2) 767527349 PDFDocument3 pagesTMP 9422-0202FIN05 (2) 767527349 PDFAnonymous oyUAtpKNo ratings yet

- LITHOGRAPHYlecs PDFDocument10 pagesLITHOGRAPHYlecs PDFNorhan AshrafNo ratings yet

- Chapter 5. Overview of The Manufacturing ProcessDocument10 pagesChapter 5. Overview of The Manufacturing ProcessVAHID KHALILINo ratings yet

- Chap 5 TFT Technology 整合 (含摻雜微影蝕刻)Document101 pagesChap 5 TFT Technology 整合 (含摻雜微影蝕刻)劉昱岑No ratings yet

- Scheme of D.C. Sputtering: StartDocument8 pagesScheme of D.C. Sputtering: StartJawahar DasNo ratings yet

- Specification For Painting Appendix-1 Coating System On Metallic SurfacesDocument18 pagesSpecification For Painting Appendix-1 Coating System On Metallic SurfacesLy Thanh HaNo ratings yet

- Toaz - Info Silicon Vlsi Technology Fundamentals Practice and Modeling PRDocument43 pagesToaz - Info Silicon Vlsi Technology Fundamentals Practice and Modeling PRNikita MadaviNo ratings yet

- Lecture 42Document18 pagesLecture 42Nathan KemboNo ratings yet

- PCB Manufacturing Process PDFDocument21 pagesPCB Manufacturing Process PDFAnima RahdriyaNo ratings yet

- ch1 (20231004)Document32 pagesch1 (20231004)jane8773No ratings yet

- IC Fabrication Technology - L3 - FinDocument23 pagesIC Fabrication Technology - L3 - FinPublicityNo ratings yet

- V Grubsky-3D Backscatter X-RayDocument30 pagesV Grubsky-3D Backscatter X-Rayugo_rossiNo ratings yet

- Micro and Smart SystemsDocument22 pagesMicro and Smart SystemsGopinath ChakrabortyNo ratings yet

- Lithography: Overview of Process StepsDocument46 pagesLithography: Overview of Process StepsPrakharNo ratings yet

- Charles Bishop - C.a.bishop Consulting LTDDocument24 pagesCharles Bishop - C.a.bishop Consulting LTDchipulinoNo ratings yet

- Lab Course Projects PDFDocument1 pageLab Course Projects PDFingenieria softwareNo ratings yet

- Introduction To Microfabrication: PHYS 534 (Fall 2008)Document34 pagesIntroduction To Microfabrication: PHYS 534 (Fall 2008)LydiaNo ratings yet

- Chapter 3 Fabrication of Cmos Integrated Circuits Jin Fu Li Department of Electrical Engineering National Central University Jhongli TaiwanDocument37 pagesChapter 3 Fabrication of Cmos Integrated Circuits Jin Fu Li Department of Electrical Engineering National Central University Jhongli TaiwanYusra AmeenNo ratings yet

- 20080701-061-LCD Lithography Process & EquipmentDocument49 pages20080701-061-LCD Lithography Process & Equipmentengineeringhandbook100% (5)

- Taining Manual PL42D5 PL42P5Document58 pagesTaining Manual PL42D5 PL42P5Adriano QuintanilhaNo ratings yet

- Exposure Light Source: - High-Pressure Mercury Lamp - Excimer Laser - Short Wavelength - High Intensity - StableDocument47 pagesExposure Light Source: - High-Pressure Mercury Lamp - Excimer Laser - Short Wavelength - High Intensity - StableMuhammad Muzammil SaleemNo ratings yet

- Introduction To Mems EA C415: Dr. N.N. SharmaDocument14 pagesIntroduction To Mems EA C415: Dr. N.N. SharmaArjit GoswamiNo ratings yet

- PCB - Fault DetectionDocument8 pagesPCB - Fault DetectionDinti SaiNo ratings yet

- LCD-TFT Tech Info and SpecsDocument45 pagesLCD-TFT Tech Info and SpecsVương AnhNo ratings yet

- Pentacene TFT Driven AM OLED DisplaysDocument3 pagesPentacene TFT Driven AM OLED DisplayskanchankonwarNo ratings yet

- 6mm Superlite 70 40t Clear +16as+6mm ClearDocument1 page6mm Superlite 70 40t Clear +16as+6mm ClearNav JavNo ratings yet

- 6mm Superlite 70 40t Clear +16as+6mm ClearDocument1 page6mm Superlite 70 40t Clear +16as+6mm ClearNav JavNo ratings yet

- Add-Vision PE Summitt 2010Document18 pagesAdd-Vision PE Summitt 2010Devin MacKenzieNo ratings yet

- 1.john Lau - ASM-CSIA - Recent Advances in PackagingDocument148 pages1.john Lau - ASM-CSIA - Recent Advances in Packagingyang100% (1)

- Proceedings of Spie: Laser Annealing of LTPSDocument10 pagesProceedings of Spie: Laser Annealing of LTPSzidan ojaNo ratings yet

- 01 Mon - Jun23 Trouble Shooting - Panel (Compatibility Mode)Document51 pages01 Mon - Jun23 Trouble Shooting - Panel (Compatibility Mode)بوند بوندNo ratings yet

- Reflectivity Study of The 2-D Macroporous Silicon Photonic CrystalsDocument23 pagesReflectivity Study of The 2-D Macroporous Silicon Photonic CrystalsJosep Ferre-BorrullNo ratings yet

- FCBGA带Core基板制造工艺流程 FCBGAProcessflowDocument18 pagesFCBGA带Core基板制造工艺流程 FCBGAProcessflowhhaiddaoNo ratings yet

- EE235 - Paper1 - DarsenDocument19 pagesEE235 - Paper1 - DarsenYusman AlrizkyNo ratings yet

- Trouble Shooting - Panel 20140612043059324Document51 pagesTrouble Shooting - Panel 20140612043059324Mohamed SalahNo ratings yet

- 9787-48370 Performance Assessment of DR SystemsDocument11 pages9787-48370 Performance Assessment of DR SystemsJames BondNo ratings yet

- ICAPE - Flex & Rigid-Flex PCB Spec Template Ver 1.2Document24 pagesICAPE - Flex & Rigid-Flex PCB Spec Template Ver 1.2digicromNo ratings yet

- OLEDDocument10 pagesOLEDGyurmoooNo ratings yet

- Recent Advances in Display Technologies: Dr. K. R. Sarma Adviser Technology Samtel GroupDocument43 pagesRecent Advances in Display Technologies: Dr. K. R. Sarma Adviser Technology Samtel Groupyadvendra2011No ratings yet

- Dewada 2021 Mater. Res. Express 8 122001Document25 pagesDewada 2021 Mater. Res. Express 8 122001AynamawNo ratings yet

- A MAIC Approach To TFT-LCD Panel Quality Improvement: Microelectronics Reliability July 2006Document11 pagesA MAIC Approach To TFT-LCD Panel Quality Improvement: Microelectronics Reliability July 2006NG JIA QIANNo ratings yet

- Digital Color Management: Encoding SolutionsFrom EverandDigital Color Management: Encoding SolutionsRating: 5 out of 5 stars5/5 (1)

- Photoalignment of Liquid Crystalline Materials: Physics and ApplicationsFrom EverandPhotoalignment of Liquid Crystalline Materials: Physics and ApplicationsNo ratings yet

- Scored Edge Strength: 4-Point-Bending Test Make Samples With ChangingDocument1 pageScored Edge Strength: 4-Point-Bending Test Make Samples With Changingghost2humanNo ratings yet

- Clamshell Test, Out Put of The Test: Display Technologies Corning Restricted Corning Technology CenterDocument1 pageClamshell Test, Out Put of The Test: Display Technologies Corning Restricted Corning Technology Centerghost2humanNo ratings yet

- Scoring Damage: Score Track by Standard Wheel Score Track by Penett® WheelDocument1 pageScoring Damage: Score Track by Standard Wheel Score Track by Penett® Wheelghost2humanNo ratings yet

- Laptop Flex-Pages-9Document2 pagesLaptop Flex-Pages-9ghost2humanNo ratings yet

- Surface Defect, Case 2Document1 pageSurface Defect, Case 2ghost2humanNo ratings yet

- Tsbrcrit 19V063 0843Document7 pagesTsbrcrit 19V063 0843ghost2humanNo ratings yet

- Cat Adoption Questionnaire: Name: Address: City: Postal Code: Telephone: CellDocument2 pagesCat Adoption Questionnaire: Name: Address: City: Postal Code: Telephone: Cellghost2humanNo ratings yet

- Engineers Act 1Document13 pagesEngineers Act 1ghost2humanNo ratings yet

- 2023 English Catalog Full CompleteDocument91 pages2023 English Catalog Full Completeghost2humanNo ratings yet

- PRS ScheduleDocument1 pagePRS Scheduleghost2humanNo ratings yet

- APSC 279 Materials Properties Lab Required Reading For Each Lab 2012-13Document2 pagesAPSC 279 Materials Properties Lab Required Reading For Each Lab 2012-13ghost2humanNo ratings yet

- NPPE Candidate GuideDocument16 pagesNPPE Candidate Guideghost2humanNo ratings yet

- Q1 Lesson 1 - Introduction To Computer & Its CharacteristicsDocument23 pagesQ1 Lesson 1 - Introduction To Computer & Its CharacteristicsAlyssaNo ratings yet

- STE Grade 10 Electronics Q1 Module 6Document21 pagesSTE Grade 10 Electronics Q1 Module 6harry timbol100% (1)

- (Teikoku Rotary Gurdian) : Bearing Wearing Monitor For Teikoku Canned Motor PumpDocument18 pages(Teikoku Rotary Gurdian) : Bearing Wearing Monitor For Teikoku Canned Motor Pumpneliomedina01No ratings yet

- Foundation of Information and Communication Technology Facilitator: DR Igwe Joseph SundayDocument15 pagesFoundation of Information and Communication Technology Facilitator: DR Igwe Joseph SundayFrancis OmongaNo ratings yet

- 1 Darlington Pair AmplifierDocument2 pages1 Darlington Pair AmplifierSheikh Noor MohammadNo ratings yet

- What Effect Does Direct Coupling Have On A Two Stage BJT AmplifierDocument63 pagesWhat Effect Does Direct Coupling Have On A Two Stage BJT Amplifierzraider50% (2)

- 772484EN-7+Pocket+Doppler+IFU SR2Document58 pages772484EN-7+Pocket+Doppler+IFU SR2Nattawut ZuesatNo ratings yet

- EMEC F FA Series Instruction Manual R1 11 03Document28 pagesEMEC F FA Series Instruction Manual R1 11 03antonio vukeNo ratings yet

- Tableau de Commande PCC1.2Document6 pagesTableau de Commande PCC1.2thainarimeNo ratings yet

- TC909A and B, TC910N and R, TC941A: Eclipse™ Series Intelligent ModulesDocument2 pagesTC909A and B, TC910N and R, TC941A: Eclipse™ Series Intelligent ModulessureshNo ratings yet

- Construction of SRMDocument5 pagesConstruction of SRMdhanusiya balamuruganNo ratings yet

- TransducersDocument24 pagesTransducersSania NowshinNo ratings yet

- LTC6810 1 6810 2Document86 pagesLTC6810 1 6810 2jonathan.hodaNo ratings yet

- Exercise Sheet 1: Buck-Converter (Step-Down Converter)Document10 pagesExercise Sheet 1: Buck-Converter (Step-Down Converter)Fury NightNo ratings yet

- ESL-429 & 449 Smoke DetectorsDocument6 pagesESL-429 & 449 Smoke DetectorsBenjamin DoverNo ratings yet

- Analysis of Commutation in DC MachinesDocument57 pagesAnalysis of Commutation in DC Machinesagnostic07No ratings yet

- Unit-1 ACADocument86 pagesUnit-1 ACArestin069No ratings yet

- History of MicroelectronicsDocument60 pagesHistory of MicroelectronicsRalph Laurence G VisayaNo ratings yet

- Led Eco Floodlight 100 W 6500 K Gray: Product DatasheetDocument3 pagesLed Eco Floodlight 100 W 6500 K Gray: Product Datasheetfirman pahrizalNo ratings yet

- Solar Cell Losses and Design: Arno SmetsDocument17 pagesSolar Cell Losses and Design: Arno SmetsGianmarco PeñaNo ratings yet

- Expected Floor Puzzle Reasoning Questions For Bank MainsDocument51 pagesExpected Floor Puzzle Reasoning Questions For Bank MainsShobhit MohtaNo ratings yet

- HI 98509 (Checktemp®1) : Instruction ManualDocument2 pagesHI 98509 (Checktemp®1) : Instruction ManualJhonatan Alexander Soto RodriguezNo ratings yet

- Czns 4 PDocument14 pagesCzns 4 PВасилий ВасильченкоNo ratings yet

- Model: Rotation: Clockwise Air Ow Outlet: Air Out Over Struts 1: Average Values in Free AirDocument2 pagesModel: Rotation: Clockwise Air Ow Outlet: Air Out Over Struts 1: Average Values in Free Airboubker2bessaiNo ratings yet

- Was-1923 CKT&PCBDocument4 pagesWas-1923 CKT&PCBReginaldo souza santosNo ratings yet

- Rac03 K PDFDocument6 pagesRac03 K PDFSimon AmplemanNo ratings yet

- EC503 Partha ChakrabortyDocument8 pagesEC503 Partha ChakrabortyPartha ChakrabortyNo ratings yet

- Cordless Impact Wrench: Instruction ManualDocument12 pagesCordless Impact Wrench: Instruction ManualCésar PérezNo ratings yet

- Danotherm WirewoundPowerResistorsDocument4 pagesDanotherm WirewoundPowerResistorsAsderaNo ratings yet

- A Novel Bridge-Type Hybrid Saturated Core Fault Current Limiter Based On Permanent MagnetsDocument4 pagesA Novel Bridge-Type Hybrid Saturated Core Fault Current Limiter Based On Permanent MagnetsGul Ahmad LudinNo ratings yet