Professional Documents

Culture Documents

Pt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection Report

Pt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection Report

Uploaded by

rmohharypermana09Copyright:

Available Formats

You might also like

- Check List For Cable Glanding & TerminationDocument1 pageCheck List For Cable Glanding & TerminationImran Khan100% (4)

- Induction Motor Problems With SolutionsDocument24 pagesInduction Motor Problems With SolutionsVíctor RojasNo ratings yet

- Cable Continuity and Insulation Test Quality Control and Inspection Report FormDocument1 pageCable Continuity and Insulation Test Quality Control and Inspection Report FormHesham Helal100% (1)

- CC 7502 - INSTRUMENT INSTALLATION & HOOK-UP INSPECTION CHECKLIST - Rev 3Document2 pagesCC 7502 - INSTRUMENT INSTALLATION & HOOK-UP INSPECTION CHECKLIST - Rev 3samboopathiNo ratings yet

- Checklist of Panels - 00047 NewDocument6 pagesChecklist of Panels - 00047 NewKarthick Natrajan100% (1)

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Pt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection ReportDocument1 pagePt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection Reportrmohharypermana09No ratings yet

- Oper Epc NGRDocument3 pagesOper Epc NGRarief bayuNo ratings yet

- Oper Epc CathodicDocument1 pageOper Epc Cathodicarief bayuNo ratings yet

- F-QAQC-17, Rev.B - FAT LV Panel PDFDocument3 pagesF-QAQC-17, Rev.B - FAT LV Panel PDFpw ptusa100% (1)

- Underground Drainage Pipes - Installation & TestingDocument1 pageUnderground Drainage Pipes - Installation & TestingBharathraj RajNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - ADocument2 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AAmyNo ratings yet

- Field Inspection: Wps / PQR (Civil Welding Works)Document1 pageField Inspection: Wps / PQR (Civil Welding Works)Ferix Orlando GultomNo ratings yet

- Itr Ew 05a - EngDocument1 pageItr Ew 05a - Engwassim nasriNo ratings yet

- Equipment Accesories Installation FurnaceDocument1 pageEquipment Accesories Installation Furnaceharisona09No ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - ADocument2 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AAmyNo ratings yet

- ElectroMechanical Completion-INTRINSICALLY SAFE (IS) - System Check ListDocument2 pagesElectroMechanical Completion-INTRINSICALLY SAFE (IS) - System Check Listhuseyinyuksel1903No ratings yet

- ICL-E-007-02 Check List For Wiring Accessories InstallationDocument1 pageICL-E-007-02 Check List For Wiring Accessories Installationislam mohamedNo ratings yet

- Itr Ew 07a - EngDocument1 pageItr Ew 07a - Engwassim nasriNo ratings yet

- IGCC-OPM-QUA-FMT-0091 Rev.0 - CABLE TRENCH AND DUCT BANK INSPECTION BEFORE CABLE PULLINGDocument1 pageIGCC-OPM-QUA-FMT-0091 Rev.0 - CABLE TRENCH AND DUCT BANK INSPECTION BEFORE CABLE PULLINGAhmedNo ratings yet

- ITR-CNI (Instrument)Document21 pagesITR-CNI (Instrument)mahmoudNo ratings yet

- ACP Cladding InstallationDocument1 pageACP Cladding InstallationGabriel GabeNo ratings yet

- OPER-EPC-Power TransformerDocument2 pagesOPER-EPC-Power Transformerarief bayuNo ratings yet

- Equipment Accesories Installation Vessel ColumnDocument1 pageEquipment Accesories Installation Vessel Columnharisona09No ratings yet

- Itr Ew 04a - EngDocument2 pagesItr Ew 04a - Engwassim nasriNo ratings yet

- Itr Ew 01a - EngDocument2 pagesItr Ew 01a - Engwassim nasriNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - CDocument2 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - CAmyNo ratings yet

- Safety ClampDocument3 pagesSafety ClampMuhammed AthaullahNo ratings yet

- IQ Procedure & Report ALP AutoclaveDocument9 pagesIQ Procedure & Report ALP AutoclavePhong LeNo ratings yet

- ICL-E-005-02 Check List For Low Volatage Cables & Building WiresDocument1 pageICL-E-005-02 Check List For Low Volatage Cables & Building Wiresislam mohamedNo ratings yet

- Itr-Pgr (GRP Piping)Document10 pagesItr-Pgr (GRP Piping)mahmoudNo ratings yet

- OPER EPC LightningDocument1 pageOPER EPC Lightningarief bayuNo ratings yet

- Field Inspection: Pt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection ReportDocument6 pagesField Inspection: Pt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection Reportrmohharypermana09No ratings yet

- ElectroMechanical Completion-PRE INSTALLATION-INSTRUMENT INSPECTIONDocument1 pageElectroMechanical Completion-PRE INSTALLATION-INSTRUMENT INSPECTIONhuseyinyuksel1903No ratings yet

- Generator Inspection Checklist: Etwork Evelopment RoupDocument2 pagesGenerator Inspection Checklist: Etwork Evelopment RoupPhel Flores100% (1)

- 7SJ62 - Directional PH OCDocument3 pages7SJ62 - Directional PH OCSanthosh Kumar VinayagamNo ratings yet

- Field Insfection Report: Project No. Item No Concrete Prepouring Check List Location SignatureDocument5 pagesField Insfection Report: Project No. Item No Concrete Prepouring Check List Location SignatureFahri Halomoan LoebisNo ratings yet

- Concrete Prepouring Check ListDocument5 pagesConcrete Prepouring Check ListFahri Halomoan LoebisNo ratings yet

- LV PanelDocument11 pagesLV PanelGajendran SriramNo ratings yet

- Epcc MBC Pilot Plant Skid For Tgast-Electrical & Instrumentation WorksDocument11 pagesEpcc MBC Pilot Plant Skid For Tgast-Electrical & Instrumentation Workssaffririzal4237No ratings yet

- Itp CCTVDocument1 pageItp CCTVDimas DimasNo ratings yet

- Site Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationDocument7 pagesSite Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationSyed Abbas100% (1)

- ICL-E-007-01 (Material Receiving Check List)Document1 pageICL-E-007-01 (Material Receiving Check List)islam mohamedNo ratings yet

- General Data and InformationDocument5 pagesGeneral Data and InformationdeltavijayakumarNo ratings yet

- PUNCH LIST - PipingDocument1 pagePUNCH LIST - PipingtalhaNo ratings yet

- Distribution PanelDocument5 pagesDistribution PanelSourav RanaNo ratings yet

- Inspection and Test Plan Cargo Barge: Page 1 of 2Document2 pagesInspection and Test Plan Cargo Barge: Page 1 of 2ferdyNo ratings yet

- CCVT-VT Test ProtocolDocument6 pagesCCVT-VT Test Protocolemad mallickNo ratings yet

- False CeilingDocument2 pagesFalse CeilingGabriel GabeNo ratings yet

- Cable Pulling and Laying Inspection Checklist: P0022-CS-E-004Document1 pageCable Pulling and Laying Inspection Checklist: P0022-CS-E-004nayumNo ratings yet

- Electrical ConduitingDocument1 pageElectrical ConduitingGabriel GabeNo ratings yet

- ElectroMechanical Completion-INSTRUMENT INSTALLATIONDocument1 pageElectroMechanical Completion-INSTRUMENT INSTALLATIONhuseyinyuksel1903No ratings yet

- Test PackDocument38 pagesTest PackAbdülHak ÖZkara100% (1)

- OPER-EPC-MV HV Cable TerminationDocument2 pagesOPER-EPC-MV HV Cable Terminationarief bayuNo ratings yet

- Current TransformerDocument12 pagesCurrent TransformerSyed AbbasNo ratings yet

- Check List For Sub Main Distribution Board InstallationDocument2 pagesCheck List For Sub Main Distribution Board InstallationNaing Win TunNo ratings yet

- Side Door ElevatorDocument3 pagesSide Door ElevatorMuhammed AthaullahNo ratings yet

- Oper Epc Cable TrayDocument1 pageOper Epc Cable Trayarief bayuNo ratings yet

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Title: Ups Installation ChecklistDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Title: Ups Installation ChecklistmeeNo ratings yet

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachFrom EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNo ratings yet

- Electrical AuditDocument55 pagesElectrical AuditSushil Kumar100% (1)

- Silicon Photonics Biosensors For Cancer Cells DetectionDocument20 pagesSilicon Photonics Biosensors For Cancer Cells Detectionpeslover46No ratings yet

- DX-1710-2690-65-19.5i-M: Electrical PropertiesDocument2 pagesDX-1710-2690-65-19.5i-M: Electrical PropertiesАлександрNo ratings yet

- Current ElectricityiDocument60 pagesCurrent ElectricityiAshok PradhanNo ratings yet

- Preliminary: Electrical System 330 and 330 GC Excavator (PILOT)Document4 pagesPreliminary: Electrical System 330 and 330 GC Excavator (PILOT)falahNo ratings yet

- Photo Effect QuestionsDocument3 pagesPhoto Effect QuestionsessaidNo ratings yet

- Model No.: YSL-R596CR3G4B5C-C10 RED/GREEN/BLUE Triple Color LEDDocument4 pagesModel No.: YSL-R596CR3G4B5C-C10 RED/GREEN/BLUE Triple Color LEDAnand ReddyNo ratings yet

- 12au7-6111 Valve Caster r2Document11 pages12au7-6111 Valve Caster r2api-325533895No ratings yet

- Fundamentals Engineering Examination 2019: Professional Engineers Registration ExaminationDocument51 pagesFundamentals Engineering Examination 2019: Professional Engineers Registration ExaminationSuper HNo ratings yet

- Operation and Installation: Residential/Commercial Generator SetsDocument52 pagesOperation and Installation: Residential/Commercial Generator SetsStevenNo ratings yet

- Zero EMIDocument4 pagesZero EMIthanna9783No ratings yet

- 06-905 Output Analyzer Manual Testing ToolDocument22 pages06-905 Output Analyzer Manual Testing Toolijas ahmedNo ratings yet

- Microwave Pinoy BixDocument48 pagesMicrowave Pinoy BixKenNo ratings yet

- Smbus Controlled Nvdc-1 Charge Controller, N-CH Mosfet Selector and Current MonitorDocument24 pagesSmbus Controlled Nvdc-1 Charge Controller, N-CH Mosfet Selector and Current MonitorfscribdNo ratings yet

- Osram HBO Guide For Design of Equipment Brochure 1975Document6 pagesOsram HBO Guide For Design of Equipment Brochure 1975Alan MastersNo ratings yet

- Danfoss Secop FR7GHDocument2 pagesDanfoss Secop FR7GHwinNo ratings yet

- Catalog Diode ZenerDocument6 pagesCatalog Diode ZenerBorcan CristiNo ratings yet

- Integrated CircuitsDocument13 pagesIntegrated CircuitsAbdelheq SaidouneNo ratings yet

- 3rd Quarter Eim SmawDocument4 pages3rd Quarter Eim Smawronaldo de guzmanNo ratings yet

- JW-PP Kejuruteraan Elektrik & Elektronik2Document13 pagesJW-PP Kejuruteraan Elektrik & Elektronik2Muhammad Izzat RoslanNo ratings yet

- Optimized Design of Salient Pole Synchronous Generators: O.W. AndersenDocument3 pagesOptimized Design of Salient Pole Synchronous Generators: O.W. AndersenguestNo ratings yet

- MTech Final ThesisDocument88 pagesMTech Final Thesisprajjawal.202vl017No ratings yet

- Design of Integrated Cmos Circuits For Parallel Detection and Storage of Optical DataDocument178 pagesDesign of Integrated Cmos Circuits For Parallel Detection and Storage of Optical DataaurybNo ratings yet

- Easun Power Technology Corp LimitedDocument45 pagesEasun Power Technology Corp LimitedIgors Spaskis100% (1)

- Grounding Busbar PDFDocument6 pagesGrounding Busbar PDFAgnolas GradeNo ratings yet

- C-453eb SigmaDocument2 pagesC-453eb SigmaJunior Ramirez ReyesNo ratings yet

- 07.09..2020 - Intrinsic Carrier ConcentrationDocument14 pages07.09..2020 - Intrinsic Carrier ConcentrationSri Mangai Nathan100% (1)

- Samsung Ws32z30hp Ws32z40ht Cw29z308t s63bDocument148 pagesSamsung Ws32z30hp Ws32z40ht Cw29z308t s63bKostas AthanasiadisNo ratings yet

- ELd 2Document1 pageELd 2sateesh83No ratings yet

Pt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection Report

Pt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection Report

Uploaded by

rmohharypermana09Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection Report

Pt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection Report

Uploaded by

rmohharypermana09Copyright:

Available Formats

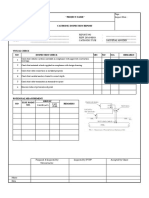

Security Level 2 BG-65132 Appendix (1) - .

PT. NIPPON SHOKUBAI INDONESIA ITP NO. : 6161

NSI ACRYLIC ACID PLANT PHASE 3 PROJECT INSPECTION Gr. : B

FIELD INSPECTION REPORT REPORT NO. :

DATE :

INSPECTION TYPE: WORK NO. :

PANEL NO. :

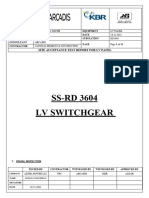

LOW-VOLTAGE SWITCHGEAR

BASIC INSPECTION LOCATION :

(VISUAL INSPECTION) SIGNATURE

INSPECTION NOTICE NO. : S/C IKPT NSI

CLIENT'S INSPECTOR : / / / / / /

IKPT'S INSPECTOR :

CONTRACTOR'S INSPECTOR:

DATE INSPECTED: / / WEATHER: TEMP: °C

REFERENCE DRAWING AND DOCUMENTS:

No of phase : -phase, -wire Short-time withstand current Manufacturer :

EQUIP. DATA

Current : A : kA, s Serial No :

Voltage : kV

Frequency : Hz

Note :

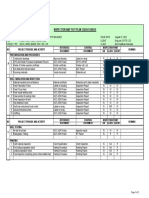

RESULT

NO.

CHECK ITEMS

Pass

N.A.

Fail

Comment

1 Compare nameplate data with approved documents/drawings and confirm no deviation. □ □ □

2 Compare rating plate data with approved documents/drawings and confirm no deviation.□ □ □

3 Check that preservation are in good conditions (no damage, no rust, no undue □ □ □

accumulation of dust and dirt, no condensation etc.).

4 Check that equipment is correctly positioned, aligned, leveled, rigid and secured □ □ □

in accordance with approved vendor drawings and construction drawings.

5 Confirm no cable entry obstructions into equipment. □ □ □

6 Check all panel mounted devices in accordance with approved vendor drawings. □ □ □

7 Check busbar and support for cleanness. □ □ □

8 Check all CTs and VTs for proper installations in accordance with approved vendor □ □ □

drawings.

9 Confirm CT secondary wiring is shorted, if external connection is not provided. □ □ □

10 Confirm CT secondary shorting link is removed, if external connection is provided. □ □ □

11 Check all protection relays for proper installations in accordance with approved □ □ □

vendor drawings.

12 Check all fuses ratings in accordance with approved vendor drawings. □ □ □

13 Check mechanical operations of all switching devices. □ □ □

14 Check all withdrawable units for smooth movements, withdrawing and insertion. □ □ □

15 Check mechanical interlocks of doors, withdrawable unit and earthing switch, if any. □ □ □

16 Check all shutters for correct operations, if provided. □ □ □

17 Check all earthing and bonding in accordance with approved construction drawings. □ □ □

18 Check cables for proper connections (no damage, within allowed cable bending □ □ □

radius, proper cable supports, cable gland tightness and accessories, floor sealing).

19 Check that non-magnetic gland plates are provided for single core cables. □ □ □

20 Check that all vendor supplied special tools and safety equipment are available. □ □ □

Security Level 2 BG-65132 Appendix (1) - .

LEGEND N.A. : Not Applicable

FORM NO. E-161

You might also like

- Check List For Cable Glanding & TerminationDocument1 pageCheck List For Cable Glanding & TerminationImran Khan100% (4)

- Induction Motor Problems With SolutionsDocument24 pagesInduction Motor Problems With SolutionsVíctor RojasNo ratings yet

- Cable Continuity and Insulation Test Quality Control and Inspection Report FormDocument1 pageCable Continuity and Insulation Test Quality Control and Inspection Report FormHesham Helal100% (1)

- CC 7502 - INSTRUMENT INSTALLATION & HOOK-UP INSPECTION CHECKLIST - Rev 3Document2 pagesCC 7502 - INSTRUMENT INSTALLATION & HOOK-UP INSPECTION CHECKLIST - Rev 3samboopathiNo ratings yet

- Checklist of Panels - 00047 NewDocument6 pagesChecklist of Panels - 00047 NewKarthick Natrajan100% (1)

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Pt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection ReportDocument1 pagePt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection Reportrmohharypermana09No ratings yet

- Oper Epc NGRDocument3 pagesOper Epc NGRarief bayuNo ratings yet

- Oper Epc CathodicDocument1 pageOper Epc Cathodicarief bayuNo ratings yet

- F-QAQC-17, Rev.B - FAT LV Panel PDFDocument3 pagesF-QAQC-17, Rev.B - FAT LV Panel PDFpw ptusa100% (1)

- Underground Drainage Pipes - Installation & TestingDocument1 pageUnderground Drainage Pipes - Installation & TestingBharathraj RajNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - ADocument2 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AAmyNo ratings yet

- Field Inspection: Wps / PQR (Civil Welding Works)Document1 pageField Inspection: Wps / PQR (Civil Welding Works)Ferix Orlando GultomNo ratings yet

- Itr Ew 05a - EngDocument1 pageItr Ew 05a - Engwassim nasriNo ratings yet

- Equipment Accesories Installation FurnaceDocument1 pageEquipment Accesories Installation Furnaceharisona09No ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - ADocument2 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AAmyNo ratings yet

- ElectroMechanical Completion-INTRINSICALLY SAFE (IS) - System Check ListDocument2 pagesElectroMechanical Completion-INTRINSICALLY SAFE (IS) - System Check Listhuseyinyuksel1903No ratings yet

- ICL-E-007-02 Check List For Wiring Accessories InstallationDocument1 pageICL-E-007-02 Check List For Wiring Accessories Installationislam mohamedNo ratings yet

- Itr Ew 07a - EngDocument1 pageItr Ew 07a - Engwassim nasriNo ratings yet

- IGCC-OPM-QUA-FMT-0091 Rev.0 - CABLE TRENCH AND DUCT BANK INSPECTION BEFORE CABLE PULLINGDocument1 pageIGCC-OPM-QUA-FMT-0091 Rev.0 - CABLE TRENCH AND DUCT BANK INSPECTION BEFORE CABLE PULLINGAhmedNo ratings yet

- ITR-CNI (Instrument)Document21 pagesITR-CNI (Instrument)mahmoudNo ratings yet

- ACP Cladding InstallationDocument1 pageACP Cladding InstallationGabriel GabeNo ratings yet

- OPER-EPC-Power TransformerDocument2 pagesOPER-EPC-Power Transformerarief bayuNo ratings yet

- Equipment Accesories Installation Vessel ColumnDocument1 pageEquipment Accesories Installation Vessel Columnharisona09No ratings yet

- Itr Ew 04a - EngDocument2 pagesItr Ew 04a - Engwassim nasriNo ratings yet

- Itr Ew 01a - EngDocument2 pagesItr Ew 01a - Engwassim nasriNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - CDocument2 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - CAmyNo ratings yet

- Safety ClampDocument3 pagesSafety ClampMuhammed AthaullahNo ratings yet

- IQ Procedure & Report ALP AutoclaveDocument9 pagesIQ Procedure & Report ALP AutoclavePhong LeNo ratings yet

- ICL-E-005-02 Check List For Low Volatage Cables & Building WiresDocument1 pageICL-E-005-02 Check List For Low Volatage Cables & Building Wiresislam mohamedNo ratings yet

- Itr-Pgr (GRP Piping)Document10 pagesItr-Pgr (GRP Piping)mahmoudNo ratings yet

- OPER EPC LightningDocument1 pageOPER EPC Lightningarief bayuNo ratings yet

- Field Inspection: Pt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection ReportDocument6 pagesField Inspection: Pt. Nippon Shokubai Indonesia Nsi Acrylic Acid Plant Phase 3 Project Field Inspection Reportrmohharypermana09No ratings yet

- ElectroMechanical Completion-PRE INSTALLATION-INSTRUMENT INSPECTIONDocument1 pageElectroMechanical Completion-PRE INSTALLATION-INSTRUMENT INSPECTIONhuseyinyuksel1903No ratings yet

- Generator Inspection Checklist: Etwork Evelopment RoupDocument2 pagesGenerator Inspection Checklist: Etwork Evelopment RoupPhel Flores100% (1)

- 7SJ62 - Directional PH OCDocument3 pages7SJ62 - Directional PH OCSanthosh Kumar VinayagamNo ratings yet

- Field Insfection Report: Project No. Item No Concrete Prepouring Check List Location SignatureDocument5 pagesField Insfection Report: Project No. Item No Concrete Prepouring Check List Location SignatureFahri Halomoan LoebisNo ratings yet

- Concrete Prepouring Check ListDocument5 pagesConcrete Prepouring Check ListFahri Halomoan LoebisNo ratings yet

- LV PanelDocument11 pagesLV PanelGajendran SriramNo ratings yet

- Epcc MBC Pilot Plant Skid For Tgast-Electrical & Instrumentation WorksDocument11 pagesEpcc MBC Pilot Plant Skid For Tgast-Electrical & Instrumentation Workssaffririzal4237No ratings yet

- Itp CCTVDocument1 pageItp CCTVDimas DimasNo ratings yet

- Site Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationDocument7 pagesSite Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationSyed Abbas100% (1)

- ICL-E-007-01 (Material Receiving Check List)Document1 pageICL-E-007-01 (Material Receiving Check List)islam mohamedNo ratings yet

- General Data and InformationDocument5 pagesGeneral Data and InformationdeltavijayakumarNo ratings yet

- PUNCH LIST - PipingDocument1 pagePUNCH LIST - PipingtalhaNo ratings yet

- Distribution PanelDocument5 pagesDistribution PanelSourav RanaNo ratings yet

- Inspection and Test Plan Cargo Barge: Page 1 of 2Document2 pagesInspection and Test Plan Cargo Barge: Page 1 of 2ferdyNo ratings yet

- CCVT-VT Test ProtocolDocument6 pagesCCVT-VT Test Protocolemad mallickNo ratings yet

- False CeilingDocument2 pagesFalse CeilingGabriel GabeNo ratings yet

- Cable Pulling and Laying Inspection Checklist: P0022-CS-E-004Document1 pageCable Pulling and Laying Inspection Checklist: P0022-CS-E-004nayumNo ratings yet

- Electrical ConduitingDocument1 pageElectrical ConduitingGabriel GabeNo ratings yet

- ElectroMechanical Completion-INSTRUMENT INSTALLATIONDocument1 pageElectroMechanical Completion-INSTRUMENT INSTALLATIONhuseyinyuksel1903No ratings yet

- Test PackDocument38 pagesTest PackAbdülHak ÖZkara100% (1)

- OPER-EPC-MV HV Cable TerminationDocument2 pagesOPER-EPC-MV HV Cable Terminationarief bayuNo ratings yet

- Current TransformerDocument12 pagesCurrent TransformerSyed AbbasNo ratings yet

- Check List For Sub Main Distribution Board InstallationDocument2 pagesCheck List For Sub Main Distribution Board InstallationNaing Win TunNo ratings yet

- Side Door ElevatorDocument3 pagesSide Door ElevatorMuhammed AthaullahNo ratings yet

- Oper Epc Cable TrayDocument1 pageOper Epc Cable Trayarief bayuNo ratings yet

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Title: Ups Installation ChecklistDocument1 pageEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Title: Ups Installation ChecklistmeeNo ratings yet

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachFrom EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNo ratings yet

- Electrical AuditDocument55 pagesElectrical AuditSushil Kumar100% (1)

- Silicon Photonics Biosensors For Cancer Cells DetectionDocument20 pagesSilicon Photonics Biosensors For Cancer Cells Detectionpeslover46No ratings yet

- DX-1710-2690-65-19.5i-M: Electrical PropertiesDocument2 pagesDX-1710-2690-65-19.5i-M: Electrical PropertiesАлександрNo ratings yet

- Current ElectricityiDocument60 pagesCurrent ElectricityiAshok PradhanNo ratings yet

- Preliminary: Electrical System 330 and 330 GC Excavator (PILOT)Document4 pagesPreliminary: Electrical System 330 and 330 GC Excavator (PILOT)falahNo ratings yet

- Photo Effect QuestionsDocument3 pagesPhoto Effect QuestionsessaidNo ratings yet

- Model No.: YSL-R596CR3G4B5C-C10 RED/GREEN/BLUE Triple Color LEDDocument4 pagesModel No.: YSL-R596CR3G4B5C-C10 RED/GREEN/BLUE Triple Color LEDAnand ReddyNo ratings yet

- 12au7-6111 Valve Caster r2Document11 pages12au7-6111 Valve Caster r2api-325533895No ratings yet

- Fundamentals Engineering Examination 2019: Professional Engineers Registration ExaminationDocument51 pagesFundamentals Engineering Examination 2019: Professional Engineers Registration ExaminationSuper HNo ratings yet

- Operation and Installation: Residential/Commercial Generator SetsDocument52 pagesOperation and Installation: Residential/Commercial Generator SetsStevenNo ratings yet

- Zero EMIDocument4 pagesZero EMIthanna9783No ratings yet

- 06-905 Output Analyzer Manual Testing ToolDocument22 pages06-905 Output Analyzer Manual Testing Toolijas ahmedNo ratings yet

- Microwave Pinoy BixDocument48 pagesMicrowave Pinoy BixKenNo ratings yet

- Smbus Controlled Nvdc-1 Charge Controller, N-CH Mosfet Selector and Current MonitorDocument24 pagesSmbus Controlled Nvdc-1 Charge Controller, N-CH Mosfet Selector and Current MonitorfscribdNo ratings yet

- Osram HBO Guide For Design of Equipment Brochure 1975Document6 pagesOsram HBO Guide For Design of Equipment Brochure 1975Alan MastersNo ratings yet

- Danfoss Secop FR7GHDocument2 pagesDanfoss Secop FR7GHwinNo ratings yet

- Catalog Diode ZenerDocument6 pagesCatalog Diode ZenerBorcan CristiNo ratings yet

- Integrated CircuitsDocument13 pagesIntegrated CircuitsAbdelheq SaidouneNo ratings yet

- 3rd Quarter Eim SmawDocument4 pages3rd Quarter Eim Smawronaldo de guzmanNo ratings yet

- JW-PP Kejuruteraan Elektrik & Elektronik2Document13 pagesJW-PP Kejuruteraan Elektrik & Elektronik2Muhammad Izzat RoslanNo ratings yet

- Optimized Design of Salient Pole Synchronous Generators: O.W. AndersenDocument3 pagesOptimized Design of Salient Pole Synchronous Generators: O.W. AndersenguestNo ratings yet

- MTech Final ThesisDocument88 pagesMTech Final Thesisprajjawal.202vl017No ratings yet

- Design of Integrated Cmos Circuits For Parallel Detection and Storage of Optical DataDocument178 pagesDesign of Integrated Cmos Circuits For Parallel Detection and Storage of Optical DataaurybNo ratings yet

- Easun Power Technology Corp LimitedDocument45 pagesEasun Power Technology Corp LimitedIgors Spaskis100% (1)

- Grounding Busbar PDFDocument6 pagesGrounding Busbar PDFAgnolas GradeNo ratings yet

- C-453eb SigmaDocument2 pagesC-453eb SigmaJunior Ramirez ReyesNo ratings yet

- 07.09..2020 - Intrinsic Carrier ConcentrationDocument14 pages07.09..2020 - Intrinsic Carrier ConcentrationSri Mangai Nathan100% (1)

- Samsung Ws32z30hp Ws32z40ht Cw29z308t s63bDocument148 pagesSamsung Ws32z30hp Ws32z40ht Cw29z308t s63bKostas AthanasiadisNo ratings yet

- ELd 2Document1 pageELd 2sateesh83No ratings yet