Professional Documents

Culture Documents

AGV Exercises

AGV Exercises

Uploaded by

Mỹ Quyên Nguyễn HữuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AGV Exercises

AGV Exercises

Uploaded by

Mỹ Quyên Nguyễn HữuCopyright:

Available Formats

AGV EXERCISES

(AUTOMATED GUIDED VECHILES)

1. A planned fleet of forklift trucks has an average travel distance per delivery =500 ft loaded and an

average empty travel distance =350 ft. The fleet must take a total of 60 del/hr. Load and unload times

are each .5 min and the speed of the vehicle = 300 ft/min. The traffic factor for the system =.85.

Availability is expected to be .95 and worker efficiency is assumed to be.90. Determine:

(a) idle cycle time per delivery,

(b) the resulting average number of deliveries per hour that a forklift truck can make, and

(c) how many trucks are required to accomplish the 60del/hr.

2. An automated guided vehicle system has an average travel distance per delivery =200m and an

average empty travel distance=150m. Load and unload times are each 24s and the speed of the

AGV=1m/s. Traffic factor=0.9. How many vehicles are needed to satisfy a delivery requirement of

30del/hr? Assume A= 0.95.

3. Four forklift trucks are used to deliver pallet loads of parts between works cells in the factory.

Average travel distance loaded is 350ft, and the travel distance empty is estimated to be the same. The

trucks are driven at an average speed of 3m/hr when loaded and4m/hr when empty. Terminal time per

delivery average 1 min (load =0.5min and unload =0.5min) If the traffic factor is assumed to be 0.90,

availability =1.0 and work efficiency = 0.95, what is the maximum hourly delivery rate of the four

trucks?

4. Pradeep Engineering is contemplating to integrate the AGVS and AS/RS with their flexible

manufacturing system. It is also in the process of determination of number of AGVSs for its

manufacturing system. It has to deliver 67 pieces per hour. The company has decided in favor of

installing a wire guided path system and the unit load AGVS. The following data has been collected as

shown in Table.

Vehicle Speed 200 ft/min

Average loaded travel distance per delivery 600ft

Average empty travel distance per delivery 400 ft

Pickup time 0.25 min

Drop-off time 0.25 min

Traffic factor 0.75

5. An automated manufacturing system for machining crankshafts in a forging industry is planning to

implement AGVs in the organization. There are five CNC workstations (A, B, C, D, E) and a load-

unload station (F). Approximate time of moving the crankshaft on AGVS between stations is shown in

Table

Table: Approximate Time of Moving the Crankshaft on AGVS between Stations

One hundred crankshafts are machined in every 8-h shift and the operations on the crankshaft are

performed in sequence from station A through E. Taking an assumption that every pickup and drop-

off operation takes approximately 0.75 min, determine the number of AGVSs to meet the demand of

moving 100 crankshafts. The load factor is assumed to be 0.75 and the traffic factor 0.95.

6. A flexible manufacturing system (FMS) is being planned. It has a ladder layout as pictured in Figure.

It uses a rail guided vehicle (RGV) system to move parts between stations in the layout.

All work parts are loaded into the system at station 1, moved to one of three processing stations (2, 3,

or 4), and then brought back to station 1 for unloading. Once loaded onto its RGV, each work part stays

onboard the vehicle throughout its time in the FMS. Load and unload times at station 1 are each 1.0

min. Processing times are: 5.0 min at station 2; 7.0 min at station 3; and 9.0 min at station 4. Hourly

production of parts through the system is: 7 parts through station 2; 6 parts through station 3 and 5 parts

through station 4. no of delivery per system per hour

(a) Develop the from-to Chart for trips and distances.

(b) Develop the network diagram.

(c) Determine the number of rails guided vehicles that are needed to meet the requirements of the

flexible manufacturing system, if vehicle speed = 60 m/min and the anticipated traffic

factor = 0.85. Assume reliability = 100%.

7. An AGVs will be used to satisfy material flows indicated in the from-to Chart in the table below,

which shows deliveries per hour between stations (above the slash) and distances in meters between

stations (below the slash). Moves indicated by "L" are trips in which the vehicle is loaded, while "E"

indicates moves in which the vehicle is empty. It is assumed that availability is 0.90, traffic factor is

0.85, and efficiency is 1.0. Speed of an AGV is 0.9 m/s. If load handling time per delivery cycle is 1.0

min, determine the number of vehicles needed to satisfy the indicated deliveries per hour? Assume that

availability is 0.90.

To: 1 2 3 4

From: 1 0/0 9L/90 7L/120 5L/75

2 5E/90 0/0 0/NA 4L/80

3 7E/120 0/NA 0/0 0/NA

4 9E/75 0/NA 0/NA 0/0

You might also like

- Deed of Agreement For Car Rent: Name: Mr. Liu Zhan Hua Company Name: Company AddressDocument2 pagesDeed of Agreement For Car Rent: Name: Mr. Liu Zhan Hua Company Name: Company AddressSiam Hossain Hr100% (3)

- Assembling Fabia Engine AZQDocument9 pagesAssembling Fabia Engine AZQbuerebista100% (2)

- Komatsu ABNORMALITY CODE LISTDocument33 pagesKomatsu ABNORMALITY CODE LISTap91997692% (13)

- Agv ProblemsDocument10 pagesAgv Problems19M647 - SRIRAM ANo ratings yet

- Assignment For FlexsimDocument5 pagesAssignment For FlexsimShubham MehlaNo ratings yet

- PARTLIST Benelli 150S 150S Key63 d2021 08 10 06 57 34pmDocument78 pagesPARTLIST Benelli 150S 150S Key63 d2021 08 10 06 57 34pmMohamed ali AmeurNo ratings yet

- Agv Ex 1Document1 pageAgv Ex 1Lương Bảo HânNo ratings yet

- Bài Tập Tiểu LuậnDocument5 pagesBài Tập Tiểu LuậnToy and MeNo ratings yet

- Assignment Urban Public TransporDocument6 pagesAssignment Urban Public TransporAmeerNo ratings yet

- Sample PM ChecklistDocument4 pagesSample PM ChecklistmohsinsafiNo ratings yet

- SD100D, SD100F: Volvo SINGLE Drum CompactorsDocument4 pagesSD100D, SD100F: Volvo SINGLE Drum CompactorsAgung ArdhanaNo ratings yet

- Agv - Ex 2Document2 pagesAgv - Ex 2Quỳnh NguyễnNo ratings yet

- Reviews 1: International UniversityDocument11 pagesReviews 1: International UniversityQuỳnh NguyễnNo ratings yet

- 23 14 SA V1 S1 - Agv Ass2Document5 pages23 14 SA V1 S1 - Agv Ass2Gaurav KhandelwalNo ratings yet

- REVIEW 1 - MhsDocument3 pagesREVIEW 1 - MhsHoang Anh Huy VoNo ratings yet

- Reviews 1 - AnswerDocument13 pagesReviews 1 - AnswerQuỳnh NguyễnNo ratings yet

- Exercises 15 10Document1 pageExercises 15 10Hiền Trang Lê ThiênNo ratings yet

- Automated Guided Vechiles: Worked Out ProblemsDocument5 pagesAutomated Guided Vechiles: Worked Out ProblemsMaria Luisa Solomon AdsuaraNo ratings yet

- MCE 439 Assignment 3Document2 pagesMCE 439 Assignment 3Ammar1994No ratings yet

- Tutorial 1 Material TransportDocument2 pagesTutorial 1 Material TransportSu YiNo ratings yet

- 15 Integrated Manufacturing Systems Lecture #15 HandoutDocument2 pages15 Integrated Manufacturing Systems Lecture #15 HandoutFelipeNo ratings yet

- EXAMPLE 1: Consider The AGVS Layout in Figure - Vehicles Travel Counterclockwise AroundDocument12 pagesEXAMPLE 1: Consider The AGVS Layout in Figure - Vehicles Travel Counterclockwise AroundQuỳnh Nguyễn100% (1)

- Noi Dung On Tap 20-11-2023Document3 pagesNoi Dung On Tap 20-11-2023hoaithanh1309.idolNo ratings yet

- Sheet 2 2017-2018Document7 pagesSheet 2 2017-2018Yahya Abdelhameed AamerNo ratings yet

- Non-Traditional Machining and Automation: B.Tech. (4 Sem) Spring 2021 Department of Mechanical Engineering NIT SrinagarDocument14 pagesNon-Traditional Machining and Automation: B.Tech. (4 Sem) Spring 2021 Department of Mechanical Engineering NIT SrinagarJatin prasad TandanNo ratings yet

- IE551 Production System Design - Chapter 6 (Solved Problems)Document3 pagesIE551 Production System Design - Chapter 6 (Solved Problems)lore0020% (1)

- Assignment No.: 02: Take This Assignment From Mr. Pai and Give That Assignment To StudentsDocument1 pageAssignment No.: 02: Take This Assignment From Mr. Pai and Give That Assignment To StudentsjcspaiNo ratings yet

- Industrial Engineering: Tutorials ForDocument18 pagesIndustrial Engineering: Tutorials ForYahya Abdelhameed AamerNo ratings yet

- Model Paper 18ME7G3Document4 pagesModel Paper 18ME7G3Xaf FarNo ratings yet

- Industrial Engineering Tutorials: 1 Page - 2016-2017Document17 pagesIndustrial Engineering Tutorials: 1 Page - 2016-2017Yahya Abdelhameed AamerNo ratings yet

- Assignment FMSDocument2 pagesAssignment FMSAnuragShrivastavNo ratings yet

- Review 1: Focus 1) Chapter 1: Introduction To MHSDocument3 pagesReview 1: Focus 1) Chapter 1: Introduction To MHSKhánh Linh NguyễnNo ratings yet

- Problem CONEN 442 Set1 S2024Document3 pagesProblem CONEN 442 Set1 S2024Wael ElDessoukiNo ratings yet

- 8450 ESE DEC21 SOE 7 B.tech (ME) MEPD4014 Automation in ManufacturingDocument2 pages8450 ESE DEC21 SOE 7 B.tech (ME) MEPD4014 Automation in ManufacturingJoy SummersNo ratings yet

- QuestionDocument18 pagesQuestionHafizul Fiqry Shahrul Anwar100% (2)

- TransportationDocument2 pagesTransportationBERNARD L. ARICOSNo ratings yet

- Material Transport Systems TutorialDocument33 pagesMaterial Transport Systems TutorialgidlavinayNo ratings yet

- 04 FMSDocument6 pages04 FMSz8699No ratings yet

- Traffic Engineering CE2060 AssignmentsDocument4 pagesTraffic Engineering CE2060 AssignmentsAkhilesh MehraNo ratings yet

- Punto 1 EVALUACIONDocument6 pagesPunto 1 EVALUACIONYenny Paola Castrillon BelloNo ratings yet

- 5-Conveyor QuestionsDocument4 pages5-Conveyor QuestionsRania ElrifaiNo ratings yet

- AN00122-003 - Rotary Axis Flying ShearDocument6 pagesAN00122-003 - Rotary Axis Flying ShearamirixmNo ratings yet

- Mid EXDocument4 pagesMid EXsabeaxNo ratings yet

- Advanced Manufacturing Technology MECH4012 Module#3 Tutorial#8 Production LinesDocument4 pagesAdvanced Manufacturing Technology MECH4012 Module#3 Tutorial#8 Production LinesahmedNo ratings yet

- Ch-7 Assembly Line BalanceDocument42 pagesCh-7 Assembly Line BalanceIndra Chandra SetiawanNo ratings yet

- Tutorial 2 Storage System PDF FreeDocument2 pagesTutorial 2 Storage System PDF Freepeter oumaNo ratings yet

- 07a81402 Flexible Manufacturing SystemsDocument4 pages07a81402 Flexible Manufacturing SystemsSharanya ThirichinapalliNo ratings yet

- Case Study: Design of A Conveyorized Production LineDocument10 pagesCase Study: Design of A Conveyorized Production LineEkta GhongeNo ratings yet

- PUC 3114 Project Assignment Work Aug 2023Document8 pagesPUC 3114 Project Assignment Work Aug 2023SKynet Movies Cyber PS4No ratings yet

- CIV516 S: Public Transit Operations and Planning Winter 2019Document3 pagesCIV516 S: Public Transit Operations and Planning Winter 2019mzh887No ratings yet

- Assembly Line Balance OKDocument42 pagesAssembly Line Balance OKLuis ValensNo ratings yet

- Eazc 4121Document1 pageEazc 4121Priyanka MahajanNo ratings yet

- Submitted To Submitted by Prof. Bibhuti Tripathi Gaurav SharmaDocument4 pagesSubmitted To Submitted by Prof. Bibhuti Tripathi Gaurav SharmaSasanka Pritom BhuyanNo ratings yet

- Automated Guided Vehicle System - Ref - Def PracticeDocument1 pageAutomated Guided Vehicle System - Ref - Def PracticeHamza MalikNo ratings yet

- Tutorial 2 Storage SystemDocument2 pagesTutorial 2 Storage SystemSu YiNo ratings yet

- Mce - 42052 Fms Tutorial-I 27.8.2019 (Tue)Document2 pagesMce - 42052 Fms Tutorial-I 27.8.2019 (Tue)Ther Htet AungNo ratings yet

- AE December 2016 98 Civ A6Document7 pagesAE December 2016 98 Civ A6Mohammed BaderNo ratings yet

- ExercisesDocument4 pagesExercisesTôn Nữ Minh UyênNo ratings yet

- Experiment No: 1: Aim: - To Study Automated Flow Line (AFL) & Transfer Line MechanismDocument8 pagesExperiment No: 1: Aim: - To Study Automated Flow Line (AFL) & Transfer Line MechanismJust for funNo ratings yet

- Dynamic Analys Is of Belt Conveyor Based On AMESimDocument2 pagesDynamic Analys Is of Belt Conveyor Based On AMESimAmit BhaduriNo ratings yet

- Final 2 DLDocument2 pagesFinal 2 DLideaNo ratings yet

- Examples FMSDocument6 pagesExamples FMSAli El-Gazzar100% (1)

- Lift and Escalator Motor SizingDocument3 pagesLift and Escalator Motor SizingNabin Shahi0% (1)

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Driver Safety: For Use in Conjunction With 5-Minute Safety TalkDocument15 pagesDriver Safety: For Use in Conjunction With 5-Minute Safety TalkthanNo ratings yet

- History of AirplaneDocument3 pagesHistory of AirplaneHai PhamNo ratings yet

- MDrive ManualDocument36 pagesMDrive ManualNick AbsalomNo ratings yet

- Various ECU Pinout For MPPS V18 With Breakout Cable - OBDexpress - Co.uk Official BlogDocument38 pagesVarious ECU Pinout For MPPS V18 With Breakout Cable - OBDexpress - Co.uk Official Bloggryzzly100% (1)

- Q150 WML 202Document46 pagesQ150 WML 202manualNo ratings yet

- 03 - Killmann - Toyota - Hybrid TechnologyDocument28 pages03 - Killmann - Toyota - Hybrid TechnologymaheshmbelgaviNo ratings yet

- ece轮胎文件Document37 pagesece轮胎文件张正No ratings yet

- Dump Truck ListDocument5 pagesDump Truck ListEko SpdNo ratings yet

- Reese SC Weight Distributing Hitch n66155Document7 pagesReese SC Weight Distributing Hitch n66155Bud HeberlingNo ratings yet

- Wiring Diagrams-6Document6 pagesWiring Diagrams-6Eduar OrtegaNo ratings yet

- AURLTJ102 1 SummaryDocument1 pageAURLTJ102 1 SummaryAWAIS ALI UnknownNo ratings yet

- EU07 ManualDocument9 pagesEU07 Manualdziobale dziobaleNo ratings yet

- 1/4 Ton M276Document427 pages1/4 Ton M276Anthony CoxNo ratings yet

- Darius John Vales Ga03r5799 23-24 PolicyDocument4 pagesDarius John Vales Ga03r5799 23-24 PolicyShreyansh AnkitNo ratings yet

- Suspension Systems and ComponentsDocument90 pagesSuspension Systems and Componentsmaheshgarg81100% (2)

- Tecumseh Model Tvs115 61601 Parts ListDocument7 pagesTecumseh Model Tvs115 61601 Parts ListthndrskiNo ratings yet

- Brochure Tamrock Axera D05Document4 pagesBrochure Tamrock Axera D05Esteban Fernando Meza IbacetaNo ratings yet

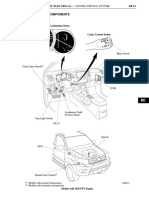

- Layout of Main Components: Body Electrical - Cruise Control System BE-93Document2 pagesLayout of Main Components: Body Electrical - Cruise Control System BE-93Maxi SardiNo ratings yet

- TGCCDocument1 pageTGCC6vvwh4gnfwNo ratings yet

- 6.auxiliary Power UnitDocument5 pages6.auxiliary Power UnitAntonio UrcuyoNo ratings yet

- Initial Quick Test LogDocument5 pagesInitial Quick Test LogFabian IrarrazabalNo ratings yet

- Regenerative Braking SystemDocument20 pagesRegenerative Braking SystemMahesh DondapatiNo ratings yet

- 9900B 10J00 000 Shogun 125 AXELO PDFDocument75 pages9900B 10J00 000 Shogun 125 AXELO PDFfajar musliminNo ratings yet

- 00 169 Panda 603.81.107 en 03 02.07 L LG PDFDocument207 pages00 169 Panda 603.81.107 en 03 02.07 L LG PDFAdi StancuNo ratings yet