Professional Documents

Culture Documents

MDA Frame 7EA Parts Web 02 03 22

MDA Frame 7EA Parts Web 02 03 22

Uploaded by

Ali kamail sadeghian0 ratings0% found this document useful (0 votes)

0 views2 pagesOriginal Title

MDA-Frame-7EA-Parts-Web-02-03-22

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

0 views2 pagesMDA Frame 7EA Parts Web 02 03 22

MDA Frame 7EA Parts Web 02 03 22

Uploaded by

Ali kamail sadeghianCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

ONE CALL. ONE SOURCE. POWERFUL SOLUTIONS.

FRAME 7EA PARTS, REPAIRS & UPGRADES

PARTS

Frame 7EA 1st, 2nd, 3rd Stage Buckets and Shrouds

MD&A NOW OFFERS SOLUTIONS TO EXTEND THE SERVICE LIFE OF YOUR 7EA PARTS.

With leading edge equipment and repair techniques, coupled with proven experience on multiple frame gas turbine hot

gas path and combustion components, our Frame 7EA parts offer unmatched durability to extend service life, all at the

competitive cost and high quality the world has come to expect from MD&A.

Frame 7EA - 1st, 2nd, 3rd Stage Buckets

The Frame 7EA buckets achieve high-temperature performance up to 2055 °F with the application of world-class metallic-

bond coating and thermal barrier coating (TBC).

Frame 7EA - 1st, 2nd, 3rd Stage Shrouds

MECHANICAL DYNAMICS & ANALYSIS

For more information on this product or service please contact MD&A at 210-256-5107 or www.mdaturbines.com

MD&A 7EA PARTS & REPAIRS

7EA 1st Stage Buckets

• Manufactured with an equiaxed nickel-based proprietary alloy

that greatly enhances the life of the part

• Coated with a proprietary coating to ensure superior oxidation

resistance at typical firing temperatures

• Includes an internal aluminide coating

7EA 2nd Stage Buckets

• Manufactured from an equiaxed nickel-based superalloy

with a MCrAly coating to provide superior protection against

oxidation, creep and thermal mechanical fatigue cracking

• The design incorporates improvements to shroud geometry

that reduce weight and improve part life

• The design has eliminated the use of the cutter tooth and

applied an abrasive rail coating, thus further reducing weight,

improving creep life and improving sealing effectiveness

at the shroud block interface

7EA 3rd Stage Buckets

• Manufactured with equiaxed nickelbased superalloy that

provides protection against oxidation and thermal-mechanical

fatigue cracking

• Improvements to shroud and airfoil geometry reduce weight Standard Operation* With Advanced Upgrades*

and extend part life 24,000 hours/1,200 starts 32,000 hours

Repairability guarantee Repairability guarantee

• The design has eliminated the use of the cutter tooth, applied

48,000 hours/2,400 starts 64,000 hours

an abrasive rail coating, and improved sealing effectiveness at Repairability guarantee

Repairability guarantee

the shroud block interface

72,000 hours/3,600 starts 96,000 hours

Repairability guarantee Technical review

Operation in accordance with GER-3620 96,000 hours/4,800 starts

Technical review

Maximum firing temperature: 2055 °F

*Subject to MD&A standard terms and conditions.

Fuel: Natural gas

Operation mode: Base or cyclic load

MECHANICAL DYNAMICS & ANALYSIS

6948 Fairgrounds Parkway • San Antonio, TX 78238 • Sales Inquires Ph: 210-256-5107 • www.MDAturbines.com

For more information on this product or service please contact MD&A at 210-256-5107 © Mechanical Dynamics & Analysis LLC 2022

You might also like

- Project Sizes - Small, Medium and LargeDocument2 pagesProject Sizes - Small, Medium and Large1105195794100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- PDS Jet Oil 2Document3 pagesPDS Jet Oil 2steve liamluntunganNo ratings yet

- Mobilgear SHC 3200 6800 PdsDocument2 pagesMobilgear SHC 3200 6800 PdsMohamed SalemNo ratings yet

- Peek High Performance Thermoplastics Material For Gear, Bushing, Washer, Valve, EtcDocument3 pagesPeek High Performance Thermoplastics Material For Gear, Bushing, Washer, Valve, EtchudileksonoNo ratings yet

- BGBRotary Swivel JointDocument4 pagesBGBRotary Swivel Jointoscar_escorza9226No ratings yet

- Liebherr Hydraulic Cylinders 380 Bar Series Production Range Product Brochure Es WebDocument10 pagesLiebherr Hydraulic Cylinders 380 Bar Series Production Range Product Brochure Es WebJesus D. Gutierrez G.No ratings yet

- GL XX Mobil Jet Oil IIDocument3 pagesGL XX Mobil Jet Oil IIJavier Renzo Cayampi PomallihuaNo ratings yet

- Atlantic Air Compressor OilsDocument1 pageAtlantic Air Compressor OilsOsman QaasimNo ratings yet

- Mobil SHC PM SeriesDocument3 pagesMobil SHC PM SeriesVictor ZhicayNo ratings yet

- PS 14 Anchor Bolt TolerancesDocument4 pagesPS 14 Anchor Bolt TolerancesjebrijaNo ratings yet

- GPCDOC Local TDS Switzerland Shell Spirax S6 GXME 75W-80 (en-CH) TDSDocument2 pagesGPCDOC Local TDS Switzerland Shell Spirax S6 GXME 75W-80 (en-CH) TDSgrs030391No ratings yet

- Acdelco Specs DexronVIDocument1 pageAcdelco Specs DexronVINamer HajiNo ratings yet

- GL XX Mobil Jet Oil IIDocument3 pagesGL XX Mobil Jet Oil IIamirsoheilgooyavarNo ratings yet

- FT Grease 22Document2 pagesFT Grease 22Edgar Leonel CortésNo ratings yet

- Tds Mibil DTE 732Document4 pagesTds Mibil DTE 732mahirtanjim50No ratings yet

- Mobil SHC 8224Document3 pagesMobil SHC 8224TCR ThailandNo ratings yet

- Dow Corning® 895 Structural Glazing Sealant: Product InformationDocument1 pageDow Corning® 895 Structural Glazing Sealant: Product Informationjaga67No ratings yet

- Quartz 7000 SN 10W-40 PDSDocument2 pagesQuartz 7000 SN 10W-40 PDSRe ZanoNo ratings yet

- Catalog EnglishDocument56 pagesCatalog EnglishDiseño 5No ratings yet

- Mobil SHC 500 Series: Supreme-Performance Synthetic Hydraulic OilsDocument2 pagesMobil SHC 500 Series: Supreme-Performance Synthetic Hydraulic OilsAgung SudrajatNo ratings yet

- ACCROLUBE SpecDocument3 pagesACCROLUBE SpecCarlos LoresNo ratings yet

- Overhaul of Raw Material Mill Gearbox Saves More Than 300,000 EurosDocument5 pagesOverhaul of Raw Material Mill Gearbox Saves More Than 300,000 Eurosjesus rodriguezNo ratings yet

- Modeling & Structural Analysis of Hydraulic Tire Curing PressDocument6 pagesModeling & Structural Analysis of Hydraulic Tire Curing PressSunil ShahNo ratings yet

- Tds Atlantic Hydraulic OilsDocument1 pageTds Atlantic Hydraulic Oilsmgamal1080No ratings yet

- Mobilgear 600 XP Series: Product DescriptionDocument4 pagesMobilgear 600 XP Series: Product DescriptionIvan BecerraNo ratings yet

- GL XX Mobiltemp SHC SeriesDocument3 pagesGL XX Mobiltemp SHC Seriestatoddo2017No ratings yet

- High-Temperature Hydrawrap: HydratechDocument3 pagesHigh-Temperature Hydrawrap: HydratechLuis Carlos BalcazarNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- Ad00267v Ledeen BrochureDocument28 pagesAd00267v Ledeen Brochureetd_1988No ratings yet

- GWB Industrial DriveshaftsDocument56 pagesGWB Industrial DriveshaftsCPVNo ratings yet

- BAC ProdAppHBii2007SupplDocument52 pagesBAC ProdAppHBii2007SupplmihdragosNo ratings yet

- Hyperseal - Expert 60Fc: One Component Fast Curing, High Hardness, Chemical Resistant Polyurethane SealantDocument2 pagesHyperseal - Expert 60Fc: One Component Fast Curing, High Hardness, Chemical Resistant Polyurethane Sealantsasikumar durairajanNo ratings yet

- Corena S3R 32Document3 pagesCorena S3R 32HANIF AKBARNo ratings yet

- Moog Servo Valves CatalogueDocument20 pagesMoog Servo Valves Cataloguemt.sasongkoNo ratings yet

- Tech Data: Turbonycoil 600 L B A G T FDocument2 pagesTech Data: Turbonycoil 600 L B A G T FJeremias UtreraNo ratings yet

- Shell Heat Transfer Oil S4 X: Performance, Features & BenefitsDocument2 pagesShell Heat Transfer Oil S4 X: Performance, Features & Benefitsrodrigonicolasdiaz1No ratings yet

- Mobil SHC 800 ReiheDocument3 pagesMobil SHC 800 ReiheJonathan Rodrigo Ruiz RuizNo ratings yet

- AeroShell Grease 22Document2 pagesAeroShell Grease 22Anonymous oAbjbl4HNo ratings yet

- Floating Seals: Your Seal of QualityDocument12 pagesFloating Seals: Your Seal of QualityMahendra Tyre Works RaigarhNo ratings yet

- Polyurea Grease TdsDocument2 pagesPolyurea Grease TdsBanti SidhiwalaNo ratings yet

- 374D & 390D Features & Benefits WalkaroundDocument3 pages374D & 390D Features & Benefits Walkaroundait mimouneNo ratings yet

- DX225 PresentationDocument11 pagesDX225 PresentationRichard Thodé JrNo ratings yet

- D40 SikaGrout 328Document2 pagesD40 SikaGrout 328Murtada MohamedNo ratings yet

- 1068 EnuDocument2 pages1068 EnuMarcos TeixeiraNo ratings yet

- Combustion Inspection Elimination KitDocument2 pagesCombustion Inspection Elimination KitP_Davies100% (1)

- Master Flash CatalogDocument28 pagesMaster Flash Catalogymkttj25zbNo ratings yet

- Bettis Cba 300 Series Pneumatic Actuators Us DataDocument6 pagesBettis Cba 300 Series Pneumatic Actuators Us DatasusantoNo ratings yet

- Moog ServoValves 72series Catalog enDocument20 pagesMoog ServoValves 72series Catalog enbhekistoNo ratings yet

- Aircol SN 68 & 100: DescriptionDocument2 pagesAircol SN 68 & 100: DescriptionantonNo ratings yet

- FE 2100 Motor Standards For The Chemical Process IndustryDocument6 pagesFE 2100 Motor Standards For The Chemical Process IndustryAvery OppegardNo ratings yet

- GL XX Mobilgear SHC SeriesDocument3 pagesGL XX Mobilgear SHC Seriesanibal_rios_rivasNo ratings yet

- Corena - S3 - R - 68 Compressor Oil.Document3 pagesCorena - S3 - R - 68 Compressor Oil.nileshNo ratings yet

- Tds-Canroyal 4T Engine Oils.Document1 pageTds-Canroyal 4T Engine Oils.catpilar274No ratings yet

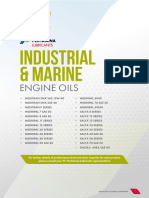

- Industrial - MarineDocument28 pagesIndustrial - MarineSuprastowo Bin SarinoNo ratings yet

- GL XX Mobil DTE 700 Series PDFDocument4 pagesGL XX Mobil DTE 700 Series PDFHANIF AKBARNo ratings yet

- TDS Shell Spirax s6 Gxme 75w-80Document2 pagesTDS Shell Spirax s6 Gxme 75w-80rstec pyNo ratings yet

- Miller Welding Generator-Big Blue 500x Eco ProDocument8 pagesMiller Welding Generator-Big Blue 500x Eco Progroshan20No ratings yet

- Pegasus: Medium Voltage AC Induction MotorsDocument6 pagesPegasus: Medium Voltage AC Induction MotorsSergio aldoNo ratings yet

- GL XX Mobil Gargoyle Arctic SHC 200 SeriesDocument3 pagesGL XX Mobil Gargoyle Arctic SHC 200 SeriesFulkan HadiyanNo ratings yet

- Proceedings of the 8th International Symposium on Superalloy 718 and DerivativesFrom EverandProceedings of the 8th International Symposium on Superalloy 718 and DerivativesNo ratings yet

- Timken t56 Aerospace Aftermarket SolutionsDocument4 pagesTimken t56 Aerospace Aftermarket SolutionsAli kamail sadeghianNo ratings yet

- PBS Brochure Investment Casting 07 23Document4 pagesPBS Brochure Investment Casting 07 23Ali kamail sadeghianNo ratings yet

- Recent Applications of Phased Array Inspection For Turbine Components and Welded StructuresDocument9 pagesRecent Applications of Phased Array Inspection For Turbine Components and Welded StructuresAli kamail sadeghianNo ratings yet

- Tuv Rheinland Reference Case Aswan Dam Refinery Egypt enDocument2 pagesTuv Rheinland Reference Case Aswan Dam Refinery Egypt enAli kamail sadeghianNo ratings yet

- Sandcasting Forming MoldingDocument6 pagesSandcasting Forming MoldingAli kamail sadeghianNo ratings yet

- Table 1 - Nonlinear Dynamic Performance of A Bolt-Disc Rotor With The Position Error of Circumferential Bolt-HolesDocument3 pagesTable 1 - Nonlinear Dynamic Performance of A Bolt-Disc Rotor With The Position Error of Circumferential Bolt-HolesAli kamail sadeghianNo ratings yet

- 70513912703Document16 pages70513912703Ali kamail sadeghianNo ratings yet

- Lemon Earing Part NumbermaxtraderDocument2 pagesLemon Earing Part NumbermaxtraderAli kamail sadeghianNo ratings yet

- A Power Amplifier With Error Correction: Part 2: The Voltage Amplifier and Input Buffer StagesDocument6 pagesA Power Amplifier With Error Correction: Part 2: The Voltage Amplifier and Input Buffer Stagesjvs57No ratings yet

- Benefits of SFRCDocument17 pagesBenefits of SFRCShubhayu_duttaNo ratings yet

- Assignment Iv PDFDocument2 pagesAssignment Iv PDFSurya TripathiNo ratings yet

- IATF Additional Requirement LocationsDocument6 pagesIATF Additional Requirement LocationsSudhagar50% (2)

- Danfoss EKC201CDocument16 pagesDanfoss EKC201CGabriel PiticasNo ratings yet

- Workshop in KL UniversityDocument1 pageWorkshop in KL UniversityGabbar SinghNo ratings yet

- NEW Spec Long Rod InsulatorDocument25 pagesNEW Spec Long Rod InsulatorbinodeNo ratings yet

- Configuring and Managing ZonesDocument46 pagesConfiguring and Managing ZoneszingerrrNo ratings yet

- Reference Handbook For EOT Cranes Table of ContentsDocument3 pagesReference Handbook For EOT Cranes Table of Contentspjustino19700% (1)

- Wastewater Treatment - Tertiary and Sludge Handling Prepared by Furby RamosDocument23 pagesWastewater Treatment - Tertiary and Sludge Handling Prepared by Furby RamosFrancisco DeLos Angeles IIINo ratings yet

- Aakash Deep - ResumeDocument3 pagesAakash Deep - Resumeaakasharora12No ratings yet

- Lean Brief Takt TimeDocument2 pagesLean Brief Takt TimeBala Kumar M PNo ratings yet

- Manual A340Document3 pagesManual A340davidNo ratings yet

- Hydrotreating & Hydrocracking Process Technology Training Course - PetroKnowledgeDocument3 pagesHydrotreating & Hydrocracking Process Technology Training Course - PetroKnowledgenishilgeorgeNo ratings yet

- Prezentare Role ModelingDocument9 pagesPrezentare Role ModelingIulia MarcuNo ratings yet

- Turbo Lux 3 Technical Data SheetDocument4 pagesTurbo Lux 3 Technical Data Sheetaashiq2006No ratings yet

- Tellspec TellSpec Case Study 09-16-2015Document2 pagesTellspec TellSpec Case Study 09-16-2015Pando DailyNo ratings yet

- DLL FormDocument4 pagesDLL FormMarlene AgcaoiliNo ratings yet

- ACMV Inspeciton Check ListDocument22 pagesACMV Inspeciton Check ListNaing Win TunNo ratings yet

- Cat Bpe PDFDocument57 pagesCat Bpe PDFJohnNo ratings yet

- Sem 3 Module 3Document5 pagesSem 3 Module 3Joshua HernandezNo ratings yet

- Dinorah DinorahDocument5 pagesDinorah DinorahMartinNo ratings yet

- Meaning of Dispersion With ObjectivesDocument11 pagesMeaning of Dispersion With ObjectivesDeepakgupta0001No ratings yet

- FCV COMBO Manual ABZ Valve W Actuator J032Document28 pagesFCV COMBO Manual ABZ Valve W Actuator J032corasaulNo ratings yet

- Design of Two Way SlabDocument180 pagesDesign of Two Way SlabGino Paolo ObsiomaNo ratings yet

- What Is An RCDDocument21 pagesWhat Is An RCDkimbalsummers801No ratings yet

- Comprehension Examples - Ipynb - ColaboratoryDocument5 pagesComprehension Examples - Ipynb - ColaboratoryVesselin NikovNo ratings yet

- Schedule & Bar Chart For RFCLDocument14 pagesSchedule & Bar Chart For RFCLSalmon SaliNo ratings yet

- Digital State-Variable Filters: 1 Normalized Second-Order Continuous-Time Lowpass FilterDocument9 pagesDigital State-Variable Filters: 1 Normalized Second-Order Continuous-Time Lowpass FilterJennifer WilliamsNo ratings yet