Professional Documents

Culture Documents

Air Pressure 2810 D161

Air Pressure 2810 D161

Uploaded by

Iman AkbariCopyright:

Available Formats

You might also like

- Hirac - DoleDocument11 pagesHirac - DoleAngela Salumbides50% (2)

- Absolute-Pressure Sensors: Micromechanics, Hybrid DesignDocument3 pagesAbsolute-Pressure Sensors: Micromechanics, Hybrid Designc20get100% (2)

- Belimo - 01DT-5MLDocument4 pagesBelimo - 01DT-5MLAlan MercesNo ratings yet

- Walker 2080 Mk2Document2 pagesWalker 2080 Mk2pardeepmanhas86No ratings yet

- Humidity Sensors From MincoDocument2 pagesHumidity Sensors From MincoSaad MuftahNo ratings yet

- TSP121 Abb DS - TSP1X1 - en - F01Document56 pagesTSP121 Abb DS - TSP1X1 - en - F01TaQuangDucNo ratings yet

- Manual Qaz21.682-101Document4 pagesManual Qaz21.682-101CezaryNo ratings yet

- Technical Data Sheet 01DT-1L..: Type OverviewDocument4 pagesTechnical Data Sheet 01DT-1L..: Type OverviewJNo ratings yet

- Belimo 22HT-52 DatasheetDocument4 pagesBelimo 22HT-52 DatasheetAhmed SofaNo ratings yet

- DS TSP3x1 EN GDocument60 pagesDS TSP3x1 EN GFranco SNo ratings yet

- DS8220 Standard EU ENDocument6 pagesDS8220 Standard EU ENAnonymous jW9BkgbQmENo ratings yet

- Temperature Sensor Manual CI 6605ADocument4 pagesTemperature Sensor Manual CI 6605AKrissia WilhelmNo ratings yet

- Belimo 22UTH-53 Datasheet En-GbDocument5 pagesBelimo 22UTH-53 Datasheet En-Gbmukanila1mp5224No ratings yet

- Sra-T Indoor Temperature Sensor: FeaturesDocument2 pagesSra-T Indoor Temperature Sensor: FeatureschinitnNo ratings yet

- SC-T, Flying Lead Contact Temperature Sensor Technical Specification Wiring & InstallationDocument2 pagesSC-T, Flying Lead Contact Temperature Sensor Technical Specification Wiring & InstallationchinitnNo ratings yet

- GASMET In-Situ Technical Data 28v1 2 29 PDFDocument2 pagesGASMET In-Situ Technical Data 28v1 2 29 PDFASTOLFONo ratings yet

- Temperature Monitoring & Protection: FeaturesDocument2 pagesTemperature Monitoring & Protection: FeaturesCARLOS LÓPEZNo ratings yet

- LaboomDocument4 pagesLaboomAndrei SpiridonNo ratings yet

- Wind Speed Sensor PDFDocument2 pagesWind Speed Sensor PDFSergioNo ratings yet

- Equation 1: The Following Products/services Are Available: 1 A Range of Standard Heatsinks and AccessoriesDocument6 pagesEquation 1: The Following Products/services Are Available: 1 A Range of Standard Heatsinks and AccessoriesgoaltechNo ratings yet

- 1 DSHK-RTDocument1 page1 DSHK-RTRama Aji Al HakimNo ratings yet

- Mechanical Temperature Switches: T2H T2HDocument2 pagesMechanical Temperature Switches: T2H T2Hipy45101No ratings yet

- DS TSP1x1 EN GDocument56 pagesDS TSP1x1 EN GUMER SHAFAATNo ratings yet

- S20 Sensor Chamber TP20 Temperature Sensor CP10 PT12-TI-9-403-USDocument2 pagesS20 Sensor Chamber TP20 Temperature Sensor CP10 PT12-TI-9-403-USTarik BenkhalloukNo ratings yet

- Brosur Orbisphere 3655Document2 pagesBrosur Orbisphere 3655ArifEkoPrasetyoNo ratings yet

- GA 40tplus AquaGas CEMS AnalyserDocument9 pagesGA 40tplus AquaGas CEMS AnalyserKaisar JamilNo ratings yet

- 8220 enDocument6 pages8220 enmoslem vesaliNo ratings yet

- Features: IC - PD.P10.F1.02 - 520B2008 11Document5 pagesFeatures: IC - PD.P10.F1.02 - 520B2008 11Knuth SchellstedeNo ratings yet

- Twin Thermo WiringDocument4 pagesTwin Thermo WiringRobin PietersieNo ratings yet

- 2 DSHK-DTDocument2 pages2 DSHK-DTRama Aji Al HakimNo ratings yet

- Stackpulse Controller: Low Cost High Performance Mold CoolingDocument8 pagesStackpulse Controller: Low Cost High Performance Mold CoolingSankuparlang ShullaiNo ratings yet

- TUC: Universal Thermostat: FeaturesDocument6 pagesTUC: Universal Thermostat: FeaturesCao Son DuongNo ratings yet

- Technical Leaflet: Liquid Level TransmitterDocument8 pagesTechnical Leaflet: Liquid Level TransmitterAnderengNo ratings yet

- Smart Stat Cut SheetDocument2 pagesSmart Stat Cut SheetryanrbosNo ratings yet

- 22HT 14 Datasheet en GBDocument4 pages22HT 14 Datasheet en GBAhmed SofaNo ratings yet

- Product Data Sheet: Impulse Counter P 2 (910 502) : Type P2 Part No. 910 502Document1 pageProduct Data Sheet: Impulse Counter P 2 (910 502) : Type P2 Part No. 910 502Hi KulphanitNo ratings yet

- Easidew 34 Transmitter 97318 UK DatasheetDocument2 pagesEasidew 34 Transmitter 97318 UK DatasheetAnonymous E3iZxnX1RFNo ratings yet

- Fluke 80TK ThermoCouple ModuleDocument4 pagesFluke 80TK ThermoCouple ModuleRenjithpr RaviNo ratings yet

- NivoCAP Manual PDFDocument6 pagesNivoCAP Manual PDFarfanNo ratings yet

- Digital Manifold: Testo 557 - With External Vacuum and BluetoothDocument2 pagesDigital Manifold: Testo 557 - With External Vacuum and BluetoothMESIN KECILNo ratings yet

- 2/2-Way Solenoid Valve, Direct-Acting: Type 741Document4 pages2/2-Way Solenoid Valve, Direct-Acting: Type 741Francisco Mones RuizNo ratings yet

- Ammolyser Pro WW ENDocument2 pagesAmmolyser Pro WW ENhai phanNo ratings yet

- EN Calibration Source M340 - DatasheetDocument2 pagesEN Calibration Source M340 - DatasheetMansour AchaourNo ratings yet

- Intelligent Differential Pressure Transmitter: Product OverviewDocument3 pagesIntelligent Differential Pressure Transmitter: Product Overviewmfg_serviciosNo ratings yet

- Pressure Sensor DatasheetDocument4 pagesPressure Sensor DatasheetSonny AdiansyahNo ratings yet

- EBT720 Series Electronic Balancing ToolsDocument4 pagesEBT720 Series Electronic Balancing Toolsdavid messierNo ratings yet

- Ray-Heat Serie 447 A 452 Original HydrometerDocument12 pagesRay-Heat Serie 447 A 452 Original HydrometerVelimir MilovanovicNo ratings yet

- TSAP Series: All Purpose Temperature SensorDocument2 pagesTSAP Series: All Purpose Temperature SensorSyed JahangirNo ratings yet

- Greisinger OXY 3690 MP User ManualDocument4 pagesGreisinger OXY 3690 MP User ManualesatpehlivanNo ratings yet

- QAE3075.016 - Immersion Temperature Sensors - High TemperatureDocument4 pagesQAE3075.016 - Immersion Temperature Sensors - High TemperatureMinh nhut LưuNo ratings yet

- K6 Series Bluetooth BeaconDocument5 pagesK6 Series Bluetooth BeaconVEGA CALIBRATIONSNo ratings yet

- Antc V1 R-EngDocument4 pagesAntc V1 R-EngGeorge ParaschivNo ratings yet

- Limit-Value Switch For Temperature Thermistor Input (NTC)Document2 pagesLimit-Value Switch For Temperature Thermistor Input (NTC)AlexanderNo ratings yet

- Mira Visibility Sensor 3544 3544 EXDocument2 pagesMira Visibility Sensor 3544 3544 EXMed MohNo ratings yet

- Cable Temperature SensorsDocument4 pagesCable Temperature Sensorskdp_806212786No ratings yet

- DPT R8-3W CatDocument2 pagesDPT R8-3W CatGovind RaoNo ratings yet

- Of2 SS1SS F15HB L Oo - PTDocument12 pagesOf2 SS1SS F15HB L Oo - PTŁukasz OlszewskiNo ratings yet

- Mobrey Squitch-2: Ultrasonic Liquid Level SwitchDocument2 pagesMobrey Squitch-2: Ultrasonic Liquid Level SwitchPhan CườngNo ratings yet

- 380 Series: Tee Meter, BTU SystemDocument2 pages380 Series: Tee Meter, BTU SystemEddi Pelaez SalinasNo ratings yet

- Humidity and Temperature Controller AR247 Data SheetDocument2 pagesHumidity and Temperature Controller AR247 Data SheetTechnoserve IndustrialNo ratings yet

- Babani 341 MS DOS 6 ExplainedDocument213 pagesBabani 341 MS DOS 6 ExplainedIman AkbariNo ratings yet

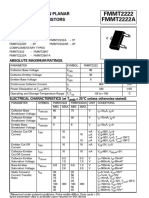

- fmmt2222, Fmmt2222a, Fmmt2222ar, fmmt2222r Zetex PDFDocument3 pagesfmmt2222, Fmmt2222a, Fmmt2222ar, fmmt2222r Zetex PDFagusNo ratings yet

- Ceramic Disc Capacitors Class 1 and 2, 1 KV To 50 KV, General PurposeDocument3 pagesCeramic Disc Capacitors Class 1 and 2, 1 KV To 50 KV, General PurposeIman AkbariNo ratings yet

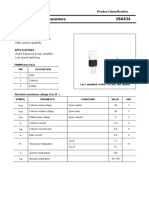

- Silicon PNP Power Transistors: Savantic Semiconductor Product SpecificationDocument3 pagesSilicon PNP Power Transistors: Savantic Semiconductor Product SpecificationIman AkbariNo ratings yet

- Wirewound - Resistors: Pulse Load - Wirewound Resistors V I T R O H MDocument6 pagesWirewound - Resistors: Pulse Load - Wirewound Resistors V I T R O H MIman AkbariNo ratings yet

- RS-422 and RS-485 Standards Overview and SystemDocument25 pagesRS-422 and RS-485 Standards Overview and SystemIman Akbari100% (1)

- Multimeter: ISO-9001, CE, IEC1010Document2 pagesMultimeter: ISO-9001, CE, IEC1010Iman AkbariNo ratings yet

- Reference: BFX50 01 Code: BFX5001 Characteristics Side Mount With 2NC Contacts For BF00, BF09-BF38Document1 pageReference: BFX50 01 Code: BFX5001 Characteristics Side Mount With 2NC Contacts For BF00, BF09-BF38Iman AkbariNo ratings yet

- CISCO2811 Datasheet: Get A QuoteDocument3 pagesCISCO2811 Datasheet: Get A QuoteIman AkbariNo ratings yet

- Lecture 4: RL Circuits. Inductive Kick. Diode Snubbers.: Filters ChokesDocument6 pagesLecture 4: RL Circuits. Inductive Kick. Diode Snubbers.: Filters ChokesIman AkbariNo ratings yet

- TIA/EIA-422-B Overview: © 1998 National Semiconductor Corporation AN012598Document8 pagesTIA/EIA-422-B Overview: © 1998 National Semiconductor Corporation AN012598Iman AkbariNo ratings yet

- FS12UMA-4A: PreliminaryDocument4 pagesFS12UMA-4A: PreliminaryIman AkbariNo ratings yet

- SD1729 (TH416) : HF SSB Applications RF & Microwave TransistorsDocument4 pagesSD1729 (TH416) : HF SSB Applications RF & Microwave TransistorsIman AkbariNo ratings yet

- @perkins: 4000 Series 4016TAG2 4016TAG2ADocument2 pages@perkins: 4000 Series 4016TAG2 4016TAG2AIman AkbariNo ratings yet

- Maxim Integrated Products: Reliability Report FOR MAX483ECPA+ Plastic Encapsulated DevicesDocument5 pagesMaxim Integrated Products: Reliability Report FOR MAX483ECPA+ Plastic Encapsulated DevicesIman AkbariNo ratings yet

- FJP13007 High Voltage Fast-Switching NPN Power Transistor: FeaturesDocument6 pagesFJP13007 High Voltage Fast-Switching NPN Power Transistor: FeaturesIman AkbariNo ratings yet

- Connector For FLEXWELL® Elliptical Waveguide E100, PBR100 FlangeDocument1 pageConnector For FLEXWELL® Elliptical Waveguide E100, PBR100 FlangeIman AkbariNo ratings yet

- Pages From Marine VHF Radiotelephone Installation ManualDocument1 pagePages From Marine VHF Radiotelephone Installation ManualIman AkbariNo ratings yet

- Connector For FLEXWELL® Elliptical Waveguide E38, PDR40 FlangeDocument1 pageConnector For FLEXWELL® Elliptical Waveguide E38, PDR40 FlangeIman AkbariNo ratings yet

- Connector For FLEXWELL® Elliptical Waveguide E38, PDR40 FlangeDocument1 pageConnector For FLEXWELL® Elliptical Waveguide E38, PDR40 FlangeIman AkbariNo ratings yet

- SWSWSWSSWDocument5 pagesSWSWSWSSWIman AkbariNo ratings yet

- Bhs Inggris - Ananda Taqiyyah Ihsani T - Xii Mipa 7Document14 pagesBhs Inggris - Ananda Taqiyyah Ihsani T - Xii Mipa 7aanandaihzzannnNo ratings yet

- Inception Report Tawang Master Plan ArunachalDocument39 pagesInception Report Tawang Master Plan Arunachalsmodi_92No ratings yet

- Multiscale Designer - IntroductionDocument31 pagesMultiscale Designer - IntroductionaliNo ratings yet

- Modelling The Behaviour of Concrete Encased Concrete Filled Steel Tube Columns Subjected To Full Range FireDocument16 pagesModelling The Behaviour of Concrete Encased Concrete Filled Steel Tube Columns Subjected To Full Range FireLeoNo ratings yet

- Engineering Physics Laboratory: Course ObjectivesDocument3 pagesEngineering Physics Laboratory: Course ObjectivesNaveenraj NNo ratings yet

- 8-Channel Saturated Sink Driver: UDN2595ADocument8 pages8-Channel Saturated Sink Driver: UDN2595AIkram UlhaqNo ratings yet

- DC Mid ImpDocument2 pagesDC Mid ImpSowmya ChowdaryNo ratings yet

- U.S. Midterm Exam ReviewerDocument4 pagesU.S. Midterm Exam ReviewerLianNo ratings yet

- EOT Crane Mechanical Equipment Calculation 1Document17 pagesEOT Crane Mechanical Equipment Calculation 1satendra sharmaNo ratings yet

- Nickel Strip For BatteriesDocument12 pagesNickel Strip For BatteriesSidNo ratings yet

- Artificial Intelligence Application in Bone Fracture DetectionDocument6 pagesArtificial Intelligence Application in Bone Fracture DetectionMEHDI JAHANIRADNo ratings yet

- Open Space - ArticleDocument25 pagesOpen Space - ArticleManogna Sai PadiNo ratings yet

- Lesson Plan Class 3 English Chapter 6 To 12Document60 pagesLesson Plan Class 3 English Chapter 6 To 12Tamuna AkhobadzeNo ratings yet

- Pre-Test On Identifying BiiasDocument2 pagesPre-Test On Identifying BiiasVee Jay GarciaNo ratings yet

- Argumentative Writing: Sajjad Iqbal KhanDocument24 pagesArgumentative Writing: Sajjad Iqbal KhanM WaseemNo ratings yet

- Report On Geology of Sitakundo, RangamatiDocument33 pagesReport On Geology of Sitakundo, RangamatiMarvel AvengerNo ratings yet

- Seminar Report-Swarm Robotics Main ContentDocument35 pagesSeminar Report-Swarm Robotics Main ContentHarshal LolgeNo ratings yet

- Grade 9 Notes Logic GateDocument10 pagesGrade 9 Notes Logic GateButterfly HuexNo ratings yet

- Architecture Curriculum Revised December 2017Document166 pagesArchitecture Curriculum Revised December 2017Desta DabiNo ratings yet

- Contoh Analytical Exposition Thesis Argument ReiterationDocument5 pagesContoh Analytical Exposition Thesis Argument Reiterationafcnzcrcf100% (2)

- Movie Recommendation Engine - IpynbDocument19 pagesMovie Recommendation Engine - Ipynbpanchalharshit0077No ratings yet

- The Finer Things Club PPT TemplateDocument23 pagesThe Finer Things Club PPT TemplatejbcNo ratings yet

- 14a - Labor Counsel ReviewDocument2 pages14a - Labor Counsel ReviewJoy M. HosfordNo ratings yet

- Research Plan: Name of Researcher/SDocument2 pagesResearch Plan: Name of Researcher/SJaeron DavidNo ratings yet

- 962 3485 1 PBDocument5 pages962 3485 1 PBPutu HendrawanNo ratings yet

- Education - and - Modernity - Amman Madan - EngDocument122 pagesEducation - and - Modernity - Amman Madan - EngChethan BasavarajNo ratings yet

- Midterm Examination Pmta 1ST 22.23Document8 pagesMidterm Examination Pmta 1ST 22.23Johnray RonaNo ratings yet

- 190102-DC10.5-Expansive and Stable Soils-Public ReviewDocument66 pages190102-DC10.5-Expansive and Stable Soils-Public Reviewvõ hoàng thái50% (2)

- DLL - Science 4 - Q1 - W8Document5 pagesDLL - Science 4 - Q1 - W8MELROSE HAMOYNo ratings yet

Air Pressure 2810 D161

Air Pressure 2810 D161

Uploaded by

Iman AkbariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Pressure 2810 D161

Air Pressure 2810 D161

Uploaded by

Iman AkbariCopyright:

Available Formats

AANDERAA INSTRUMENTS

DATA COLLECTING INSTRUMENTS FOR LAND, SEA AND AIR

AIR PRESSURE SENSOR 2810

A barometric pressure sensor for Aanderaa Automatic

Weather Stations and Display Units.

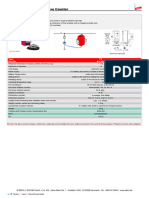

The monolithic technology used in modern electronic devices The sensor consists of a PC-board with components fastened

may also be used for making small pressure sensors. to the sensor base and protected by a cylindrical cover. The

Sensors made using this method have very small hysteresis cover is screwed onto the base and sealed with an O-ring.

and a very low rate of ageing. Six holes in the base provide atmospheric pressure to the

sensing element inside the sensor.

To eliminate error due to ambient temperature changes the

small sensing element can be heated to a specific temperature The sensor shows outstanding performance as it has practically

before the measurement is taken. no hysteresis, no temperature drift and no ageing. It is also

insensitive to mechanical acceleration and can be operated

Air Pressure Sensor 2810 utilizes a 4 x 4 mm small silicon in any position. The sensor is waterproof.

chip as a sensing element. In the central area of this chip is

a thin membrane that is exposed to atmospheric pressure Before measurement the sensor is heated to 47°C and to allow

on one side and to a vacuum on the other. The membrane enough time for temperature stabilization the sensor should

is furnished with 4 diffused resistors that form a Wheatstone be connected to one of the last channels in the measuring

bridge. The output signal is proportional to the atmospheric system.

pressure. The chip thus acts as an absolute pressure-sensing

device. Current consumption for silicon chip heating varies with am-

bient temperature. At 47°C the heating current is zero. This

A temperature sensing resistor and 4 heating resistors are increases linearly as temperature decreases. A maximum of

also diffused onto the chip. In conjunction with an external 70 mA for heating is reached at –40°C. The heating current

control circuit, these resistors allow the chip to be held at a is normally switched off between readings.

constant temperature of 47°C during the measurement.

DATA SHEET, D 161, APRIL 1999 1

SPECIFICATIONS FOR AIR PRESSURE SENSOR 2810

50 mm Measuring Range: 920–1080hP a (other ranges on

request)

Cover . . . . . . . . . . . . . . . . . .hPa

Accuracy: ±0.2 hPa

Electronic board Resolution: 0.2 hPa

for heating control

and signal Operation Temp. Range: –40 to +47°C

conditioning Sensor Output: Aanderaa half-bridge, VR22

Silicon chip Supply Voltage: 7–14V DC (9 volt nominal)

Current Consumption: 5 mA + heating: (47 – T) 0.75 mA

T = ambient temperature in °C

Electrical Connection: Automatic Weather Station (AWS)

99 Sensor Arm or Sensor Cable 2842

mm

Material and Finish: Aluminum 6061-T6, anodized 10µ

Silica gel bag Weight: 200 grams

Packing: Cardboard box

Gross Weight: 400 grams

Receptacle 2843 Warranty: Two years against faulty materials

and workmanship

Annular groove

O-ring SOR 139 certified

Air inlet

O-ring,863002 PIN CONFIGURATION

Fastening screw Receptacle, exterior view; pin = ; bushing =

9 volts 3 4 Bridge voltage

Sensor Foot

Orientation hole 6 volts 2 5 Signal output

ID 25.5 mm System ground 1 6 Bridge ground

CALIBRATION Serial No:

Calibration is performed at room temperature. Reference: Note!

Dr. A Müller, Berlin Hg Barometer Type IIi. Sensor Scanning The sensor is RF sensitive.

Unit 3010. ( Frequency range ≤ 500MHz, field strength ≥ 3V/m )

Giving the following raw data readings:

Pressure hPa Raw data Pressure hPa Raw data The standard range can be used up to an installation alti-

tude of approximately 400 meters. For higher altitudes the

range must be set by the factory prior to delivery.

To refer the measured air pressure to sea level add a factor

according to the table below (approx.value):

Installation Add 1hPa Installation Add 1hPa

altitude (m) each altitude (m) each

0 - 200 8m 801 - 1000 9m

201 - 400 8.5 m 1001 - 2000 9.6 m

These readings give a set of coefficients used when con- 401 - 600 8.7 m 2001 - 3000 10.7 m

verting a sensor reading to engineering units. The coeffi- 601 - 800 8.9 m 3001 - 5000 12.4 m

cients are:

A C 0 Representative’s stamp

B D 0

To convert raw data reading to engineering units use the

formula:

Pressure (hPa)= A + BN + CN2 + DN3

Date: ------------------------- Sign: - - - - - - - - - - - - - - - - - - - - - - - - - - -

Latest version on the Internet

PO BOX 160, NESTTUN FANAVEIEN 13B TEL. +47 55 132500 E-MAIL: info@aanderaa.no

5852 BERGEN, NORWAY NESTTUN, NORWAY FAX. +47 55 137950 WEB: http://www.aanderaa.com

DATA SHEET D 161, APRIL 1999 2

You might also like

- Hirac - DoleDocument11 pagesHirac - DoleAngela Salumbides50% (2)

- Absolute-Pressure Sensors: Micromechanics, Hybrid DesignDocument3 pagesAbsolute-Pressure Sensors: Micromechanics, Hybrid Designc20get100% (2)

- Belimo - 01DT-5MLDocument4 pagesBelimo - 01DT-5MLAlan MercesNo ratings yet

- Walker 2080 Mk2Document2 pagesWalker 2080 Mk2pardeepmanhas86No ratings yet

- Humidity Sensors From MincoDocument2 pagesHumidity Sensors From MincoSaad MuftahNo ratings yet

- TSP121 Abb DS - TSP1X1 - en - F01Document56 pagesTSP121 Abb DS - TSP1X1 - en - F01TaQuangDucNo ratings yet

- Manual Qaz21.682-101Document4 pagesManual Qaz21.682-101CezaryNo ratings yet

- Technical Data Sheet 01DT-1L..: Type OverviewDocument4 pagesTechnical Data Sheet 01DT-1L..: Type OverviewJNo ratings yet

- Belimo 22HT-52 DatasheetDocument4 pagesBelimo 22HT-52 DatasheetAhmed SofaNo ratings yet

- DS TSP3x1 EN GDocument60 pagesDS TSP3x1 EN GFranco SNo ratings yet

- DS8220 Standard EU ENDocument6 pagesDS8220 Standard EU ENAnonymous jW9BkgbQmENo ratings yet

- Temperature Sensor Manual CI 6605ADocument4 pagesTemperature Sensor Manual CI 6605AKrissia WilhelmNo ratings yet

- Belimo 22UTH-53 Datasheet En-GbDocument5 pagesBelimo 22UTH-53 Datasheet En-Gbmukanila1mp5224No ratings yet

- Sra-T Indoor Temperature Sensor: FeaturesDocument2 pagesSra-T Indoor Temperature Sensor: FeatureschinitnNo ratings yet

- SC-T, Flying Lead Contact Temperature Sensor Technical Specification Wiring & InstallationDocument2 pagesSC-T, Flying Lead Contact Temperature Sensor Technical Specification Wiring & InstallationchinitnNo ratings yet

- GASMET In-Situ Technical Data 28v1 2 29 PDFDocument2 pagesGASMET In-Situ Technical Data 28v1 2 29 PDFASTOLFONo ratings yet

- Temperature Monitoring & Protection: FeaturesDocument2 pagesTemperature Monitoring & Protection: FeaturesCARLOS LÓPEZNo ratings yet

- LaboomDocument4 pagesLaboomAndrei SpiridonNo ratings yet

- Wind Speed Sensor PDFDocument2 pagesWind Speed Sensor PDFSergioNo ratings yet

- Equation 1: The Following Products/services Are Available: 1 A Range of Standard Heatsinks and AccessoriesDocument6 pagesEquation 1: The Following Products/services Are Available: 1 A Range of Standard Heatsinks and AccessoriesgoaltechNo ratings yet

- 1 DSHK-RTDocument1 page1 DSHK-RTRama Aji Al HakimNo ratings yet

- Mechanical Temperature Switches: T2H T2HDocument2 pagesMechanical Temperature Switches: T2H T2Hipy45101No ratings yet

- DS TSP1x1 EN GDocument56 pagesDS TSP1x1 EN GUMER SHAFAATNo ratings yet

- S20 Sensor Chamber TP20 Temperature Sensor CP10 PT12-TI-9-403-USDocument2 pagesS20 Sensor Chamber TP20 Temperature Sensor CP10 PT12-TI-9-403-USTarik BenkhalloukNo ratings yet

- Brosur Orbisphere 3655Document2 pagesBrosur Orbisphere 3655ArifEkoPrasetyoNo ratings yet

- GA 40tplus AquaGas CEMS AnalyserDocument9 pagesGA 40tplus AquaGas CEMS AnalyserKaisar JamilNo ratings yet

- 8220 enDocument6 pages8220 enmoslem vesaliNo ratings yet

- Features: IC - PD.P10.F1.02 - 520B2008 11Document5 pagesFeatures: IC - PD.P10.F1.02 - 520B2008 11Knuth SchellstedeNo ratings yet

- Twin Thermo WiringDocument4 pagesTwin Thermo WiringRobin PietersieNo ratings yet

- 2 DSHK-DTDocument2 pages2 DSHK-DTRama Aji Al HakimNo ratings yet

- Stackpulse Controller: Low Cost High Performance Mold CoolingDocument8 pagesStackpulse Controller: Low Cost High Performance Mold CoolingSankuparlang ShullaiNo ratings yet

- TUC: Universal Thermostat: FeaturesDocument6 pagesTUC: Universal Thermostat: FeaturesCao Son DuongNo ratings yet

- Technical Leaflet: Liquid Level TransmitterDocument8 pagesTechnical Leaflet: Liquid Level TransmitterAnderengNo ratings yet

- Smart Stat Cut SheetDocument2 pagesSmart Stat Cut SheetryanrbosNo ratings yet

- 22HT 14 Datasheet en GBDocument4 pages22HT 14 Datasheet en GBAhmed SofaNo ratings yet

- Product Data Sheet: Impulse Counter P 2 (910 502) : Type P2 Part No. 910 502Document1 pageProduct Data Sheet: Impulse Counter P 2 (910 502) : Type P2 Part No. 910 502Hi KulphanitNo ratings yet

- Easidew 34 Transmitter 97318 UK DatasheetDocument2 pagesEasidew 34 Transmitter 97318 UK DatasheetAnonymous E3iZxnX1RFNo ratings yet

- Fluke 80TK ThermoCouple ModuleDocument4 pagesFluke 80TK ThermoCouple ModuleRenjithpr RaviNo ratings yet

- NivoCAP Manual PDFDocument6 pagesNivoCAP Manual PDFarfanNo ratings yet

- Digital Manifold: Testo 557 - With External Vacuum and BluetoothDocument2 pagesDigital Manifold: Testo 557 - With External Vacuum and BluetoothMESIN KECILNo ratings yet

- 2/2-Way Solenoid Valve, Direct-Acting: Type 741Document4 pages2/2-Way Solenoid Valve, Direct-Acting: Type 741Francisco Mones RuizNo ratings yet

- Ammolyser Pro WW ENDocument2 pagesAmmolyser Pro WW ENhai phanNo ratings yet

- EN Calibration Source M340 - DatasheetDocument2 pagesEN Calibration Source M340 - DatasheetMansour AchaourNo ratings yet

- Intelligent Differential Pressure Transmitter: Product OverviewDocument3 pagesIntelligent Differential Pressure Transmitter: Product Overviewmfg_serviciosNo ratings yet

- Pressure Sensor DatasheetDocument4 pagesPressure Sensor DatasheetSonny AdiansyahNo ratings yet

- EBT720 Series Electronic Balancing ToolsDocument4 pagesEBT720 Series Electronic Balancing Toolsdavid messierNo ratings yet

- Ray-Heat Serie 447 A 452 Original HydrometerDocument12 pagesRay-Heat Serie 447 A 452 Original HydrometerVelimir MilovanovicNo ratings yet

- TSAP Series: All Purpose Temperature SensorDocument2 pagesTSAP Series: All Purpose Temperature SensorSyed JahangirNo ratings yet

- Greisinger OXY 3690 MP User ManualDocument4 pagesGreisinger OXY 3690 MP User ManualesatpehlivanNo ratings yet

- QAE3075.016 - Immersion Temperature Sensors - High TemperatureDocument4 pagesQAE3075.016 - Immersion Temperature Sensors - High TemperatureMinh nhut LưuNo ratings yet

- K6 Series Bluetooth BeaconDocument5 pagesK6 Series Bluetooth BeaconVEGA CALIBRATIONSNo ratings yet

- Antc V1 R-EngDocument4 pagesAntc V1 R-EngGeorge ParaschivNo ratings yet

- Limit-Value Switch For Temperature Thermistor Input (NTC)Document2 pagesLimit-Value Switch For Temperature Thermistor Input (NTC)AlexanderNo ratings yet

- Mira Visibility Sensor 3544 3544 EXDocument2 pagesMira Visibility Sensor 3544 3544 EXMed MohNo ratings yet

- Cable Temperature SensorsDocument4 pagesCable Temperature Sensorskdp_806212786No ratings yet

- DPT R8-3W CatDocument2 pagesDPT R8-3W CatGovind RaoNo ratings yet

- Of2 SS1SS F15HB L Oo - PTDocument12 pagesOf2 SS1SS F15HB L Oo - PTŁukasz OlszewskiNo ratings yet

- Mobrey Squitch-2: Ultrasonic Liquid Level SwitchDocument2 pagesMobrey Squitch-2: Ultrasonic Liquid Level SwitchPhan CườngNo ratings yet

- 380 Series: Tee Meter, BTU SystemDocument2 pages380 Series: Tee Meter, BTU SystemEddi Pelaez SalinasNo ratings yet

- Humidity and Temperature Controller AR247 Data SheetDocument2 pagesHumidity and Temperature Controller AR247 Data SheetTechnoserve IndustrialNo ratings yet

- Babani 341 MS DOS 6 ExplainedDocument213 pagesBabani 341 MS DOS 6 ExplainedIman AkbariNo ratings yet

- fmmt2222, Fmmt2222a, Fmmt2222ar, fmmt2222r Zetex PDFDocument3 pagesfmmt2222, Fmmt2222a, Fmmt2222ar, fmmt2222r Zetex PDFagusNo ratings yet

- Ceramic Disc Capacitors Class 1 and 2, 1 KV To 50 KV, General PurposeDocument3 pagesCeramic Disc Capacitors Class 1 and 2, 1 KV To 50 KV, General PurposeIman AkbariNo ratings yet

- Silicon PNP Power Transistors: Savantic Semiconductor Product SpecificationDocument3 pagesSilicon PNP Power Transistors: Savantic Semiconductor Product SpecificationIman AkbariNo ratings yet

- Wirewound - Resistors: Pulse Load - Wirewound Resistors V I T R O H MDocument6 pagesWirewound - Resistors: Pulse Load - Wirewound Resistors V I T R O H MIman AkbariNo ratings yet

- RS-422 and RS-485 Standards Overview and SystemDocument25 pagesRS-422 and RS-485 Standards Overview and SystemIman Akbari100% (1)

- Multimeter: ISO-9001, CE, IEC1010Document2 pagesMultimeter: ISO-9001, CE, IEC1010Iman AkbariNo ratings yet

- Reference: BFX50 01 Code: BFX5001 Characteristics Side Mount With 2NC Contacts For BF00, BF09-BF38Document1 pageReference: BFX50 01 Code: BFX5001 Characteristics Side Mount With 2NC Contacts For BF00, BF09-BF38Iman AkbariNo ratings yet

- CISCO2811 Datasheet: Get A QuoteDocument3 pagesCISCO2811 Datasheet: Get A QuoteIman AkbariNo ratings yet

- Lecture 4: RL Circuits. Inductive Kick. Diode Snubbers.: Filters ChokesDocument6 pagesLecture 4: RL Circuits. Inductive Kick. Diode Snubbers.: Filters ChokesIman AkbariNo ratings yet

- TIA/EIA-422-B Overview: © 1998 National Semiconductor Corporation AN012598Document8 pagesTIA/EIA-422-B Overview: © 1998 National Semiconductor Corporation AN012598Iman AkbariNo ratings yet

- FS12UMA-4A: PreliminaryDocument4 pagesFS12UMA-4A: PreliminaryIman AkbariNo ratings yet

- SD1729 (TH416) : HF SSB Applications RF & Microwave TransistorsDocument4 pagesSD1729 (TH416) : HF SSB Applications RF & Microwave TransistorsIman AkbariNo ratings yet

- @perkins: 4000 Series 4016TAG2 4016TAG2ADocument2 pages@perkins: 4000 Series 4016TAG2 4016TAG2AIman AkbariNo ratings yet

- Maxim Integrated Products: Reliability Report FOR MAX483ECPA+ Plastic Encapsulated DevicesDocument5 pagesMaxim Integrated Products: Reliability Report FOR MAX483ECPA+ Plastic Encapsulated DevicesIman AkbariNo ratings yet

- FJP13007 High Voltage Fast-Switching NPN Power Transistor: FeaturesDocument6 pagesFJP13007 High Voltage Fast-Switching NPN Power Transistor: FeaturesIman AkbariNo ratings yet

- Connector For FLEXWELL® Elliptical Waveguide E100, PBR100 FlangeDocument1 pageConnector For FLEXWELL® Elliptical Waveguide E100, PBR100 FlangeIman AkbariNo ratings yet

- Pages From Marine VHF Radiotelephone Installation ManualDocument1 pagePages From Marine VHF Radiotelephone Installation ManualIman AkbariNo ratings yet

- Connector For FLEXWELL® Elliptical Waveguide E38, PDR40 FlangeDocument1 pageConnector For FLEXWELL® Elliptical Waveguide E38, PDR40 FlangeIman AkbariNo ratings yet

- Connector For FLEXWELL® Elliptical Waveguide E38, PDR40 FlangeDocument1 pageConnector For FLEXWELL® Elliptical Waveguide E38, PDR40 FlangeIman AkbariNo ratings yet

- SWSWSWSSWDocument5 pagesSWSWSWSSWIman AkbariNo ratings yet

- Bhs Inggris - Ananda Taqiyyah Ihsani T - Xii Mipa 7Document14 pagesBhs Inggris - Ananda Taqiyyah Ihsani T - Xii Mipa 7aanandaihzzannnNo ratings yet

- Inception Report Tawang Master Plan ArunachalDocument39 pagesInception Report Tawang Master Plan Arunachalsmodi_92No ratings yet

- Multiscale Designer - IntroductionDocument31 pagesMultiscale Designer - IntroductionaliNo ratings yet

- Modelling The Behaviour of Concrete Encased Concrete Filled Steel Tube Columns Subjected To Full Range FireDocument16 pagesModelling The Behaviour of Concrete Encased Concrete Filled Steel Tube Columns Subjected To Full Range FireLeoNo ratings yet

- Engineering Physics Laboratory: Course ObjectivesDocument3 pagesEngineering Physics Laboratory: Course ObjectivesNaveenraj NNo ratings yet

- 8-Channel Saturated Sink Driver: UDN2595ADocument8 pages8-Channel Saturated Sink Driver: UDN2595AIkram UlhaqNo ratings yet

- DC Mid ImpDocument2 pagesDC Mid ImpSowmya ChowdaryNo ratings yet

- U.S. Midterm Exam ReviewerDocument4 pagesU.S. Midterm Exam ReviewerLianNo ratings yet

- EOT Crane Mechanical Equipment Calculation 1Document17 pagesEOT Crane Mechanical Equipment Calculation 1satendra sharmaNo ratings yet

- Nickel Strip For BatteriesDocument12 pagesNickel Strip For BatteriesSidNo ratings yet

- Artificial Intelligence Application in Bone Fracture DetectionDocument6 pagesArtificial Intelligence Application in Bone Fracture DetectionMEHDI JAHANIRADNo ratings yet

- Open Space - ArticleDocument25 pagesOpen Space - ArticleManogna Sai PadiNo ratings yet

- Lesson Plan Class 3 English Chapter 6 To 12Document60 pagesLesson Plan Class 3 English Chapter 6 To 12Tamuna AkhobadzeNo ratings yet

- Pre-Test On Identifying BiiasDocument2 pagesPre-Test On Identifying BiiasVee Jay GarciaNo ratings yet

- Argumentative Writing: Sajjad Iqbal KhanDocument24 pagesArgumentative Writing: Sajjad Iqbal KhanM WaseemNo ratings yet

- Report On Geology of Sitakundo, RangamatiDocument33 pagesReport On Geology of Sitakundo, RangamatiMarvel AvengerNo ratings yet

- Seminar Report-Swarm Robotics Main ContentDocument35 pagesSeminar Report-Swarm Robotics Main ContentHarshal LolgeNo ratings yet

- Grade 9 Notes Logic GateDocument10 pagesGrade 9 Notes Logic GateButterfly HuexNo ratings yet

- Architecture Curriculum Revised December 2017Document166 pagesArchitecture Curriculum Revised December 2017Desta DabiNo ratings yet

- Contoh Analytical Exposition Thesis Argument ReiterationDocument5 pagesContoh Analytical Exposition Thesis Argument Reiterationafcnzcrcf100% (2)

- Movie Recommendation Engine - IpynbDocument19 pagesMovie Recommendation Engine - Ipynbpanchalharshit0077No ratings yet

- The Finer Things Club PPT TemplateDocument23 pagesThe Finer Things Club PPT TemplatejbcNo ratings yet

- 14a - Labor Counsel ReviewDocument2 pages14a - Labor Counsel ReviewJoy M. HosfordNo ratings yet

- Research Plan: Name of Researcher/SDocument2 pagesResearch Plan: Name of Researcher/SJaeron DavidNo ratings yet

- 962 3485 1 PBDocument5 pages962 3485 1 PBPutu HendrawanNo ratings yet

- Education - and - Modernity - Amman Madan - EngDocument122 pagesEducation - and - Modernity - Amman Madan - EngChethan BasavarajNo ratings yet

- Midterm Examination Pmta 1ST 22.23Document8 pagesMidterm Examination Pmta 1ST 22.23Johnray RonaNo ratings yet

- 190102-DC10.5-Expansive and Stable Soils-Public ReviewDocument66 pages190102-DC10.5-Expansive and Stable Soils-Public Reviewvõ hoàng thái50% (2)

- DLL - Science 4 - Q1 - W8Document5 pagesDLL - Science 4 - Q1 - W8MELROSE HAMOYNo ratings yet