Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewsShackle Crosby

Shackle Crosby

Uploaded by

Ilham KelanaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Obituary: Record of Yale Graduates 1918-1919Document493 pagesObituary: Record of Yale Graduates 1918-1919Jason McDonaldNo ratings yet

- Lifting Plan Calculation (STC250)Document3 pagesLifting Plan Calculation (STC250)Ilham Kelana100% (1)

- 24 Crosby Shackle MetricDocument1 page24 Crosby Shackle MetricAsnawirNo ratings yet

- Crosby G-2130 Shackle Data Sheet PDFDocument1 pageCrosby G-2130 Shackle Data Sheet PDFdavidandrewleggNo ratings yet

- Crossby Shackles Catalog G-2130 PDFDocument1 pageCrossby Shackles Catalog G-2130 PDFSam LowNo ratings yet

- G-2130 / S-2130 Bolt Type Anchor ShacklesDocument1 pageG-2130 / S-2130 Bolt Type Anchor ShacklesRaul GutierrezNo ratings yet

- CROSBY Shackle Anchor 1Document1 pageCROSBY Shackle Anchor 1Tapan MehtaNo ratings yet

- ShacklesDocument9 pagesShacklesMuhammad Najam AbbasNo ratings yet

- Alloy Screw Pin Shackle G209ADocument1 pageAlloy Screw Pin Shackle G209ARony Prayitno SimeonNo ratings yet

- G-277 Cancamo CrosbyDocument1 pageG-277 Cancamo CrosbyDavid Borja HuarachiNo ratings yet

- Crosby G-209R ROV ShackleDocument1 pageCrosby G-209R ROV ShacklenatNo ratings yet

- cROSBY LINKSDocument1 pagecROSBY LINKSTheo van der BergNo ratings yet

- G-450 Crosby Clips: Red U-BoltDocument1 pageG-450 Crosby Clips: Red U-BoltEduardo Da Silva PereiraNo ratings yet

- Angular Contact Bearing SwivelsDocument1 pageAngular Contact Bearing SwivelsmeromikhaNo ratings yet

- Shackles - CrosbyDocument9 pagesShackles - CrosbyjsprtanNo ratings yet

- G-2130 / S-2130 Bolt Type Anchor ShacklesDocument1 pageG-2130 / S-2130 Bolt Type Anchor Shacklesramy abazaNo ratings yet

- Crosby ShackleDocument1 pageCrosby ShacklevrandyNo ratings yet

- Clevis Grab Hook Crosby® A338 (Grade 80)Document1 pageClevis Grab Hook Crosby® A338 (Grade 80)CROSBYNo ratings yet

- Crosby - HG-228 Jaw Jaw Turnbuckles SpecsDocument1 pageCrosby - HG-228 Jaw Jaw Turnbuckles SpecsSalmanNo ratings yet

- S G209 CrosbyDocument1 pageS G209 CrosbyJS168No ratings yet

- Sling Saver ShackleDocument1 pageSling Saver ShackleFatihTufanNo ratings yet

- Jaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyDocument1 pageJaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyGustavo ArancibiaNo ratings yet

- CANAN Steel Deck Catalogue - 2023Document48 pagesCANAN Steel Deck Catalogue - 2023Clarice Lispector100% (1)

- Master Link A345Document1 pageMaster Link A345Hunnymijie NorNo ratings yet

- Crosby 2130 2150Document1 pageCrosby 2130 2150Sumner TingNo ratings yet

- Release & Retrieve ROV Shackle With Non - Thread Bolt Release & Retrieve ROV Shackle With QUIC - Thread BoltDocument1 pageRelease & Retrieve ROV Shackle With Non - Thread Bolt Release & Retrieve ROV Shackle With QUIC - Thread BoltAugusto.FilhoNo ratings yet

- Chain Crosby® Grade 100Document1 pageChain Crosby® Grade 100CROSBYNo ratings yet

- 4 Ball Valves Long BW Ends Screwed EndsDocument5 pages4 Ball Valves Long BW Ends Screwed Endstamtour7No ratings yet

- Crosby 1016313 DatasheetDocument1 pageCrosby 1016313 Datasheetedi hendrikusNo ratings yet

- HDT/GPT/TWP: ApplicationsDocument1 pageHDT/GPT/TWP: Applicationshui luoNo ratings yet

- Shackle PDFDocument1 pageShackle PDFSutar MiyaldiNo ratings yet

- A-344 & A347 Welded Master Link - ImperialDocument1 pageA-344 & A347 Welded Master Link - Imperialaiyubi2No ratings yet

- DID 180 Standard Roller Chain: Roller Chains For Power TransmissionDocument1 pageDID 180 Standard Roller Chain: Roller Chains For Power TransmissionJhampol Rosales MuñozNo ratings yet

- C Purlin Data SheetDocument6 pagesC Purlin Data SheetAkhil VN100% (1)

- SHS & RHS PropertiesDocument11 pagesSHS & RHS Propertieslavinkg7681No ratings yet

- Apostila Flange 02Document3 pagesApostila Flange 02Mauro BrajãoNo ratings yet

- Din en 856 4Sp: Multispiral Hydraulic Hose Acc. To EN 856 4SP - MSHA ApprovedDocument1 pageDin en 856 4Sp: Multispiral Hydraulic Hose Acc. To EN 856 4SP - MSHA ApprovedSergio AlbaNo ratings yet

- Jaw & Eye Turnbuckles: All Rights Reserved 188Document1 pageJaw & Eye Turnbuckles: All Rights Reserved 188agustinNo ratings yet

- IPNDocument1 pageIPNarianto32No ratings yet

- Deltacatalog 90Document1 pageDeltacatalog 90mahmoud abdulsalamNo ratings yet

- A029 A030 H05VVC4V5 K - NYSLYCYO - ControlDocument2 pagesA029 A030 H05VVC4V5 K - NYSLYCYO - ControlJosé CamposNo ratings yet

- Dsi-Usa Dywidag Tie Rods Us 02Document12 pagesDsi-Usa Dywidag Tie Rods Us 02Hery Mardiono HeryNo ratings yet

- Dimensions of Steel Beams Type IPE European Standard EN 10025-1/2Document1 pageDimensions of Steel Beams Type IPE European Standard EN 10025-1/2Petar Topic100% (1)

- Pompa Flans TipleriDocument3 pagesPompa Flans TipleriKvncGmz DzrNo ratings yet

- HG 226Document1 pageHG 226Konstantinos SynodinosNo ratings yet

- Gunnebo Industries - Dee Shackle No 834Document2 pagesGunnebo Industries - Dee Shackle No 834REDDYNo ratings yet

- Forged Machinery Eye Bolts: See Application and Warning InformationDocument1 pageForged Machinery Eye Bolts: See Application and Warning InformationHasrul SunNo ratings yet

- Green Pin Bow Shackle SC: Rua Buri, 149 - Laranjeiras - CAIEIRAS/SP - CEP: 07739-600Document1 pageGreen Pin Bow Shackle SC: Rua Buri, 149 - Laranjeiras - CAIEIRAS/SP - CEP: 07739-600Alexandre GermanoNo ratings yet

- (N) Shtöu VDocument1 page(N) Shtöu VLuis AguilarNo ratings yet

- 20CV321-MOS-Kaware AkshayDocument68 pages20CV321-MOS-Kaware AkshayYashvardhan TodmalNo ratings yet

- Cable Gland: Type VBL 453 FlameproofDocument2 pagesCable Gland: Type VBL 453 FlameproofLucas ElliottNo ratings yet

- Crosby Eye Bolt G 291Document1 pageCrosby Eye Bolt G 291pandiangvNo ratings yet

- Nsgafoeu CPR 1,8/3 KV: ApplicationDocument2 pagesNsgafoeu CPR 1,8/3 KV: ApplicationAttila HorvathNo ratings yet

- Deltacatalog 92Document1 pageDeltacatalog 92mahmoud abdulsalamNo ratings yet

- Type VBL 153 IndustrialDocument2 pagesType VBL 153 Industrialpouya alizadehNo ratings yet

- Assymetrical WedgeDocument1 pageAssymetrical WedgeNurettin IsikNo ratings yet

- Dim Bridas PDFDocument2 pagesDim Bridas PDFSiles LimberdsNo ratings yet

- The Dryfit Range For Modular Performance Adaption.: Sonnenschein A412 / 120 FTDocument2 pagesThe Dryfit Range For Modular Performance Adaption.: Sonnenschein A412 / 120 FTglukkerNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- Slope Cable Tray Support Plate Cutting SizeDocument1 pageSlope Cable Tray Support Plate Cutting SizeIlham KelanaNo ratings yet

- Pipes Wall Thickness Calculation According ASME B31 3Document74 pagesPipes Wall Thickness Calculation According ASME B31 3Ilham KelanaNo ratings yet

- Fire Sprinklers Hydraulic Calculations CPSDocument27 pagesFire Sprinklers Hydraulic Calculations CPSIlham KelanaNo ratings yet

- Welding ProgressDocument2 pagesWelding ProgressIlham KelanaNo ratings yet

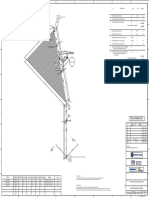

- Lifting Plan Calculation (QTZ200 Tower Crane)Document3 pagesLifting Plan Calculation (QTZ200 Tower Crane)Ilham KelanaNo ratings yet

- Weight CalculationDocument52 pagesWeight CalculationIlham KelanaNo ratings yet

- Manhole Cover Load CalculationDocument1 pageManhole Cover Load CalculationIlham KelanaNo ratings yet

- Non Critical Lifting Plan - TMC 8TDocument1 pageNon Critical Lifting Plan - TMC 8TIlham KelanaNo ratings yet

- Design Calculation For Embedment PlateDocument3 pagesDesign Calculation For Embedment PlateIlham KelanaNo ratings yet

- LIFTING PLAN (Use) - 120T SumitomoDocument3 pagesLIFTING PLAN (Use) - 120T SumitomoIlham KelanaNo ratings yet

- Pipe Rack Critical Lifting PlanDocument1 pagePipe Rack Critical Lifting PlanIlham KelanaNo ratings yet

- Sump Discharge Piping - ISOMETRIC DrawingDocument9 pagesSump Discharge Piping - ISOMETRIC DrawingIlham KelanaNo ratings yet

- Welding Progress 17 - 37Document4 pagesWelding Progress 17 - 37Ilham KelanaNo ratings yet

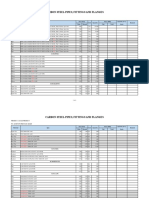

- BOM (Bolt, Nut & Washer) Silo Stair TowerDocument6 pagesBOM (Bolt, Nut & Washer) Silo Stair TowerIlham KelanaNo ratings yet

- Bill of Material (Pipes - Fittings - Flanges)Document4 pagesBill of Material (Pipes - Fittings - Flanges)Ilham KelanaNo ratings yet

- BOM (Bolt, Nut & Washer) Silo Stair TowerDocument5 pagesBOM (Bolt, Nut & Washer) Silo Stair TowerIlham KelanaNo ratings yet

- Packing List JW910-DHIC-PL-354 REV02Document7 pagesPacking List JW910-DHIC-PL-354 REV02Ilham KelanaNo ratings yet

- Fire Sprinklers Hydraulic CalculationsDocument27 pagesFire Sprinklers Hydraulic CalculationsIlham Kelana100% (1)

- Stair Tower Welding Joint ListDocument14 pagesStair Tower Welding Joint ListIlham KelanaNo ratings yet

- Hazen Williams EquationDocument1 pageHazen Williams EquationIlham KelanaNo ratings yet

- BCIP Application: Mode of Investment Ocbc Deposit Account Ocbc Online Banking Ocbc SRS AccountDocument6 pagesBCIP Application: Mode of Investment Ocbc Deposit Account Ocbc Online Banking Ocbc SRS Accountmugger123456No ratings yet

- DeyanaDocument9 pagesDeyanahagos dargoNo ratings yet

- Growing Pains in World Football: Haiti and Zaire at The 1974 World CupDocument46 pagesGrowing Pains in World Football: Haiti and Zaire at The 1974 World CupMatt RobertshawNo ratings yet

- Question Analysis: Taxation IDocument9 pagesQuestion Analysis: Taxation IIQBALNo ratings yet

- 323-1851-160 (6500 5400 8700 Interworking Solution) Issue7Document168 pages323-1851-160 (6500 5400 8700 Interworking Solution) Issue7José Pedro Batista Leite100% (1)

- Crash Report 85853814 - Marco Island Police DepartmentDocument4 pagesCrash Report 85853814 - Marco Island Police DepartmentOmar Rodriguez OrtizNo ratings yet

- Accounting Fundamentals: The Accounting Equation and The Double-Entry SystemDocument70 pagesAccounting Fundamentals: The Accounting Equation and The Double-Entry SystemAllana Mier100% (1)

- Guidelines of RA 11222 LatestDocument52 pagesGuidelines of RA 11222 LatestAna Shiella SaavedraNo ratings yet

- Cabang vs. BasayDocument7 pagesCabang vs. BasayAlfred LacandulaNo ratings yet

- Itc Limited: India First: J Ramachandran and K S ManikandanDocument22 pagesItc Limited: India First: J Ramachandran and K S ManikandanMani Raja MNo ratings yet

- Land Administration in BangladeshDocument32 pagesLand Administration in BangladeshManjare Hassin RaadNo ratings yet

- Guided Exercises Investment in AssociateDocument2 pagesGuided Exercises Investment in AssociateMireya YueNo ratings yet

- Securities and Exchange Commission v. Heinen Et Al - Document No. 23Document3 pagesSecurities and Exchange Commission v. Heinen Et Al - Document No. 23Justia.comNo ratings yet

- PALE Musmud SantiagoDocument10 pagesPALE Musmud SantiagoKathNo ratings yet

- List of Statutory Instruments 2016 Up To 2016-11-04Document6 pagesList of Statutory Instruments 2016 Up To 2016-11-04miti victorNo ratings yet

- In The Court of Judge Banking Court LahoreDocument3 pagesIn The Court of Judge Banking Court Lahorehearthacker_302No ratings yet

- Introduction To Financial Markets and Institutions NotesDocument11 pagesIntroduction To Financial Markets and Institutions NotesFe ValenciaNo ratings yet

- Player Contracts: Italy's Serie B Salary Cap: AnalysisDocument2 pagesPlayer Contracts: Italy's Serie B Salary Cap: AnalysisLuca FerrariNo ratings yet

- 7 Blastgel 1000 - 1070Document2 pages7 Blastgel 1000 - 1070danielNo ratings yet

- Introduction To Jamaat e Islah e Muasharah Wa Izala e MunkaratDocument2 pagesIntroduction To Jamaat e Islah e Muasharah Wa Izala e MunkaratmusarhadNo ratings yet

- Digested Banking CasesDocument11 pagesDigested Banking CasesJunivenReyUmadhayNo ratings yet

- Account For Home Office and Branch Transactions. ProblemDocument2 pagesAccount For Home Office and Branch Transactions. ProblemDevine Grace A. MaghinayNo ratings yet

- Coke Contract. Texas A&M College StationDocument35 pagesCoke Contract. Texas A&M College StationCampaign to Stop Killer CokeNo ratings yet

- S4611 EN Col14 ILT FV CO A4Document23 pagesS4611 EN Col14 ILT FV CO A4Tabe TambeNo ratings yet

- Chapter 17 (E17-7) Dinah Diyanah Burhan A31115506Document1 pageChapter 17 (E17-7) Dinah Diyanah Burhan A31115506dina burhanNo ratings yet

- Tatlong Taong Walang DiyosDocument2 pagesTatlong Taong Walang DiyosCyberVODSNo ratings yet

- GA 132-180 VSD Part List (AIF 079019 Den)Document78 pagesGA 132-180 VSD Part List (AIF 079019 Den)Sales AydinkayaNo ratings yet

- Analysis of Bitcoin in Illicit FinanceDocument11 pagesAnalysis of Bitcoin in Illicit FinanceZennie AbrahamNo ratings yet

- A Pagan Witches TouchstoneDocument64 pagesA Pagan Witches TouchstoneTaranisaNo ratings yet

Shackle Crosby

Shackle Crosby

Uploaded by

Ilham Kelana0 ratings0% found this document useful (0 votes)

1 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views1 pageShackle Crosby

Shackle Crosby

Uploaded by

Ilham KelanaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

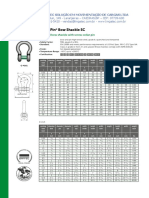

SHACKLES

G-213 / S-213 • Forged, Quenched & Tempered, with alloy pins.

• Working Load Limit permanently shown on every shackle.

• Hot-dip galvanized (G) or self colored (S).

• Sizes 3/8 inch and below are mechanically galvanized.

• Fatigue rated to 20,000 cycles at 1-1/2 times the Working Load Limit.

• Shackles 25t and larger are RFID equipped.

• Shackles can be furnished proof tested with certificates to designated

standards, such as ABS, DNV, Lloyds, or other certification. Charges for

proof testing and certification available when requested at the time of order.

• Shackles are Quenched & Tempered and can meet DNV impact requirements

of 42 Joules (31 ft-Ib) at -20° C (-4° F).

• G-213 Round pin anchor shackles meet the performance requirements of

Federal Specification RR-C-271G, Type IVA, Grade A, Class 1, except for

those provisions required of the contractor.

• DO NOT SIDE LOAD ROUND PIN SHACKLES.

• Look for the Red Pin®... the mark of genuine Crosby quality.

G-213 / S-213 Round Pin Anchor Shackles

Working Stock Dimensions Tolerance

Nominal Load No. Weight (mm) (+ / - mm)

Size Limit Each

(in) (t) G-213 S-213 (kg) A B C D E F G H N P C A

1/4 0.5 1018017 1018026 .06 11.9 7.85 28.7 6.35 19.8 15.5 32.5 46.7 34.0 6.35 1.50 1.50

5/16 0.75 1018035 1018044 .08 13.5 9.65 31.0 7.85 21.3 19.1 37.3 53.0 40.4 7.85 1.50 1.50

3/8 1 1018053 1018062 .13 16.8 11.2 36.6 9.65 26.2 23.1 45.2 63.0 47.2 9.65 3.30 1.50

7/16 1.5 1018071 1018080 .17 19.1 12.7 42.9 11.2 29.5 26.9 51.5 74.0 54.0 11.2 3.30 1.50

1/2 2 1018099 1018106 .32 20.6 16.0 47.8 12.7 33.3 30.2 58.5 83.5 60.5 12.7 3.30 1.50

5/8 3.25 1018115 1018124 .68 26.9 19.1 60.5 16.0 42.9 38.1 74.5 106 74.0 17.5 3.30 1.50

3/4 4.75 1018133 1018142 1.05 31.8 22.4 71.5 19.1 51.0 46.0 89.0 126 87.0 20.6 6.35 1.50

7/8 6.5 1018151 1018160 1.58 36.6 25.4 84.0 22.4 58.0 53.0 102 148 96.5 24.6 6.35 1.50

1 8.5 1018179 1018188 2.27 42.9 28.7 95.5 25.4 68.5 60.5 119 167 115 26.9 6.35 1.50

1-1/8 9.5 1018197 1018204 3.16 46.0 31.8 108 28.7 74.0 68.5 131 190 130 31.8 6.35 1.50

1-1/4 12 1018213 1018222 4.42 51.5 35.1 119 32.8 82.5 76.0 146 210 140 35.1 6.35 1.50

1-3/8 13.5 1018231 1018240 6.01 57.0 38.1 133 36.1 92.0 84.0 162 233 156 38.1 6.35 3.30

1-1/2 17 1018259 1018268 7.82 60.5 41.4 146 39.1 98.5 92.0 175 254 165 41.1 6.35 3.30

1-3/4 25 1018277 1018286 13.4 73.0 51.0 178 46.7 127 106 225 313 197 57.0 6.35 3.30

2 35 1018295 1018302 20.8 82.5 57.0 197 53.0 146 122 253 348 222 61.0 6.35 3.30

6:1 Design Factor. Maximum Proof Load is 2 times the Working Load Limit.

APPLICATION AND WARNING INFORMATION

SECTION 17

22 thecrosbygroup.com Copyright © 2022 The Crosby Group LLC All Rights Reserved

You might also like

- Obituary: Record of Yale Graduates 1918-1919Document493 pagesObituary: Record of Yale Graduates 1918-1919Jason McDonaldNo ratings yet

- Lifting Plan Calculation (STC250)Document3 pagesLifting Plan Calculation (STC250)Ilham Kelana100% (1)

- 24 Crosby Shackle MetricDocument1 page24 Crosby Shackle MetricAsnawirNo ratings yet

- Crosby G-2130 Shackle Data Sheet PDFDocument1 pageCrosby G-2130 Shackle Data Sheet PDFdavidandrewleggNo ratings yet

- Crossby Shackles Catalog G-2130 PDFDocument1 pageCrossby Shackles Catalog G-2130 PDFSam LowNo ratings yet

- G-2130 / S-2130 Bolt Type Anchor ShacklesDocument1 pageG-2130 / S-2130 Bolt Type Anchor ShacklesRaul GutierrezNo ratings yet

- CROSBY Shackle Anchor 1Document1 pageCROSBY Shackle Anchor 1Tapan MehtaNo ratings yet

- ShacklesDocument9 pagesShacklesMuhammad Najam AbbasNo ratings yet

- Alloy Screw Pin Shackle G209ADocument1 pageAlloy Screw Pin Shackle G209ARony Prayitno SimeonNo ratings yet

- G-277 Cancamo CrosbyDocument1 pageG-277 Cancamo CrosbyDavid Borja HuarachiNo ratings yet

- Crosby G-209R ROV ShackleDocument1 pageCrosby G-209R ROV ShacklenatNo ratings yet

- cROSBY LINKSDocument1 pagecROSBY LINKSTheo van der BergNo ratings yet

- G-450 Crosby Clips: Red U-BoltDocument1 pageG-450 Crosby Clips: Red U-BoltEduardo Da Silva PereiraNo ratings yet

- Angular Contact Bearing SwivelsDocument1 pageAngular Contact Bearing SwivelsmeromikhaNo ratings yet

- Shackles - CrosbyDocument9 pagesShackles - CrosbyjsprtanNo ratings yet

- G-2130 / S-2130 Bolt Type Anchor ShacklesDocument1 pageG-2130 / S-2130 Bolt Type Anchor Shacklesramy abazaNo ratings yet

- Crosby ShackleDocument1 pageCrosby ShacklevrandyNo ratings yet

- Clevis Grab Hook Crosby® A338 (Grade 80)Document1 pageClevis Grab Hook Crosby® A338 (Grade 80)CROSBYNo ratings yet

- Crosby - HG-228 Jaw Jaw Turnbuckles SpecsDocument1 pageCrosby - HG-228 Jaw Jaw Turnbuckles SpecsSalmanNo ratings yet

- S G209 CrosbyDocument1 pageS G209 CrosbyJS168No ratings yet

- Sling Saver ShackleDocument1 pageSling Saver ShackleFatihTufanNo ratings yet

- Jaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyDocument1 pageJaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyGustavo ArancibiaNo ratings yet

- CANAN Steel Deck Catalogue - 2023Document48 pagesCANAN Steel Deck Catalogue - 2023Clarice Lispector100% (1)

- Master Link A345Document1 pageMaster Link A345Hunnymijie NorNo ratings yet

- Crosby 2130 2150Document1 pageCrosby 2130 2150Sumner TingNo ratings yet

- Release & Retrieve ROV Shackle With Non - Thread Bolt Release & Retrieve ROV Shackle With QUIC - Thread BoltDocument1 pageRelease & Retrieve ROV Shackle With Non - Thread Bolt Release & Retrieve ROV Shackle With QUIC - Thread BoltAugusto.FilhoNo ratings yet

- Chain Crosby® Grade 100Document1 pageChain Crosby® Grade 100CROSBYNo ratings yet

- 4 Ball Valves Long BW Ends Screwed EndsDocument5 pages4 Ball Valves Long BW Ends Screwed Endstamtour7No ratings yet

- Crosby 1016313 DatasheetDocument1 pageCrosby 1016313 Datasheetedi hendrikusNo ratings yet

- HDT/GPT/TWP: ApplicationsDocument1 pageHDT/GPT/TWP: Applicationshui luoNo ratings yet

- Shackle PDFDocument1 pageShackle PDFSutar MiyaldiNo ratings yet

- A-344 & A347 Welded Master Link - ImperialDocument1 pageA-344 & A347 Welded Master Link - Imperialaiyubi2No ratings yet

- DID 180 Standard Roller Chain: Roller Chains For Power TransmissionDocument1 pageDID 180 Standard Roller Chain: Roller Chains For Power TransmissionJhampol Rosales MuñozNo ratings yet

- C Purlin Data SheetDocument6 pagesC Purlin Data SheetAkhil VN100% (1)

- SHS & RHS PropertiesDocument11 pagesSHS & RHS Propertieslavinkg7681No ratings yet

- Apostila Flange 02Document3 pagesApostila Flange 02Mauro BrajãoNo ratings yet

- Din en 856 4Sp: Multispiral Hydraulic Hose Acc. To EN 856 4SP - MSHA ApprovedDocument1 pageDin en 856 4Sp: Multispiral Hydraulic Hose Acc. To EN 856 4SP - MSHA ApprovedSergio AlbaNo ratings yet

- Jaw & Eye Turnbuckles: All Rights Reserved 188Document1 pageJaw & Eye Turnbuckles: All Rights Reserved 188agustinNo ratings yet

- IPNDocument1 pageIPNarianto32No ratings yet

- Deltacatalog 90Document1 pageDeltacatalog 90mahmoud abdulsalamNo ratings yet

- A029 A030 H05VVC4V5 K - NYSLYCYO - ControlDocument2 pagesA029 A030 H05VVC4V5 K - NYSLYCYO - ControlJosé CamposNo ratings yet

- Dsi-Usa Dywidag Tie Rods Us 02Document12 pagesDsi-Usa Dywidag Tie Rods Us 02Hery Mardiono HeryNo ratings yet

- Dimensions of Steel Beams Type IPE European Standard EN 10025-1/2Document1 pageDimensions of Steel Beams Type IPE European Standard EN 10025-1/2Petar Topic100% (1)

- Pompa Flans TipleriDocument3 pagesPompa Flans TipleriKvncGmz DzrNo ratings yet

- HG 226Document1 pageHG 226Konstantinos SynodinosNo ratings yet

- Gunnebo Industries - Dee Shackle No 834Document2 pagesGunnebo Industries - Dee Shackle No 834REDDYNo ratings yet

- Forged Machinery Eye Bolts: See Application and Warning InformationDocument1 pageForged Machinery Eye Bolts: See Application and Warning InformationHasrul SunNo ratings yet

- Green Pin Bow Shackle SC: Rua Buri, 149 - Laranjeiras - CAIEIRAS/SP - CEP: 07739-600Document1 pageGreen Pin Bow Shackle SC: Rua Buri, 149 - Laranjeiras - CAIEIRAS/SP - CEP: 07739-600Alexandre GermanoNo ratings yet

- (N) Shtöu VDocument1 page(N) Shtöu VLuis AguilarNo ratings yet

- 20CV321-MOS-Kaware AkshayDocument68 pages20CV321-MOS-Kaware AkshayYashvardhan TodmalNo ratings yet

- Cable Gland: Type VBL 453 FlameproofDocument2 pagesCable Gland: Type VBL 453 FlameproofLucas ElliottNo ratings yet

- Crosby Eye Bolt G 291Document1 pageCrosby Eye Bolt G 291pandiangvNo ratings yet

- Nsgafoeu CPR 1,8/3 KV: ApplicationDocument2 pagesNsgafoeu CPR 1,8/3 KV: ApplicationAttila HorvathNo ratings yet

- Deltacatalog 92Document1 pageDeltacatalog 92mahmoud abdulsalamNo ratings yet

- Type VBL 153 IndustrialDocument2 pagesType VBL 153 Industrialpouya alizadehNo ratings yet

- Assymetrical WedgeDocument1 pageAssymetrical WedgeNurettin IsikNo ratings yet

- Dim Bridas PDFDocument2 pagesDim Bridas PDFSiles LimberdsNo ratings yet

- The Dryfit Range For Modular Performance Adaption.: Sonnenschein A412 / 120 FTDocument2 pagesThe Dryfit Range For Modular Performance Adaption.: Sonnenschein A412 / 120 FTglukkerNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- Slope Cable Tray Support Plate Cutting SizeDocument1 pageSlope Cable Tray Support Plate Cutting SizeIlham KelanaNo ratings yet

- Pipes Wall Thickness Calculation According ASME B31 3Document74 pagesPipes Wall Thickness Calculation According ASME B31 3Ilham KelanaNo ratings yet

- Fire Sprinklers Hydraulic Calculations CPSDocument27 pagesFire Sprinklers Hydraulic Calculations CPSIlham KelanaNo ratings yet

- Welding ProgressDocument2 pagesWelding ProgressIlham KelanaNo ratings yet

- Lifting Plan Calculation (QTZ200 Tower Crane)Document3 pagesLifting Plan Calculation (QTZ200 Tower Crane)Ilham KelanaNo ratings yet

- Weight CalculationDocument52 pagesWeight CalculationIlham KelanaNo ratings yet

- Manhole Cover Load CalculationDocument1 pageManhole Cover Load CalculationIlham KelanaNo ratings yet

- Non Critical Lifting Plan - TMC 8TDocument1 pageNon Critical Lifting Plan - TMC 8TIlham KelanaNo ratings yet

- Design Calculation For Embedment PlateDocument3 pagesDesign Calculation For Embedment PlateIlham KelanaNo ratings yet

- LIFTING PLAN (Use) - 120T SumitomoDocument3 pagesLIFTING PLAN (Use) - 120T SumitomoIlham KelanaNo ratings yet

- Pipe Rack Critical Lifting PlanDocument1 pagePipe Rack Critical Lifting PlanIlham KelanaNo ratings yet

- Sump Discharge Piping - ISOMETRIC DrawingDocument9 pagesSump Discharge Piping - ISOMETRIC DrawingIlham KelanaNo ratings yet

- Welding Progress 17 - 37Document4 pagesWelding Progress 17 - 37Ilham KelanaNo ratings yet

- BOM (Bolt, Nut & Washer) Silo Stair TowerDocument6 pagesBOM (Bolt, Nut & Washer) Silo Stair TowerIlham KelanaNo ratings yet

- Bill of Material (Pipes - Fittings - Flanges)Document4 pagesBill of Material (Pipes - Fittings - Flanges)Ilham KelanaNo ratings yet

- BOM (Bolt, Nut & Washer) Silo Stair TowerDocument5 pagesBOM (Bolt, Nut & Washer) Silo Stair TowerIlham KelanaNo ratings yet

- Packing List JW910-DHIC-PL-354 REV02Document7 pagesPacking List JW910-DHIC-PL-354 REV02Ilham KelanaNo ratings yet

- Fire Sprinklers Hydraulic CalculationsDocument27 pagesFire Sprinklers Hydraulic CalculationsIlham Kelana100% (1)

- Stair Tower Welding Joint ListDocument14 pagesStair Tower Welding Joint ListIlham KelanaNo ratings yet

- Hazen Williams EquationDocument1 pageHazen Williams EquationIlham KelanaNo ratings yet

- BCIP Application: Mode of Investment Ocbc Deposit Account Ocbc Online Banking Ocbc SRS AccountDocument6 pagesBCIP Application: Mode of Investment Ocbc Deposit Account Ocbc Online Banking Ocbc SRS Accountmugger123456No ratings yet

- DeyanaDocument9 pagesDeyanahagos dargoNo ratings yet

- Growing Pains in World Football: Haiti and Zaire at The 1974 World CupDocument46 pagesGrowing Pains in World Football: Haiti and Zaire at The 1974 World CupMatt RobertshawNo ratings yet

- Question Analysis: Taxation IDocument9 pagesQuestion Analysis: Taxation IIQBALNo ratings yet

- 323-1851-160 (6500 5400 8700 Interworking Solution) Issue7Document168 pages323-1851-160 (6500 5400 8700 Interworking Solution) Issue7José Pedro Batista Leite100% (1)

- Crash Report 85853814 - Marco Island Police DepartmentDocument4 pagesCrash Report 85853814 - Marco Island Police DepartmentOmar Rodriguez OrtizNo ratings yet

- Accounting Fundamentals: The Accounting Equation and The Double-Entry SystemDocument70 pagesAccounting Fundamentals: The Accounting Equation and The Double-Entry SystemAllana Mier100% (1)

- Guidelines of RA 11222 LatestDocument52 pagesGuidelines of RA 11222 LatestAna Shiella SaavedraNo ratings yet

- Cabang vs. BasayDocument7 pagesCabang vs. BasayAlfred LacandulaNo ratings yet

- Itc Limited: India First: J Ramachandran and K S ManikandanDocument22 pagesItc Limited: India First: J Ramachandran and K S ManikandanMani Raja MNo ratings yet

- Land Administration in BangladeshDocument32 pagesLand Administration in BangladeshManjare Hassin RaadNo ratings yet

- Guided Exercises Investment in AssociateDocument2 pagesGuided Exercises Investment in AssociateMireya YueNo ratings yet

- Securities and Exchange Commission v. Heinen Et Al - Document No. 23Document3 pagesSecurities and Exchange Commission v. Heinen Et Al - Document No. 23Justia.comNo ratings yet

- PALE Musmud SantiagoDocument10 pagesPALE Musmud SantiagoKathNo ratings yet

- List of Statutory Instruments 2016 Up To 2016-11-04Document6 pagesList of Statutory Instruments 2016 Up To 2016-11-04miti victorNo ratings yet

- In The Court of Judge Banking Court LahoreDocument3 pagesIn The Court of Judge Banking Court Lahorehearthacker_302No ratings yet

- Introduction To Financial Markets and Institutions NotesDocument11 pagesIntroduction To Financial Markets and Institutions NotesFe ValenciaNo ratings yet

- Player Contracts: Italy's Serie B Salary Cap: AnalysisDocument2 pagesPlayer Contracts: Italy's Serie B Salary Cap: AnalysisLuca FerrariNo ratings yet

- 7 Blastgel 1000 - 1070Document2 pages7 Blastgel 1000 - 1070danielNo ratings yet

- Introduction To Jamaat e Islah e Muasharah Wa Izala e MunkaratDocument2 pagesIntroduction To Jamaat e Islah e Muasharah Wa Izala e MunkaratmusarhadNo ratings yet

- Digested Banking CasesDocument11 pagesDigested Banking CasesJunivenReyUmadhayNo ratings yet

- Account For Home Office and Branch Transactions. ProblemDocument2 pagesAccount For Home Office and Branch Transactions. ProblemDevine Grace A. MaghinayNo ratings yet

- Coke Contract. Texas A&M College StationDocument35 pagesCoke Contract. Texas A&M College StationCampaign to Stop Killer CokeNo ratings yet

- S4611 EN Col14 ILT FV CO A4Document23 pagesS4611 EN Col14 ILT FV CO A4Tabe TambeNo ratings yet

- Chapter 17 (E17-7) Dinah Diyanah Burhan A31115506Document1 pageChapter 17 (E17-7) Dinah Diyanah Burhan A31115506dina burhanNo ratings yet

- Tatlong Taong Walang DiyosDocument2 pagesTatlong Taong Walang DiyosCyberVODSNo ratings yet

- GA 132-180 VSD Part List (AIF 079019 Den)Document78 pagesGA 132-180 VSD Part List (AIF 079019 Den)Sales AydinkayaNo ratings yet

- Analysis of Bitcoin in Illicit FinanceDocument11 pagesAnalysis of Bitcoin in Illicit FinanceZennie AbrahamNo ratings yet

- A Pagan Witches TouchstoneDocument64 pagesA Pagan Witches TouchstoneTaranisaNo ratings yet