Professional Documents

Culture Documents

Req. For Visual Inspection of Surfaces: Certificate No. 10-4-1-9-03 RHA

Req. For Visual Inspection of Surfaces: Certificate No. 10-4-1-9-03 RHA

Uploaded by

chudinhthuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Req. For Visual Inspection of Surfaces: Certificate No. 10-4-1-9-03 RHA

Req. For Visual Inspection of Surfaces: Certificate No. 10-4-1-9-03 RHA

Uploaded by

chudinhthuCopyright:

Available Formats

Req.

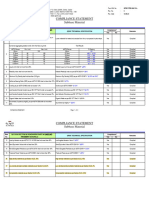

for Visual Inspection of Surfaces NAME PAGE

Certificate no. 10-4-1-9-03 RHA 1

Purpose

This instruction defines the guidelines for identification of the visible surfaces of the product, at the same time

stating measuring methods and fault criteria for subjective deviations.

Background

Division and definition of zones reflect how the customer observes the surfaces during use of the product.

Extent

The instruction applies to classification of non-conformance of surface quality.

Performance

Deviations are checked in appropriate lighting Lux light 600.

In zone AA and A max. 2 faults are allowed, however not within a distance of 40 mm in relation to each other.

In zone B and C max. 4 faults are allowed, however not within a distance of 40 mm in relation to each other.

Zone AA A B C D

Zone color

Inspection distance 50 cm 50 cm 50 cm 100 cm 100 cm

Inspection time 10 sec. 10 sec. 5 sec. 3 sec. 3 sec.

Lugs, holes and marks 0,25 mm 0,45 mm 0,9 mm 2 mm 2 mm

0,15 x 25

Scratches 0,1 x 5 mm 0,1 x 5 mm Acceptable Acceptable

mm

Not Not Not

Grinding faults Acceptable Acceptable

acceptable acceptable acceptable

Insufficient or lacking surface

coating Not Not Not Not Not

(the material shines through the acceptable acceptable acceptable acceptable acceptable

surface coating)

Not Not Not Not Not

Blisters

acceptable acceptable acceptable acceptable acceptable

Not Not Not Not

Blemishes Acceptable

acceptable acceptable acceptable acceptable

Not Not Not Not

Dirt and dust Acceptable

acceptable acceptable acceptable acceptable

Not Not Not Not

Plating dust Acceptable

acceptable acceptable acceptable acceptable

DATE: DRW.NO. REV

10-06-2010 13:38:55 10-4-1-9-03C2

THIS DRAWING IS THE PROPERTY OF MICRO-MATIC A/S AND MUST NOT BE USED, DISCLOSED OR REPRODUCED WHITOUT PRIOR WRITTEN AUTHORITY

FILENAME: W:\MDOC\Archives\PROD\kontrolspec._testpro\10-4-1-9-03

You might also like

- Lab Reports For NDTDocument30 pagesLab Reports For NDTBeryl SeweNo ratings yet

- Hes D2016Document15 pagesHes D2016PPC100% (1)

- RT Acceptance Criteria B31.3 2020, Api 1104 (2021), IX 2021Document6 pagesRT Acceptance Criteria B31.3 2020, Api 1104 (2021), IX 2021Kader KaderNo ratings yet

- Deadliest EarthquakesDocument15 pagesDeadliest EarthquakesAndre ChandraNo ratings yet

- The UFO Evidence - Richard H. HallDocument342 pagesThe UFO Evidence - Richard H. HallCarlos Rodriguez100% (2)

- LINEA Technical ManualDocument14 pagesLINEA Technical Manual5555kevlarNo ratings yet

- DC 958Document2 pagesDC 958mkarthiNo ratings yet

- MMC Hardmetal India Pvt. LTD.: Part Number Part Name Edp No. Inspected DateDocument1 pageMMC Hardmetal India Pvt. LTD.: Part Number Part Name Edp No. Inspected DateshrikantNo ratings yet

- Confidential: TSWW Glass Quality StandardsDocument2 pagesConfidential: TSWW Glass Quality StandardsRNo ratings yet

- Deakin Wire Industries: Enamelled Copper WiresDocument13 pagesDeakin Wire Industries: Enamelled Copper WiresAMAN VERMANo ratings yet

- 11 ProductSelectionGuide Masking ENDocument1 page11 ProductSelectionGuide Masking ENKarinaNo ratings yet

- Magnetic Flux LeakageDocument2 pagesMagnetic Flux LeakagesujinlongNo ratings yet

- Acrypoly Cast Acrylic - Data SheetDocument3 pagesAcrypoly Cast Acrylic - Data SheetAbhijit BhavsarNo ratings yet

- Iso 10042Document5 pagesIso 10042Nur Diana100% (3)

- INT AMERICA - Visual Inspection Standards For Stainless Steel Sill PlatesDocument2 pagesINT AMERICA - Visual Inspection Standards For Stainless Steel Sill PlatesPanda JacksonNo ratings yet

- Remote-Field Testing (RFT)Document3 pagesRemote-Field Testing (RFT)shahgardezNo ratings yet

- Internal Rotary Inspection System (IRIS)Document4 pagesInternal Rotary Inspection System (IRIS)ShakirNo ratings yet

- Black Rust ProcessingDocument2 pagesBlack Rust ProcessingJulius Mark CerrudoNo ratings yet

- Compliance Statement For Subbase Material (2014)Document2 pagesCompliance Statement For Subbase Material (2014)TAN DAYANo ratings yet

- Recommendations For Use: Corrosion PrimerDocument1 pageRecommendations For Use: Corrosion PrimergamuljNo ratings yet

- Trescal Calibration LA 2013 0551 C 1Document53 pagesTrescal Calibration LA 2013 0551 C 1thorster12345No ratings yet

- Copie de Weekly Fabric Meeting W18Document17 pagesCopie de Weekly Fabric Meeting W18Tantely RAKOTOARISOANo ratings yet

- QIS-NH00001687180-Rev 00Document4 pagesQIS-NH00001687180-Rev 00Karthick KrishnaNo ratings yet

- Automotive Coaches and Components LTD Proto Gun Hardened Cab Final Inspection Check List PART No: GENERAL DIM A0Y45400 - Rev - #1 Sl. NoDocument5 pagesAutomotive Coaches and Components LTD Proto Gun Hardened Cab Final Inspection Check List PART No: GENERAL DIM A0Y45400 - Rev - #1 Sl. NoSridharan VenkatNo ratings yet

- Johnson Marbonite Floor 40x40cm 12mm THK Catalogue RJKT Jan 23Document12 pagesJohnson Marbonite Floor 40x40cm 12mm THK Catalogue RJKT Jan 23Prasad MsrkNo ratings yet

- GreenlamDocument1 pageGreenlamSK Emran AliNo ratings yet

- Paints and Coatings: Safsil ProductsDocument4 pagesPaints and Coatings: Safsil Productskensley oliveiraNo ratings yet

- S 5-2 E V03N-0 Black enDocument1 pageS 5-2 E V03N-0 Black enWilliam Enrique Rodriguez PinzonNo ratings yet

- A Closer Look at "Grit":: Quick LinksDocument2 pagesA Closer Look at "Grit":: Quick LinksmiguelNo ratings yet

- TPM-600 Forms - Audit AM1Document1 pageTPM-600 Forms - Audit AM1Pham GHNo ratings yet

- Dow Corning 785 Silicone Sealant: Sanitary (Previously DC 915)Document2 pagesDow Corning 785 Silicone Sealant: Sanitary (Previously DC 915)candyamNo ratings yet

- 10ml CTVDocument1 page10ml CTVMd.Tarikul Islam FarhadNo ratings yet

- 5MS FRDocument15 pages5MS FRJose LuisNo ratings yet

- Assignment 4Document3 pagesAssignment 4Abhishek VishwakarmaNo ratings yet

- Dokumen Inspeksi VisualDocument5 pagesDokumen Inspeksi Visualroy rezkyNo ratings yet

- Technical Information & Guidelines - ICCTASDocument4 pagesTechnical Information & Guidelines - ICCTASGiriPrasathNo ratings yet

- Cube Manufacturers GuaranteeDocument2 pagesCube Manufacturers GuaranteeKevin LiNo ratings yet

- Ecotec 710 19mm BB Reff MTCDocument1 pageEcotec 710 19mm BB Reff MTCcarville33eownerswcNo ratings yet

- 7.5mlDocument1 page7.5mlMd.Tarikul Islam FarhadNo ratings yet

- Cho-Bond 1030Document2 pagesCho-Bond 1030Jose MYCNo ratings yet

- Simplifying The IndustryDocument56 pagesSimplifying The IndustryResidente ObraNo ratings yet

- KR2DB2403 enDocument1 pageKR2DB2403 enCustomer ServiceNo ratings yet

- Laminate TDSDocument1 pageLaminate TDSSK Emran AliNo ratings yet

- Inspection Form: Please Attached For ConDocument1 pageInspection Form: Please Attached For ConWahyu Rohmad DiantoNo ratings yet

- Gutters, Downpipes and Overflow: CalculatorDocument5 pagesGutters, Downpipes and Overflow: CalculatorThaiNguyenNo ratings yet

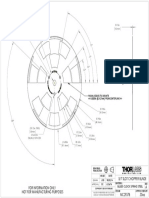

- A MC2F57B 5/7 Slot Chopper Blade For Information Only Not For Manufacturing Purposes .35ozDocument1 pageA MC2F57B 5/7 Slot Chopper Blade For Information Only Not For Manufacturing Purposes .35ozDanielOnelogNo ratings yet

- AspenDocument4 pagesAspenDinorah SNo ratings yet

- Katalog TacoDocument30 pagesKatalog Tacosabry technoNo ratings yet

- Unit 6 - Week 4: Abrasive Mass Finishing Operations & Surface Integrity in Abrasive ProcessDocument3 pagesUnit 6 - Week 4: Abrasive Mass Finishing Operations & Surface Integrity in Abrasive ProcessAbhishek VishwakarmaNo ratings yet

- Deglazing FormDocument1 pageDeglazing FormPham LamNo ratings yet

- M-Sand: A Fine Aggregate That Is Produced by Crushing Stone, Gravel, orDocument6 pagesM-Sand: A Fine Aggregate That Is Produced by Crushing Stone, Gravel, orNagha RamasamyNo ratings yet

- Natural Rubber Insertion TDSDocument2 pagesNatural Rubber Insertion TDSwawan setiawanNo ratings yet

- QMF 301 Casting and Finishing Cosmetic Grade Matrix PDFDocument1 pageQMF 301 Casting and Finishing Cosmetic Grade Matrix PDFLuu DangNo ratings yet

- Laminates Catalog PVC Sheet Compressed A79a0d5954Document18 pagesLaminates Catalog PVC Sheet Compressed A79a0d5954kufrapinkNo ratings yet

- Seal Selection Chart For SNL Series 2, 3, 5 & 6Document1 pageSeal Selection Chart For SNL Series 2, 3, 5 & 6osito2012No ratings yet

- Fabrix™: Corner Load Bevel EdgeDocument1 pageFabrix™: Corner Load Bevel EdgeFreddy SampayoNo ratings yet

- SOUNDNESS OF Fine AGGREGATE - QC 469 - 19-11-2020Document1 pageSOUNDNESS OF Fine AGGREGATE - QC 469 - 19-11-2020jajajajNo ratings yet

- Layered Process Audits: How To Improve Quality From The Ground UpDocument22 pagesLayered Process Audits: How To Improve Quality From The Ground UpMoraru Ciprian100% (1)

- Bathtub and Shower Tray Repair: How to Prevent Remedials and Make the Repair Future-proofFrom EverandBathtub and Shower Tray Repair: How to Prevent Remedials and Make the Repair Future-proofNo ratings yet

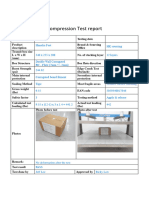

- ISTA 2A Báo CáoDocument6 pagesISTA 2A Báo CáochudinhthuNo ratings yet

- Ista 3aDocument19 pagesIsta 3achudinhthuNo ratings yet

- BYK-Gardner Digital-Catalog 2018 EDocument324 pagesBYK-Gardner Digital-Catalog 2018 EchudinhthuNo ratings yet

- Brushed Brass PVD+Lacquer Colour Sample - Italisa - RD22-175-EDocument5 pagesBrushed Brass PVD+Lacquer Colour Sample - Italisa - RD22-175-EchudinhthuNo ratings yet

- ColorEye7000A Manual enDocument44 pagesColorEye7000A Manual enchudinhthuNo ratings yet

- Aryan WilleyDocument8 pagesAryan WilleyAryan DeepNo ratings yet

- Display ImageDocument1 pageDisplay Imageshreyasghosh515No ratings yet

- Hunt UC 2017 Microtunneling in Mixed Ground Slides-FDocument21 pagesHunt UC 2017 Microtunneling in Mixed Ground Slides-FswhuntNo ratings yet

- Liquid Extraction OperationDocument19 pagesLiquid Extraction OperationOky TresiaNo ratings yet

- Choke Flow CVDocument5 pagesChoke Flow CVpca97No ratings yet

- RF Series-Catalog 3800 - SectionADocument3 pagesRF Series-Catalog 3800 - SectionAStefan DinuNo ratings yet

- Heat Reflecting PaintsDocument13 pagesHeat Reflecting PaintsEsau AguillónNo ratings yet

- Circular Motion PracticalDocument2 pagesCircular Motion PracticalMaan PatelNo ratings yet

- PoloniumDocument20 pagesPoloniumKosuke IchinichiNo ratings yet

- 5.modeling of Three Phase Self Excited Induction Generator (26-32)Document7 pages5.modeling of Three Phase Self Excited Induction Generator (26-32)ijcctsNo ratings yet

- Site Visit Full ReportDocument34 pagesSite Visit Full ReportNinie Azrin100% (2)

- Cad Lab Manual - MujDocument29 pagesCad Lab Manual - MujAabhaş AgrawałNo ratings yet

- Tool & Die Design Lecture Jan2011 13mar12Document100 pagesTool & Die Design Lecture Jan2011 13mar12azizmaarof100% (8)

- Concrete Technology and Highway Material Lab MANUALDocument60 pagesConcrete Technology and Highway Material Lab MANUALPriyadharshini MohanakrishnanNo ratings yet

- Hand-Waving and Interpretive Dance: An Introductory Course On Tensor Networks Lecture NotesDocument62 pagesHand-Waving and Interpretive Dance: An Introductory Course On Tensor Networks Lecture NotesToon PillaertNo ratings yet

- Paint Pigment Solvent Coating Emulsion Paint Additives and FormulationsDocument9 pagesPaint Pigment Solvent Coating Emulsion Paint Additives and FormulationschayanunNo ratings yet

- Centrifugal Pump Troubleshooting Guide - 1Document1 pageCentrifugal Pump Troubleshooting Guide - 1BhaiJan59No ratings yet

- ASAT - Volume 17 - Issue AEROSPACE SCIENCES & AVIATION TECHNOLOGY, ASAT - 17 &ndash April 11 - 13, 2017 - Pages 1-21Document21 pagesASAT - Volume 17 - Issue AEROSPACE SCIENCES & AVIATION TECHNOLOGY, ASAT - 17 &ndash April 11 - 13, 2017 - Pages 1-21yubrany gonzalezNo ratings yet

- Project Report On Lathe MachineDocument33 pagesProject Report On Lathe Machinesanu7blyNo ratings yet

- Chem 28 1st LE SamplexDocument5 pagesChem 28 1st LE SamplexFrances Abegail QuezonNo ratings yet

- Physics: Crash Course For JEE Main 2020Document15 pagesPhysics: Crash Course For JEE Main 2020Ayush SharmaNo ratings yet

- HYTEKDocument1 pageHYTEKHeather MurphyNo ratings yet

- TMC Setup Guide Lab Table 20 SeriesDocument24 pagesTMC Setup Guide Lab Table 20 SeriesDiabloNo ratings yet

- PS 1Document8 pagesPS 1naverfallNo ratings yet

- Additional-Notes STATSDocument8 pagesAdditional-Notes STATSDonna Claire AngusNo ratings yet

- 01 Contact NastranDocument26 pages01 Contact NastranGustavoYippeekayyayGusNo ratings yet

- On Safety in Safe Bayesian Optimization: Christian FiedlerDocument29 pagesOn Safety in Safe Bayesian Optimization: Christian FiedlerlarrylynnmailNo ratings yet

- Force and Acceleration WSDocument2 pagesForce and Acceleration WSMIS NURUL IMAN JakbarNo ratings yet