Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

0 views23 Boiler Operation Routine Check & Test List

23 Boiler Operation Routine Check & Test List

Uploaded by

Darul walidiCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You might also like

- Boilers SOPDocument18 pagesBoilers SOPPrakash WarrierNo ratings yet

- Workshop Manual: Training CenterDocument5 pagesWorkshop Manual: Training CenterStasNo ratings yet

- Diagnostico Bus TermoKingDocument75 pagesDiagnostico Bus TermoKingCesar Villar100% (6)

- P&id Boiler DrawingDocument22 pagesP&id Boiler Drawingmanh hung leNo ratings yet

- Vibration Monitoring System For Steam TurbineDocument24 pagesVibration Monitoring System For Steam TurbineRahul Jawda67% (3)

- Autonomous Maintenance Standards & ChecklistDocument7 pagesAutonomous Maintenance Standards & ChecklistPanch BNo ratings yet

- Quotation For Diesel Type GeneratorDocument2 pagesQuotation For Diesel Type GeneratorHassan Rauf RaoNo ratings yet

- Preventative Maintenance Tasks Sheet: Item Weekly Service Monthly ServiceDocument1 pagePreventative Maintenance Tasks Sheet: Item Weekly Service Monthly ServiceMohammad Anwar0% (1)

- 5.7.3 Diesel Elctrical Firefighting Pump InspectionDocument2 pages5.7.3 Diesel Elctrical Firefighting Pump Inspectionloay.shemeisNo ratings yet

- Daily Checklist TeknisiDocument1 pageDaily Checklist TeknisiAffan SetiawanNo ratings yet

- MANTENIMIENTODocument5 pagesMANTENIMIENTOalextlv1996cvNo ratings yet

- Startup BoilerDocument51 pagesStartup BoilerSahariar Bin ShafiqueNo ratings yet

- Sandmill ChecksheetDocument8 pagesSandmill Checksheetpnmohan27No ratings yet

- Ablandador Manual-Hankscraft-Runxin PDFDocument37 pagesAblandador Manual-Hankscraft-Runxin PDFgonzaloagustin84No ratings yet

- Autonomous Maintenance Standards & ChecklistDocument4 pagesAutonomous Maintenance Standards & ChecklistPanch BNo ratings yet

- Ashrae Variable Flow Chiller Plant DesignDocument43 pagesAshrae Variable Flow Chiller Plant Designcarmen hernandez100% (1)

- Chiller Plant: S.No Hydrogen Part Problems Results 1Document9 pagesChiller Plant: S.No Hydrogen Part Problems Results 1Shahzad AhmedNo ratings yet

- Heat Machine: Checklist For Autonomous MaintenanceDocument3 pagesHeat Machine: Checklist For Autonomous MaintenanceSangavi KaviNo ratings yet

- Boiler HT CommDocument3 pagesBoiler HT CommBatsi BatsiNo ratings yet

- Super Critical Boiler Commissioning1Document44 pagesSuper Critical Boiler Commissioning1Vishal SinghNo ratings yet

- Unit 3 ReviewDocument34 pagesUnit 3 ReviewزهديابوانسNo ratings yet

- M1 - VLE Lab ManualDocument27 pagesM1 - VLE Lab ManualdaabgchiNo ratings yet

- Log IzaniDocument1 pageLog IzaniIzani AriffNo ratings yet

- Boiler Test RecordDocument2 pagesBoiler Test RecordIzani AriffNo ratings yet

- Building Management System: Direct Digital Controller ApplicationsDocument14 pagesBuilding Management System: Direct Digital Controller ApplicationsHatem OmerNo ratings yet

- Sop For Boiler Hydro TestDocument4 pagesSop For Boiler Hydro TestHardik ThumarNo ratings yet

- Microsoft PowerPoint - BoileroperationsDocument55 pagesMicrosoft PowerPoint - BoileroperationsGOBLIN XXXNo ratings yet

- Action Plans For Micro Issue Tracker - Sent Per ShiftDocument10 pagesAction Plans For Micro Issue Tracker - Sent Per ShiftDave GianganNo ratings yet

- Boiler MaintenanceDocument36 pagesBoiler Maintenancebenjiy80No ratings yet

- Salt Spray Cabinet BGD 800SDocument5 pagesSalt Spray Cabinet BGD 800SRoyNo ratings yet

- Standard Operating Procedure For Hy-Lp Bypass System: ObjectiveDocument8 pagesStandard Operating Procedure For Hy-Lp Bypass System: ObjectiveSonratNo ratings yet

- 10 23 520 07 enDocument44 pages10 23 520 07 enmstra929No ratings yet

- Spe Boiler Water AlarmDocument9 pagesSpe Boiler Water AlarmLuqman SaidNo ratings yet

- Steam Systems Basics, Challenges and TroubleshootingDocument31 pagesSteam Systems Basics, Challenges and TroubleshootingLutfi NugrahaNo ratings yet

- Daily Preventive Mantainence SheetDocument4 pagesDaily Preventive Mantainence Sheetcer.qualityNo ratings yet

- Chiller Everin Mitra PerkasaDocument8 pagesChiller Everin Mitra PerkasaIwan SetiawanNo ratings yet

- PM ProgramDocument29 pagesPM Programemad youssefNo ratings yet

- ORR 2020 68 John Quarterman SOPs Mud Creek WPCP 030520Document20 pagesORR 2020 68 John Quarterman SOPs Mud Creek WPCP 030520vNo ratings yet

- Check-List For DomexDocument2 pagesCheck-List For DomexKapil MukhopadhyayNo ratings yet

- Control Valves:: Specifications, Sizing & TechnologiesDocument71 pagesControl Valves:: Specifications, Sizing & TechnologiesSamuel OnyewuenyiNo ratings yet

- SimpleDocument46 pagesSimpleMukeshNo ratings yet

- Simple Descriptions of ValvesDocument46 pagesSimple Descriptions of ValvesAhmed AlhinaiNo ratings yet

- ValvesDocument46 pagesValvesashirNo ratings yet

- ValvesDocument46 pagesValvesashirNo ratings yet

- Group 1A - Lab Report Combine PDFDocument87 pagesGroup 1A - Lab Report Combine PDFHanifatur AffiqNo ratings yet

- 使用说明书Document23 pages使用说明书huutinhNo ratings yet

- 9.boiler House InstrumentationDocument5 pages9.boiler House Instrumentationkcp1986No ratings yet

- Valves Type & FunctionDocument47 pagesValves Type & Functionkvbg1980No ratings yet

- Boiler CommissioningDocument35 pagesBoiler CommissioningNikhil MalhotraNo ratings yet

- 2016 Boiler Safety Checklist and Preventative MaintenanceDocument185 pages2016 Boiler Safety Checklist and Preventative MaintenanceAcid Burns100% (1)

- !1. (Iw Ia Wo) Drilling MR 20dec21Document219 pages!1. (Iw Ia Wo) Drilling MR 20dec21anugrah.setiaoneNo ratings yet

- SLK-KTG1-OPR-CL-TBN-002 Filling Water Condensate Check ListDocument1 pageSLK-KTG1-OPR-CL-TBN-002 Filling Water Condensate Check ListoksaNo ratings yet

- Learning CommuniqueDocument56 pagesLearning CommuniqueSanjay AnbarasanNo ratings yet

- Ac & Ventilation System: Presented BY Suresh ChandrakarDocument28 pagesAc & Ventilation System: Presented BY Suresh ChandrakarDhiraj KumarNo ratings yet

- Boiler Hydro TestDocument12 pagesBoiler Hydro TestSachin PandeyNo ratings yet

- ValvesDocument46 pagesValvesAuthers Raj SNo ratings yet

- Simple Descriptions of ValvesDocument46 pagesSimple Descriptions of ValvesThe Engineers EDGE, CoimbatoreNo ratings yet

- Bioinstrumentation Ii Lecture 3: Oxygen Concentrator: Hundessa Daba (MSC)Document40 pagesBioinstrumentation Ii Lecture 3: Oxygen Concentrator: Hundessa Daba (MSC)Hundessa Daba100% (1)

- LearningsDocument52 pagesLearningsSanjay AnbarasanNo ratings yet

- 50 KG Per H Liquid Co2Document11 pages50 KG Per H Liquid Co2AhNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- International Journal of Chemtech Research: S.Anandan, R.Rajesh, K. GaneshDocument8 pagesInternational Journal of Chemtech Research: S.Anandan, R.Rajesh, K. GaneshPutrii MaharaniiNo ratings yet

- 5 Pump ControlersDocument22 pages5 Pump ControlersJose Manuel Barroso PantojaNo ratings yet

- Nammiaca 000043Document614 pagesNammiaca 000043gangadhark196No ratings yet

- Auxiliary Power ConsumptionDocument3 pagesAuxiliary Power ConsumptionNicko LastardaNo ratings yet

- Casting deDocument4 pagesCasting dePrasadNo ratings yet

- Solar Energy Utilization For The BarangaysDocument3 pagesSolar Energy Utilization For The BarangaysErwin MoraNo ratings yet

- MPPT PV ThesisDocument4 pagesMPPT PV Thesisbk3q07k5100% (2)

- TG ExcelDocument5 pagesTG ExcelJAY PARIKHNo ratings yet

- HDTB SectorDocument7 pagesHDTB SectorPartha AichNo ratings yet

- ME Lab 2 Module No. 3 PDFDocument36 pagesME Lab 2 Module No. 3 PDFIsmaeli KielNo ratings yet

- MPR MicroprojectDocument11 pagesMPR MicroprojectNight fadeNo ratings yet

- RSO FlyerDocument1 pageRSO Flyerk5sksngkdsNo ratings yet

- Wiring Diagram DSE 7320 AMF PDFDocument1 pageWiring Diagram DSE 7320 AMF PDFKo Thet100% (5)

- HALO TurboCharger Brochure PDFDocument2 pagesHALO TurboCharger Brochure PDF0t0m0tief100% (1)

- 3684 Ronesans 3009-PSV-9101 GBDocument1 page3684 Ronesans 3009-PSV-9101 GBmed chabaneNo ratings yet

- Transportation of Fluids: Prepared By: Engr. Joseph R. OrteneroDocument48 pagesTransportation of Fluids: Prepared By: Engr. Joseph R. OrteneroChristianNo ratings yet

- Unit 4 - Layout of Engine RoomDocument17 pagesUnit 4 - Layout of Engine Roombhauh4586No ratings yet

- Baudouin GEB6W105S Marine Generating SetDocument2 pagesBaudouin GEB6W105S Marine Generating SetagusmaulanaNo ratings yet

- Back Pressure c27Document4 pagesBack Pressure c27Jose FavaNo ratings yet

- Clean Coal Technologies in Japan PDFDocument102 pagesClean Coal Technologies in Japan PDFsanthoshneo02@gmail.com100% (1)

- Energy Storage DevicesDocument10 pagesEnergy Storage DevicesRishav DevkotaNo ratings yet

- 3AS 38319 App - Boiler Plant Lay Out SFBW2728226SATFG .BakDocument3 pages3AS 38319 App - Boiler Plant Lay Out SFBW2728226SATFG .BakRabindranath Hendy TagoreNo ratings yet

- ME 8792 Power Plant Engineering NOV DEC 18Document2 pagesME 8792 Power Plant Engineering NOV DEC 18sunil1237No ratings yet

- Water GasDocument3 pagesWater GaschristopheNo ratings yet

- 97 - 009 - 14 BL 01 enDocument4 pages97 - 009 - 14 BL 01 enrodcorjoNo ratings yet

- J612V22 enDocument4 pagesJ612V22 enMartin Kratky100% (1)

- Coro CleanDocument18 pagesCoro Cleanlaminar ersNo ratings yet

23 Boiler Operation Routine Check & Test List

23 Boiler Operation Routine Check & Test List

Uploaded by

Darul walidi0 ratings0% found this document useful (0 votes)

0 views2 pagesCopyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

0 views2 pages23 Boiler Operation Routine Check & Test List

23 Boiler Operation Routine Check & Test List

Uploaded by

Darul walidiCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 2

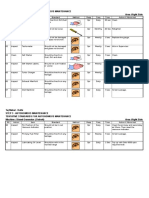

BOILER OPERATION ROUTINE CHECK LIST AND TEST

Routine Checkup And Test For Low Pressure Boilers

No Fittings / Device Check & Test Required Frequency Setting

/Conditions

- Pull Try lever with Weekly Valve blow

1 Safety /relief Valves

pressure on

-Test Main Gauge Glass. 8 hourly Free passage of

2 Main Gauge Glass -Drain and Check Prompt water

Refill

-Test Main Gauge Glass. 8 hourly Free passage of

3 Secondary Gauge Glass -Drain and Check Prompt water

Refill

-Test Water Column. Daily Free passage of

4 Water Column - Drain and Check Prompt water

Refill

Test High , Low & Daily Alarm

5 Water Column Extreme Low Water functioning

Alarm function

Automatic Drum Level Check automatic function Daily Functioning

6

Control

Extreme Low Water ID Test Trip Function Daily ID Fan Trip

7

Fan Trip Function

8 Boiler Casing Check leakages Daily No leakage

Check steam / water 2 hourly No leakage

9 Valves

leakages

-Check no dust chokage. 2 hourly - No Chokage.

10 Dust Collector - Check regular dust – Dust removed

removal

Drain during boiler start Daily No chokage

11 Header Drain Valves

up

12 Steam Pressure Take Readings 2 hourly + - 20 bar

13 Soot Blower Soot blowing 8 hourly -

14 Grate Cleaning Blow grate with dry steam 2 hourly No chokage

15 Furnace Cleaning Rake out clingers 4 hourly Proper cleaning

Feed Water Pump Take Readings 2 hourly > 26 bar

16

Pressure

-Take tank level readings 2 hourly Full

17 BFW Tank Level - Check level indicator

free movement

Take Readings ( vacuum 2 hourly 75 or 92°C

18 Feed Water Temperature

75°C , Thermal DA 92°C)

Flue Gas Temperature at Take Readings 2 hourly < 260°C

19

ID Fan Inlet

-Check bearings 2 hourly Normal

20 ID Fan temperature with hand

-Check vibration

-Check bearings 2 hourly Normal

21 FD Fan temperature with hand

-Check vibration

-Check bearings 2 hourly Normal

22 Secondary Air Fan temperature with hand

-Check vibration

-Check bearings 2 hourly Normal

23 Fuel Distribution Fan temperature with hand

-Check vibration

24 Boiler Feed Water Pump Visual Inspection 2 hourly Good

Take sample for water 2 hourly Analyse

25 Boiler Water Treatment

analysis

Take PH or Conductivity 2 hourly PH < 5

26 Cation Exchanger readings of Cat ion

Exchanger

Take PH or Conductivity 2 hourly PH>7

27 Anion Exchanger readings of Anion

Exchanger

28 Boiler Blow down valve Blow down mud drum 4 hourly TDS< 2000 ppm

Check Vacuum / Steam 2 hourly -0.8 barg vacuum

Vacuum /Thermal Pressure for Thermal DA minimum or 2

29

Deaerator barg steam

pressure

Check air pressure & 2 hourly Functioning

30 Air Compressor pressure switch is

functioning

Boiler chemical Dosing Check suction 2 hourly Functioning

31

Pump

Take solution level 2 hourly > 250 mm

32 Boiler Chemical Solution

readings .

You might also like

- Boilers SOPDocument18 pagesBoilers SOPPrakash WarrierNo ratings yet

- Workshop Manual: Training CenterDocument5 pagesWorkshop Manual: Training CenterStasNo ratings yet

- Diagnostico Bus TermoKingDocument75 pagesDiagnostico Bus TermoKingCesar Villar100% (6)

- P&id Boiler DrawingDocument22 pagesP&id Boiler Drawingmanh hung leNo ratings yet

- Vibration Monitoring System For Steam TurbineDocument24 pagesVibration Monitoring System For Steam TurbineRahul Jawda67% (3)

- Autonomous Maintenance Standards & ChecklistDocument7 pagesAutonomous Maintenance Standards & ChecklistPanch BNo ratings yet

- Quotation For Diesel Type GeneratorDocument2 pagesQuotation For Diesel Type GeneratorHassan Rauf RaoNo ratings yet

- Preventative Maintenance Tasks Sheet: Item Weekly Service Monthly ServiceDocument1 pagePreventative Maintenance Tasks Sheet: Item Weekly Service Monthly ServiceMohammad Anwar0% (1)

- 5.7.3 Diesel Elctrical Firefighting Pump InspectionDocument2 pages5.7.3 Diesel Elctrical Firefighting Pump Inspectionloay.shemeisNo ratings yet

- Daily Checklist TeknisiDocument1 pageDaily Checklist TeknisiAffan SetiawanNo ratings yet

- MANTENIMIENTODocument5 pagesMANTENIMIENTOalextlv1996cvNo ratings yet

- Startup BoilerDocument51 pagesStartup BoilerSahariar Bin ShafiqueNo ratings yet

- Sandmill ChecksheetDocument8 pagesSandmill Checksheetpnmohan27No ratings yet

- Ablandador Manual-Hankscraft-Runxin PDFDocument37 pagesAblandador Manual-Hankscraft-Runxin PDFgonzaloagustin84No ratings yet

- Autonomous Maintenance Standards & ChecklistDocument4 pagesAutonomous Maintenance Standards & ChecklistPanch BNo ratings yet

- Ashrae Variable Flow Chiller Plant DesignDocument43 pagesAshrae Variable Flow Chiller Plant Designcarmen hernandez100% (1)

- Chiller Plant: S.No Hydrogen Part Problems Results 1Document9 pagesChiller Plant: S.No Hydrogen Part Problems Results 1Shahzad AhmedNo ratings yet

- Heat Machine: Checklist For Autonomous MaintenanceDocument3 pagesHeat Machine: Checklist For Autonomous MaintenanceSangavi KaviNo ratings yet

- Boiler HT CommDocument3 pagesBoiler HT CommBatsi BatsiNo ratings yet

- Super Critical Boiler Commissioning1Document44 pagesSuper Critical Boiler Commissioning1Vishal SinghNo ratings yet

- Unit 3 ReviewDocument34 pagesUnit 3 ReviewزهديابوانسNo ratings yet

- M1 - VLE Lab ManualDocument27 pagesM1 - VLE Lab ManualdaabgchiNo ratings yet

- Log IzaniDocument1 pageLog IzaniIzani AriffNo ratings yet

- Boiler Test RecordDocument2 pagesBoiler Test RecordIzani AriffNo ratings yet

- Building Management System: Direct Digital Controller ApplicationsDocument14 pagesBuilding Management System: Direct Digital Controller ApplicationsHatem OmerNo ratings yet

- Sop For Boiler Hydro TestDocument4 pagesSop For Boiler Hydro TestHardik ThumarNo ratings yet

- Microsoft PowerPoint - BoileroperationsDocument55 pagesMicrosoft PowerPoint - BoileroperationsGOBLIN XXXNo ratings yet

- Action Plans For Micro Issue Tracker - Sent Per ShiftDocument10 pagesAction Plans For Micro Issue Tracker - Sent Per ShiftDave GianganNo ratings yet

- Boiler MaintenanceDocument36 pagesBoiler Maintenancebenjiy80No ratings yet

- Salt Spray Cabinet BGD 800SDocument5 pagesSalt Spray Cabinet BGD 800SRoyNo ratings yet

- Standard Operating Procedure For Hy-Lp Bypass System: ObjectiveDocument8 pagesStandard Operating Procedure For Hy-Lp Bypass System: ObjectiveSonratNo ratings yet

- 10 23 520 07 enDocument44 pages10 23 520 07 enmstra929No ratings yet

- Spe Boiler Water AlarmDocument9 pagesSpe Boiler Water AlarmLuqman SaidNo ratings yet

- Steam Systems Basics, Challenges and TroubleshootingDocument31 pagesSteam Systems Basics, Challenges and TroubleshootingLutfi NugrahaNo ratings yet

- Daily Preventive Mantainence SheetDocument4 pagesDaily Preventive Mantainence Sheetcer.qualityNo ratings yet

- Chiller Everin Mitra PerkasaDocument8 pagesChiller Everin Mitra PerkasaIwan SetiawanNo ratings yet

- PM ProgramDocument29 pagesPM Programemad youssefNo ratings yet

- ORR 2020 68 John Quarterman SOPs Mud Creek WPCP 030520Document20 pagesORR 2020 68 John Quarterman SOPs Mud Creek WPCP 030520vNo ratings yet

- Check-List For DomexDocument2 pagesCheck-List For DomexKapil MukhopadhyayNo ratings yet

- Control Valves:: Specifications, Sizing & TechnologiesDocument71 pagesControl Valves:: Specifications, Sizing & TechnologiesSamuel OnyewuenyiNo ratings yet

- SimpleDocument46 pagesSimpleMukeshNo ratings yet

- Simple Descriptions of ValvesDocument46 pagesSimple Descriptions of ValvesAhmed AlhinaiNo ratings yet

- ValvesDocument46 pagesValvesashirNo ratings yet

- ValvesDocument46 pagesValvesashirNo ratings yet

- Group 1A - Lab Report Combine PDFDocument87 pagesGroup 1A - Lab Report Combine PDFHanifatur AffiqNo ratings yet

- 使用说明书Document23 pages使用说明书huutinhNo ratings yet

- 9.boiler House InstrumentationDocument5 pages9.boiler House Instrumentationkcp1986No ratings yet

- Valves Type & FunctionDocument47 pagesValves Type & Functionkvbg1980No ratings yet

- Boiler CommissioningDocument35 pagesBoiler CommissioningNikhil MalhotraNo ratings yet

- 2016 Boiler Safety Checklist and Preventative MaintenanceDocument185 pages2016 Boiler Safety Checklist and Preventative MaintenanceAcid Burns100% (1)

- !1. (Iw Ia Wo) Drilling MR 20dec21Document219 pages!1. (Iw Ia Wo) Drilling MR 20dec21anugrah.setiaoneNo ratings yet

- SLK-KTG1-OPR-CL-TBN-002 Filling Water Condensate Check ListDocument1 pageSLK-KTG1-OPR-CL-TBN-002 Filling Water Condensate Check ListoksaNo ratings yet

- Learning CommuniqueDocument56 pagesLearning CommuniqueSanjay AnbarasanNo ratings yet

- Ac & Ventilation System: Presented BY Suresh ChandrakarDocument28 pagesAc & Ventilation System: Presented BY Suresh ChandrakarDhiraj KumarNo ratings yet

- Boiler Hydro TestDocument12 pagesBoiler Hydro TestSachin PandeyNo ratings yet

- ValvesDocument46 pagesValvesAuthers Raj SNo ratings yet

- Simple Descriptions of ValvesDocument46 pagesSimple Descriptions of ValvesThe Engineers EDGE, CoimbatoreNo ratings yet

- Bioinstrumentation Ii Lecture 3: Oxygen Concentrator: Hundessa Daba (MSC)Document40 pagesBioinstrumentation Ii Lecture 3: Oxygen Concentrator: Hundessa Daba (MSC)Hundessa Daba100% (1)

- LearningsDocument52 pagesLearningsSanjay AnbarasanNo ratings yet

- 50 KG Per H Liquid Co2Document11 pages50 KG Per H Liquid Co2AhNo ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- International Journal of Chemtech Research: S.Anandan, R.Rajesh, K. GaneshDocument8 pagesInternational Journal of Chemtech Research: S.Anandan, R.Rajesh, K. GaneshPutrii MaharaniiNo ratings yet

- 5 Pump ControlersDocument22 pages5 Pump ControlersJose Manuel Barroso PantojaNo ratings yet

- Nammiaca 000043Document614 pagesNammiaca 000043gangadhark196No ratings yet

- Auxiliary Power ConsumptionDocument3 pagesAuxiliary Power ConsumptionNicko LastardaNo ratings yet

- Casting deDocument4 pagesCasting dePrasadNo ratings yet

- Solar Energy Utilization For The BarangaysDocument3 pagesSolar Energy Utilization For The BarangaysErwin MoraNo ratings yet

- MPPT PV ThesisDocument4 pagesMPPT PV Thesisbk3q07k5100% (2)

- TG ExcelDocument5 pagesTG ExcelJAY PARIKHNo ratings yet

- HDTB SectorDocument7 pagesHDTB SectorPartha AichNo ratings yet

- ME Lab 2 Module No. 3 PDFDocument36 pagesME Lab 2 Module No. 3 PDFIsmaeli KielNo ratings yet

- MPR MicroprojectDocument11 pagesMPR MicroprojectNight fadeNo ratings yet

- RSO FlyerDocument1 pageRSO Flyerk5sksngkdsNo ratings yet

- Wiring Diagram DSE 7320 AMF PDFDocument1 pageWiring Diagram DSE 7320 AMF PDFKo Thet100% (5)

- HALO TurboCharger Brochure PDFDocument2 pagesHALO TurboCharger Brochure PDF0t0m0tief100% (1)

- 3684 Ronesans 3009-PSV-9101 GBDocument1 page3684 Ronesans 3009-PSV-9101 GBmed chabaneNo ratings yet

- Transportation of Fluids: Prepared By: Engr. Joseph R. OrteneroDocument48 pagesTransportation of Fluids: Prepared By: Engr. Joseph R. OrteneroChristianNo ratings yet

- Unit 4 - Layout of Engine RoomDocument17 pagesUnit 4 - Layout of Engine Roombhauh4586No ratings yet

- Baudouin GEB6W105S Marine Generating SetDocument2 pagesBaudouin GEB6W105S Marine Generating SetagusmaulanaNo ratings yet

- Back Pressure c27Document4 pagesBack Pressure c27Jose FavaNo ratings yet

- Clean Coal Technologies in Japan PDFDocument102 pagesClean Coal Technologies in Japan PDFsanthoshneo02@gmail.com100% (1)

- Energy Storage DevicesDocument10 pagesEnergy Storage DevicesRishav DevkotaNo ratings yet

- 3AS 38319 App - Boiler Plant Lay Out SFBW2728226SATFG .BakDocument3 pages3AS 38319 App - Boiler Plant Lay Out SFBW2728226SATFG .BakRabindranath Hendy TagoreNo ratings yet

- ME 8792 Power Plant Engineering NOV DEC 18Document2 pagesME 8792 Power Plant Engineering NOV DEC 18sunil1237No ratings yet

- Water GasDocument3 pagesWater GaschristopheNo ratings yet

- 97 - 009 - 14 BL 01 enDocument4 pages97 - 009 - 14 BL 01 enrodcorjoNo ratings yet

- J612V22 enDocument4 pagesJ612V22 enMartin Kratky100% (1)

- Coro CleanDocument18 pagesCoro Cleanlaminar ersNo ratings yet