Professional Documents

Culture Documents

The Mechanism of The Restoration of Obliterated Serial

The Mechanism of The Restoration of Obliterated Serial

Uploaded by

santino.passarinoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Mechanism of The Restoration of Obliterated Serial

The Mechanism of The Restoration of Obliterated Serial

Uploaded by

santino.passarinoCopyright:

Available Formats

J. Forens. Sci. Soc. (1976), 16, 69.

The Mechanism of the Restoration of

Obliterated Serial Numbers by Acid Etching

J. I. THORNTON

Department of Biomedical and Environmental Health Sciences, School of Public Health,

University of California, Berkeley, California, 94720, U.S.A.

and

P. J. CASHMAN

Department of Criminal Justice Administration, California State University at Sacramento,

Sacramento, Calfornia, 95819, U.S.A.

The mechanisms involved in the restoration of obliterated punch marks is discussed in

relation to the chemistry and physics of steel.

Introduction

A review of the forensic literature reveals a paucity of information pertaining

to the mechanism by which obliterated serial numbcrs or other markings are

visualized by acid etching. Although a number of papers describe the efficacyof

various etching reagents (Forbes, 1939; Law, 1944; Nickolls, 1956; Mathews,

1972), few attempts have been made to explain the restoration phenomenon

in terms of the chemistry and physics involved.

O n the other hand, there is at least one article (Paholke, 1969) which con-

tains an erroneous explanation of the restoration process. I t is the purpose of

the present work to clarify certain points in the matter of the restoration of

obliterated marks by means of acid etching.

I n the article referred to previously (Paholke, 1969), it was asserted that the

obliterated serial number is visualized because the metal nearest the number is

"work-hardened" or "cold-worked" and is not as susceptible to the action of

the etching solution. According to this explanation, the etching treatment

therefore results in an escarpment of harder metal in the vicinity of the obli-

terated mark projecting bcyond the background of the unaffected metal. The

number, presumably, is visualized by means of shadow and relief effects.

Unfortunately, this explanation is not in consonance with the chemistry or

physics of the etching of metals. Perhaps our intuition would suggest to us that

the cold-worked (and therefore harder) metal would be less susceptible to the

action of the acid. I n reality, however, the opposite occurs. The phenomenon

of relief does play a r81e in the visualization of a restored number, but in a

subtlc fashion and not as a projection of structure from the background.

The Effects of P u n c h M a r k i n g Metal

When a serial number is punched into metal, a plastic deformation occurs.

(The term plastic is used here in the engineering sense to indicate a permanent

deformation). The impression remains even though the force causing it has been

removed. I n this way, the metal is permanently strained in the area which has

been compressed. This strained area extends for a considerable distance

below the surface of the punched mark. I n pure zinc the affected area may be up

to 20 times the depth of the impression (Kehl, 1943), while in steel the affected

area may be approximately 6 times as deep as the stamped mark. When plastic

deformation occurs a t a temperature below the recrystallization temperature

of a metal, the metal is said to be "cold-worked".

The cold-working process increases the hardness of the metal, its tensile

strength, and its yield point. I t decreases the malleability and ductility of the

metal. Besides these mechanical properties, the position of the metal in the

elcctromotive series is raised, which results in a lowering of resistance to chemical

oxidation in general, and to the actions of acids in particular. The practical

significance of this phenomenon is that the areas of an obliterated mark which

have been affected by the stamping process will be removed (oxidized) by the

etching solution more rapidly than the surrounding metal. I t is not apparent

from the forensic literature that this is fully appreciated, or that its implications

are fully recognized.

Evcry metal or alloy contains irregularities in the atomic structure. The more

common irregularities consist of dislocations, which are a misalignment of

atomic planes, and point defects, which are "holes", or areas in which an atom

is missing. These irregularities are associated with a certain free energy. When

the crystal lattice of a metal is disturbed by a cold-working process such as the

stamping of serial numbers, an increase of internal free energy occurs. This

results in an increase in the electron density in the interstitial space of the

lattice of the deformed metal. The increase in the electron density implies a

certain weakening of the chemical bonds, with a resultant proclivity toward

oxidation (Gubkin, 1960).

In reality, unworked metal contains an enormous number of dislocations,

perhaps as many as 1012 per cubic inch of metal. The process of stamping a

serial number, however, creates a much greater number of these dislocations,

perhaps as much as a millionfold increase (Bunshah, 1968), and increases the

degree of entanglemcnt of dislocations. Along with the increase in the number

of dislocations there is a commensurate increase in free energy. The disruption

of the crystal lattice also results in the formation of somewhat smaller and

chaotically arranged crystals. The atomic bonds are disrupted and reformed,

often in a different manner than before the original forming process. The

process, then, results in what metallurgists call a "change in grain." The

material is still steel, for instance, but a somewhat different sort of steel. Etching

simply enables us to visualize the difference in grain.

Etching of Steel

Steel is a mixture of a number of elements. I t always contains iron and carbon.

Nickel, manganese, chromium, cobalt, vanadium, and molybdenum may be

purposefully included to alter the properties of the steel, while sulfur and

phosphorus are invariably present as impurities. These components are bound

a t the atomic level by specific chemical bonds, which are differentially affected

by chemical reagents. Strong acids, such as hydrochloric or sulfuric, will

rapidly attack the manganese sulphide, leaving voids in the lattice occupied

by the manganese. Copper salts, which are common to many etching reagents

for steel, are reduced to metallic copper by areas of the metal rich in iron or

deficient in phosphorus. The chemical reactions involved follow classical

oxidation-reduction phenomena (Bloor, 1962).

Anodic reaction: FeO-, Fe++ 2e- +

Cathodic reaction: Cu++ + CuO + 2e-

The etching solution does not act in a uniform manner on different faces of

the crystals, or on different areas of the grain. Acid will initially attack the grain

boundaries to a greater extent because they represent regions of higher energy

than the interior of the grains. Upon further etching the grains themselves are

attacked, the rate being dependent in part on the orientation of the grains. An

unworked sample of steel will show a regularity of grain after etching. The sur-

face will appear only slightly and uniformly pitted from the removal of man-

ganese, sulfur and phosphorous. (An exception is steel in the cast form, where

the presence of dendrites is apparent).

The structural detail in the areas affected by the stamping process is revealed

by selective removal of portions of the surface downward, resulting from the

differing rates of solubility of the various constituents of the metal, and the

orientation of the faces of the crystals.

Visualization After Etching

The principal mechanism by which the mark is visualized, however, is

specular reflection. Consider a surface as depicted in Figure 1. A sample of

otherwise homogeneous steel contains a cold-worked area resulting from the

Figure I . Light striking a metal surface after acid etching. The cold-worked area resulting

from the stamping of the serial number is much more disrupted than the surrounding metal,

the etching solution having acted in a differential manner upon the faces of the different

crystals, and having attacked the grain boundaries to a greater extent than the other portions

of the grain. The light striking this area is reflected differently, resulting in a visual image

of the affected area. (In reality many more reflections would be involved due to the fact

that in general practice the light would be polychromatic, and would not be collimated as in

this diagram).

stamping of a serial number. (It is assumed that the serial number has been

ground off previously). The etching has resulted in the selective removal of

certain components of the steel from different faces of the crystals, causing an

irregular surface. The unaffected metal is acted upon by the etching solution,

certainly, but to a lesser extent and in a much more uniform manner. Light

incident on this surface follows the classical laws of physical optics (Crawford,

1965), and will therefore be differentially reflected by the surface. This differ-

ence in reflectivity will delineate those areas of discontinuity, i.e., will show the

grain boundaries separating the affected metal from that which is not affected

I t is this difference in specular reflectivity which is responsible for the image

received by the eye and perceived by the brain, and which permits the restora-

tion of the obliterated number.

References

BLOOR, D. W., 1962, Metallurgica, 66, 139.

BUNSHAH, R. F., 1968, Techniques of Metals Research, Interscience, New York.

CRAWFORD, F. S., 1965, Waves, McGraw-Hill, New York.

FORBES,G., 1939, Scientific Aids to Criminal Investigation, Her Majesty's

Stationary Office, London.

GUBKIN, S. I., 1960, Plastic Deformation of Metals, State Scientific-Technical

Publishing House for Literature on Ferrous and Nonferrous Metallurgy,

Moscow.

KEHL, G. L., 1943, Principles of Metallographic Laboratory Practice,

McGraw-Hill, New York.

LAW,P., 1944, Police Journal, 17, 44.

MATHEWS, J. H., 1972, Firearms Identification, Thomas, Springfield, Illinois.

NICKOLLS, L. C., 1956, The Scientific Investigation of Crime, Butterworth,

London.

PAHOLKE, A. R., 1969, Assoc. Firearms and Toolmarks Examiners J., 1 (4), 38.

You might also like

- Lab Photoelectric Effect PhET Simulation KeyDocument5 pagesLab Photoelectric Effect PhET Simulation KeyAnil KrishnanNo ratings yet

- The Metallurgy of Anodizing Aluminum: Connecting Science to PracticeFrom EverandThe Metallurgy of Anodizing Aluminum: Connecting Science to PracticeNo ratings yet

- Kennell - 2008 - CS - A Critical Crevice Solution and IR Drop Crevice Corrosion ModelDocument10 pagesKennell - 2008 - CS - A Critical Crevice Solution and IR Drop Crevice Corrosion ModelKassia Cristina Kafer EscherNo ratings yet

- Step7 Corrosion GuideDocument18 pagesStep7 Corrosion GuideShariff Zaffar100% (1)

- Chap 07 PDFDocument26 pagesChap 07 PDFdada jamdarNo ratings yet

- MIC in Heat Exchanger TubingDocument6 pagesMIC in Heat Exchanger TubingdutuconstantinNo ratings yet

- Effect of Silicon Content On Iron Loss and Magnetic Domain Structure of Grain-Oriented Electrical Steel SheetDocument6 pagesEffect of Silicon Content On Iron Loss and Magnetic Domain Structure of Grain-Oriented Electrical Steel SheetLaerte PinhedoNo ratings yet

- CPUT - Phys Chem 4 Notes On Corrosion 2010Document40 pagesCPUT - Phys Chem 4 Notes On Corrosion 2010Justin JohnNo ratings yet

- StressDocument6 pagesStresskevinjunNo ratings yet

- Metals Oxygen Rusting Iron Oxide Salt Ceramics Polymers Alloys Air PitDocument4 pagesMetals Oxygen Rusting Iron Oxide Salt Ceramics Polymers Alloys Air Pitaien_atomNo ratings yet

- Corrosion and Corrosion InhibitorsDocument5 pagesCorrosion and Corrosion InhibitorsRizwan FaridNo ratings yet

- Chemical Analysis of Dental Alloys: Name: Mahmoud Mohamed Owais ID:200043957 Subject: Prof. Dr. El-Zeiny Mousa EbeidDocument12 pagesChemical Analysis of Dental Alloys: Name: Mahmoud Mohamed Owais ID:200043957 Subject: Prof. Dr. El-Zeiny Mousa Ebeid3bdallah.mseNo ratings yet

- 1.corrosion TheoryDocument77 pages1.corrosion Theoryamitvaze316100% (1)

- Mono74 6Document47 pagesMono74 6Mihaela DenisaNo ratings yet

- Stress Corrosion Cracking of Various Alloys - Part 1Document7 pagesStress Corrosion Cracking of Various Alloys - Part 1Christian MezaNo ratings yet

- Revisao de Literatura SAWDocument41 pagesRevisao de Literatura SAWbiancogallazziNo ratings yet

- A. R. Bailey M.SC., PH.D., D.I.C., A.I.M. (Auth.) - A Text-Book of Metallurgy (1960, Macmillan Education UK)Document627 pagesA. R. Bailey M.SC., PH.D., D.I.C., A.I.M. (Auth.) - A Text-Book of Metallurgy (1960, Macmillan Education UK)MyameSirame100% (2)

- VTG 2012 Vol. LX, No. 1Document14 pagesVTG 2012 Vol. LX, No. 1Ana AlilNo ratings yet

- Nature of Adherence of Porcelain Enamels To MetalsDocument22 pagesNature of Adherence of Porcelain Enamels To MetalsFernando BarreraNo ratings yet

- Corrosion Types and PreventionDocument5 pagesCorrosion Types and PreventionSachin pagarNo ratings yet

- Different Types of CorrosionDocument19 pagesDifferent Types of CorrosionbabmirNo ratings yet

- Metals: Effects of Rare Earth (Ce and La) On Steel Corrosion Behaviors Under Wet-Dry Cycle Immersion ConditionsDocument14 pagesMetals: Effects of Rare Earth (Ce and La) On Steel Corrosion Behaviors Under Wet-Dry Cycle Immersion ConditionsThanhluan NguyenNo ratings yet

- Project P 1 CLGG AhsbhDocument16 pagesProject P 1 CLGG Ahsbhpranav mahajanNo ratings yet

- CorrosionDocument5 pagesCorrosionsamyuldarosaNo ratings yet

- ScientificDocument12 pagesScientificbalajiNo ratings yet

- Extended Abstract (Wheel Sparks Cavite NHS)Document3 pagesExtended Abstract (Wheel Sparks Cavite NHS)api-283862617100% (2)

- Corrosion EngineeringDocument27 pagesCorrosion EngineeringMỹ Linh Lê100% (1)

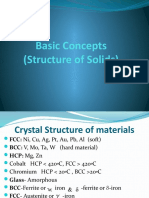

- Ch-27.1 Basic Concepts On Structure of SolidsDocument45 pagesCh-27.1 Basic Concepts On Structure of SolidsdSGDASUDNo ratings yet

- Corrosion of Stainless SteelDocument16 pagesCorrosion of Stainless SteelDanie-Els100% (1)

- Technical Data SheetDocument14 pagesTechnical Data SheetRichard FebrinoNo ratings yet

- Surface Effects of Ordering in Binary Alloys: Topical ReviewDocument34 pagesSurface Effects of Ordering in Binary Alloys: Topical RevieweidelsayedNo ratings yet

- Corrosion Protection 7.1 Causes of Corrosion:: (2) Combined StateDocument10 pagesCorrosion Protection 7.1 Causes of Corrosion:: (2) Combined Stateحاتم غيدان خلفNo ratings yet

- Factors Influencing Corrosion: By: Mohamed Adil MechtronicsDocument12 pagesFactors Influencing Corrosion: By: Mohamed Adil MechtronicsAdil MayatNo ratings yet

- Ch-27.1 Basic Concepts On Structure of SolidsDocument39 pagesCh-27.1 Basic Concepts On Structure of SolidsJyotilal SahuNo ratings yet

- Kornel Csach, Jozef Miškuf, Mária Huráková, Václav Ocelík, Jeff Th.M. de HossonDocument5 pagesKornel Csach, Jozef Miškuf, Mária Huráková, Václav Ocelík, Jeff Th.M. de Hossonjarray abdesslemNo ratings yet

- Crevice Corrosion Cathodic Reactions and Crevice Scaling LawsDocument8 pagesCrevice Corrosion Cathodic Reactions and Crevice Scaling LawsSheri WilliamsNo ratings yet

- Unit 3Document114 pagesUnit 3pthangarasu sctengNo ratings yet

- CorrosionDocument59 pagesCorrosionsparkshock100% (1)

- 8 Types of CorrosionDocument21 pages8 Types of CorrosionJunaldi75% (4)

- Industrial Materials and ProcessesDocument24 pagesIndustrial Materials and ProcessesJamie Christine0% (1)

- Lecture Three: Biomaterial Surface ChemistryDocument12 pagesLecture Three: Biomaterial Surface Chemistryحنين حسن شعبانNo ratings yet

- The Effect of Pitting Corrosion On The Fatigue Strength of 304 and 316 Stainless Steel AlloysDocument6 pagesThe Effect of Pitting Corrosion On The Fatigue Strength of 304 and 316 Stainless Steel AlloysAhmad AhmadNo ratings yet

- A Seminar On Pitting Corrosion: Department of Metallurgical and Materials Engg. M.S.University, BarodaDocument18 pagesA Seminar On Pitting Corrosion: Department of Metallurgical and Materials Engg. M.S.University, BarodarohanNo ratings yet

- CH 06 - Corrosion & ErosionDocument22 pagesCH 06 - Corrosion & ErosionvegaronNo ratings yet

- Keanu Husein Material TestingDocument2 pagesKeanu Husein Material TestingKeanu MitchellNo ratings yet

- Corrosion and Corrosion ControlDocument11 pagesCorrosion and Corrosion ControlTechnical ShortcutsNo ratings yet

- 06 - Uet FM LecDocument48 pages06 - Uet FM LecAbcNo ratings yet

- Crevice CorrosionDocument28 pagesCrevice Corrosionprakush01975225403No ratings yet

- Distribution of Metal Droplets in Top Slags During Ladle TreatmentDocument14 pagesDistribution of Metal Droplets in Top Slags During Ladle TreatmentRasul BzNo ratings yet

- Development of Microstructure in FCC Metals During Cold WorkDocument25 pagesDevelopment of Microstructure in FCC Metals During Cold Workanh hoang phamNo ratings yet

- Corrosion Studies KitDocument26 pagesCorrosion Studies KitMurphy MofeNo ratings yet

- Adaqat LI: S A 13CH26Document31 pagesAdaqat LI: S A 13CH26Junaid AhmadNo ratings yet

- Modelling The Influence of Surface Oxidation On High Temperature ErosionDocument7 pagesModelling The Influence of Surface Oxidation On High Temperature ErosionLarry SmithNo ratings yet

- Failure Analysis of An Oxidative Chlorination Reactor Clad With AISI 304L Stainless SteelDocument2 pagesFailure Analysis of An Oxidative Chlorination Reactor Clad With AISI 304L Stainless SteelAlfredo Caballero RomeroNo ratings yet

- Failure Due To CorrosionDocument19 pagesFailure Due To CorrosionAbhijit RoyNo ratings yet

- Caustic CrackingDocument17 pagesCaustic CrackingDurga PrasadNo ratings yet

- EN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyDocument13 pagesEN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyMad Max100% (1)

- Basic Principles of Corrosion of Food Metal PackagingDocument28 pagesBasic Principles of Corrosion of Food Metal PackagingHồ ThanhNo ratings yet

- Molecular Modeling of Corrosion Processes: Scientific Development and Engineering ApplicationsFrom EverandMolecular Modeling of Corrosion Processes: Scientific Development and Engineering ApplicationsNo ratings yet

- DELTA-FC 1720 Tds - EngDocument2 pagesDELTA-FC 1720 Tds - EngFarouk El Naggar100% (1)

- Vinegar Planning and Design LabDocument3 pagesVinegar Planning and Design LabKim ThaiNo ratings yet

- KITZ ProductDocument44 pagesKITZ Productkingathur26681No ratings yet

- Periodic Table and Periodicity of Properties: Major ConceptsDocument14 pagesPeriodic Table and Periodicity of Properties: Major ConceptsAbdullah AdeelNo ratings yet

- 341 Life Beyond MOCADocument16 pages341 Life Beyond MOCAmysabetNo ratings yet

- Conceptual Improvement of GOC ExerciseDocument44 pagesConceptual Improvement of GOC ExerciseOmendra Singh100% (2)

- Exp#5 Lab ReportDocument6 pagesExp#5 Lab ReportJake Macneal100% (1)

- Desulphurisation: Bo HartvigsenDocument24 pagesDesulphurisation: Bo HartvigsenRong RêuNo ratings yet

- Offshore BrochureDocument5 pagesOffshore BrochureAhmed Ben Hmida0% (1)

- Report On Pervaporation 2Document15 pagesReport On Pervaporation 2merveNo ratings yet

- Iso 16967 2015Document11 pagesIso 16967 2015Fer NandoNo ratings yet

- Stress Concentrations - Lab ReportDocument6 pagesStress Concentrations - Lab ReportArunodha HettiarachchiNo ratings yet

- Pre-Lab: Microscopes II: Plant Cells and OsmosisDocument2 pagesPre-Lab: Microscopes II: Plant Cells and Osmosisapi-234540318No ratings yet

- RT Interpretation ReferenceDocument25 pagesRT Interpretation ReferenceRichard MitchellNo ratings yet

- Chapter 4 Capillary PressureDocument16 pagesChapter 4 Capillary PressureHericane StudioNo ratings yet

- Tension Test On Hot Rolled Plain Steel Bar (ASTM-A615/615-M)Document19 pagesTension Test On Hot Rolled Plain Steel Bar (ASTM-A615/615-M)Adil Javed Chaudhary67% (3)

- Fatigue: TorsionalDocument9 pagesFatigue: TorsionalShankar RamanNo ratings yet

- Gaswelcome: AV.S Ram PrasadDocument50 pagesGaswelcome: AV.S Ram PrasadAkhil MetlaNo ratings yet

- ME104 2 B Chua Kim Lian 25062012Document51 pagesME104 2 B Chua Kim Lian 25062012kkkNo ratings yet

- Role of Kidneys in The Regulation of Acid-Base BalanceDocument83 pagesRole of Kidneys in The Regulation of Acid-Base BalanceBea SamonteNo ratings yet

- Structural Steel en 10025-10027Document2 pagesStructural Steel en 10025-10027apply19842371No ratings yet

- VizagSteel MgmtTRAINEEDocument28 pagesVizagSteel MgmtTRAINEERaghu88% (16)

- Natl 05 Part1Document8 pagesNatl 05 Part1api-3736052No ratings yet

- Chemical Engineering Syllabus For GateDocument2 pagesChemical Engineering Syllabus For Gatechintz BhatNo ratings yet

- The Dyeing of Woollen Fabrics by Beech, FranklinDocument198 pagesThe Dyeing of Woollen Fabrics by Beech, FranklinGutenberg.orgNo ratings yet

- Named ReactionsDocument15 pagesNamed Reactionsabhiramiajith0203No ratings yet

- PSV Sizing CalculationsDocument53 pagesPSV Sizing CalculationsAMITH OK93% (29)

- Validation of Process Gas SystemsDocument6 pagesValidation of Process Gas SystemsJuan Manuel Valdez Von FürthNo ratings yet

- Parametric Study of The TIG Welding Parameter For SS317L SteelDocument6 pagesParametric Study of The TIG Welding Parameter For SS317L SteelIJRASETPublicationsNo ratings yet