Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

4 viewsHydraulic Diagram, Working Hydraulics: Información de Servicio

Hydraulic Diagram, Working Hydraulics: Información de Servicio

Uploaded by

Alejandro RamosCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- CS2001 Group Project Report FinalDocument8 pagesCS2001 Group Project Report FinalHugh MatthewsNo ratings yet

- SMAG Grab 88912071 New 01 MZG s3 Ng30 Service PDFDocument108 pagesSMAG Grab 88912071 New 01 MZG s3 Ng30 Service PDFanon_550921395100% (3)

- HydraulicCA251 W2 10241 1ENDocument13 pagesHydraulicCA251 W2 10241 1ENAdrian Alonso Bustos Gonzalez100% (1)

- GEA Compr TrainingDocument22 pagesGEA Compr TrainingAsif100% (1)

- Hydraulic Scheme JCB JS130WDocument2 pagesHydraulic Scheme JCB JS130Wkokosik22100% (1)

- Water Cycle Test SchoologyDocument5 pagesWater Cycle Test Schoologyapi-241192726No ratings yet

- 150C VOLVO Steering.&.Hydraulic DiagramDocument5 pages150C VOLVO Steering.&.Hydraulic Diagramgabriel pomaNo ratings yet

- Torque Converter TransmissionDocument36 pagesTorque Converter Transmissionparkelj.letaliskaNo ratings yet

- TENDLLOD0007Document24 pagesTENDLLOD0007Kan KhabourNo ratings yet

- HYD0046 DL Transmission DL200-250-300Document24 pagesHYD0046 DL Transmission DL200-250-300Erfan.TNo ratings yet

- Regulagem Pressão EC210BDocument3 pagesRegulagem Pressão EC210BRodrigo ViegasNo ratings yet

- دائرة المشحمة لونش مانتوكDocument138 pagesدائرة المشحمة لونش مانتوكMohamed Rashed100% (1)

- VOLVO EW160B-6 SteeringDocument21 pagesVOLVO EW160B-6 SteeringPIKO MOBNo ratings yet

- HYD0047 DL Transmission DL400-500Document26 pagesHYD0047 DL Transmission DL400-500Erfan.TNo ratings yet

- Breaker Piping InstallationDocument11 pagesBreaker Piping InstallationZawminhtunNo ratings yet

- Testing & Adjusting PW200/ 220-7Document13 pagesTesting & Adjusting PW200/ 220-7Teknik Makina100% (2)

- Rexroth AA4VGDocument64 pagesRexroth AA4VGSedin MurtićNo ratings yet

- Rexroth A4VG PumpDocument16 pagesRexroth A4VG PumpFrancisco OcantoNo ratings yet

- SIF1007 DL-A Wheel Loaders - 12 - TransmissionDocument25 pagesSIF1007 DL-A Wheel Loaders - 12 - Transmissionbasem elhosanyNo ratings yet

- Accumulator Charging Valve: 1 Product DescriptionDocument6 pagesAccumulator Charging Valve: 1 Product DescriptionVagabond HuynhNo ratings yet

- Kip KIPDocument28 pagesKip KIPAndrijana MajoNo ratings yet

- 2009 G3500 VAN Transmission Connector PinoutDocument3 pages2009 G3500 VAN Transmission Connector PinoutcarlosNo ratings yet

- AT Nissan EnglishDocument20 pagesAT Nissan EnglishjoseNo ratings yet

- SIS 2.0 320c Akh00182Document5 pagesSIS 2.0 320c Akh00182Jorge RojasNo ratings yet

- Chapter 7 Rev 2 Rotation CircuitsDocument19 pagesChapter 7 Rev 2 Rotation CircuitsAnonymous 340A7vnwV1No ratings yet

- m731 e K3 v04 5554 en PDFDocument22 pagesm731 e K3 v04 5554 en PDFtsdcnNo ratings yet

- Re92003 2009-06Document64 pagesRe92003 2009-06suriantoNo ratings yet

- Dynapac CP 132 Workshop Manual: Traction, Drain, Steering and Brake SystemDocument16 pagesDynapac CP 132 Workshop Manual: Traction, Drain, Steering and Brake SystemFelipe Douglas da Silva50% (2)

- Valve Hyva PTDocument2 pagesValve Hyva PTAnangtri WahyudiNo ratings yet

- Hyundai 180-250D - Cutoff - AdjustmentDocument3 pagesHyundai 180-250D - Cutoff - AdjustmentAaronNo ratings yet

- Variable Displacement Pump A4VGDocument44 pagesVariable Displacement Pump A4VGАртурNo ratings yet

- Especificaciones Sistema HyD 312B LDocument4 pagesEspecificaciones Sistema HyD 312B LLuis Carlos VeraNo ratings yet

- Piston Pump PVDocument16 pagesPiston Pump PVtreinamentoNo ratings yet

- SM Bit Cla As Quadrant 2200 RCDocument11 pagesSM Bit Cla As Quadrant 2200 RCManuals CE & AgNo ratings yet

- A4vg eDocument43 pagesA4vg eHarun VijayakumaranNo ratings yet

- Linde - HPV Data and SpecificationsDocument33 pagesLinde - HPV Data and SpecificationsxxshNo ratings yet

- 00000177-04 Valves HyvaDocument14 pages00000177-04 Valves HyvaYasir RehmanNo ratings yet

- Main Relief Valve, AdjustmentDocument3 pagesMain Relief Valve, Adjustmentsunil singhNo ratings yet

- Valvula Redutora Bloco FugroDocument3 pagesValvula Redutora Bloco FugroJoyce AlmeidaNo ratings yet

- EH4500-2 Hoist RevOct05Document61 pagesEH4500-2 Hoist RevOct05FAF majorNo ratings yet

- Valvulas de Linea 336dDocument9 pagesValvulas de Linea 336dANTONIO CRUZNo ratings yet

- © Festo Didactic GMBH & Co. KG, 02/2003 Subject To ChangeDocument2 pages© Festo Didactic GMBH & Co. KG, 02/2003 Subject To ChangecioranescuNo ratings yet

- HT 1220 TNKDocument2 pagesHT 1220 TNKyudi kurniawanNo ratings yet

- Variable Pump T2VK, Bent Axis Design: For Open & Closed CircutDocument6 pagesVariable Pump T2VK, Bent Axis Design: For Open & Closed CircutPrime HydraulicsNo ratings yet

- Hidraulic CA-511Document13 pagesHidraulic CA-511Adrian Alonso Bustos GonzalezNo ratings yet

- Hydraulic Diagram, Neutral ( To 5001) : Service InformationDocument2 pagesHydraulic Diagram, Neutral ( To 5001) : Service InformationĐoàn LựcNo ratings yet

- 320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP (MACHINE) POWERED BY 3066 ENGINE (XEBP7645 - 03) - DocumentaciónDocument6 pages320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP (MACHINE) POWERED BY 3066 ENGINE (XEBP7645 - 03) - Documentaciónjohana ruiz cervantesNo ratings yet

- HDDocument44 pagesHDkha nguyenNo ratings yet

- Training Tail Lift Technology Mod 4 Signs & Symbols enDocument19 pagesTraining Tail Lift Technology Mod 4 Signs & Symbols enArmin PatelNo ratings yet

- 2-1. Structure and Function hx85x HyundaiDocument83 pages2-1. Structure and Function hx85x HyundaiAlfonso BerRamNo ratings yet

- Chapter 10 Rev 3 Rod ChangingDocument13 pagesChapter 10 Rev 3 Rod ChangingAnonymous 340A7vnwV1No ratings yet

- CC2800 Hydraulic InteractivDocument31 pagesCC2800 Hydraulic InteractivDemian Leiva100% (2)

- SteeringDocument7 pagesSteeringyeremia kristianNo ratings yet

- DM 50 Middle Range Hydraulics SystemsDocument107 pagesDM 50 Middle Range Hydraulics SystemsVALENTIN PEREZNo ratings yet

- Sistema de Levante Volteo y Dirección ST14Document27 pagesSistema de Levante Volteo y Dirección ST14SIM 1975No ratings yet

- Beaker Installation.: Hydraulic Circuit For BreakerDocument7 pagesBeaker Installation.: Hydraulic Circuit For BreakerMasterrNo ratings yet

- R4V and R6VDocument13 pagesR4V and R6VElias80No ratings yet

- A4VGDocument68 pagesA4VGИгорь ИгорьNo ratings yet

- 660III HYD CircuitDocument32 pages660III HYD CircuitaugustoNo ratings yet

- Material SpecificationsDocument27 pagesMaterial Specificationssat palNo ratings yet

- Application of FMEA in An Aluminium Pot Manufacturing IndustryDocument5 pagesApplication of FMEA in An Aluminium Pot Manufacturing IndustryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Part SD200N TenggarongDocument2 pagesPart SD200N TenggarongAndre STANo ratings yet

- Checklist For C-172 Before Starting Engine Instrument Cockpit CheckDocument2 pagesChecklist For C-172 Before Starting Engine Instrument Cockpit CheckKonstantinos AirmanNo ratings yet

- UgCS User Manual-DraftDocument34 pagesUgCS User Manual-DraftLucas Matías MolinaNo ratings yet

- 16SN2500FEDocument1 page16SN2500FEGergely IvánovicsNo ratings yet

- Ruport Book 1.1.0Document164 pagesRuport Book 1.1.0Alex BayNo ratings yet

- RotexDocument50 pagesRotexliyuping200809No ratings yet

- BAR CODE PresentationDocument18 pagesBAR CODE PresentationAnKit SiNghNo ratings yet

- Electrical Power System Protection PDFDocument540 pagesElectrical Power System Protection PDFMohamed Federer93% (14)

- Slurry Pooling and Transport Issues in SAG Mills PDFDocument10 pagesSlurry Pooling and Transport Issues in SAG Mills PDFMartin.c.figueroaNo ratings yet

- 4 Shear and Moment Daigrams Graphical MethodDocument24 pages4 Shear and Moment Daigrams Graphical MethodWassan IdreesNo ratings yet

- Google Play Supported Devices - Sheet 1Document193 pagesGoogle Play Supported Devices - Sheet 1Miguel S SNo ratings yet

- Oxygen Enrichment Atmosphere HazardsDocument24 pagesOxygen Enrichment Atmosphere HazardsfrancisNo ratings yet

- Va1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellDocument17 pagesVa1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellKhang TrangNo ratings yet

- Design and Fabrication of Screw Conveyor Report DownloadDocument3 pagesDesign and Fabrication of Screw Conveyor Report Downloadyohannes wendwesenNo ratings yet

- Faster. Smarter. Safer.: The Cat R1600H Underground LoaderDocument2 pagesFaster. Smarter. Safer.: The Cat R1600H Underground LoaderMario TerrazaNo ratings yet

- NN Examples MatlabDocument91 pagesNN Examples MatlabAnonymous 1dVLJSVhtrNo ratings yet

- A0 - Winch Operators ManualDocument34 pagesA0 - Winch Operators ManualEze FrigugliettiNo ratings yet

- Ascotran: Flash-Rust / In-Can ProtectionDocument6 pagesAscotran: Flash-Rust / In-Can ProtectiondiablomatiNo ratings yet

- AITS 2324 FT III JEEM TD SolDocument15 pagesAITS 2324 FT III JEEM TD Soladoranto737No ratings yet

- KTA38-M0 FR6219 - 850 at 1800Document4 pagesKTA38-M0 FR6219 - 850 at 1800javierdieselengineNo ratings yet

- Wheel Weight SizeDocument56 pagesWheel Weight SizeHerciu FlavianNo ratings yet

- Extensometro Strain Gauge P 66.81 Dehnungsaufnehmer Stahl DSC enDocument1 pageExtensometro Strain Gauge P 66.81 Dehnungsaufnehmer Stahl DSC enFreddy Sanchez LuckNo ratings yet

- ElectEngin BSCDocument72 pagesElectEngin BSCVicNo ratings yet

- F5 2 TekananDocument176 pagesF5 2 TekananAZRI AZMI BIN ABD AZIZ MoeNo ratings yet

- Machine Learning Inspired Sound-Based Amateur Drone Detection For Public Safety ApplicationsDocument9 pagesMachine Learning Inspired Sound-Based Amateur Drone Detection For Public Safety ApplicationsKhurram AzizNo ratings yet

- Alcatel 7300 ASAM PDFDocument12 pagesAlcatel 7300 ASAM PDFGuilherme Vilas BoasNo ratings yet

Hydraulic Diagram, Working Hydraulics: Información de Servicio

Hydraulic Diagram, Working Hydraulics: Información de Servicio

Uploaded by

Alejandro Ramos0 ratings0% found this document useful (0 votes)

4 views8 pagesOriginal Title

12c

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

4 views8 pagesHydraulic Diagram, Working Hydraulics: Información de Servicio

Hydraulic Diagram, Working Hydraulics: Información de Servicio

Uploaded by

Alejandro RamosCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 8

Información de servicio

Título de documento: Grupo funcional: Tipo de información: Fecha:

Hydraulic diagram, working 910 Información de servicio 13/10/2023

hydraulics

Perfil:

Hydraulic diagram, working hydraulics

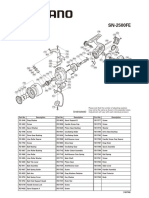

Figure 1

Hydraulic diagram L90C/L120C basic machine

A Hydraulic oil pump, steering, brake and servo systems

B Hydraulic oil pump, working hydraulics

D Return-oil filter

E Hydraulic oil cooler

F Pressure-limiting valve, servo system, 3.0 - 4.0 MPa (435 - 580

psi)

H Control valve, brake and servo systems (mounted in the brake

valve)

J Servo valve

K Control valve

K1 Pressure-limiting valve, working pressure 22.5 MPa (3263 psi)

K2 Shock and anti-cavitation valve for piston rod end of tilting

cylinder, 17.5 ±0.9 MPa (2538 ±131 psi)

K3 Shock and anti-cavitation valve for piston end of tilting

cylinder, 24.5 ±0.9 MPa (3553 ±131 psi)

K4 Shock and anti-cavitation valve for piston end of lifting

cylinders, 32.0 ±0.9 MPa (4641 ±131 psi)

K5 Back-up valve for return pressure in connection with lowering

or tilting forward, 1.0 - 2.0 MPa (145 - 290 psi)

K6 Anti-cavitation valve for piston rod end of lifting cylinders

K7 Anti-cavitation valve for piston rod end of tilting cylinder

P Solenoid valve block MA9: Differential Lock MA41: Floating

position

Z Accumulator for pressure back-up in servo circuit

1 Hydraulic oil tank

2 Non-return valve, by-pass for oil cooler

41 Pressure outlet, servo pressure

42 Pressure outlet, working pressure

43 Pressure outlet, shock pressure (piston end of tilting cylinder)

44 Pressure outlet, shock pressure (piston rod end of tilting

cylinder)

8 Tilting cylinder

9 Lifting cylinders

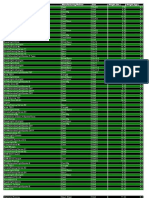

Figure 2

Hydraulic diagram L90C/L120C

The following equipment can be found on the hydraulic diagram:

Basic machine

3rd hydraulic function

Pressure draining of quick-action couplings

Separate attachment locking

A Hydraulic oil pump, steering, brake and servo systems

B Hydraulic oil pump, working hydraulics

D Return-oil filter

E Hydraulic oil cooler

G Valve block, separate attachment locking

G1 Pressure-limiting valve, 15.0 ±0.5 MPa (2176 ±73 psi), for

raised servo pressure

G2 Pressure-limiting valve, 3.0 - 4.0 MPa (435 - 580 psi), ordinary

servo pressure

H Control valve, brake and servo systems (mounted in the brake

valve)

J Servo valve

K Control valve

K1 Pressure-limiting valve, working pressure 22.5 MPa (3263 psi)

K2 Shock and anti-cavitation valve for piston rod end of tilting

cylinder, 17.5 ±0.9 MPa (2538 ±131 psi)

K3 Shock and anti-cavitation valve for piston end of tilting

cylinder, 24.5 ±0.9 MPa (3553 ±131 psi)

K4 Shock and anti-cavitation valve for piston end of lifting

cylinders, 32.0 ±0.9 MPa (4641 ±131 psi)

K5 Back-up valve for return pressure in connection with lowering

or tilting forward, 1.0 - 2.0 MPa (145 - 290 psi)

K6 Anti-cavitation valve for piston rod end of lifting cylinders

K7 Anti-cavitation valve for piston rod end of tilting cylinder

P Solenoid valve block MA9: Differential lock MA41: Floating

position MA51: Attachment locking (Optional equipment)

MA52: Raised servo pressure

R Hydraulic cylinders attachment locking (Optional equipment)

Z Accumulator for pressure back-up in servo circuit

1 Hydraulic oil tank

2 Non-return valve, by-pass for oil cooler

41 Pressure outlet, servo pressure

42 Pressure outlet, working pressure

43 Pressure outlet, shock pressure (piston end of tilting cylinder)

44 Pressure outlet, shock pressure (piston rod end of tilting

cylinder)

8 Tilting cylinder

9 Lifting cylinders

Figure 3

Hydraulic diagram L90C/L120C

The following equipment can be found on the hydraulic diagram:

Basic machine

3rd hydraulic function

Pressure draining of quick-action couplings

Separate attachment locking

A Hydraulic oil pump, steering, brake and servo systems

B Hydraulic oil pump, working hydraulics

D Return-oil filter

E Hydraulic oil cooler

G Valve block, separate attachment locking

G1 Pressure-limiting valve, 15.0 ±0.5 MPa (2176 ±73 psi), for

raised servo pressure

G2 Pressure-limiting valve, 3.0 - 4.0 MPa (435 - 580 psi), ordinary

servo pressure

H Control valve, brake and servo system (mounted in the brake

valve)

J Servo valve

K Control valve

K1 Pressure-limiting valve, working pressure 22.5 MPa (3263 psi)

K2 Shock and anti-cavitation valve for piston rod end of tilting

cylinder, 17.5 ±0.9 MPa (2538 ±131 psi)

K3 Shock and anti-cavitation valve for piston end of tilting

cylinder, 24.5 ±0.9 MPa 3553 ±131 psi)

K4 Shock and anti-cavitation valve for piston end of lifting

cylinders, 32.0 ±0.9 MPa (4641 ±131 psi)

K5 Back-up valve for return pressure in connection with lowering

or tilting forward, 1.0 - 2.0 MPa (145 - 290 psi)

K6 Anti-cavitation valve for piston rod end of lifting cylinders

K7 Anti-cavitation valve for piston rod end of tilting cylinder

P Solenoid valve block MA9: Differential lock MA36: 3rd

hydraulic function MA41: Floating position MA51: Attachment

locking (Optional equipment) MA52: Raised servo pressure

R Hydraulic cylinders attachment locking (Optional equipment)

T Change-over valve 4th/5th hydraulic function (Optional

equipment)

X MA55 Single-acting lifting function (Optional equipment)

Z Accumulator for pressure back-up in servo circuit

1 Hydraulic oil tank

2 Non-return valve, by-pass for oil cooler

41 Pressure outlet, servo pressure

42 Pressure outlet, working pressure

43 Pressure outlet, shock pressure (piston end of tilting cylinder)

44 Pressure outlet, shock pressure (piston rod end of tilting

cylinder)

8 Tilting cylinder

9 Lifting cylinders

You might also like

- CS2001 Group Project Report FinalDocument8 pagesCS2001 Group Project Report FinalHugh MatthewsNo ratings yet

- SMAG Grab 88912071 New 01 MZG s3 Ng30 Service PDFDocument108 pagesSMAG Grab 88912071 New 01 MZG s3 Ng30 Service PDFanon_550921395100% (3)

- HydraulicCA251 W2 10241 1ENDocument13 pagesHydraulicCA251 W2 10241 1ENAdrian Alonso Bustos Gonzalez100% (1)

- GEA Compr TrainingDocument22 pagesGEA Compr TrainingAsif100% (1)

- Hydraulic Scheme JCB JS130WDocument2 pagesHydraulic Scheme JCB JS130Wkokosik22100% (1)

- Water Cycle Test SchoologyDocument5 pagesWater Cycle Test Schoologyapi-241192726No ratings yet

- 150C VOLVO Steering.&.Hydraulic DiagramDocument5 pages150C VOLVO Steering.&.Hydraulic Diagramgabriel pomaNo ratings yet

- Torque Converter TransmissionDocument36 pagesTorque Converter Transmissionparkelj.letaliskaNo ratings yet

- TENDLLOD0007Document24 pagesTENDLLOD0007Kan KhabourNo ratings yet

- HYD0046 DL Transmission DL200-250-300Document24 pagesHYD0046 DL Transmission DL200-250-300Erfan.TNo ratings yet

- Regulagem Pressão EC210BDocument3 pagesRegulagem Pressão EC210BRodrigo ViegasNo ratings yet

- دائرة المشحمة لونش مانتوكDocument138 pagesدائرة المشحمة لونش مانتوكMohamed Rashed100% (1)

- VOLVO EW160B-6 SteeringDocument21 pagesVOLVO EW160B-6 SteeringPIKO MOBNo ratings yet

- HYD0047 DL Transmission DL400-500Document26 pagesHYD0047 DL Transmission DL400-500Erfan.TNo ratings yet

- Breaker Piping InstallationDocument11 pagesBreaker Piping InstallationZawminhtunNo ratings yet

- Testing & Adjusting PW200/ 220-7Document13 pagesTesting & Adjusting PW200/ 220-7Teknik Makina100% (2)

- Rexroth AA4VGDocument64 pagesRexroth AA4VGSedin MurtićNo ratings yet

- Rexroth A4VG PumpDocument16 pagesRexroth A4VG PumpFrancisco OcantoNo ratings yet

- SIF1007 DL-A Wheel Loaders - 12 - TransmissionDocument25 pagesSIF1007 DL-A Wheel Loaders - 12 - Transmissionbasem elhosanyNo ratings yet

- Accumulator Charging Valve: 1 Product DescriptionDocument6 pagesAccumulator Charging Valve: 1 Product DescriptionVagabond HuynhNo ratings yet

- Kip KIPDocument28 pagesKip KIPAndrijana MajoNo ratings yet

- 2009 G3500 VAN Transmission Connector PinoutDocument3 pages2009 G3500 VAN Transmission Connector PinoutcarlosNo ratings yet

- AT Nissan EnglishDocument20 pagesAT Nissan EnglishjoseNo ratings yet

- SIS 2.0 320c Akh00182Document5 pagesSIS 2.0 320c Akh00182Jorge RojasNo ratings yet

- Chapter 7 Rev 2 Rotation CircuitsDocument19 pagesChapter 7 Rev 2 Rotation CircuitsAnonymous 340A7vnwV1No ratings yet

- m731 e K3 v04 5554 en PDFDocument22 pagesm731 e K3 v04 5554 en PDFtsdcnNo ratings yet

- Re92003 2009-06Document64 pagesRe92003 2009-06suriantoNo ratings yet

- Dynapac CP 132 Workshop Manual: Traction, Drain, Steering and Brake SystemDocument16 pagesDynapac CP 132 Workshop Manual: Traction, Drain, Steering and Brake SystemFelipe Douglas da Silva50% (2)

- Valve Hyva PTDocument2 pagesValve Hyva PTAnangtri WahyudiNo ratings yet

- Hyundai 180-250D - Cutoff - AdjustmentDocument3 pagesHyundai 180-250D - Cutoff - AdjustmentAaronNo ratings yet

- Variable Displacement Pump A4VGDocument44 pagesVariable Displacement Pump A4VGАртурNo ratings yet

- Especificaciones Sistema HyD 312B LDocument4 pagesEspecificaciones Sistema HyD 312B LLuis Carlos VeraNo ratings yet

- Piston Pump PVDocument16 pagesPiston Pump PVtreinamentoNo ratings yet

- SM Bit Cla As Quadrant 2200 RCDocument11 pagesSM Bit Cla As Quadrant 2200 RCManuals CE & AgNo ratings yet

- A4vg eDocument43 pagesA4vg eHarun VijayakumaranNo ratings yet

- Linde - HPV Data and SpecificationsDocument33 pagesLinde - HPV Data and SpecificationsxxshNo ratings yet

- 00000177-04 Valves HyvaDocument14 pages00000177-04 Valves HyvaYasir RehmanNo ratings yet

- Main Relief Valve, AdjustmentDocument3 pagesMain Relief Valve, Adjustmentsunil singhNo ratings yet

- Valvula Redutora Bloco FugroDocument3 pagesValvula Redutora Bloco FugroJoyce AlmeidaNo ratings yet

- EH4500-2 Hoist RevOct05Document61 pagesEH4500-2 Hoist RevOct05FAF majorNo ratings yet

- Valvulas de Linea 336dDocument9 pagesValvulas de Linea 336dANTONIO CRUZNo ratings yet

- © Festo Didactic GMBH & Co. KG, 02/2003 Subject To ChangeDocument2 pages© Festo Didactic GMBH & Co. KG, 02/2003 Subject To ChangecioranescuNo ratings yet

- HT 1220 TNKDocument2 pagesHT 1220 TNKyudi kurniawanNo ratings yet

- Variable Pump T2VK, Bent Axis Design: For Open & Closed CircutDocument6 pagesVariable Pump T2VK, Bent Axis Design: For Open & Closed CircutPrime HydraulicsNo ratings yet

- Hidraulic CA-511Document13 pagesHidraulic CA-511Adrian Alonso Bustos GonzalezNo ratings yet

- Hydraulic Diagram, Neutral ( To 5001) : Service InformationDocument2 pagesHydraulic Diagram, Neutral ( To 5001) : Service InformationĐoàn LựcNo ratings yet

- 320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP (MACHINE) POWERED BY 3066 ENGINE (XEBP7645 - 03) - DocumentaciónDocument6 pages320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP (MACHINE) POWERED BY 3066 ENGINE (XEBP7645 - 03) - Documentaciónjohana ruiz cervantesNo ratings yet

- HDDocument44 pagesHDkha nguyenNo ratings yet

- Training Tail Lift Technology Mod 4 Signs & Symbols enDocument19 pagesTraining Tail Lift Technology Mod 4 Signs & Symbols enArmin PatelNo ratings yet

- 2-1. Structure and Function hx85x HyundaiDocument83 pages2-1. Structure and Function hx85x HyundaiAlfonso BerRamNo ratings yet

- Chapter 10 Rev 3 Rod ChangingDocument13 pagesChapter 10 Rev 3 Rod ChangingAnonymous 340A7vnwV1No ratings yet

- CC2800 Hydraulic InteractivDocument31 pagesCC2800 Hydraulic InteractivDemian Leiva100% (2)

- SteeringDocument7 pagesSteeringyeremia kristianNo ratings yet

- DM 50 Middle Range Hydraulics SystemsDocument107 pagesDM 50 Middle Range Hydraulics SystemsVALENTIN PEREZNo ratings yet

- Sistema de Levante Volteo y Dirección ST14Document27 pagesSistema de Levante Volteo y Dirección ST14SIM 1975No ratings yet

- Beaker Installation.: Hydraulic Circuit For BreakerDocument7 pagesBeaker Installation.: Hydraulic Circuit For BreakerMasterrNo ratings yet

- R4V and R6VDocument13 pagesR4V and R6VElias80No ratings yet

- A4VGDocument68 pagesA4VGИгорь ИгорьNo ratings yet

- 660III HYD CircuitDocument32 pages660III HYD CircuitaugustoNo ratings yet

- Material SpecificationsDocument27 pagesMaterial Specificationssat palNo ratings yet

- Application of FMEA in An Aluminium Pot Manufacturing IndustryDocument5 pagesApplication of FMEA in An Aluminium Pot Manufacturing IndustryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Part SD200N TenggarongDocument2 pagesPart SD200N TenggarongAndre STANo ratings yet

- Checklist For C-172 Before Starting Engine Instrument Cockpit CheckDocument2 pagesChecklist For C-172 Before Starting Engine Instrument Cockpit CheckKonstantinos AirmanNo ratings yet

- UgCS User Manual-DraftDocument34 pagesUgCS User Manual-DraftLucas Matías MolinaNo ratings yet

- 16SN2500FEDocument1 page16SN2500FEGergely IvánovicsNo ratings yet

- Ruport Book 1.1.0Document164 pagesRuport Book 1.1.0Alex BayNo ratings yet

- RotexDocument50 pagesRotexliyuping200809No ratings yet

- BAR CODE PresentationDocument18 pagesBAR CODE PresentationAnKit SiNghNo ratings yet

- Electrical Power System Protection PDFDocument540 pagesElectrical Power System Protection PDFMohamed Federer93% (14)

- Slurry Pooling and Transport Issues in SAG Mills PDFDocument10 pagesSlurry Pooling and Transport Issues in SAG Mills PDFMartin.c.figueroaNo ratings yet

- 4 Shear and Moment Daigrams Graphical MethodDocument24 pages4 Shear and Moment Daigrams Graphical MethodWassan IdreesNo ratings yet

- Google Play Supported Devices - Sheet 1Document193 pagesGoogle Play Supported Devices - Sheet 1Miguel S SNo ratings yet

- Oxygen Enrichment Atmosphere HazardsDocument24 pagesOxygen Enrichment Atmosphere HazardsfrancisNo ratings yet

- Va1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellDocument17 pagesVa1-Lici-00eg-I-m4d-Das-0009 RTD & ThermowellKhang TrangNo ratings yet

- Design and Fabrication of Screw Conveyor Report DownloadDocument3 pagesDesign and Fabrication of Screw Conveyor Report Downloadyohannes wendwesenNo ratings yet

- Faster. Smarter. Safer.: The Cat R1600H Underground LoaderDocument2 pagesFaster. Smarter. Safer.: The Cat R1600H Underground LoaderMario TerrazaNo ratings yet

- NN Examples MatlabDocument91 pagesNN Examples MatlabAnonymous 1dVLJSVhtrNo ratings yet

- A0 - Winch Operators ManualDocument34 pagesA0 - Winch Operators ManualEze FrigugliettiNo ratings yet

- Ascotran: Flash-Rust / In-Can ProtectionDocument6 pagesAscotran: Flash-Rust / In-Can ProtectiondiablomatiNo ratings yet

- AITS 2324 FT III JEEM TD SolDocument15 pagesAITS 2324 FT III JEEM TD Soladoranto737No ratings yet

- KTA38-M0 FR6219 - 850 at 1800Document4 pagesKTA38-M0 FR6219 - 850 at 1800javierdieselengineNo ratings yet

- Wheel Weight SizeDocument56 pagesWheel Weight SizeHerciu FlavianNo ratings yet

- Extensometro Strain Gauge P 66.81 Dehnungsaufnehmer Stahl DSC enDocument1 pageExtensometro Strain Gauge P 66.81 Dehnungsaufnehmer Stahl DSC enFreddy Sanchez LuckNo ratings yet

- ElectEngin BSCDocument72 pagesElectEngin BSCVicNo ratings yet

- F5 2 TekananDocument176 pagesF5 2 TekananAZRI AZMI BIN ABD AZIZ MoeNo ratings yet

- Machine Learning Inspired Sound-Based Amateur Drone Detection For Public Safety ApplicationsDocument9 pagesMachine Learning Inspired Sound-Based Amateur Drone Detection For Public Safety ApplicationsKhurram AzizNo ratings yet

- Alcatel 7300 ASAM PDFDocument12 pagesAlcatel 7300 ASAM PDFGuilherme Vilas BoasNo ratings yet