Professional Documents

Culture Documents

AHA - Confined Space Entry

AHA - Confined Space Entry

Uploaded by

Jon CarloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AHA - Confined Space Entry

AHA - Confined Space Entry

Uploaded by

Jon CarloCopyright:

Available Formats

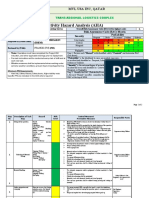

Activity/Work Task: Confined Space Entry Overall Risk Assessment Code (RAC) (Use M

highest code)

Project Location: Risk Assessment Code (RAC) Matrix

Contract Number: Probability

Severity

Date Prepared: Frequent Likely Occasion Seldo Unlikely

al m

Catastrophic E E H H M

Prepared by (Name/Title):

Critical E H H M L

Marginal H M M L L

Reviewed by (Name/Title):

Negligible M L L L L

Notes: (Field Notes, Review Comments, etc.)

Step 1: Review each “Hazard” with identified safety “Controls” and determine RAC (See above)

“Probability” is the likelihood to cause an incident, near miss,

or accident and identified as: Frequent, Likely, Occasional, RAC Chart

Seldom or Unlikely.

“Severity” is the outcome/degree if an incident, near miss, or E = Extremely High Risk

accident did occur and identified as: Catastrophic, Critical, H = High Risk

Marginal, or Negligible

Step 2: Identify the RAC (Probability/Severity) as E, H, M, or M = Moderate Risk

L for each “Hazard” on AHA. Annotate the overall highest L = Low Risk

RAC at the top of AHA.

No Job Steps Potential Hazard Critical Actions

NOTE: For specific details always refer to the

relevant SAFE WORK PRACTICES Standard.

1. Lack of hazard awareness of the

Identify need to conduct confined space specific confined space leading to injury 1. Ensure description of work identifies the

entry during job planning. or fatality. specific type of confined space: pit, tank,

1 excavation, pipe, tunnel, etc. and those

2. Loss of time, potential injury or

competent personnel conduct the hazard

fatality if wrong location is identified,

assessment.

assessed or entered.

2. Confirm the entry/work location, and

communicate work intentions to appropriate

personnel.

Prepare Work Permit and Confined

Space Entry Form.

1. Potential confined space hazards not 1. Follow the Confined Space Entry SAFE

2 identified may cause injury or incident. WORK PRACTICES Standard instructions.

NOTE: Other forms may be needed

depending on type and location of

confined space.

Conduct job site and equipment

preparation. 1. Hazardous energy sources affecting 1a. Include competent persons in AHA

confined space not properly identified development to ensure identification of all

3 or positively isolated. sources of hazardous energy.

NOTE: separate AHA(s) may be required 2. Unauthorized access of personnel to 1b. Identify and isolate sources of hazardous

to address specific job site or equipment work area leading to injury. energy. Review and implement controls of

preparation tasks within this step.

3. Evacuation routes not identified GD Shared – SAFE WORK PRACTICES Baseline

leading to workers confusion in an AHA for Isolation of Hazardous Energy.

emergency.

2. Place barricades and signs to restrict

4. Previous contents of confined space access to work site.

not evaluated for hazards leading to

3a. Identify evacuation routes during site

injury.

assessment and include in AHA.

5. Equipment with internal combustion

3b. Develop contingency and emergency

engines in close proximity to the

rescue plans. Include the following in the

confined space may cause accumulation

Rescue Plan:

of carbon monoxide (CO) inside the

space or create a source of ignition for • Procedures for reporting

flammable vapors venting from the emergencies

confined space.

• Emergency escape routes

6. Gas detector not calibrated, not

properly maintained (faulty sensors, • Rescue equipment required

battery not fully charged, etc.) or not • The designated emergency

fitted with sensors for the suspected assembly area

leading to erroneous readings.

• Rescue and first aid procedures and

7. Competent personnel not identified

duties

or not available leading to poor decision

quality. 4. Review existing information about the

previous contents, including material safety

8. Improper access to entry and exit

data sheets (MSDS) and other relevant

point openings leading to injury.

information. If sufficient information does

9. Toxic or flammable vapors released by not exist, get help from the appropriate

disturbing sludge product inside tanks subject matter experts.

leading to fire, injury or fatality.

5. Locate equipment with internal

combustion engines at least 50 feet (15

meters) away from entry openings and

10. Slips, trips and falls due to poor ensure their exhausts are directed away

housekeeping leading to injury. from entry points.

11. Delay in work beginning due to a 6. Review gas detector records, including

lack of or incorrect work permit annual calibration record sheet, monthly

documentation for the job. calibration sheet and daily field response

sheet. Also verify that the correct sensor for

12. Inadequate ventilation and/or

the gas being detected is installed in the

cooling which could result in a buildup

monitor.

of hazardous vapors and/or heat

resulting in suffocation, poisoning 7. Review personnel training records to

and/or heat stress. verify that they have the competencies to

perform their roles (e.g., Gas Testers, Entry

Watch, Fire Watch, Entrants, Rescue

Workers, excavation competent person,

etc.).

8a. Provide secured ladders or stairs to

elevated entry/egress points to verify that

proper fall protection controls are in place.

8b. Evaluate the size and shape of the entry

opening and potential obstacles at entry

point. Review drawings of the space, if

available, to select best location for entry to

avoid awkward entry and obstacles.

8c. Designate a standby person assist with

safe entry and egress of work crew.

9. Review MSDSs to identify precautions and

appropriate PPE. Perform continuous gas

monitoring while sludge is present in the

space.

10. Review housekeeping and correct

deficiencies.

11. Plan the work with competent personnel

and the appropriate subject matter experts

(SMEs) to prepare the correct

documentation per the schedule. Examples

of documentation include work permits with

the required gas testing readings, signatures,

and hazard mitigation and PPE

requirements.

12. Provide adequate ventilation and cooling

equipment (if necessary). Verify that the

equipment is functioning as intended.

NOTE: Refer to the Gas Testing with LFL Gas

1. Gas Tester not qualified to test the

Detection Equipment SAFE WORK PRACTICES

atmosphere and interpret the readings

Baseline AHA

leading to incorrect readings that may

cause injury or fire.

Gas tests the work site and/or 2. Readings taken at confined space 1. Verify that the Gas Tester is qualified to

equipment. opening may not be representative of perform the testing.

the internal atmosphere of the confined

4 2a. Gas test initially at the opening of the

space.

NOTE: separate AHA(s) and permits may confined space after the ventilation has been

be required to address specific job tasks 3. Failure to test for specific toxic or turned off for a minimum of 15 minutes. If

within this step. flammable gases and vapors may cause the readings indicate that it is safe to do so,

injury or fatality. test further inside the confined space before

allowing work to start. Note: A separate

4. Failure to conduct follow-up or

permit and Confined Space Entry form is

continuous gas tests (as appropriate)

required if the Gas Tester needs to enter and

could result in injury or fatality.

test inside the confined space.

5. Not wearing the required PPE or 2b. Entry Watch must be present for all

wearing the incorrect PPE could result in confined space entries.

injury or fatality.

3. Conduct gas testing for oxygen (O2), toxic

6. Undetected hazardous gases due to and flammable gases and vapors and record

malfunctioning of gas detection the results on the permit along with date,

equipment may cause injury or fire. time and Gas Tester’s signature.

4. Implement continuous or periodic gas

testing (as specified in the permit) to verify

that the confined space atmosphere remains

safe for entry. Record gas testing results on

the permit or applicable form (example: if

entrants are out of confined space for more

than one hour).

5. Identify the correct PPE and require that

personnel wear it before they enter into the

confined space. Note: When the Gas Tester

must enter into the confined space to

conduct internal gas tests, the PPE must be

specified on the permit and the Gas Tester

must put it on prior to entering the confined

space. PPE may include supplied air

respirator, coveralls, rubber boots and

personal monitor.

6. Confirm that the gas testing equipment is

calibrated and bump tested.

1. Entry Watch does not recognize

Position dedicated Entry Watch hazards and react appropriately. 1a. Verify that the Entry Watch is competent

5

personnel at the confined space. for the task.

2. Entry Watch could be overcome by 1b. Provide the Entry Watch with a

gases or vapors originating from work in communication device to raise the alarm if

confined space leading to injury or there is an emergency.

fatality.

2. Ensure Entry Watch is up wind from any

3. Other unit/equipment may be or potential gas or vapor hazard and is wearing

become a source of flammable or the appropriate PPE.

combustible material which may cause

3. Monitor the Entrants and their work and

personal injury or fire.

look for potential hazards arising from and to

nearby operations/work. Confirm that the

Entry Watch has the knowledge and ability

to contact operations personnel.

1a. Involve the affected personnel in the pre-

job briefing to review the JLA, associated

1. Entrants unaware of the hazards, not

hazards and controls, including PPE

wearing the correct personal protective

requirements. Consult and follow JLAs,

equipment (PPE) or not following JLAs,

procedures, standards and instructions.

procedures, standards or instructions for

work tasks being performed could result 1b. Before personnel enter the confined

in injury or fatality. space, the Permit Issuer, the Entry Watch

Enter the confined space and begin and operating personnel must check the

6 2. Personnel unaware of emergency

work. work location/conditions and the controls

procedures could result in injury or

(including ventilation requirements, if

fatality (e.g. communication between

applicable) to validate the permit

entry-watch and entrants unclear or

requirements.

does not occur).

1c. Conduct LPSA before starting work tasks

3. Constricted entry points could result

and each time there is a change.

in injury.

2. Review the Rescue or Emergency Plan and

facility emergency procedures (including

4. Inadequate lighting in a confined evacuation routes, rally points and alarms)

space can make it difficult to see and with personnel.

could result in injury or fatality.

3. Be aware of surroundings and hazards by

5. Temperatures inside the confined looking inside the confined space and

spaces can become hot due to the planning body position during entry. Pay

weather conditions or due to the work attention to sharp edges, protrusions,

occurring inside the space and may scaffold, etc.

result in heat-related injury or fatality.

4. Use approved lighting to perform work

6. Personal injury or fatality due to task.

unauthorized entries or entrants not

5a. Verify that personnel maintain adequate

accounted for.

hydration and ensure that they take breaks

7. Entrants may exit from an un- to avoid heat stress.

monitored egress point that would

5b. Use ventilation to cool the confined

compromise the entry log and could

space or provide the appropriate PPE, such

result in inadequate communications of

as cooling vests.

hazards to entrants in the confined

space. 6. Establish an Entry Watch and keep an

entry log of all entries and exits.

7. Instruct entrants to communicate

intentions with all Entry Watches if vessel

entry/egress points are different (example:

column top entry and column bottom

egress).

1. Conditions change during work that

may introduce new hazards causing 1. Stop work and cancel the work permit if

7 Work is in progress. potential injuries or incidents. the work scope or condition changes. Review

the AHA to identify changes to work

2. Inadequate gas testing (proper conditions and any new hazards. Perform a

intervals, continuous testing when

required, etc.) may cause injuries or LPSA. Complete and re-issue the work

fires. permit.

3. Faulty communication equipment 2. Ensure that the confined space

may lead to potential losses. atmosphere is tested with the frequency

specified in the permit.

4. Changes in atmospheric conditions

outside the confined space and/or inside 3. Confirm that communication equipment is

the confined space may result in working correctly. Fully recharge radio

asphyxiation and/or introduction of fuel batteries prior to work beginning.

to an ignition source that may cause a

4. Verify that PPE is identified in hazard

fire/explosion.

assessment and that personnel know the

Rescue/Emergency Plan. Confirm that the

Rescue Personnel are on site and are

available to perform a rescue, if needed.

Complete the work and clean up the job

8

site.

Equipment to be Used Training Requirements/Competent or Inspection Requirements

Qualified Personnel name(s)

• Cellular telephone, radio, or other approved Training Requirements (All AHA training: as Personal Protective Equipment (PPE)

communication device applicable; determined by SSHO) Hard Hat

• Barricades/postings • Access Control protocols/requirements Lifeline/Body Harness

• Radiological monitoring/sampling equipment • First aid/cardiopulmonary resuscitation Air Purifying Respirator

• Dust particulate IH monitoring/sampling equipment (CPR)/AED Supplied Air Respirator - SCBA

• Welding/hot work 1H monitoring/sampling equipment • Escorting requirements (delivery personnel, Supplied Respirator

• 1H monitoring/sampling equipment (heat stress, cold visitors, etc.) Gloves

stress, noise dosimetry, etc.) • PPE training

• PPE • Motor Vehicle Safety and Defensive Driving

• Handling aids (hand truck or cart, hand tool, jack, etc.) training

• Rebar caps or similar devices to prevent impalement • Spotter training

• Ground fault circuit interrupter (GFCI) protection • Electrical Safety Procedure required read

• Fire extinguishers • Tools and Equipment procedure required read

• Compressed gas cylinder storage • Fire extinguisher training

• Flammable storage • Hot work fire watch training

• Hot Worker/Hot Work Supervisor training

• Cold Stress briefing

• Heat Stress briefing

• Hearing Conservation Program training

• Bloodborne Pathogen/Exposure Control Plan

training

• HazCom training

You might also like

- JSA Demolition and DisposalDocument7 pagesJSA Demolition and Disposalm4l4ysia60% (5)

- AHA Excavation and Backfill 030922-BDocument3 pagesAHA Excavation and Backfill 030922-BYug Dobariya75% (4)

- Job Safety Analysis: 1 Confined Space Entry JSA ExampleDocument7 pagesJob Safety Analysis: 1 Confined Space Entry JSA Examplerashid zamanNo ratings yet

- JHA - Ladders TemplateDocument3 pagesJHA - Ladders TemplateShannon Williams100% (2)

- L Risk Assessment Code (RAC) MatrixDocument6 pagesL Risk Assessment Code (RAC) MatrixMario Marasigan50% (2)

- AHA Example For Scaffolding PDFDocument6 pagesAHA Example For Scaffolding PDFkaruna100% (1)

- AHA Temp Power - 03.03.2020 - RemarksDocument3 pagesAHA Temp Power - 03.03.2020 - RemarksJerry Word100% (1)

- Mercedes C-W205 Speaker ReplacementDocument13 pagesMercedes C-W205 Speaker ReplacementFredVerstraaten100% (2)

- The Chemistry of Process Development in Pharmaceutical Industry 1Document60 pagesThe Chemistry of Process Development in Pharmaceutical Industry 1Venugopal Rao Veeramaneni100% (1)

- Activity Hazard AnalysisDocument7 pagesActivity Hazard AnalysisAnthony MacatangayNo ratings yet

- Activity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityDocument6 pagesActivity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityAnthony MacatangayNo ratings yet

- AHA - Working On Slope RoofDocument2 pagesAHA - Working On Slope RoofTopsun Energy100% (1)

- 1 MobilizationDocument8 pages1 MobilizationAnthony Macatangay100% (1)

- P-985-SH-AHA-005, AHA For Earthwork (General Excavation)Document5 pagesP-985-SH-AHA-005, AHA For Earthwork (General Excavation)Patrick Bibila Ndansi75% (4)

- Cement Stucco (Exterior Application)Document3 pagesCement Stucco (Exterior Application)Alvene TagocNo ratings yet

- EPMS System Guide For Subcontractor - V1 2Document13 pagesEPMS System Guide For Subcontractor - V1 2AdouaneNassim100% (2)

- 14310A ch4 PDFDocument96 pages14310A ch4 PDFmiguelNo ratings yet

- AHA Ductbank InstallationDocument5 pagesAHA Ductbank InstallationYug DobariyaNo ratings yet

- 02-Aha Pavement RemovalDocument5 pages02-Aha Pavement Removalpascua.jpmNo ratings yet

- X.9.1 Safety AHADocument5 pagesX.9.1 Safety AHABunyamin SelimogluNo ratings yet

- AHA-003, ExcavationDocument5 pagesAHA-003, ExcavationBuddhika100% (2)

- ADA Ramp Installation 061322-BDocument11 pagesADA Ramp Installation 061322-BYug Dobariya0% (1)

- Jsa Confined Space EntryDocument11 pagesJsa Confined Space EntryNii AshiiiNo ratings yet

- AHA - Bucket Truck OperationDocument2 pagesAHA - Bucket Truck OperationJon CarloNo ratings yet

- MVL USA INC Site Telecomunication AHADocument7 pagesMVL USA INC Site Telecomunication AHALawrence adeleke OmisakinNo ratings yet

- Earth WorksDocument4 pagesEarth WorksLawrence adeleke OmisakinNo ratings yet

- Road Crushing Aha DuctDocument5 pagesRoad Crushing Aha DuctLawrence adeleke OmisakinNo ratings yet

- Activity Hazard Analysis For Erection and Dismantling of ScaffoldDocument2 pagesActivity Hazard Analysis For Erection and Dismantling of ScaffoldCherrycherry Betonio0% (1)

- KCF1-27 Activity Hazard METHOD STATEMENT FOR ABORTIVE WORK (DEMOLISHING)Document3 pagesKCF1-27 Activity Hazard METHOD STATEMENT FOR ABORTIVE WORK (DEMOLISHING)ansarabdul773No ratings yet

- Gadzoom Sample Activity Hazard Analysis TemplateDocument8 pagesGadzoom Sample Activity Hazard Analysis TemplateΝικολιδάκης ΒαγγέληςNo ratings yet

- Activity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Document4 pagesActivity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Anthony MacatangayNo ratings yet

- Activity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Document9 pagesActivity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Anthony Macatangay50% (2)

- Activity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Document14 pagesActivity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Anthony Macatangay100% (2)

- AHA Flushing & Disinfection of Water SupplyDocument5 pagesAHA Flushing & Disinfection of Water SupplyLawrence adeleke OmisakinNo ratings yet

- Confined Space Risk Assessment & Entry Permit (1) - 1Document4 pagesConfined Space Risk Assessment & Entry Permit (1) - 1MAB AliNo ratings yet

- AHA-006, Installation Underground UtilitiesDocument6 pagesAHA-006, Installation Underground UtilitiesBuddhikaNo ratings yet

- (En) Roof Repair Works 2019-03-14Document8 pages(En) Roof Repair Works 2019-03-14Anthony MacatangayNo ratings yet

- All Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicableDocument6 pagesAll Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicablecrnkarlosNo ratings yet

- Job Safety Analysis For Confined Space WorkDocument7 pagesJob Safety Analysis For Confined Space Work69housepartyNo ratings yet

- Above Ground Chilled Water Pipe InsulationDocument3 pagesAbove Ground Chilled Water Pipe InsulationLawrence adeleke OmisakinNo ratings yet

- P-985-SH-AHA-003. AHA For Outage Lock Our Tag OutDocument3 pagesP-985-SH-AHA-003. AHA For Outage Lock Our Tag OutPatrick Bibila NdansiNo ratings yet

- AHA Fixed Scaffold OnlyDocument7 pagesAHA Fixed Scaffold OnlyJon CarloNo ratings yet

- AHA-004, Earth Work Site PrepDocument6 pagesAHA-004, Earth Work Site PrepBuddhikaNo ratings yet

- Activity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityDocument2 pagesActivity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityYug DobariyaNo ratings yet

- AHA - DrywallDocument2 pagesAHA - DrywallJon CarloNo ratings yet

- X.9.1.a - Light Framed Steel Framing AHA - AnswerDocument7 pagesX.9.1.a - Light Framed Steel Framing AHA - AnswerBunyamin SelimogluNo ratings yet

- Installation of PVC Conduit and AccessoriesDocument5 pagesInstallation of PVC Conduit and AccessoriesLawrence adeleke OmisakinNo ratings yet

- AHA - Heavy Vehicle ParkingDocument16 pagesAHA - Heavy Vehicle Parkingvimal alaberahNo ratings yet

- P-985-SH-AHA-008, AHA For Demolision WorksDocument4 pagesP-985-SH-AHA-008, AHA For Demolision WorksPatrick Bibila NdansiNo ratings yet

- Column Casting AHADocument6 pagesColumn Casting AHALawrence OmisakinNo ratings yet

- AHA Example For ScaffoldingDocument7 pagesAHA Example For ScaffoldingVepxvia NadiradzeNo ratings yet

- AHA - Lead and Asbestos WorkDocument3 pagesAHA - Lead and Asbestos Workdg6xkzxsc9No ratings yet

- Excavation Permmit To WorkDocument3 pagesExcavation Permmit To WorkWilson Wambua0% (1)

- Electrical and Telecom WorksDocument7 pagesElectrical and Telecom WorksLawrence adeleke OmisakinNo ratings yet

- Backfilling and Compaction MVLDocument3 pagesBackfilling and Compaction MVLLawrence adeleke OmisakinNo ratings yet

- Generator Installation - AHADocument9 pagesGenerator Installation - AHATravis PhillipsNo ratings yet

- Waterline Tie-In With Existing Service AHADocument2 pagesWaterline Tie-In With Existing Service AHALawrence adeleke OmisakinNo ratings yet

- Lifting - CraneDocument9 pagesLifting - CraneR Sahadeo ReddyNo ratings yet

- AHA-001, MobilizationDocument9 pagesAHA-001, MobilizationBuddhikaNo ratings yet

- Activity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityDocument6 pagesActivity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityAnthony MacatangayNo ratings yet

- Jsa For Painting PipesDocument6 pagesJsa For Painting PipesGeorge OgbecheNo ratings yet

- Concrete Works AHADocument9 pagesConcrete Works AHALawrence adeleke OmisakinNo ratings yet

- Section 2 - Nichia Welding ConsumableDocument9 pagesSection 2 - Nichia Welding ConsumableLodyNo ratings yet

- Student Paperette CompetitionDocument15 pagesStudent Paperette CompetitionFrancis Tanaka MutonhodzaNo ratings yet

- HD Video USB DISK (Mini U8) ManualDocument5 pagesHD Video USB DISK (Mini U8) Manualthommcsi2013No ratings yet

- Current FlyerDocument5 pagesCurrent FlyerAdriana EstradaNo ratings yet

- Effects of Harmonic Distortion On Power SystemsDocument13 pagesEffects of Harmonic Distortion On Power SystemsJorge MazorraNo ratings yet

- Parker (Catalog) ValvesDocument20 pagesParker (Catalog) ValvesNickath BanuNo ratings yet

- Elastec TDS-118 Skimmer Brochure PDFDocument2 pagesElastec TDS-118 Skimmer Brochure PDFGiorgiana RosuNo ratings yet

- Macro and MacroprocessorsDocument92 pagesMacro and MacroprocessorsRitesh SharmaNo ratings yet

- PIRMH Rigging Techniques PIDocument9 pagesPIRMH Rigging Techniques PITri SubaktiNo ratings yet

- Parker Valve Mounting PatternsDocument6 pagesParker Valve Mounting PatternspeterNo ratings yet

- 13-Hole & String Volumes Calculation (1029.4)Document14 pages13-Hole & String Volumes Calculation (1029.4)Glen RoelNo ratings yet

- Mathematical Modelling of GTAW and GMAWDocument240 pagesMathematical Modelling of GTAW and GMAWferayNo ratings yet

- DB2 10 For Z - OS Technical OverviewDocument722 pagesDB2 10 For Z - OS Technical Overviewtstfree2001No ratings yet

- Mechanical Design Exit Exam Reviewer PDFDocument70 pagesMechanical Design Exit Exam Reviewer PDFRyan Togonon100% (1)

- Stability BookletDocument25 pagesStability BookletMad MaxNo ratings yet

- Rbe ProjectDocument15 pagesRbe Project1170 Jagdale AtharvNo ratings yet

- Oracle EAM Failure AnalysisDocument4 pagesOracle EAM Failure AnalysisDock N DenNo ratings yet

- Cut Videos With VLC Media PlayerDocument19 pagesCut Videos With VLC Media Playercalculus calculusNo ratings yet

- Material Testing Report - Phagwara-Hoshiarpur Section PDFDocument135 pagesMaterial Testing Report - Phagwara-Hoshiarpur Section PDFPrashantNo ratings yet

- Rcme 03.2022Document100 pagesRcme 03.2022Martijn HinfelaarNo ratings yet

- RX8 Manual InformationDocument49 pagesRX8 Manual InformationwillyhuaNo ratings yet

- Consistency As A Service: Trading Consistency For AvailabilityDocument4 pagesConsistency As A Service: Trading Consistency For AvailabilityPratik MahajanNo ratings yet

- Arduino Microcontroller Processing For Everyone-Steven F. BarrettDocument358 pagesArduino Microcontroller Processing For Everyone-Steven F. BarrettPedro LimaNo ratings yet

- 50-Hz Frequency PDFDocument14 pages50-Hz Frequency PDFOscar Galo100% (1)

- ResumeDocument4 pagesResumeRegina VrikkisNo ratings yet

- JIS G3101 2004 Chem MechDocument1 pageJIS G3101 2004 Chem Mechtonaoh2009No ratings yet