Professional Documents

Culture Documents

Mimake DB40270-07 - CFL-605RT - EN

Mimake DB40270-07 - CFL-605RT - EN

Uploaded by

sunnyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mimake DB40270-07 - CFL-605RT - EN

Mimake DB40270-07 - CFL-605RT - EN

Uploaded by

sunnyCopyright:

Available Formats

Software enhancing Mimaki cutting plotters performance

Possible to download from Mimaki Website !

Plug-in software for Illustrator and CorelDRAW Standard feature

The combination of FineCut/Coat9 and a register-mark sensor allows

calibrated inclination of coordinates or distance to assure accurate

cutting. The [Mark separation] function can also handle long media by

cutting it multiple times.

Creating four resister Cutting sheets with Cutting foam material Assembling every part

〈Main features〉 marks and printing with CFL-605RT for finishing!

● Direct and simple cutting from Adobe Illustrator

CFL-605RT

● [Multiple Cutting] function cuts the same place with different conditions such as pressure.

● [Line Separation] function prevents over-cutting of media.

● ID Cut auto-starts cutting after reading cut data during Print&Cut operation.

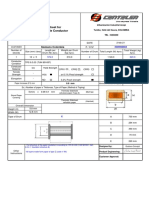

Specifications Supplies

Type Flatbed cutting plotter Product QTY per package

Product name Compatible product model Note

Driving method X/Y/Z/Θ 4 axes: DC servo motor number

Material holding method Air suctioning by a vacuum unit Pen holder One refill is attached

SPA-0183 1 CG/CF series

Maximum media 630mm×530mm for MITSUBISHI Compatible refill: SPC-0726

Cutting area 610mm×510mm Refill for MITSUBISHI

SPC-0726 10 CG/CF series Compatible holder: SPA-0183

Maximum cutting speed XY: 423 mm/s (45° angle direction) Z: 30 mm/s ballpoint pen

Maximum downforce pressure Eccentric cutter:1,000g / Tangential cutter and Creasing roller: 1,500 g Super hard edge One blade is attached

SPB-0086 5 CFL

Maximum media thickness Reciprocating cutter: 10 mm / Tangential cutter: 2 mm 2°x 10 mm as a standard accessory

Maximum media weight 10 kg / 22lb (This is not one-point-load strength) SPA-0260 Cutter holder 07L 1 CFL Standard accessory

Rapidly bringing ideas into shape

Repeatability 0.2 mm or lower (Material shrinkage is ignored) SPB-0043 High-speed steel blade 30° 200 CF series Standard accessory

Static

accuracy Distance accuracy Moving distance × ±0.2% or lower or ±0.1 mm or lower Larger value is applied SPB-0045 Carbide blade 30° 3 CF series

Original repetition accuracy 0.1 mm or lower Tangential

SPA-0261 1 CFL Standard accessory

A unit Attachable tools: Eccentric cutter, Pen Cutter holder 2Nα

B unit Attachable tools: Reciprocating/Tangential cutter, Creasing roller

ECCENTRIC CUTTER HOLDER C Offset value of cutter blade: 0.75mm

Command MGL-Ⅱc3 SPA-0267 1 CFL

WITH EDGE * The blade is not replaceable.

Interface USB 2.0(High Speed), RS-232C, Ethernet

Power specification Single phase AC 100–120 V/200–240 V, 50/60 Hz SPC-0785 Felt mat 605 1 CFL Standard accessory

Noise level 70 db or lower(The maximum level is generated while a reciprocating cutter or a vacuum blower is used.) SPC-0849 Cutting mat 605 1 CFL Standard accessory

Power consumption 500W SPC-0787 Adsorption sheet 1 CFL 100 m per roll

Dimensions (W×D×H) 1,320mm×1,045mm×1,100mm SPA-0262 Creasing holder L 1 CFL Standard accessory

Weight 109 kg or lower (Blower, 20 kg, included) SPB-0087 Creasing roller φ9 1 CFL Standard accessory

VCCI class A, CE marking (Machinery directive, RoHS directive), CB, UL Swivel Blade for PVC

Certifications SPB-0030 3 All cutting plotter models

60950-1, REACH, FCC class A with low-pressure

SPB-0006 Swivel Blade for reflecting sheet 2 All cutting plotter models

SPB-0007 Swivel Blade for fluorescent sheet 3 All cutting plotter models

SPB-0001 Swivel Blade for PVC sheet 3 All cutting plotter models

SPB-0003 Swivel Blade for small letters 3 All cutting plotter models

SPA-0001 Cutter holder 1 All cutting plotter models

SPA-0090 Cutter holder 1 All cutting plotter models Standard accessory

OPT-C0240 Blade tip adjuster 1 All cutting plotter models Loupe

OPT-C0066 Blade tip adjuster 1 All cutting plotter models Dial type

SPA-0163 Grease 1 All cutting plotter models Standard accessory

●Some of sample images in this catalog are artificial renderings.●Specifications, design and dimensions stated in this catalog may be subject to change without notice (for technical improvements

etc). ●The corporate names and merchandise names written on this catalog are the trademark or registered trademark of the respective corporations.●Inkjet printers print using extremely fine dots,

so colors may very slightly vary after replacement of the printing heads. Also note that if using multiple printer units, colors could vary slightly from one unit to other unit due to slight individual

differences. ●The specifications described in this catalog are as of September 2022.

2182-3 Shigeno-Otsu, Tomi-city, Nagano 389-0512, Japan

TEL:+81-268-64-2281

USA MIMAKI USA, INC. Europe MIMAKI EUROPE B.V.

Brazil MIMAKI BRASIL COMERCIO E IMPORTACAO LTDA Indonesia PT. MIMAKI INDONESIA

India MIMAKI INDIA PRIVATE LIMITED Australia MIMAKI AUSTRALIA PTY. LTD.

Taiwan MIMAKI ENGINEERING (TAIWAN) CO.,LTD. China SHANGHAI MIMAKI TRADING CO.,LTD.

Singapore MIMAKI SINGAPORE PTE. LTD. Thailand MIMAKI (THAILAND) CO.,LTD. DB40270-07

Eccentric cutter

Usage

example Compact flatbed cutting plotter

Creasing roller

LED UV curing flatbed inkjet printer

Easy mock-up production in combination with UV inkjet printer!

This combination offers a total solution for printing and production

of your original packages and creation of enclosed cushioning

Plus! support ID Cut!

materials. On-demand sample creation and small-lot production for

high-mix low-volume manufacturing reduce the cost and lead time Reading cut data with ID enables

auto-start cutting !

Reciprocating cutter to completion.

(vertical reciprocating cutting) It helps to further reduce work!

Smooth printing and cutting ensured by ID Cut function

&

Tangential cutter CUT

(Cutting materials by downforce pressure) What is ID Cut?

POINT

Vertical reciprocating Eliminating the need to select cut data before cutting.

cutter

While cutting the printings with variable data, the plotter auto- starts cutting once register marks are read.

System configuration Workflow Acquire the

Design PC Design PC data automatically

Cutting by downforce ②P&C Data

pressure

①Create Print&Cut data

RIP PC

RIP PC ③Print Data

Set the media without

minding media direction!

You might also like

- CNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WDocument16 pagesCNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WSot DesignNo ratings yet

- Assure Model Lesson PlanDocument2 pagesAssure Model Lesson PlanNicole Hernandez71% (17)

- PE11 - MELC 4 Module 4 - Week7 For Teacher PDFDocument24 pagesPE11 - MELC 4 Module 4 - Week7 For Teacher PDFRommel Cando80% (5)

- N1 FitnessDocument84 pagesN1 FitnessDiana PruneanNo ratings yet

- Kenneth Clark PDFDocument12 pagesKenneth Clark PDFsuryanandiniNo ratings yet

- XIAOMIDocument10 pagesXIAOMISrinath Saravanan75% (4)

- Cutting Head BrochureDocument8 pagesCutting Head BrochureAdrian Valentin Cortes RamirezNo ratings yet

- Compact Flatbed Cutting Plotter ... : Finecut8 Software Maximizes Product PerformanceDocument2 pagesCompact Flatbed Cutting Plotter ... : Finecut8 Software Maximizes Product PerformanceEdgarMorenoNo ratings yet

- ks132 Ps GBDocument2 pagesks132 Ps GBNelson Andrade VelasquezNo ratings yet

- HGS Introduction PDFDocument23 pagesHGS Introduction PDFirfan bNo ratings yet

- B Cutting Plotter With Servo MotorDocument1 pageB Cutting Plotter With Servo MotorEpica PrintNo ratings yet

- A100M 3D Fiber Laser Cutting Head Users ManualDocument19 pagesA100M 3D Fiber Laser Cutting Head Users Manualmohamad eslamiNo ratings yet

- Revised GTP Ab CableDocument1 pageRevised GTP Ab Cableer.manishnhpcNo ratings yet

- nc20 Nano Cut TurningDocument5 pagesnc20 Nano Cut TurningferNo ratings yet

- Brosur Rhinotec Cutting Machine Plus BepDocument4 pagesBrosur Rhinotec Cutting Machine Plus BepIndonesiaPrint MataramNo ratings yet

- Product Specifications: Specification Sheet 12 1/4" (311 MM)Document1 pageProduct Specifications: Specification Sheet 12 1/4" (311 MM)WHWENNo ratings yet

- RZ dh608 Engl Web PDFDocument2 pagesRZ dh608 Engl Web PDFOliveira eletricidadeNo ratings yet

- F-Series F1612 & F2630Document16 pagesF-Series F1612 & F2630Drew DouglasNo ratings yet

- Summary of Cutting Data For Profile Surface - Torical/radiusDocument4 pagesSummary of Cutting Data For Profile Surface - Torical/radiusAndrei MihaiNo ratings yet

- 4 Different Base Assemblies For Added Versatility: Easy-to-CustomizeDocument2 pages4 Different Base Assemblies For Added Versatility: Easy-to-CustomizeOnagro XNo ratings yet

- TM-U220 Feb18Document2 pagesTM-U220 Feb18SuhariNo ratings yet

- Craftrobo Brochure LowDocument2 pagesCraftrobo Brochure LowRiaz AhmadNo ratings yet

- ks172 Ps GBDocument2 pagesks172 Ps GBNelson Andrade VelasquezNo ratings yet

- RS984 - BEX-T1 Spec SHTDocument2 pagesRS984 - BEX-T1 Spec SHTAqui FrkNo ratings yet

- Roland 900 Datasheet enDocument2 pagesRoland 900 Datasheet enEmbagraf TINo ratings yet

- JRF RMSD62522Document16 pagesJRF RMSD62522Duraid FalihNo ratings yet

- E Compac T: JR3051T Recipro SawDocument2 pagesE Compac T: JR3051T Recipro SawhartonopkuNo ratings yet

- Raytools Cutting 2022.9Document32 pagesRaytools Cutting 2022.9ibrahim toptasNo ratings yet

- VF HVRBDocument12 pagesVF HVRBNAHRUDIN KOLIĆNo ratings yet

- SBT Inch-1Document16 pagesSBT Inch-1Rodolfo AlbinoNo ratings yet

- Laser Cutting Machine Infinity f1Document6 pagesLaser Cutting Machine Infinity f1Divyaba DodiyaNo ratings yet

- SpindleSpeed & FeedRateDocument4 pagesSpindleSpeed & FeedRateMohamed Ben SalemNo ratings yet

- Spindle Speeds & Feed Rates: Page B1 Techsoft 2D Design Tools Guide WWW - Denford.co - UkDocument4 pagesSpindle Speeds & Feed Rates: Page B1 Techsoft 2D Design Tools Guide WWW - Denford.co - UkBerheNo ratings yet

- ks92 Ps GBDocument2 pagesks92 Ps GBNelson Andrade VelasquezNo ratings yet

- GPS Report 2020-03-18Document3 pagesGPS Report 2020-03-18AlexNo ratings yet

- 200-1 Rich MillDocument20 pages200-1 Rich MillReginaldo MatosNo ratings yet

- WalterGPS Report 2023-12-22Document4 pagesWalterGPS Report 2023-12-22lanhtraitim81No ratings yet

- Summary of Cutting Data For Int. Cylindrical Surface: Material DetailsDocument3 pagesSummary of Cutting Data For Int. Cylindrical Surface: Material DetailsTurcanu ClaudiuNo ratings yet

- 移动式破碎机S ZR450JC规格说明书Document1 page移动式破碎机S ZR450JC规格说明书walk111No ratings yet

- 移动式破碎机S ZR450JC规格说明书 PDFDocument1 page移动式破碎机S ZR450JC规格说明书 PDFwalk111No ratings yet

- Samurai 120H BrochureDocument17 pagesSamurai 120H BrochurehoriaNo ratings yet

- DDL-7000A Series: Energy-Saving Servomotor Is Installed in The Direct-Drive StyleDocument2 pagesDDL-7000A Series: Energy-Saving Servomotor Is Installed in The Direct-Drive StyleYM TsaiNo ratings yet

- Báo Cáo Test DaikouDocument1 pageBáo Cáo Test Daikoutuananhngo19096No ratings yet

- Bosch07 Wood MetalCutting WebDocument90 pagesBosch07 Wood MetalCutting WebKaze KunNo ratings yet

- BCP Technical ConstructionDocument22 pagesBCP Technical ConstructionKarthik KarthikNo ratings yet

- ISCAR. Turning and Threading ToolsDocument466 pagesISCAR. Turning and Threading ToolsJuan Carlos Encalada100% (2)

- Kongsberg C: The New Dimension in Digital FinishingDocument37 pagesKongsberg C: The New Dimension in Digital FinishingCésarMarinNo ratings yet

- High-Speed Flexible Mounter: Lowest Cost of OwnershipDocument4 pagesHigh-Speed Flexible Mounter: Lowest Cost of Ownershipbella chenNo ratings yet

- Shantui SD32Document2 pagesShantui SD32Oscar DelgadoNo ratings yet

- Bopp Matt Film, Both Sides Heat Sealable, Treated: PropertiesDocument2 pagesBopp Matt Film, Both Sides Heat Sealable, Treated: PropertiesMatteo DMNo ratings yet

- MP B158aDocument6 pagesMP B158aSurhidayat Ibn MusthafaNo ratings yet

- Mimaki Sij320uv enDocument2 pagesMimaki Sij320uv enalekapeks kuntulNo ratings yet

- Im-022-21 Oc 4500008668 Siemens (Col)Document1 pageIm-022-21 Oc 4500008668 Siemens (Col)Gustaavo Caarvaajal HeerreraNo ratings yet

- kc202 Ps GBDocument2 pageskc202 Ps GBNelson Andrade VelasquezNo ratings yet

- BP Roo: Product SpecificationsDocument1 pageBP Roo: Product SpecificationsWHWENNo ratings yet

- AlimasterDocument12 pagesAlimastert.meynoldsNo ratings yet

- Professional Cutting Pliers: 5-Inch, Side CutterDocument1 pageProfessional Cutting Pliers: 5-Inch, Side CutternormNo ratings yet

- Jigs and Fixtures FDM - EN A4 Buyers GuideDocument4 pagesJigs and Fixtures FDM - EN A4 Buyers GuideChittakorn SrongtohsrisakulNo ratings yet

- Flat Cylinder DZF-50-80-P-A: Data SheetDocument1 pageFlat Cylinder DZF-50-80-P-A: Data SheettapiaescobarjuandiegoNo ratings yet

- FL HighfeedDocument48 pagesFL Highfeedbob smithNo ratings yet

- ERDWICH M465/3: Erdwich Three-Shaft-ShredderDocument2 pagesERDWICH M465/3: Erdwich Three-Shaft-ShredderVedant KapoorNo ratings yet

- GS-3000 GS-2000: SeriesDocument28 pagesGS-3000 GS-2000: SeriessunhuynhNo ratings yet

- Buffered Anaesthetic S: DR Shazeena QaiserDocument25 pagesBuffered Anaesthetic S: DR Shazeena QaiserShazeena OfficialNo ratings yet

- Algo Trading BasicsDocument15 pagesAlgo Trading BasicsRajvin DongaNo ratings yet

- Zabala Auto SupplyDocument7 pagesZabala Auto SupplyLeighsen VillacortaNo ratings yet

- Just Say No To Big Brother's Smart Meters: The Latest in Bio-Hazard Technology by Orlean KoehleDocument148 pagesJust Say No To Big Brother's Smart Meters: The Latest in Bio-Hazard Technology by Orlean KoehleVen GeanciaNo ratings yet

- Parliament Denies Amidu's AllegationsDocument3 pagesParliament Denies Amidu's Allegationsmyjoyonline.comNo ratings yet

- Rle Week 7 Bed Bath DocsDocument2 pagesRle Week 7 Bed Bath DocsCHRISTINE KEITH NEPOMUCENONo ratings yet

- Medicinal Benefits of HoneyDocument8 pagesMedicinal Benefits of HoneyTauseef AshrafNo ratings yet

- Ce24 Lesson 2Document63 pagesCe24 Lesson 2movieboxpro482No ratings yet

- Air Is Allowed To Flow From A Large Reservoir ThroDocument3 pagesAir Is Allowed To Flow From A Large Reservoir Throsid202pkNo ratings yet

- Overtime in NursingDocument5 pagesOvertime in NursingallisonNo ratings yet

- Grail Quest 4Document123 pagesGrail Quest 4Tamás Viktor TariNo ratings yet

- LEARNING ACTIVITY SHEET-CHEM 1 q1 Week 1 StudentDocument6 pagesLEARNING ACTIVITY SHEET-CHEM 1 q1 Week 1 StudentJhude JosephNo ratings yet

- Fy2023 FWS Budget RequestDocument8 pagesFy2023 FWS Budget RequestinforumdocsNo ratings yet

- Virtue Ethics-: Prepared By: Lagman, Joshua Punzalan, Marlon Lopez, Alaine Carl Sicat, Ariel Medrano, Kervin TroyDocument40 pagesVirtue Ethics-: Prepared By: Lagman, Joshua Punzalan, Marlon Lopez, Alaine Carl Sicat, Ariel Medrano, Kervin TroyKyla RodriguezaNo ratings yet

- Subcontract Agreement (Jenesis) V.1.1Document4 pagesSubcontract Agreement (Jenesis) V.1.1sigit l.prabowoNo ratings yet

- Nep Schools - VZM Dist - 26072021Document27 pagesNep Schools - VZM Dist - 26072021WHO IS ITNo ratings yet

- Foss Lab ManualDocument34 pagesFoss Lab ManualArunKumarIjjadaNo ratings yet

- TracebackDocument3 pagesTracebackCristi LazărNo ratings yet

- Artigo Hambate BaDocument19 pagesArtigo Hambate BaRayza GiardiniNo ratings yet

- Mes 007Document4 pagesMes 007dr_ashishvermaNo ratings yet

- Function of The Criticism by TS EliotDocument18 pagesFunction of The Criticism by TS EliotRISHIKA SINHANo ratings yet

- Ceramic TilesDocument340 pagesCeramic TilesMihai ȘtefanNo ratings yet

- Business Analytics AssignmentDocument3 pagesBusiness Analytics AssignmentDevansh RaiNo ratings yet

- Group Poject CONTRACT ESTIMATION BaruDocument21 pagesGroup Poject CONTRACT ESTIMATION BarualnzNo ratings yet

- Integrated NLP Train The Trainer BootcampDocument8 pagesIntegrated NLP Train The Trainer BootcampHitesh ParmarNo ratings yet