Professional Documents

Culture Documents

Low Pressure Epoxy Injection

Low Pressure Epoxy Injection

Uploaded by

Jet ToledoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Low Pressure Epoxy Injection

Low Pressure Epoxy Injection

Uploaded by

Jet ToledoCopyright:

Available Formats

MATERIAL & METHOD STATEMENT

Type of Defect : Crack

(Map, craze, drying or plastic shrinkage)

Repair Technique : Low Pressure Epoxy Injection

INJECTION SYRINGE

This outline describes the filling of cracks by low pressure injection of cracks with epoxy resin.

1. Preparation of the surface for basic work.

2. Deciding the location for installing rack

3. Seal the region around the crack

4. Attaching the plate for fixing crack

5. Injection Epoxy

6. Finishing Work

I. Preparation of the surface for basic work.

Check the state, width and depth of crack before working

and decide work process. First of all, remove the dust and

foreign substances around the region of sealing by using

spatula or wire brush and if there are oily substance including

oil attached on the surface, remove the dirt on the surface

completely using air compressor.

II. Deciding the location for installing rack

Decide the suitable interval for installation of plate for fixing

straight washer depending on the state and depth of cracks.

Generally, it is attached at about 20cm’s interval and interval

maybe enlarged according to the state of crack.

III. Seal the region around the crack

In order for the epoxy injection material not be leaked, seal the

region along the crack evenly with epoxy mortar by using a spatula.

IV. Attaching the plate for fixing crack

Apply adhesive mortar to the below side of straight washer’s

edge evenly rolling sealant and attach straight washer on the

installation location as twisting straight washer a little .

(Hardening takes about 24 hours at 25 degree Celsius)

V. Injection Epoxy

After mixing epoxy injection material 2 to 1 in stirring container

(small basin) completely and put about 30cc of epoxy injection

material into injection capsule and then hang rubber band on

the straight washer

*When you hang injection capsule with rubber band, support the

other side to prevent leaking due to the raising of the other side.

*If there is air in the injection, expel the air.

VI. Finishing Work

Remove injection capsule and straight washer after confirming

hardening of injection material. Clean the surface by surface

grinder,spatula and grinder and finish it as almost original state

by using of one coat crack covering material, or paint (after applying)

and other material.

*If you use torch to remove injection capsule, epoxy sealant and

straight washer, it may cause the risk of fire and burning epoxy.

Be careful.

Client Name:

Job Name :

CRS

Concrete

Repair Date :

Systems

You might also like

- BAUTISTA, DARLENE JOY C. - 2CE-C - Activity 1-Prelim TermDocument24 pagesBAUTISTA, DARLENE JOY C. - 2CE-C - Activity 1-Prelim TermDARLENE JOY C. BAUTISTA67% (3)

- Uk Drawing Jan09 PDFDocument17 pagesUk Drawing Jan09 PDFMirko Flores Jimenez100% (1)

- O & M Manual For BoilerDocument146 pagesO & M Manual For BoilerAshwani Dogra100% (15)

- 2945 - 002 - Technical Specification - Epoxy Flooring PDFDocument3 pages2945 - 002 - Technical Specification - Epoxy Flooring PDFChandrakant Kulkarni100% (1)

- Method Statement For Concrete RepairDocument3 pagesMethod Statement For Concrete RepairShahril Zainul100% (8)

- Methodology For Groove Filling in VDFDocument2 pagesMethodology For Groove Filling in VDFDeepak Patil100% (1)

- Microsoft Word - MasterInject 1320 User GuideDocument11 pagesMicrosoft Word - MasterInject 1320 User GuideMaamar BergerNo ratings yet

- Composite Materials and MechanicsDocument2 pagesComposite Materials and MechanicsroscillaNo ratings yet

- PQC PATCH Repair Methodology Kashedi ProjectDocument8 pagesPQC PATCH Repair Methodology Kashedi ProjectDeven PatleNo ratings yet

- Nitowrap Method StatementDocument10 pagesNitowrap Method StatementBalasubramanian AnanthNo ratings yet

- Fosroc GMS Nitoplate LaminateDocument6 pagesFosroc GMS Nitoplate Laminatejohn paulNo ratings yet

- Basic Acrylic Material Handling & Installation GuidelinesDocument5 pagesBasic Acrylic Material Handling & Installation GuidelinesMario J SoaresNo ratings yet

- Remedy For ColsDocument3 pagesRemedy For ColsMohammedNo ratings yet

- What Are The Methods of Concrete Crack RepairDocument10 pagesWhat Are The Methods of Concrete Crack RepairsadanandNo ratings yet

- Method For Concrete Repair - 11.12.13Document3 pagesMethod For Concrete Repair - 11.12.13imran11novNo ratings yet

- General Repair MethodologyDocument11 pagesGeneral Repair MethodologyAnhera enterpriseNo ratings yet

- What Are The Methods of Concrete Crack RepairDocument11 pagesWhat Are The Methods of Concrete Crack RepairEvello MercanoNo ratings yet

- Repair SOP - Rebar Loose Bonding 1Document1 pageRepair SOP - Rebar Loose Bonding 1shahrilzainul77No ratings yet

- Especificaciones Del Suelo Segun HovairDocument7 pagesEspecificaciones Del Suelo Segun HovairCarlos Gallardo LagosNo ratings yet

- 240Document1 page240mirfanjpcgmailcomNo ratings yet

- DR Fixit Epoxy Injection Grout 64 1Document3 pagesDR Fixit Epoxy Injection Grout 64 1Rajaram RamanNo ratings yet

- Chapter 12Document22 pagesChapter 12Erick JanNo ratings yet

- Car Parking System - 17.04.13Document13 pagesCar Parking System - 17.04.13raj06740100% (1)

- WMS Concrete Repair WorkDocument8 pagesWMS Concrete Repair WorkRepl microsoft, PuneNo ratings yet

- Epoxy Fiberglass Pipe Wrap Directions: SnopsisDocument4 pagesEpoxy Fiberglass Pipe Wrap Directions: SnopsisdroidsNo ratings yet

- 0 - Sika Grout With Sikadur 732 Epoxy Bonding AgentDocument4 pages0 - Sika Grout With Sikadur 732 Epoxy Bonding AgentRA SamsonNo ratings yet

- Pavement Repair Manual RAZONDocument9 pagesPavement Repair Manual RAZONshrikrishna rathodNo ratings yet

- Epoxy Application GuideDocument24 pagesEpoxy Application GuideAhmed Emad AhmedNo ratings yet

- Concrete RepairDocument7 pagesConcrete RepairjjahaddinNo ratings yet

- Method Statement For Crack RepairingDocument5 pagesMethod Statement For Crack RepairingZaheer Hussain100% (1)

- C. 7.4 - Construction MethodsDocument4 pagesC. 7.4 - Construction MethodsJhoycee MiclatNo ratings yet

- Methodology RehabilationDocument3 pagesMethodology RehabilationbvsubramanyamNo ratings yet

- TDS DR Fixit Epoxy Injection Grout Eng 01-04-10Document3 pagesTDS DR Fixit Epoxy Injection Grout Eng 01-04-10sarvagya.tftNo ratings yet

- Quikrete Guide Specification: Quikrete® Concrete Bonding Adhesive (No. 9902)Document3 pagesQuikrete Guide Specification: Quikrete® Concrete Bonding Adhesive (No. 9902)Gonzalo AlvarezNo ratings yet

- Euclid Chemical Dry Shake Floor Hardeners Application Instructions Installation Instructions B26664Document2 pagesEuclid Chemical Dry Shake Floor Hardeners Application Instructions Installation Instructions B26664John ShaneNo ratings yet

- Method Statement For Structural StrengtheningDocument2 pagesMethod Statement For Structural StrengtheningRudrabir Ghanti100% (2)

- Epoxy Painting MethodDocument3 pagesEpoxy Painting MethodKaram MoatasemNo ratings yet

- Can Fast Installation and Maintenance ManualDocument25 pagesCan Fast Installation and Maintenance ManualTongxiang Shanhe Composite Materials Co., Ltd.No ratings yet

- BT Chapter 2Document6 pagesBT Chapter 2temanidalex14No ratings yet

- TamRez 220-220TG (Epoxy Binder and - Injection Resin) MS R00 (1) - 1 - 1Document2 pagesTamRez 220-220TG (Epoxy Binder and - Injection Resin) MS R00 (1) - 1 - 1Patrick manuelNo ratings yet

- BestPractices Thermoplastic Sep08Document10 pagesBestPractices Thermoplastic Sep08geverett2765No ratings yet

- Gunite & ShortcreteDocument146 pagesGunite & ShortcreteSushil DhunganaNo ratings yet

- RC RepairDocument4 pagesRC RepairPcEngNo ratings yet

- Guide Specification For Sealtight Liqui-Hard: Concrete Densifier and Chemical Hardener CompoundDocument4 pagesGuide Specification For Sealtight Liqui-Hard: Concrete Densifier and Chemical Hardener CompoundPriyesh DubeyNo ratings yet

- FSEL Strain Gage For Concrete Rev 00Document7 pagesFSEL Strain Gage For Concrete Rev 00jbmune6683No ratings yet

- Concrete Pavement RepairDocument10 pagesConcrete Pavement Repairgorafd449No ratings yet

- MS For Crack RectificationDocument5 pagesMS For Crack RectificationThushara WickramasuriyaNo ratings yet

- Zerokorr - Method StatementDocument8 pagesZerokorr - Method StatementAshif AkhtarNo ratings yet

- Apron Concrete Repair Method R01Document19 pagesApron Concrete Repair Method R01ayhanarman0% (1)

- KORAFIT Adhesive Is The Really Reliable ConnectionDocument2 pagesKORAFIT Adhesive Is The Really Reliable ConnectionhudileksonoNo ratings yet

- Dr. Fixit Epoxy Injection GroutDocument3 pagesDr. Fixit Epoxy Injection GroutChandan MirajkarNo ratings yet

- Aci Rap-1Document7 pagesAci Rap-1Mauricio De Stefani100% (1)

- Government Engineering College Civil Engineering Department: Internship Project 2021-22Document23 pagesGovernment Engineering College Civil Engineering Department: Internship Project 2021-22PranavRajsinh ZalaNo ratings yet

- Solvent Jointing of CPVC PipesDocument20 pagesSolvent Jointing of CPVC PipesHamza HashimNo ratings yet

- Solvent Jointing of CPVC PipesDocument20 pagesSolvent Jointing of CPVC PipesHamza Hashim100% (1)

- Method Statement For Concrete Slab Crack RepairsDocument5 pagesMethod Statement For Concrete Slab Crack RepairsJayakoteswarara Reddy100% (1)

- Dr. Fixit Pidiseal Ps 41gDocument2 pagesDr. Fixit Pidiseal Ps 41gRb143No ratings yet

- Anticorossive Epoxy FlooringDocument2 pagesAnticorossive Epoxy Flooringtejas_tNo ratings yet

- ACI Crack RepairDocument6 pagesACI Crack RepairelmerbarrerasNo ratings yet

- Work Methodology For VDFDocument4 pagesWork Methodology For VDFrahulNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- 0005-0006 Residential Masonry 00Document6 pages0005-0006 Residential Masonry 00Jet ToledoNo ratings yet

- WFC 600Document4 pagesWFC 600Jet ToledoNo ratings yet

- MasterRoc STS 1512 - MY v1 - 01.2024Document2 pagesMasterRoc STS 1512 - MY v1 - 01.2024Jet ToledoNo ratings yet

- 0007 Residential Metal Works 00Document3 pages0007 Residential Metal Works 00Jet ToledoNo ratings yet

- 0020 Residential Dry Wall 00Document2 pages0020 Residential Dry Wall 00Jet ToledoNo ratings yet

- 0001 Residential General Preliminaries 01Document4 pages0001 Residential General Preliminaries 01Jet ToledoNo ratings yet

- 0004 Residential Formworks 00Document8 pages0004 Residential Formworks 00Jet ToledoNo ratings yet

- RC Column - Axially Loaded - NSCP by RGCEDocument3 pagesRC Column - Axially Loaded - NSCP by RGCEJet ToledoNo ratings yet

- 0014 Residential Painting 00Document4 pages0014 Residential Painting 00Jet ToledoNo ratings yet

- 0003 Residential Concreting 01Document8 pages0003 Residential Concreting 01Jet ToledoNo ratings yet

- 0016 Residential Plumbing 00Document39 pages0016 Residential Plumbing 00Jet ToledoNo ratings yet

- 0000 Residential Compiled 00Document128 pages0000 Residential Compiled 00Jet ToledoNo ratings yet

- Page 5 - VC - TCDocument1 pagePage 5 - VC - TCJet ToledoNo ratings yet

- Excel FunctionsDocument9 pagesExcel FunctionsJet ToledoNo ratings yet

- Page 6 - Locker Room - PerspectiveDocument1 pagePage 6 - Locker Room - PerspectiveJet ToledoNo ratings yet

- Gate Elevations: Front Elevation C1Document1 pageGate Elevations: Front Elevation C1Jet ToledoNo ratings yet

- Page 4 - Electrical Layout (Court)Document1 pagePage 4 - Electrical Layout (Court)Jet ToledoNo ratings yet

- Page 3 - Light PostDocument1 pagePage 3 - Light PostJet ToledoNo ratings yet

- Maghaway PDF Final1Document10 pagesMaghaway PDF Final1Jet ToledoNo ratings yet

- Footing - Axially Loaded - NSCP by RGCEDocument5 pagesFooting - Axially Loaded - NSCP by RGCEJet ToledoNo ratings yet

- Page 2 - Perimeter FenceDocument1 pagePage 2 - Perimeter FenceJet ToledoNo ratings yet

- RC Column - Axially Loaded - NSCP by RGCEDocument3 pagesRC Column - Axially Loaded - NSCP by RGCEJet ToledoNo ratings yet

- Production RatesDocument2 pagesProduction RatesJet Toledo100% (1)

- RC Beam - Singly - NSCP 2015 by RgceDocument4 pagesRC Beam - Singly - NSCP 2015 by RgceJet ToledoNo ratings yet

- Rebar EstimateDocument2 pagesRebar EstimateJet ToledoNo ratings yet

- Equipment RatesDocument4 pagesEquipment RatesJet ToledoNo ratings yet

- One Way Slab DesignDocument2 pagesOne Way Slab DesignKenneth CajefeNo ratings yet

- Quicseal 703: PVC WaterstopDocument4 pagesQuicseal 703: PVC WaterstopJet ToledoNo ratings yet

- QS 701 220811 PDFDocument3 pagesQS 701 220811 PDFJet ToledoNo ratings yet

- Quicseal Fabric: DescriptionDocument2 pagesQuicseal Fabric: DescriptionJet ToledoNo ratings yet

- Pds Hempel's Silicone Aluminium 56910 En-GbDocument2 pagesPds Hempel's Silicone Aluminium 56910 En-GbjakelowNo ratings yet

- DB Wiring DiagramDocument1 pageDB Wiring DiagrammhofuNo ratings yet

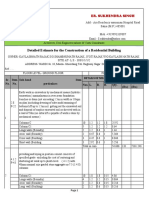

- Detailed Estimate For The Construction of A Residential BuildingDocument8 pagesDetailed Estimate For The Construction of A Residential BuildingSukhendra SinghNo ratings yet

- Viton FDADocument6 pagesViton FDAAlejandro ZagalNo ratings yet

- Bolted Truss Column Connections - xlsx-29!14!2020Document34 pagesBolted Truss Column Connections - xlsx-29!14!2020Vineetha KrishnanNo ratings yet

- TALAT Lecture 3703: Stretch FormingDocument13 pagesTALAT Lecture 3703: Stretch FormingCORE MaterialsNo ratings yet

- Curbe MCXDocument4 pagesCurbe MCXNico NicoNo ratings yet

- Ventec VT 47Document3 pagesVentec VT 47kpNo ratings yet

- PVengDocument3 pagesPVengDiana SoareNo ratings yet

- 415V LVAC Switchborad Ver1Document7 pages415V LVAC Switchborad Ver1g.HtrughtreNo ratings yet

- DVS Technical Codes On Plastics Joining TechnologiesDocument11 pagesDVS Technical Codes On Plastics Joining TechnologiesEmanuel NovoaNo ratings yet

- UTP Raiilways BrochureDocument8 pagesUTP Raiilways Brochurekamals55No ratings yet

- Computational Fluid Dynamics in Turbulent Flow Applications: August 2016Document25 pagesComputational Fluid Dynamics in Turbulent Flow Applications: August 2016kvvp94No ratings yet

- Vl5091-Mems and NemsDocument2 pagesVl5091-Mems and NemsPALANIVEL RAJAN0% (1)

- Zantingh Flue Gas CondenserDocument2 pagesZantingh Flue Gas CondenserMarco Alberto Cardona MedelNo ratings yet

- Site Analysis and Quality PDFDocument4 pagesSite Analysis and Quality PDFmnmNo ratings yet

- Whisper Flo XF 3 PhaseDocument16 pagesWhisper Flo XF 3 Phasehargote_2No ratings yet

- Tedds Engineering Library (GB)Document213 pagesTedds Engineering Library (GB)CSEC Uganda Ltd.100% (2)

- Mac 2007 (60hz)Document26 pagesMac 2007 (60hz)airmacmex100% (1)

- DCC 3113 Nota Bab 10Document6 pagesDCC 3113 Nota Bab 10Alif KarimiNo ratings yet

- Catenary Catlogue PDFDocument19 pagesCatenary Catlogue PDFRamiro FelicianoNo ratings yet

- Duct InsulationDocument3 pagesDuct InsulationShashi Kant KumarNo ratings yet

- 18 Fisher-Regulators CatalogDocument110 pages18 Fisher-Regulators CatalogEnrique MurgiaNo ratings yet

- Construction Drawings Church-LayoutDocument24 pagesConstruction Drawings Church-Layoutiunm2638650% (2)

- AF C-Clamp Beam Clamp AF JR Top Beam Clamp AF Wide Mouth Top Beam ClampDocument4 pagesAF C-Clamp Beam Clamp AF JR Top Beam Clamp AF Wide Mouth Top Beam ClampWaqas NasirNo ratings yet

- 319 Docol Product ProgramDocument2 pages319 Docol Product Programchristos032No ratings yet