Professional Documents

Culture Documents

Alpha Pir Duct Data Sheet 2023

Alpha Pir Duct Data Sheet 2023

Uploaded by

Ruben Elvis Piza MerchanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alpha Pir Duct Data Sheet 2023

Alpha Pir Duct Data Sheet 2023

Uploaded by

Ruben Elvis Piza MerchanCopyright:

Available Formats

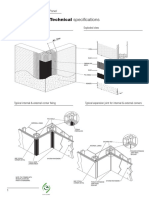

Technical Data Sheet

AD-PIR-20-10

GENERAL CHARACTERISTICS

Aluminum / polyurethane sandwich panel composed of expanded polyurethane rigid foam board covered on both

sides by an aluminum foil, suitable for the construction of air ducts in heating and air-conditioning installations.

TECHNICAL CHARACTERISTICS

Dimension of the panel 4000 x 1200 mm or 3000 x 1200

Thickness of the panel 20 mm

Thickness of the aluminum 80/80 microns- Embossed- Embossed

Density of the foam 50±3 kg/m3

Weight of the panel 1.71 kg/m2

Aluminum finishing embossed / embossed

The external side of the aluminum is lacquered with a 3g/m2 of

corrosion resistant and ultraviolet rays protection

INSULATING CHARACTERISTICS

Insulating Material: Closed cell rigid expanded polyurethane foam, CFC and HCFC free.

Density 50±3 kg/m3.

Thermal Conductivity: 0.023 at 10oC

Closed Cell: >95%

The aluminum foils covering the panel assure a perfect vapor barrier.

FIRE REACTION

Class O, according to British Standard 476 Part 6 and 7.

Class A, according to ASTM E84

EN 13501: B-S1-d0

TEMPERATURE OF USE

The air ducts made with AD-PIR-20-10 panels can be used in installations with temperatures ranging from -80oC

to +110oC, always operating. No relevant reduction of the insulating, chemical or physical characteristics of the panel

will be observed.

PRESSURE OF USE

The air ducts made with AD-PIR-20-10 panels can be used in installations with pressures up to 1750 Pa,

always inaccordance with the Alpha construction guidelines.

SPECFICATION OF USE

The air ducts fabricated by using AD-PIR-20-10 panels can be installed in plants:

with air speed up to 15 m/s

with pressures up to 1750 Pa

indoor

You might also like

- Air Handling Unit PDFDocument16 pagesAir Handling Unit PDFizani_idrisNo ratings yet

- Technical Specifications of EXIN Lightweight Building PanelDocument6 pagesTechnical Specifications of EXIN Lightweight Building Panelandrewb20050% (1)

- Atcoatr 111Document3 pagesAtcoatr 111farid bashaNo ratings yet

- Air Handling UnitDocument44 pagesAir Handling Unitpostboxsg100% (1)

- Bostik Paneltack HM Dekton Tds en 2020Document5 pagesBostik Paneltack HM Dekton Tds en 2020Miguel ZuzaNo ratings yet

- Mcquay Dmahu Catalogue - 1.0Document55 pagesMcquay Dmahu Catalogue - 1.0Vishal Mohite100% (2)

- KlimallcoDocument8 pagesKlimallcoshahzad32552372No ratings yet

- PAL Polyurethane Panel Spec 31102008Document4 pagesPAL Polyurethane Panel Spec 31102008Mohd Fahmie Bin MustapaNo ratings yet

- D 8 Acoustics - Job Specification (D10-PMC-JSF-011)Document6 pagesD 8 Acoustics - Job Specification (D10-PMC-JSF-011)aftabshekh624462No ratings yet

- FRS Electrical Panel Spec EOIDocument20 pagesFRS Electrical Panel Spec EOITravis WoodNo ratings yet

- Polyethylene InsulationDocument2 pagesPolyethylene InsulationJeghi100% (1)

- TD Pre-Insulated Duct: Michael Zheng Send Message View BlogDocument1 pageTD Pre-Insulated Duct: Michael Zheng Send Message View Blogalmig200No ratings yet

- Panels LeafletDocument3 pagesPanels Leafletshahul hameedNo ratings yet

- Catalogue of Roof SheetDocument8 pagesCatalogue of Roof Sheetcvsatheeh1No ratings yet

- Catalogue DM AhuDocument54 pagesCatalogue DM AhurianaNo ratings yet

- McQuay AHUDocument77 pagesMcQuay AHUJustine Morris Arcayna Refuerzo50% (2)

- Panelex DataDocument1 pagePanelex DataTimothy GordonNo ratings yet

- Type Xka Be260142c98aaad9Document8 pagesType Xka Be260142c98aaad9vladimirkulf2142No ratings yet

- Aneka PanelDocument20 pagesAneka PanelWahyu YudhoNo ratings yet

- 03 en PSI Kebu Anti Corrosion TapesDocument13 pages03 en PSI Kebu Anti Corrosion Tapesmechanical_engineer11No ratings yet

- Duct InsulationDocument9 pagesDuct Insulationphyolwin ooNo ratings yet

- Spec Geocell PDFDocument9 pagesSpec Geocell PDFsankhaginNo ratings yet

- 39HQM Guide SpecificationsDocument8 pages39HQM Guide SpecificationsAyman KamelNo ratings yet

- Piping and Equipment InsulationDocument4 pagesPiping and Equipment InsulationttshareefNo ratings yet

- Technopanel en 20141023Document39 pagesTechnopanel en 20141023GeorgiStoyanovNo ratings yet

- Detailed Specification PE Casing Jacket With Standard UIP System 1) GeneralDocument3 pagesDetailed Specification PE Casing Jacket With Standard UIP System 1) GeneralMina MagdyNo ratings yet

- Thermal InsulationDocument2 pagesThermal InsulationPrabhat DhekaleNo ratings yet

- Hvac Duct Insulation SpecificationDocument2 pagesHvac Duct Insulation SpecificationPrabhat DhekaleNo ratings yet

- PDA Compliance ReportDocument4 pagesPDA Compliance ReportScribdTranslationsNo ratings yet

- TROSTEN Mechanical Specification - AHUDocument6 pagesTROSTEN Mechanical Specification - AHUBalaji JenarthananNo ratings yet

- UP PWD WP SpecDocument9 pagesUP PWD WP Specsanjay kumarNo ratings yet

- Technical Characteristics and Reference Standards: Zintek® in The Building IndustryDocument2 pagesTechnical Characteristics and Reference Standards: Zintek® in The Building Industryapi-112807037No ratings yet

- Sectional TankDocument4 pagesSectional TankGT2013No ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07500-1 RoofingDocument8 pagesITCC in Riyadh Residential Complex J10-13300 07500-1 RoofinguddinnadeemNo ratings yet

- FibranCatalog PDFDocument16 pagesFibranCatalog PDFIonut JilNo ratings yet

- 10 - Acoustic Insulation - 2Document3 pages10 - Acoustic Insulation - 2Anonymous BbZceWkVnNo ratings yet

- Thermal Expansion CalcsDocument6 pagesThermal Expansion CalcsGokulnath TgNo ratings yet

- Product Catalogue: Modular Air Handling Unit Senator 25Document4 pagesProduct Catalogue: Modular Air Handling Unit Senator 25József DankóNo ratings yet

- Complaince Statement - 01 - CMS AF-TDCS050404523 - R04Document7 pagesComplaince Statement - 01 - CMS AF-TDCS050404523 - R04Arun CDNo ratings yet

- Lariphon Ing PDFDocument1 pageLariphon Ing PDFmanolito55No ratings yet

- Aeropan 2017 GBDocument20 pagesAeropan 2017 GBPaulo DiasNo ratings yet

- Purmo-Technical-catalogue-UFH HKS 06 2013 en PLDocument36 pagesPurmo-Technical-catalogue-UFH HKS 06 2013 en PLanna_pomaranskaNo ratings yet

- TDS-Tembutil IF GBDocument2 pagesTDS-Tembutil IF GBHung Mai VanNo ratings yet

- (Application of Wall and Insulation Materials On Green Building) (Availability and Costs) (Abdelrahman Ababneh) (Dr. Abdullah Alshorman)Document3 pages(Application of Wall and Insulation Materials On Green Building) (Availability and Costs) (Abdelrahman Ababneh) (Dr. Abdullah Alshorman)Ashraf Ahmed OqoolNo ratings yet

- Alumna Specification For Mono PanelsDocument1 pageAlumna Specification For Mono Panelsrohith eticalaNo ratings yet

- DESMOFLEX TOP COΑΤ v2 ENDocument3 pagesDESMOFLEX TOP COΑΤ v2 ENprestigebuild888No ratings yet

- Hameg Hm1004-3 Oscilloscope UmDocument8 pagesHameg Hm1004-3 Oscilloscope UmprasongNo ratings yet

- Product Data Sheet: Product: Ks1000 SF EcosafeDocument4 pagesProduct Data Sheet: Product: Ks1000 SF EcosafeSamuel RICEANNo ratings yet

- Technical Data Sheet2Document1 pageTechnical Data Sheet2riteish singhNo ratings yet

- Duct Work Method StatementDocument5 pagesDuct Work Method StatementAla Makram Sunna0% (1)

- Duct Work Method StatementDocument5 pagesDuct Work Method StatementHai LeNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationDocument5 pagesITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationuddinnadeemNo ratings yet

- Product Selected: Hydroproof Pmma T5 16mmø 2X49W Lamp With A2 BallastDocument1 pageProduct Selected: Hydroproof Pmma T5 16mmø 2X49W Lamp With A2 BallastJairo Enrique Duran AcostaNo ratings yet

- Roof Insulation - NewDocument4 pagesRoof Insulation - NewasijitengineeringNo ratings yet

- Easy Duct PDFDocument8 pagesEasy Duct PDFSameera Sri VidurangaNo ratings yet

- Isocop Rev 07-11-2012 - ENGLDocument15 pagesIsocop Rev 07-11-2012 - ENGLAlexandru RucareanuNo ratings yet

- Cold StoreDocument32 pagesCold StoreAl Jamaheer Gen TrdNo ratings yet

- Zeco PID CatalogDocument15 pagesZeco PID CatalogDarshan BhayaniNo ratings yet

- FILTER Aeropac CAMFILDocument2 pagesFILTER Aeropac CAMFILRuben Elvis Piza MerchanNo ratings yet

- Reporte Sie7eDocument11 pagesReporte Sie7eRuben Elvis Piza MerchanNo ratings yet

- VariGreenControls FlyerDocument1 pageVariGreenControls FlyerRuben Elvis Piza MerchanNo ratings yet

- Quotation AFMS CommentsDocument8 pagesQuotation AFMS CommentsRuben Elvis Piza MerchanNo ratings yet

- Nest Thermostat e Install GuideDocument20 pagesNest Thermostat e Install GuideRuben Elvis Piza MerchanNo ratings yet

- Instructions IOMs CleanSeal Exhaust IntegrityDocument2 pagesInstructions IOMs CleanSeal Exhaust IntegrityRuben Elvis Piza MerchanNo ratings yet