Professional Documents

Culture Documents

Anexo 10 - Ficha Tecnica Venteo de Mergencia 4pulg

Anexo 10 - Ficha Tecnica Venteo de Mergencia 4pulg

Uploaded by

lquinter75Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anexo 10 - Ficha Tecnica Venteo de Mergencia 4pulg

Anexo 10 - Ficha Tecnica Venteo de Mergencia 4pulg

Uploaded by

lquinter75Copyright:

Available Formats

Model 244 Emergency Vents | 4-inch

SPECIFICATION SHEET

Application

UL Listed emergency vent (pressure relief only) used on aboveground

storage tanks, as a code requirement, to help prevent the tank from

becoming over-pressurized and possibly rupturing if ever exposed

to fire. The vent must be used in conjunction with a “normal vent”.

Correct application of this vent requires proper vent size and selection

for the tank system in order to meet the specific venting capacity

requirements.

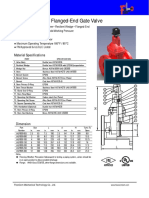

Fig. 244OF

The new design increases protection against weather, improves

UL

manufacturability and helps limit and control dust accumulation. 2583

Code Compliance

When properly sized for the tank, this vent will conform to the

requirements of the International Fire Code; National Fire Code of

Canada; National Fire Protection Agency—NFPA 20, 30, 30A, 31,

37, 110; Petroleum Equipment Institute—PEI RP200, PEI RP800;

Underwriters Laboratories Inc.—UL-142, UL-2085, UL-2244;

Underwriters Laboratories of Canada—CAN/ULC S601, CAN/

ULC S602, CAN/ULC S652

Approvals

Fig. 244OM

California Air Resource Board (CARB) Phase 1 Enhanced Vapor

Recovery (EVR) AST Certified Products (VR-402-B) EVR ; UL

Underwriters Laboratories Inc. UL-2583 2583

WARNING: DO NOT FILL OR UNLOAD FUEL FROM A STORAGE TANK UNLESS IT IS CERTAIN THAT THE TANK VENTS WILL

OPERATE PROPERLY. Morrison tank vents are designed only for use on shop fabricated atmospheric tanks which have been built and tested in

accordance with UL 142, NFPA 30 & 30A, and API 650 and in accordance with all applicable local, state, and federal laws. In normal operation,

dust and debris can accumulate in vent openings and block air passages. Certain atmospheric conditions such as a sudden drop in temperature,

below freezing temperatures, and freezing rain can cause moisture to enter the vent and freeze which can restrict internal movement of vent

mechanisms and block air passages. All storage tank vent air passages must be completely free of restriction and all vent mechanisms must have

free movement in order to insure proper operation. Any restriction of airflow can cause excessive pressure or vacuum to build up in the storage

tank, which can result in structural damage to the tank, fuel spillage, property damage, fire, injury, and death. Monthly inspection, and immediate

inspection during freezing conditions, by someone familiar with the proper operation of storage tank vents, is required to insure venting devices

are functioning properly before filling or unloading a tank.

Item numbers on next page...

Model 244 Emergency Vents | 4-inch (continued)

SPECIFICATION SHEET

Overall

Item Number A B C D E F G Diameter Height Weight Screen

244O--0100 AV 4” 131,700 8 I A AL 7.1” 3.4” 10.0

244O--0170 AV 4” 131,700 16 I A AL 7.1” 4.29” 18.0

244O--0170AVEVR 4” 131,700 16 I B AL 7.1” 4.29” 18.0

EVR

244OB-0100 AV 4” 131,700 B 8 I A AL 7.1” 3.4” 10.0

244OB-0170 AV 4” 131,700 B 16 I A AL 7.1” 4.29” 18.0

244OS-0100 AV 4” 117,160 8 I A AL 7.1” 3.4” 10.0 S SPECIFICATION OPTIONS:

A—Size (inches)

244OS-0170 AV 4” 117,160 16 I A AL 7.1” 4.29” 18.0 S

B—Venting capacity / SCFH at 2.5 P.S.I.

244OS-0170AVEVR 4” 117,160 16 I B AL 7.1” 4.29” 18.0 S C—Mounting connection: Female N.P.T. (BLANK);

EVR Male N.P.T.(M); Flanged (F); BSP (B)

244OSBSP0100 AV 4” 117,160 B 8 I A AL 7.1” 3.4” 10.0 S

D—Pressure settings: 8, 16 oz/in2. Pressure required

244OF-0170 AV † 4” 131,700 F 16 I A AL 9” 3.4” 20.0 to open vent.

244OF-0170AVEVR 4” 131,700 F 16 I B AL 9” 3.4” 20.0 E—Cover: Cast iron powder coated (I) or

EVR Cast iron nickel plated (N)

244OF-0600 AV † 4” 131,700 F 8 I A AL 9” 2.5” 11.0

F—Seat material: Viton A (A) or Viton B (B)

244OF-0600 AVE 4” 131,700 F 8 I B AL 9” 2.5” 11.0 G—Body material: Aluminum (AL)

244OFS0170 AV 4” 117,160 F 16 I A AL 9” 3.4” 20.0 S Diameter—Dimension across vent (inches)

Height—Dimension from base to top when closed

244OFS0600 AV 4” 117,160 F 8 I A AL 9” 2.5” 11.0 S (inches)

244OM-0100 AV 4” 131,700 M 8 I A AL 7.1” 4.79” 10.0 Weight—Shipping weight (lbs)

Screen (3 mesh stainless steel)—Yes (S), No (blank)

244OM-0170 AV 4” 131,700 M 16 I A AL 7.1” 5.70” 19.0

244OM-0170AVEVR 4” 131,700 M 16 I B AL 7.1” 5.70” 19.0 Bolt—Zinc plated steel

EVR

244OM-0170 AVNP 4” 131,700 M 16 N A AL 7.1” 5.70” 19.0

244OMB0100 AV 4” 131,700 B 8 I A AL 7.1” 4.79” 10.0

244OMB0170 AV 4” 131,700 B 16 I A AL 7.1” 5.70” 19.0

244OMBS0170 AV 4” 117,160 B 16 I A AL 7.1” 5.70” 19.0 S

244OMS0100 AV 4” 117,160 M 8 I A AL 7.1” 4.79” 10.0 S

244OMS0170 AV 4” 117,160 M 16 I A AL 7.1” 5.70” 19.0 S

244OMS0170AVEVR 4” 117,160 M 16 I B AL 7.1” 5.70” 19.0 S

EVR

244OMSB0100 AV 4” 117,160 B 8 I A AL 7.1” 4.79” 10.0 S

Flange = 9” OD; eight (8) .75” diameter holes on 7.5” diameter B.C.

†

Indicates model is available in a kit.

Size Item Number Flanged Kits Weight (lbs)

244OF-04080 AK Includes 244OF-0600 AV vent, flange adaptor, gasket, and nuts/bolts N/A

4"

244OF-04160 AK Includes 244OF-0170 AV vent, flange adaptor, gasket, and nuts/bolts N/A

570 E. 7th Street, P.O. Box 238 | Dubuque, IA 52004-0238

t. 563.583.5701 | 800.553.4840 | f. 563.583.5028

www.morbros.com

June 2021

You might also like

- Ed Soja ThirdspaceDocument193 pagesEd Soja Thirdspacepoemadelsol69% (13)

- 3500 Start Up and Commissioning ChecklistDocument23 pages3500 Start Up and Commissioning Checklistlquinter75100% (2)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Happy Teachers Intro PDFDocument8 pagesHappy Teachers Intro PDFObscure33% (6)

- Ampgard Medium Voltage Panel CatalogueDocument2 pagesAmpgard Medium Voltage Panel Cataloguefire123123No ratings yet

- Abn ExtractionDocument2 pagesAbn Extractionuttamkumar_mondol_5No ratings yet

- Activity 1: Making Words Meaningful Directions: GROUP WORK. Working in Triads, Answer The Question About The ItalicizedDocument3 pagesActivity 1: Making Words Meaningful Directions: GROUP WORK. Working in Triads, Answer The Question About The ItalicizedKristian Lloyd Evardo100% (4)

- Anexo 11 - Ficha Tecnica Veneto de Emergencia 10pulgDocument2 pagesAnexo 11 - Ficha Tecnica Veneto de Emergencia 10pulglquinter75No ratings yet

- Complete 245 Vent Listing SS 1Document2 pagesComplete 245 Vent Listing SS 1budi hanindoNo ratings yet

- F607RWSFPDocument1 pageF607RWSFPleonardo ramirezNo ratings yet

- Nibco 609Document1 pageNibco 609juanbcarrizales08No ratings yet

- Valvula CompuertaDocument1 pageValvula CompuertaRobertoNo ratings yet

- Nibco 14 and 16 Gate ValvesDocument1 pageNibco 14 and 16 Gate ValvesNarendra Reddy BhumaNo ratings yet

- Lug & W Afer Style Butter Fly V AlvesDocument4 pagesLug & W Afer Style Butter Fly V AlvesMalissa ClarkNo ratings yet

- C900 BLUE: Vinyltech AwwaDocument2 pagesC900 BLUE: Vinyltech AwwaRaul ArmendarizNo ratings yet

- Wafer Style Twin Disc Ductile Iron Check ValveDocument1 pageWafer Style Twin Disc Ductile Iron Check ValveAlbeiro LeivaNo ratings yet

- 300 PSI CWP Iron Body Gate Valves: 300 PSI/20 .6 Bar Non-Shock Cold Working PressureDocument1 page300 PSI CWP Iron Body Gate Valves: 300 PSI/20 .6 Bar Non-Shock Cold Working PressureayaNo ratings yet

- 250 PSI WWP Iron Body Gate ValvesDocument1 page250 PSI WWP Iron Body Gate Valvesstalin vNo ratings yet

- 4 Inch Morisson Emergency VentDocument1 page4 Inch Morisson Emergency VentSudeep SNo ratings yet

- Valvetop D-Series With AS-interface: Installation, Operation & Maintenance ManualDocument16 pagesValvetop D-Series With AS-interface: Installation, Operation & Maintenance ManualAdeel RazaNo ratings yet

- 250 PSI CWP Iron Body Gate Valve: 250 PSI/17.2 Bar Non-Shock Cold Working PressureDocument1 page250 PSI CWP Iron Body Gate Valve: 250 PSI/17.2 Bar Non-Shock Cold Working PressureStephanie AdkinsNo ratings yet

- Ficha NibcoDocument1 pageFicha NibcoMilagros Camacho HuizaNo ratings yet

- Order-No.: 849 Installation and Dismantling Device For Pipes in BAIO Sockets DN 80-200Document2 pagesOrder-No.: 849 Installation and Dismantling Device For Pipes in BAIO Sockets DN 80-200CalinGiosanNo ratings yet

- ECON 3-Piece Firesafe Ball ValveDocument6 pagesECON 3-Piece Firesafe Ball ValveKunming WangNo ratings yet

- F607RWDocument1 pageF607RWEli Antonio Cruz FloresNo ratings yet

- Ductile Iron Gate ValveDocument4 pagesDuctile Iron Gate ValveShuvro Soikot0% (1)

- LDWD3510C8FPDocument1 pageLDWD3510C8FPanuarsgNo ratings yet

- Manual - HAKI Universal S4 AL - INTDocument28 pagesManual - HAKI Universal S4 AL - INTThomas RisingNo ratings yet

- 6ga Series MODELS 610F, 611F, 620F & 621F Iron Gate Valve Installation Operation Maintenance GuideDocument8 pages6ga Series MODELS 610F, 611F, 620F & 621F Iron Gate Valve Installation Operation Maintenance Guidekeroppifrog647No ratings yet

- Quick UnionsDocument2 pagesQuick UnionsCARLOSELSOARES100% (1)

- Topworx Valvetop D-Series With GO Switches ManualDocument20 pagesTopworx Valvetop D-Series With GO Switches ManualJuan LuisNo ratings yet

- Descarga 1er Paso Mercer 91-52j11t84u1Document16 pagesDescarga 1er Paso Mercer 91-52j11t84u1Alberto Esau Reyes CruzNo ratings yet

- NRV - IntervalveDocument2 pagesNRV - IntervalveRajkishorNo ratings yet

- Firsa Catalog 2009Document53 pagesFirsa Catalog 2009alankar2050No ratings yet

- Valvula OS&Y 2-1.2 y Mas (175 Psi WWP)Document1 pageValvula OS&Y 2-1.2 y Mas (175 Psi WWP)Paul Gide Lopez ZarateNo ratings yet

- SPO Subsea Applications v003Document2 pagesSPO Subsea Applications v003Baskar KannaiahNo ratings yet

- Fire Protection Gate Valves - OMDocument11 pagesFire Protection Gate Valves - OMmaged.iccNo ratings yet

- Intervalve-Butterfly ValvesDocument4 pagesIntervalve-Butterfly ValvesMurli RamchandranNo ratings yet

- KG-900-W-350 - 350 PSI CWP Iron Body Grooved Silent Check ValveDocument1 pageKG-900-W-350 - 350 PSI CWP Iron Body Grooved Silent Check ValveIlyas sagriNo ratings yet

- Flowcom - NRS - BridadaDocument1 pageFlowcom - NRS - BridadaErickNo ratings yet

- Installation and Maintenance Guidelines For Nibco Cast Iron, Alloy Iron and Ductile Iron Gate Valves 2" To 24" Class 125, 150, 175 and 250Document10 pagesInstallation and Maintenance Guidelines For Nibco Cast Iron, Alloy Iron and Ductile Iron Gate Valves 2" To 24" Class 125, 150, 175 and 250Ajesh kumarNo ratings yet

- Valvula Compuerta NibcoDocument1 pageValvula Compuerta NibcoRobertoNo ratings yet

- Blowout Preventers: Invention Unique Design & Extraordinary CraftsmanshipDocument40 pagesBlowout Preventers: Invention Unique Design & Extraordinary CraftsmanshipRoxxana Roxxana1990No ratings yet

- Butterfly ValveDocument14 pagesButterfly ValveSingSareblakKanaManahNo ratings yet

- New Gen Trunnion Soft Seat Ball ValveDocument7 pagesNew Gen Trunnion Soft Seat Ball ValvedirtylsuNo ratings yet

- Especificaciones Del Codo 90 Color OcreDocument24 pagesEspecificaciones Del Codo 90 Color OcreMario JoséNo ratings yet

- VCF01 - 350PSI Flanged Swing Check ValveDocument1 pageVCF01 - 350PSI Flanged Swing Check ValveErickNo ratings yet

- Catalog (1) API 600 GATE VALVES PDFDocument140 pagesCatalog (1) API 600 GATE VALVES PDFMohsen HalweniNo ratings yet

- Isv B50Document5 pagesIsv B50deborazoletNo ratings yet

- Valvula Check de Una y MediaDocument1 pageValvula Check de Una y MediaRobertoNo ratings yet

- ComparativeDocument190 pagesComparativeSatish BabuNo ratings yet

- FLUSH BOTTOM VALVE SERIES 500nDocument5 pagesFLUSH BOTTOM VALVE SERIES 500nvedant.pokharkarNo ratings yet

- Series 3 & 4 U BonnetedDocument9 pagesSeries 3 & 4 U BonnetedBaskaran RathinamNo ratings yet

- Flanged NRS Gate Valve: Main Parts and MaterialDocument1 pageFlanged NRS Gate Valve: Main Parts and Materialmourad laatatNo ratings yet

- Compuerta RoscadaDocument1 pageCompuerta RoscadajuandenismamanihuancaNo ratings yet

- FT918BBI (1) Cheque NipcoDocument1 pageFT918BBI (1) Cheque NipcoRobertoNo ratings yet

- KW900WFPDocument1 pageKW900WFPAlfredo BravoNo ratings yet

- F607OTSFP Válvula de Compuerta NibcoDocument1 pageF607OTSFP Válvula de Compuerta NibcoAlberth Rojas CastellanosNo ratings yet

- NR-040 FS: Removable Cover Check Valves For Reclaimed Water, Wastewater and SludgeDocument4 pagesNR-040 FS: Removable Cover Check Valves For Reclaimed Water, Wastewater and SludgeOleg ShkolnikNo ratings yet

- FlowCon EVS Tech 08.2013Document7 pagesFlowCon EVS Tech 08.2013Jeff Anderson CollinsNo ratings yet

- Uni FlangeDocument8 pagesUni FlangeBobbie RuckNo ratings yet

- En ArpolDocument44 pagesEn ArpoldenemeuserNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- Emotron Option AFE Manual 01-5076-01r1 English PDFDocument66 pagesEmotron Option AFE Manual 01-5076-01r1 English PDFlquinter75No ratings yet

- ACS2000 CatalogoDocument34 pagesACS2000 Catalogolquinter75No ratings yet

- VFXL69-250-54CE (Rev.3 - 25.08.16) PDFDocument26 pagesVFXL69-250-54CE (Rev.3 - 25.08.16) PDFlquinter75No ratings yet

- Orion RD1 Instruction ManualDocument4 pagesOrion RD1 Instruction Manuallquinter75No ratings yet

- Emotron VFX2-0 - Manual - 01-5326-01r4 - EN PDFDocument244 pagesEmotron VFX2-0 - Manual - 01-5326-01r4 - EN PDFlquinter75No ratings yet

- 2724079-01 DLC Photometric T&e Lm-79 (Bs100led4sa70wwt41)Document15 pages2724079-01 DLC Photometric T&e Lm-79 (Bs100led4sa70wwt41)lquinter75No ratings yet

- Uptime Tiers Vs TIA942Document1 pageUptime Tiers Vs TIA942rethier1No ratings yet

- ZOLLERN-Broschuere ZAT Drewerksgetriebe ENGDocument20 pagesZOLLERN-Broschuere ZAT Drewerksgetriebe ENGMomin G.S.100% (1)

- TDI Turbo T20 Product SheetDocument2 pagesTDI Turbo T20 Product Sheetandistwn99No ratings yet

- What Is ABM Strand?: Acquire Basic Industry SkillsDocument6 pagesWhat Is ABM Strand?: Acquire Basic Industry SkillsAngelaNo ratings yet

- Developing A Global Transport Costs Dataset - UNCTAD - Paper85 - Ser-Rp-2022d5 - enDocument68 pagesDeveloping A Global Transport Costs Dataset - UNCTAD - Paper85 - Ser-Rp-2022d5 - enLean ZechNo ratings yet

- PH301: Microprocessor Architecture and Programming (3-0-0-6)Document2 pagesPH301: Microprocessor Architecture and Programming (3-0-0-6)NiKhil ShindeNo ratings yet

- Good Things Come To Those Who Wait, But Only Those Things Left by Those Who Hustle' by Abraham LincolnDocument12 pagesGood Things Come To Those Who Wait, But Only Those Things Left by Those Who Hustle' by Abraham Lincolnsiva_mmNo ratings yet

- 2.07 Ripple Factor, PIV, TUF, Form Factor, Peak FactorDocument1 page2.07 Ripple Factor, PIV, TUF, Form Factor, Peak FactorVamsiMadupu100% (2)

- Control ComponentsDocument74 pagesControl ComponentsJothi PriyaNo ratings yet

- GeeCee VenturesDocument1 pageGeeCee VenturesNaveen kishore100% (1)

- BRC V9 - ArDocument180 pagesBRC V9 - Ars.salah07100% (1)

- Presentations For Tensor CategoriesDocument34 pagesPresentations For Tensor CategoriesEstadistica EPSONo ratings yet

- CSE 1004: Network and Communication (L23+L24) Lab - Assignment Mid TermDocument22 pagesCSE 1004: Network and Communication (L23+L24) Lab - Assignment Mid TermMajety S LskshmiNo ratings yet

- 12 BytesDocument9 pages12 BytesAlinfa1No ratings yet

- Documents ShakeebDocument15 pagesDocuments ShakeebNaukriNo ratings yet

- The Mechanica LUniverse - Mechanics and HeatDocument8 pagesThe Mechanica LUniverse - Mechanics and Heatjmgg5808No ratings yet

- Lecture 01Document27 pagesLecture 01Tahminul IslamNo ratings yet

- Macmillan English 3 Unit 5 Worksheet Teaching Notes: 4 MarksDocument2 pagesMacmillan English 3 Unit 5 Worksheet Teaching Notes: 4 MarksCarmenNo ratings yet

- Mau Dich Hoc Ba Cap 3 Sang Tieng AnhDocument7 pagesMau Dich Hoc Ba Cap 3 Sang Tieng Anhlinhphung2306No ratings yet

- 3rdquarter SummativeDocument6 pages3rdquarter SummativeJig Pael FaburadaNo ratings yet

- Veterinary Mittalam NEW 220.30 SQ - MM 15.12Document130 pagesVeterinary Mittalam NEW 220.30 SQ - MM 15.12Panneerselvam KarunanidhiNo ratings yet

- Connection Lost - Modern FamilyDocument3 pagesConnection Lost - Modern FamilydanNo ratings yet

- Unit 2 Definition of Knowledge and Its Basic AssumptionsDocument9 pagesUnit 2 Definition of Knowledge and Its Basic AssumptionssubhayudanNo ratings yet

- Navigating Digital Ethiopia A Look Into EthiopiaDocument4 pagesNavigating Digital Ethiopia A Look Into Ethiopiabekyab53No ratings yet

- Organizational Structure of PRDocument127 pagesOrganizational Structure of PRgopalmeb6368No ratings yet

- People StrategyDocument2 pagesPeople StrategyRiddhi SinghalNo ratings yet