Professional Documents

Culture Documents

DT 5

DT 5

Uploaded by

mahmoudmasri630Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DT 5

DT 5

Uploaded by

mahmoudmasri630Copyright:

Available Formats

ADEDEJI Bukola Peter, et. al.

International Journal of Engineering Research and Applications

www.ijera.com

ISSN: 2248-9622, Vol. 11, Issue 5, (Series-III) May 2021, pp. 07-11

RESEARCH ARTICLE \ OPEN ACCESS

Design and Fabrication of a Portable Concrete Mixer

ADEDEJI Bukola Peter, Abiola Aderinto, Akano Isaac, Akinrinola Temitayo,

Olafimihan Emmanuel.

(Department of Mechanical Engineering, Ladoke Akintola University of Technology,Nigeria

ABSTRACT

In major construction works such as building, roads and bridges, it is highly important to make use of concrete

for rigidity of the structure. Hence, the design and fabrication of portable concrete mixer is essential at a low

cost in which an average man can afford. The portable concrete mixer consists of an electric motor which

transmits power via the belt pulley system to the mixing drum. The drum does the major parts with the shaft,

and paddles. The efficiency of the designed Portable Concrete Mixer is approximately 95%. It has a capacity of

233.05Kg/m3.Materials used in the fabrication were carefully selected, considering suitability factors and

economic consideration.

Keywords - Concrete, Concrete Mixer, design

---------------------------------------------------------------------------------------------------------------------------------------

Date of Submission: 01-05-2021 Date of Acceptance: 15-05-2021

---------------------------------------------------------------------------------------------------------------------------------------

I. INTRODUCTION The new development has led to the

The Romans are general credited as being invention of better performance concrete mixer,

the first Concrete Engineers, but archaeological Nabataean concrete mixer, Mortal concrete mixer,

evidence says otherwise. Archaeologists have found Mobile concrete mixer and Cement mixer. The

a type of concrete dating to 6500BC, when Stone above-mentioned machines are complex and

Age Syrians used permanent fire pit for heating and expensive. Therefore, there is a need for a portable,

cooking. The newly discovered technology was simple and less expensive mixer that can perform the

widely used in Syrian as centered lime burning kills same operation but at minimal cost with an

were constructed, concrete floors and water proofing appropriate output. To overrule the afore-mentioned

cisterns. problem, a portable concrete mixer is designed and

The Egyptians used cement as far back as fabricated.

2500BC. Some scholars believed that a cementing

material produced from either lime concrete or burnt 1.1 Development of portable concrete Mixer

gypsums was used in forming the great pyramid at These concrete mixers are designed to meet the

Giza. The earliest known illustration (dating to about needs of small batch requirements or where large

1950 B.C.) of concrete being used on Egypt is ready mixed truck delivery is impossible.

shown in a mural on a wall Thebes. Archeologists They have several job applications, transport

have long thought that the Egyptians were masters of concrete from ready-mix plant to job, can be

the stone as stone artifacts (hard stone vessels, operated as a concrete batch plant at the site or they

statues) made of metamorphic schist, diorite basalt can be added to rental equipment market.

were produced. These smooth and glossy stone

artifacts bear no trace of tool marks. Some 1.2 Components of Portable Concrete Mixer.

archeologists believe that the ancient Egyptian artists The portable mixer consists of the

knew how to convert ores and minerals into a following essential parts:

mineral binder for producing stone artifacts. They i. Electric motor (prime mover)

believed that many of the Egyptian status were not ii. The mixing drum

carved from rock, but rather were cast in moulds, iii. The belt and pulley

and are synthetic stone status. Some years this age, iv. Conical head

the mixing of concrete components for construction v. Rotation shaft

works are often done using hand tools such as vi. Miscellaneous items such as bolts, nuts and

shovels and spade. This has proved tedious, slow washers

and less efficient. Thereafter, a Kenmore washing vii. Bearings

machine tube, was also made. viii. Paddles

www.ijera.com DOI: 10.9790/9622-1105030711 7|Page

ADEDEJI Bukola Peter, et. al. International Journal of Engineering Research and Applications

www.ijera.com

ISSN: 2248-9622, Vol. 11, Issue 5, (Series-III) May 2021, pp. 07-11

ix. Angle iron tripod stand transmit the power from the prime mover to the

x. prime mover seat rotation shaft because of the following reasons.

i. It can easily be installed and removed

ii. The belt has the ability to reduce the shock

1.2.2 Uses of Portable Concrete Mixers when the machine is started.

The portable concrete mixer can be use or iii. The drive is positive, because the slip

found applicable in the following are: between the belt and the pulley groove is

i. Commercial and residential fence negligible.

installation

ii. Street, sidewalk curb and gutter 1.4.2 Pulley Analysis

repair Assuming a factor of safety of 1.2 and availability of

iii. Concrete footings a 2hp electric motor, the power available for driving

iv. Special mixers (latex, mortax, etc) the shaft is approximately 1.53kw. Using standard

v. Sea wall, swimming pool belt type and the corresponding size, we have

construction and repair Top width (b) – 17mm

vi. Farm and ranch use Thickness (t) – 11mm

Groove angle of pulley – 380 (KURMI and GUPTA

Advantages of Portable Concrete Mixer 2003)

The major advantages of the machine are Speed of the electric motor, Se = 600rpm

highlighted below: Calculated speed of the shaft, S= 247rpm

i. It is less expensive in terms of Diameter of pulley on the electric motor, De=70mm

cost of production Diameter of pulley on the shaft, Ds = 170mm

ii. It is easy to maintain

iii. It can be easily dismantled and 1.4.3 Determination of angle of contact, angle of

assembled for troubleshooting wrap and length of the belt.

iv. It has less vibration and noise For the belt: the angle of contact ‘β’ is given as

during the operation when β = sin-1(D-d) or sin-1 (R-r)

compare with the complex type 2c 2c

v. It can easily be operated without Where: β = angle of contact

stress D = diameter of the large pulley

d = diameter of the small pulley

1.3. Principal of Operation of a Portable R = radius of the large pulley

Concrete Mixer r = radius of the small pulley

The portable mixer operates with the The angle of wrap is given as:

conversion of electrical energy from the electric α1=Л 2 β = 1800 – 2 sin-1 D-d OR

motor to the kinetic energy of the belt and the pulley 2c

transmitted to the driven shaft. 1800 – 2 sin-1 R-r

The rotation of the output shaft of the C

electric motor is transmitted through the pulley and Where α1 = angle of wrap of the large pulley

belt to the driven shaft. The rotation shaft of the αs= angle of wrap of the small pulley

concrete mixer equally rotates the paddles since they From figure 3.1, the total length of the belt can be

are welded together. The rotation action of the calculated as follows:

paddles due to the rotation shaft causes the mixing L = Arc GJE + EF +Arc FKH + HG

of the concrete components by sweeping at about an = 2 (Arc JE + EF+ Arc FK)

angle of 300 to the shaft. Sand, stones, cement and The power transmitted through the belt from the

quantified amount of water ready to be mixed are electric motor to the driven shaft is

fed through the conical head into the mixing drum. P = (T1 – T2) V watts

The paddles’ rotation leads to the mixing of the Where: P =Power transmitted (watts)

concrete components for a period of about 15 T1 = Tension on the tight side (N)

seconds depending on the amount of the input T2 = Tension on the slack side (N)

components. The outlet is then opened to allow for V = Velocity of the pulley on the motor (m/s)

the passage of concrete. But V = ЛdN

1.3 Designed of Power Transmission System. 60

1.4.1 Belt and Pulley Where, d = diameter of the pulley on the electric

The choice of best for this design is totally based on motor (m)

efficiency of power transmission, capacity, speed of N = evolutional speed of the pulley (rpm)

rotation and durability. The v- belt is chosen to

www.ijera.com DOI: 10.9790/9622-1105030711 8|Page

ADEDEJI Bukola Peter, et. al. International Journal of Engineering Research and Applications

www.ijera.com

ISSN: 2248-9622, Vol. 11, Issue 5, (Series-III) May 2021, pp. 07-11

1.7 Volumetric Capacity of The Portable Vb= 1/3 rb2hb

Concrete Mixer rb = 590/2 = 295mm = 0.295m;

3.7.1 Determination Of The Volume Of The ha = x = 183.8mm = 0.184m.

Mixing Space Va = 1/3 × 0.1252 ×0.184 =

The total volume of the mixing space comprises the 0.030m3

volume of the cylindrical mixing drum and that of Volume of the conical head V2 = Vb – Va

the conical head. V2 = 0.0395 – 0.0301

i.e. V = V1 + V2 V2 = 0.094m3

Where V = total volume of the mixing space (m3) Total volume of the mixing space V = V1 + V2

V1 = total volume of the mixing drum (m3) V= 0.175 + 0.094

V2 = volume of the conical head (m3) V = 0.295m3

V1= r2h 1.7.2 Capacity of the Mixing Drum

V1 = 3.142 (0.295)2 (0.64) The capacity of the mixing drum is the mass of the

V1 = 0.175m3 concrete components that the mixing drum can

This can be shown in figure 3.6. contain at a particular time without any negative

The volume of the conical head is determined by effect on the performance of the device.

assuming that is a frustum since a bigger cone is The capacity of the mixing drum can be ascertained

beheaded. if the permissible weight of the concrete and volume

Volume of the frustum = Volume of the bigger cone of the mixing space are known.

(Vb) – Volume of the smaller cone (Vs) Capacity of the mixing drum = permissible weight/

Therefore V2 = Vb -Vs mass of the concrete

Volume of the mixing drum

C = M/V (kg/m3)

C = 60kg/0.29 = 223.05kg/m3

1.7.3 Output Rating

The output rating is the ratio of the mass to the time

taken to completely or satisfactorily mix specified

masses of sand, cement, stones and water under

specified working conditions.

Output rating = mass of the Concrete

Components/Time taken

R = M/t (kg/s)

Where R = output rating (kg/s)

M = Mass of the concrete components (kg)

t = Time taken for complete mixture (s)

Given that the time taken to completely mix 60kg of

concrete components is 11/2 minutes, then the output

rating can be calculated as:

From fig 3.6: Conical Head

Efficiency= power output × 100%

From fig. 3.6

Power input

X = (250+ x)

The output power is derived from the rotating shaft

d1 d2

and can be written as:

Where x = height of the smaller cone.

P1 = 2N1T

250 + x = height of the bigger cone.

60

d1 = diameter of the smaller cone.

whereN1 = shaft revolution per minute

d2 = diameter of the bigger cone.

T = Torque on the rotating shaft (Nm)

d1 = 250mm; d2 = 590mm.

Power input is the power transmitted from the

x= 250 + x

electric motor through the belt to the shaft.

250 590

Power input, P2 = (T1 –T2)V

250(250 + x) = 590x

62500 + 250x = 590x But V = dN2

62500 = 590x - 250x 60

62500 = 340x So that

x = 62500 P2 = (T1 –T2)dN2

340 60

x = 183.8mm Where N1 = speed of the electric motor (rpm)

T1 = Tension in the tight side (N)

www.ijera.com DOI: 10.9790/9622-1105030711 9|Page

ADEDEJI Bukola Peter, et. al. International Journal of Engineering Research and Applications

www.ijera.com

ISSN: 2248-9622, Vol. 11, Issue 5, (Series-III) May 2021, pp. 07-11

T2 = Tension in the slack side (N)

V = Velocity of the belt (m/s)

d = Diameter of the belt rotating shaft

pulley (m)

Efficiency, E = P1/P2 × 100%

= {2N1T1} / {(T1 –T2) dN2}

60 60

E= 2N1T × 100%

(T1 –T2)d P2 = N2

Fig. 3.9 Photogragh of portable concrete mixer

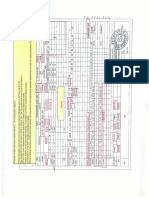

4.2 Material Types, Dimensions, Quantities,

Cost and Specifications

The selected material for design and fabrication are

summarized in the table shown below:

www.ijera.com DOI: 10.9790/9622-1105030711 10 | P a g e

ADEDEJI Bukola Peter, et. al. International Journal of Engineering Research and Applications

www.ijera.com

ISSN: 2248-9622, Vol. 11, Issue 5, (Series-III) May 2021, pp. 07-11

II. CONCLUSION AND Table 1: Material Specification

RECOMMENDATION

S/N Components Materials Qty Dimensions

The designed and fabricated portable (mm)

concrete mixer performed satisfactorily when tested. Rotating Low carbon 1 24

1

The limitation is that it can only be used where there shaft steel

is electric power supply. There are no wheels

incorporated into the design. It can only be used for 2 Bearings Mild steel 2 6305

(standard)

gravel of a maximum sieve number 13.2mm. KG

It is commended that a source of electrical international

supply should be made available in rural areas where FZCo

electricity is not available. It is also recommended 3 Mixing Mild steel 1 295 × 640

drum

that a means of mobility should be made available to

avoid unnecessary stresses. 4 Conical Mild steel 1 590×250

head

REFERENCES

5 Pulley Iron rods 1 170

[1]. Carcopino, J.,Daily Life in Ancient Rome. and plates

Yale University Press, Oxford, 1968, p.63

[2]. Macaulay,D., City – A Story of Roman 6 Belt Rubber 1 12.5×1050L

Planning and Construction. Houghton Miffin aA40

Company. Boston, 1974,p. 28.

7 Bolts & Mild steel 8 13,17 sizes

[3]. Daumas, M., A., History of Technology and nuts

Invention. Crown Publisher, New York 1969,

p. 246. 8 Paddles Mild steel 3 212 × 220

[4]. Hamey, L.A and J. A., The Roman Engineers. plate

Cambridge University, Cambridge, 1981, p. Tripod Angle iron 3 46 × 46

9

42. stand

[5]. Scott R. F., and J. J Schoustra, Soil Mechanics

and Engineering McGraw-Hill Book Co., New 10 Prime Angle iron 2 46 × 46

mover seat

York, p.283.

[6]. Wilby, C.B., Concrete for Structural 11 Bearing Iron rod 3 10

Engineers. Newness Butterworths, London, support

1977, p.142.

12 Electric 1

[7]. Lucas, E. B., Advanced Mechanical motor

Engineering Design, Lecture Note,

LAUTECH, Nigeria, 2006.

ADEDEJI Bukola Peter, et. al. “Design and Fabrication of a Portable Concrete Mixer.”

International Journal of Engineering Research and Applications (IJERA), vol.11 (5), 2021, pp

07-11.

www.ijera.com DOI: 10.9790/9622-1105030711 11 | P a g e

You might also like

- 05 - Build Crate ChairDocument4 pages05 - Build Crate ChairMartin GyurikaNo ratings yet

- Ramniranjan Jhunjhunwala College of Arts, Science and Commerce (Autonomous)Document1 pageRamniranjan Jhunjhunwala College of Arts, Science and Commerce (Autonomous)Angelina JoyNo ratings yet

- Cem 704 QBDocument6 pagesCem 704 QBJinshad UppukodenNo ratings yet

- Three Storey BuildingDocument49 pagesThree Storey BuildingDebashishParida89% (9)

- Bangkok Cable Tunnel 230KVDocument10 pagesBangkok Cable Tunnel 230KVSivagnana SundaramNo ratings yet

- Reaching For The Sky FDDocument17 pagesReaching For The Sky FDHARSHITA JAINNo ratings yet

- 21Document20 pages21štatebolidupeNo ratings yet

- Tower Transmission Foundation Barrette FoundationDocument6 pagesTower Transmission Foundation Barrette FoundationWr ArNo ratings yet

- My Bhokar Site Report Final Check...Document24 pagesMy Bhokar Site Report Final Check...Md IsmailNo ratings yet

- Curve Jacking - Paper Bangkok T-1ThorenDocument10 pagesCurve Jacking - Paper Bangkok T-1ThorenCheng KimHuaNo ratings yet

- Design of A Portable Hydraulic Water Borehole Drilling Rig: AbstractDocument10 pagesDesign of A Portable Hydraulic Water Borehole Drilling Rig: AbstractRonaldNo ratings yet

- Effect of Foundation Soil Stiffness On The Seismic Performance of Integral BridgesDocument7 pagesEffect of Foundation Soil Stiffness On The Seismic Performance of Integral BridgessharvinNo ratings yet

- Final ReportDocument12 pagesFinal ReportG PNo ratings yet

- Analysis and Design of Prestressed Concrete Box Girder Bridge PDFDocument12 pagesAnalysis and Design of Prestressed Concrete Box Girder Bridge PDFvrajan1988No ratings yet

- A A AaaaaaaaaaaaaaaDocument19 pagesA A AaaaaaaaaaaaaaaSolmon SharmaNo ratings yet

- Olawoyin Oladokun Volume IiDocument32 pagesOlawoyin Oladokun Volume IiOlayinka AwoyaleNo ratings yet

- Name of The Work Nabard Construction FoDocument48 pagesName of The Work Nabard Construction FodiablopapanatasNo ratings yet

- Parametric Study of Cable Stayed Bridge Using Different Pylon ConfigurationDocument7 pagesParametric Study of Cable Stayed Bridge Using Different Pylon ConfigurationTanjil MominNo ratings yet

- Cho S M Et Al 2008 Geotextile Tube Application As The Cofferdam at The Foreshore With Large Tidal Range For Incheon Bridge Project PDFDocument6 pagesCho S M Et Al 2008 Geotextile Tube Application As The Cofferdam at The Foreshore With Large Tidal Range For Incheon Bridge Project PDFMuhammad Rizki AnwarNo ratings yet

- IRJET-V7I51387-Effect of Micropile On Foundation SettlementDocument4 pagesIRJET-V7I51387-Effect of Micropile On Foundation SettlementDevesh Kumar PandeyNo ratings yet

- Construction of Railway Over BridgeDocument45 pagesConstruction of Railway Over BridgejaffnaNo ratings yet

- Pile Foundations As Settlement Reducer For Large Ms Storage TanksDocument4 pagesPile Foundations As Settlement Reducer For Large Ms Storage Tanksrtwueee fcbcNo ratings yet

- E3sconf - Iims2018 - 01003 Rope Shovel or HydraulicDocument5 pagesE3sconf - Iims2018 - 01003 Rope Shovel or HydraulicОбо всём на светеNo ratings yet

- Study On Pre-Stressed Concrete Grain Silo Based On Non-Cohesive PropertiesDocument5 pagesStudy On Pre-Stressed Concrete Grain Silo Based On Non-Cohesive PropertiesAfzalNo ratings yet

- Ground Floor Tbong Kmom-Market Noted HypotheseDocument5 pagesGround Floor Tbong Kmom-Market Noted HypotheseEng PhearumNo ratings yet

- Development of Cassava Grating Machine - A Dual-Operational Mode From Leonardo JDocument6 pagesDevelopment of Cassava Grating Machine - A Dual-Operational Mode From Leonardo Jryxor-mrbl100% (1)

- Prestressed Concrete Developments in Japan: Ben C. Gerwick, JRDocument11 pagesPrestressed Concrete Developments in Japan: Ben C. Gerwick, JRsecateNo ratings yet

- Pressure Shaft - Bakfill ConcreteDocument5 pagesPressure Shaft - Bakfill ConcreteSrihariKyatamNo ratings yet

- Class Note Concrete Moddified 10 01 2069 PDFDocument63 pagesClass Note Concrete Moddified 10 01 2069 PDFPratik Babu GhimireNo ratings yet

- Jntuworld: Set No. 1Document80 pagesJntuworld: Set No. 1Sai KiranNo ratings yet

- Analysis and Design of Prestressed Concrete Box Girder BridgeDocument18 pagesAnalysis and Design of Prestressed Concrete Box Girder BridgeYati AggarwalNo ratings yet

- Po 37Document7 pagesPo 37Harold TaylorNo ratings yet

- Analysis of Shear Forces and Flaxural Moment at Joints in PCI-Girder Precast Concrete Segmental BridgeDocument7 pagesAnalysis of Shear Forces and Flaxural Moment at Joints in PCI-Girder Precast Concrete Segmental BridgeInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analysis and Design of A Heavy Cargo Berthing Structure: February 2018Document9 pagesAnalysis and Design of A Heavy Cargo Berthing Structure: February 2018Karim OuNo ratings yet

- Design of A Portable Hydraulic Water Borehole Drilling RigDocument10 pagesDesign of A Portable Hydraulic Water Borehole Drilling RigAlexander DeckerNo ratings yet

- Present Status and Technology of Shield Tunneling Method in JapanDocument15 pagesPresent Status and Technology of Shield Tunneling Method in JapanKhuê - 64XE1 Nguyễn TuấnNo ratings yet

- Design of Steel Structures-Ii: Inst Ruct Ions T O Cand Idat EsDocument2 pagesDesign of Steel Structures-Ii: Inst Ruct Ions T O Cand Idat EsIshfaq AbassNo ratings yet

- Ms 42Document80 pagesMs 42Ahi Sriya EvaniNo ratings yet

- Design, Fabrication and Performance of ADocument12 pagesDesign, Fabrication and Performance of AnaveenNo ratings yet

- Literature SurveyDocument46 pagesLiterature SurveyjosephfelixNo ratings yet

- 03 Bridge ReportDocument38 pages03 Bridge ReportMUUTHUKRISHNANNo ratings yet

- Industrial Visit ..... Final ReportDocument21 pagesIndustrial Visit ..... Final ReportÃjâY Sîñgh ÇhãûhâñNo ratings yet

- Evaluation of Bearing Capacity of Caissons Subject To ScourDocument9 pagesEvaluation of Bearing Capacity of Caissons Subject To ScourIEREKPRESSNo ratings yet

- Special Purpose Simulation Template For Utility Tunnel ConstructionDocument8 pagesSpecial Purpose Simulation Template For Utility Tunnel ConstructionLittleNikoNo ratings yet

- Earthquake Assignment2Document4 pagesEarthquake Assignment2Faisal MohammedNo ratings yet

- 10.3 Micropile Foundations - The Easy Way - Brandner PDFDocument11 pages10.3 Micropile Foundations - The Easy Way - Brandner PDFVandolph Quilab LozanoNo ratings yet

- JL Summer 2012 6Document6 pagesJL Summer 2012 6lukas0910No ratings yet

- Unu-Gtp-Sc-19-0206 Drilling in Menengai High Temperature Field - The Experience and LessonsDocument9 pagesUnu-Gtp-Sc-19-0206 Drilling in Menengai High Temperature Field - The Experience and LessonsPrince MubaiwaNo ratings yet

- A Large Three-Spindle, Vertical-Bridge, Numerically Controlled ProfilerDocument7 pagesA Large Three-Spindle, Vertical-Bridge, Numerically Controlled ProfilerWilly UioNo ratings yet

- Micro Pile ExampleDocument21 pagesMicro Pile ExampledulancivilNo ratings yet

- Pile Work Presentation at IITK Summer Camp 08Document82 pagesPile Work Presentation at IITK Summer Camp 08praxie0% (1)

- Elective-I: Advanced Steel Design: M.Tech. First Semester (Structural Engineering) (C.B.C.S.)Document2 pagesElective-I: Advanced Steel Design: M.Tech. First Semester (Structural Engineering) (C.B.C.S.)Dhiraj NimjeNo ratings yet

- Design and Fabrication of Motorized ScreDocument63 pagesDesign and Fabrication of Motorized ScreMadan KumarNo ratings yet

- Civil Engineering Is Arguably The Oldest Engineering Discipline. It Deals With The Designed Setting and May Be Dated ToDocument29 pagesCivil Engineering Is Arguably The Oldest Engineering Discipline. It Deals With The Designed Setting and May Be Dated Tobasum matNo ratings yet

- Research On Micropile Foundation of Transmission Tower On Soft Soil AreaDocument6 pagesResearch On Micropile Foundation of Transmission Tower On Soft Soil AreaSandeep BandipallyNo ratings yet

- Ce6702 Pcs Civil Viist Au Unit VDocument16 pagesCe6702 Pcs Civil Viist Au Unit VraviciviltNo ratings yet

- StaadDocument90 pagesStaadsthapatyadesignconsultantsNo ratings yet

- Cost Effectiveness of Different Canal Lining Materials: Mr. Amrut Sangale, Dr. S. S. ValunjkarDocument3 pagesCost Effectiveness of Different Canal Lining Materials: Mr. Amrut Sangale, Dr. S. S. ValunjkarerpublicationNo ratings yet

- Hot Rotary Kiln Deformability For Cement Plant ExpDocument10 pagesHot Rotary Kiln Deformability For Cement Plant ExpAmran WiratmaNo ratings yet

- Binder 2Document7 pagesBinder 2JaineshNo ratings yet

- When New Manager FailsDocument6 pagesWhen New Manager Failssultan alassamNo ratings yet

- Can One Use The Dynamic Cone Penetrometer To Predict The Allowable Bearing Pressure?Document11 pagesCan One Use The Dynamic Cone Penetrometer To Predict The Allowable Bearing Pressure?sarvaiyahimmatNo ratings yet

- Bhoomika Kedia ResumeDocument1 pageBhoomika Kedia Resumerajeev456No ratings yet

- Plegadora WC67YDocument5 pagesPlegadora WC67YJhonny AlvarezNo ratings yet

- Assignment 2 - EconometricsDocument7 pagesAssignment 2 - EconometricsFatlinda Kuqi SulejmaniNo ratings yet

- 2 HIE ENG HardwareDocument21 pages2 HIE ENG HardwareWalter Lazo100% (1)

- Experimental Optimization of Radiological Markers For Artificial Disk Implants With Imaging/Geometrical ApplicationsDocument11 pagesExperimental Optimization of Radiological Markers For Artificial Disk Implants With Imaging/Geometrical ApplicationsSEP-PublisherNo ratings yet

- SSRN Id3139808Document5 pagesSSRN Id3139808Carlo L. TongolNo ratings yet

- How To Write An Analysis (With Examples and Tips)Document2 pagesHow To Write An Analysis (With Examples and Tips)Al Jairo KaishiNo ratings yet

- Activity-Based Costing SampleDocument16 pagesActivity-Based Costing SampleRam KnowlesNo ratings yet

- ESOL Nexus Teaching MathematicsDocument38 pagesESOL Nexus Teaching MathematicsArnold HoNo ratings yet

- Report of The Task Force On DyslexiaDocument153 pagesReport of The Task Force On Dyslexiacumannstaire7586No ratings yet

- Effects of Kingpin and Caster Offset On Braking Stability of Long Wheelbase BusDocument16 pagesEffects of Kingpin and Caster Offset On Braking Stability of Long Wheelbase BusZetman Poco90No ratings yet

- Convolution of Discrete-Time Signals: - ObjectivesDocument14 pagesConvolution of Discrete-Time Signals: - ObjectivesMylavarapu SriprithamNo ratings yet

- Weekly Grid 6Document6 pagesWeekly Grid 6api-543292029No ratings yet

- Technical Drawing ToolsDocument11 pagesTechnical Drawing Toolsdaphne brown-mundleNo ratings yet

- Department of Education: Republic of The PhilippinesDocument3 pagesDepartment of Education: Republic of The PhilippinesAirishAinneNo ratings yet

- Mil-Dtl-248 TNTDocument20 pagesMil-Dtl-248 TNTCorina RomanNo ratings yet

- Training Regulations: Motorcycle/ Small Engine Servicing NC IiDocument102 pagesTraining Regulations: Motorcycle/ Small Engine Servicing NC IiAmit Chopra AmitNo ratings yet

- MTC 17022021063931Document1 pageMTC 17022021063931Ahmed LepdaNo ratings yet

- Lines On A Chart Joining Places of Equal Grivation Are Named IsogrivsDocument5 pagesLines On A Chart Joining Places of Equal Grivation Are Named IsogrivsFirdaus92No ratings yet

- Temas de Ensayo de MacroeconomíaDocument6 pagesTemas de Ensayo de Macroeconomíag69zer9d100% (1)

- KL202232 PSRPT 2022-05-18 18.01.51Document19 pagesKL202232 PSRPT 2022-05-18 18.01.51Thuy AnhNo ratings yet

- Digital Student Manual For Computer Engineering StudentsDocument15 pagesDigital Student Manual For Computer Engineering StudentsJasper Paul GarinNo ratings yet

- Prof Ed 104 SG 5Document27 pagesProf Ed 104 SG 5smileydaintyNo ratings yet

- EDI Application in Various FieldsDocument7 pagesEDI Application in Various Fieldsonlinep410No ratings yet

- Combustion in Swirling Flow - A ReviewDocument59 pagesCombustion in Swirling Flow - A ReviewTimothy Edward Dawson100% (1)

- Mode of Failure FoundationDocument11 pagesMode of Failure FoundationFirash ImranNo ratings yet