Professional Documents

Culture Documents

Sagarmatha Readymix Concrete PVT .LTD Parbatipur Nepalgunj, Banke

Sagarmatha Readymix Concrete PVT .LTD Parbatipur Nepalgunj, Banke

Uploaded by

Røshän Kumar PatelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sagarmatha Readymix Concrete PVT .LTD Parbatipur Nepalgunj, Banke

Sagarmatha Readymix Concrete PVT .LTD Parbatipur Nepalgunj, Banke

Uploaded by

Røshän Kumar PatelCopyright:

Available Formats

SAGARMATHA READYMIX CONCRETE PVT .

LTD

PARBATIPUR NEPALGUNJ, BANKE

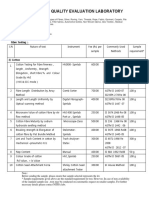

SIEVE ANALYSIS 12.5MM

(In accordance with IS 383 - 1970)

Sample Sources :- Dhakeri Plant :-

Deepak crusher

Pit/Wharf/Quary*

Material :- 12.5MM Sampled By :- ABHISHEK

Current Prod./Stock/Delivery*

Sample Date :- 80-9-1 Date of Testing :- 80-9-1

Dry Weight :- 5000 gm

WEIGHT RETAINED

SIEVE SIZE % RETAINED % PASSING LIMITS asper IS - 383

(CUMULATIVE) (gm)

16MM 0 0.00 100.00 100 100

12.5MM 238 4.76 95.24 85 100

10MM 2940 58.80 41.20 0 45

4.75MM 4780 95.60 4.40 0 10

Pan 5000 100.00 0.00 0 0

TESTED BY : VERIFIED BY : Abhishek jaiswal

SAGARMATHA READYMIX CONCRETE PVT .LTD

PARBATIPUR NEPALGUNJ, BANKE

SIEVE ANALYSIS 20 MM

(In accordance with IS 383 - 1970)

Sample Sources :- Dhakeri Plant :-

Deepak crusher

Pit/Wharf/Quary*

Material :- 20MM Sampled By :- ABHISHEK

Current Prod./Stock/Delivery*

Sample Date :- 80-9-1 Date of Testing :- 80-9-1

Dry Weight :- 5000 gm

WEIGHT RETAINED

SIEVE SIZE % RETAINED % PASSING LIMITS asper IS - 383

(CUMULATIVE) (gm)

40MM 0 0.00 100.00 100 100

20MM 480 9.60 90.40 85 100

10MM 4787 95.74 4.26 0 20

4.75MM 4950 99.00 1.00 0 5

Pan 5000 100.00 0.00 0 0

TESTED BY : VERIFIED BY : ABHISHEK jaiswal

SAGARMATHA READYMIX CONCRETE PVT .LTD

PARBATIPUR NEPALGUNJ, BANKE

SIEVE ANALYSIS SAND

(In accordance with IS 383 - 1970)

Sample Sources :- Dhakeri Plant :-

Deepak crusher

Quary*

Material :- SAND Sampled By :- ABHISHEK

Current Prod./Stock/Delivery*

Sample Date :- 79-10-2 Date of Testing :- 79-10-2

Include Sample time if appropriate

Dry Weight :- 500 gm

WEIGHT RETAINED

SIEVE SIZE % RETAINED % PASSING LIMITS asper IS - 383 (Zone - II)

(CUMULATIVE) (gm)

10MM 0 0.00 100.00 100 100

4.75MM 32 6.40 93.60 90 100

2.36MM 105 21.00 79.00 75 100

1.18MM 178 35.60 64.40 55 90

0.600MM 277 55.40 44.60 35 59

0.300MM 435 87.00 13.00 8 30

150MM 490 98.00 2.00 0 10

Pan 500 100.00 0.00

Silt and Clay Content in Accordance IS 2386 ( PART II) -1963 :-

1. Weight of oven dried sample before washed 300.0 gm * PASS / FAIL

2. Weight retained 75µm after washed 295.0 gm * ACCEPTABLE

3. Weight passing 75µm after washed 5.0 gm

4. Percentage of silt and clay content 1.7 % : 3 % max by weight

TESTED BY :

VERIFIED BY : ABHISHEK jaiswal

SAGARMATHA READYMIX CONCRETE PVT. LTD

PARBATIPUR, NEPALGUNJ

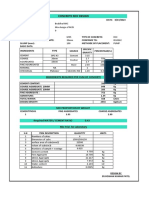

AGGREGATE IMPACT VALUE TEST

Test Report No : Format no: SRMC-QC

Supply By : Deepak crusher Date of Sampling : 80-9-1

Source of Material : Dhakeri Sample details : 12.5 MM

Sampling Location : Aggregate Bag Test Location : Qa/Qc Lab

Contract NO. BBPCU-DB-337011224-077/78-004

Project Design and Build of Kusumbaghat Bridge,Bardiya

TEST :- Test-1 Test-2 Test-3

Total

WeightWeight

of theof Sample

Sample byTaken

whole(gms)

of which passes 12.5 mm sieve & retained

on

After the test whole sieved in 2.36cup

10 mm sieve which is filled in mm(gms) (A)

sieve, the weight of aggregate 355 349 358

passing in 2.36 mm sieve (gms) (B) 50 49 54

Aggregate Impact Value, (A.I.V.)= B x 100 / A 14.08 14.04 15.08

Average: 14.40%

Result :-Passed

Test Method : IS 2386 (Part-4)

Acceptance Criteria : IS 383

Maximum requirment : 30% for Wearing surface & 45% for Non-Wearing surface

Remarks : The test result is Satisfactory/Not Satisfactory

Checked by

Signature

Name Abhishek jaiswal

Date 80-9-1

SAGARMATH READYMIX CONCRETE PVT. LTD

PARBATIPUR, NEPALJUNG BANKE

CRUSHING VALUE TEST

Test Report No : Format no: SRMC-QC

Supplier by Deepak crusher Date of Sampling : 80-9-1

Source of Material : Dhakeri Sample details : 12.5

Sampling Location : Sample Bags Test Location : Qa/Qc Lab

Contract NO. BBPCU-DB-337011224-077/78-004

Project Design and Build of Kusumbaghat Bridge,Bardiya

TEST :- Test-1 Test-2 Test-3

Total Weight of Sample Taken (gms) 5000 5000 5000

Weight of the Sample by whole of which passes 12.5 mm sieve & retained

on 10 mm sieve which is filled in cup (gms) (A) 2680 2672 2684

After the test whole sieved in 2.36 mm sieve, the weight of aggregate

passing in 2.36 mm sieve (gms) (B) 553 549 557

Aggregate Crushing Value, (A.I.V.)= B x 100 / A 20.63 20.55 20.75

Average: 20.64%

Result :-Accepted

Test Method : IS 2386 (Part-4)

Acceptance Criteria : IS 383

Maximum requirment : 30% for Wearing surface & 45% for Non-Wearing surface

Remarks : The test result is Satisfactory/Not Satisfactory

Signature

Name Abhishek jaiswal

Date 80-9-1

You might also like

- Project DestinyDocument10 pagesProject Destinyashish chopra75% (4)

- DNV GL ETO-2017 Maritime Forecast To 2050Document82 pagesDNV GL ETO-2017 Maritime Forecast To 2050Pritish Tandon100% (2)

- Partnership Deed-Compressed PDFDocument11 pagesPartnership Deed-Compressed PDFAssistant Inspector of Labour Krishnagiri0% (1)

- Ultratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Document24 pagesUltratech Cement Limited: Sieve Analysis of Coarse Aggregate For Concrete (As Per Is: 383 - 1970)Mamata BhangaleNo ratings yet

- My Creat 9.5mm To 19mm New Import Dubai StoneDocument1 pageMy Creat 9.5mm To 19mm New Import Dubai Stonesujanislam811No ratings yet

- 1883 CS Tow R0Document4 pages1883 CS Tow R0Parikshit GaurNo ratings yet

- M40 Kekaraw-PqcDocument38 pagesM40 Kekaraw-PqcrajaramNo ratings yet

- Sieve Analysis Coarse AggregateDocument1 pageSieve Analysis Coarse Aggregatefaizan aliNo ratings yet

- Sieve Analysis of Coarse Aggregates For ConcreteDocument4 pagesSieve Analysis of Coarse Aggregates For Concreteajit karandikar50% (2)

- 1883 CS Lad R0Document1 page1883 CS Lad R0Parikshit GaurNo ratings yet

- Material Baja DR PK Agus Prima SurabayaDocument1 pageMaterial Baja DR PK Agus Prima Surabayaintan karyaNo ratings yet

- Crown Cement Concrete & Building Products LTD.: Quality Assurance & Laboratory DepartmentDocument2 pagesCrown Cement Concrete & Building Products LTD.: Quality Assurance & Laboratory DepartmentHasan al MahmudNo ratings yet

- Combined Test of 20mm&10mmDocument1 pageCombined Test of 20mm&10mmRøshän Kumar PatelNo ratings yet

- Siewe Analiysis of Course SandDocument1 pageSiewe Analiysis of Course SandAkash katiyarNo ratings yet

- 20MM Rajpushpa 17-11-2020Document1 page20MM Rajpushpa 17-11-2020Chandu AddankiNo ratings yet

- S-GarDocument5 pagesS-GarkassovNo ratings yet

- Material Consumption Pkg-3Document3 pagesMaterial Consumption Pkg-3suchit singhNo ratings yet

- Bny JV 2a RD de 0002Document1 pageBny JV 2a RD de 0002harihfclNo ratings yet

- Form Lab TanahDocument13 pagesForm Lab Tanahimmanuel lumbantobingNo ratings yet

- Sieve Analysis of Fine AggregateDocument8 pagesSieve Analysis of Fine Aggregatemp SinghNo ratings yet

- 20mm Sieve AnalysisDocument7 pages20mm Sieve AnalysisRahul RanjanNo ratings yet

- COMBINE of Sieve Analysis FGHFDocument3 pagesCOMBINE of Sieve Analysis FGHFASHOKKUMARNo ratings yet

- Gradation FineDocument3 pagesGradation FineRajKommineniNo ratings yet

- P7 QuototionDocument7 pagesP7 QuototionDharmesh SutarNo ratings yet

- Pasir 1 Pasir 2 Pasir 3 Pasir 4 Pasir 5 Split 1 Split 2 Combine SNIDocument37 pagesPasir 1 Pasir 2 Pasir 3 Pasir 4 Pasir 5 Split 1 Split 2 Combine SNItaufikNo ratings yet

- Sieve Analysis For 12.5 MMDocument4 pagesSieve Analysis For 12.5 MMShesha ShayanNo ratings yet

- Pages From EXE-TAR-T-00105 Request For Approval of Asphalt Mix Design (Al Yamama Company) PDFDocument25 pagesPages From EXE-TAR-T-00105 Request For Approval of Asphalt Mix Design (Al Yamama Company) PDFSalahudin AbbasiNo ratings yet

- Test Result: Procurement and Construction of 1X300 MW Thermal Power PlantDocument1 pageTest Result: Procurement and Construction of 1X300 MW Thermal Power PlantRitesh kumarNo ratings yet

- Physical Quality Evaluation LaboratoryDocument11 pagesPhysical Quality Evaluation LaboratoryAmit GuptaNo ratings yet

- Ei & Fi, Nov-23Document2 pagesEi & Fi, Nov-23KunalNaskarNo ratings yet

- List of Wages, Building Material and Equipment Unit PriceDocument12 pagesList of Wages, Building Material and Equipment Unit PriceJeme KebonNo ratings yet

- NQM PWD QC FormatDocument24 pagesNQM PWD QC FormatdhurviconsultantNo ratings yet

- Combined Gradation of Coarse Aggregate - Astm C33-Size 67-1Document106 pagesCombined Gradation of Coarse Aggregate - Astm C33-Size 67-1Hasan al MahmudNo ratings yet

- Seive Analysis Fine AggregateDocument1 pageSeive Analysis Fine AggregatesishelpolicepatilNo ratings yet

- 08 - TRF (Seive Analysis - Fine Aggreagte)Document1 page08 - TRF (Seive Analysis - Fine Aggreagte)Santosh KumarNo ratings yet

- Sieve Analysis-05.07.2018 Coarse & FineDocument3 pagesSieve Analysis-05.07.2018 Coarse & FineASHOKKUMARNo ratings yet

- R M P I P (90% A) : AW Aterial Lant NstructionDocument7 pagesR M P I P (90% A) : AW Aterial Lant NstructionIssam LahlouNo ratings yet

- Copy of Aggregate Gradation-06-09-2022Document8 pagesCopy of Aggregate Gradation-06-09-2022Bagish Upadhyay UpadhyayNo ratings yet

- Company Name: Project: Client: Sub Contractor Sieve Analysis of 20 MMDocument2 pagesCompany Name: Project: Client: Sub Contractor Sieve Analysis of 20 MMpravin mahawarNo ratings yet

- Sieve Analysis Coarse - 30.06.18Document2 pagesSieve Analysis Coarse - 30.06.18ASHOKKUMARNo ratings yet

- Omega: ConsultantDocument7 pagesOmega: ConsultantSumit JainNo ratings yet

- Microtech Testing & Research Laboratory: Condition of Sample, When Received: SatisfactoryDocument1 pageMicrotech Testing & Research Laboratory: Condition of Sample, When Received: SatisfactoryKumar Abhishek0% (1)

- Sieve Analysis-03.11Document2 pagesSieve Analysis-03.11ASHOKKUMARNo ratings yet

- (Nominal Size 37.5 MM) Sampling Station: Sampling Date: Sieve AnalysisDocument1 page(Nominal Size 37.5 MM) Sampling Station: Sampling Date: Sieve AnalysisTewodros TadesseNo ratings yet

- Gradation of Fine Aggregate For ConcretingDocument125 pagesGradation of Fine Aggregate For ConcretingkapishsharmaNo ratings yet

- Sieve Analysis-28-03-19Document2 pagesSieve Analysis-28-03-19ASHOKKUMARNo ratings yet

- WBM 05Document6 pagesWBM 05Safdar HasnainNo ratings yet

- 2022 12 December Inward PHDocument361 pages2022 12 December Inward PHHitesh PrajapatiNo ratings yet

- Cost of MaterialsDocument11 pagesCost of MaterialsAlexander de GuzmanNo ratings yet

- M30Easycrete, Trial SheetDocument1 pageM30Easycrete, Trial Sheetabir senguptaNo ratings yet

- Sieve Analysis-08.08Document4 pagesSieve Analysis-08.08ASHOKKUMARNo ratings yet

- Test of Corse Agg and Fine AggDocument28 pagesTest of Corse Agg and Fine Aggahmed alyNo ratings yet

- Sample Test Required Item Rate AmountDocument1 pageSample Test Required Item Rate AmountTheodore Teddy KahiNo ratings yet

- EAG567 - Material Test ReportDocument2 pagesEAG567 - Material Test ReportDurai NaiduNo ratings yet

- Sieve Analysis Fine AggregateDocument1 pageSieve Analysis Fine AggregateAkash SaikiaNo ratings yet

- Exp 4 - Size Reduction Using Ball MillDocument7 pagesExp 4 - Size Reduction Using Ball MillafifiNo ratings yet

- C.A-20 MMDocument11 pagesC.A-20 MMChandra Prakash KarkiNo ratings yet

- Bijay Chaudhary TharuDocument5 pagesBijay Chaudhary TharuRøshän Kumar PatelNo ratings yet

- M 25 Lakshmi InfraDocument21 pagesM 25 Lakshmi InfraKA25 ConsultantNo ratings yet

- Graduation Test 40mm Single SizeDocument1 pageGraduation Test 40mm Single SizesishelpolicepatilNo ratings yet

- Vasundhra Krishi YantraDocument1 pageVasundhra Krishi YantraSHAILENDRA KUMAR NARWARENo ratings yet

- QuarryDocument1 pageQuarryanon_789699787No ratings yet

- Fleki & Elongation TestDocument4 pagesFleki & Elongation TestRøshän Kumar PatelNo ratings yet

- Lab Print-1Document1 pageLab Print-1Røshän Kumar PatelNo ratings yet

- M-25 Mix DesignDocument1 pageM-25 Mix DesignRøshän Kumar PatelNo ratings yet

- M-35 Mix DesignDocument1 pageM-35 Mix DesignRøshän Kumar PatelNo ratings yet

- Devaluation of The RupeeDocument7 pagesDevaluation of The RupeeReevu AdhikaryNo ratings yet

- Chapter 3 (A) : The Economic Circular Flow ModelDocument43 pagesChapter 3 (A) : The Economic Circular Flow ModelNtsikelelo MosikareNo ratings yet

- eDIV 71 LETTER TO MBB New LHDocument2 pageseDIV 71 LETTER TO MBB New LHAnonymous suDTvDKmNo ratings yet

- Ge 3 Contemporary WorldDocument51 pagesGe 3 Contemporary WorldDarioz Basanez Lucero100% (8)

- Trading With GMMADocument5 pagesTrading With GMMAonyxperidotNo ratings yet

- Value-Added Tax Matrix Buyer PH or Customs Territory: 0% 1. If Reg. Activity Thru PEZA 0% 1. If Reg. Activity Thru PEZADocument1 pageValue-Added Tax Matrix Buyer PH or Customs Territory: 0% 1. If Reg. Activity Thru PEZA 0% 1. If Reg. Activity Thru PEZAana mae bangudNo ratings yet

- Transfer PricingDocument29 pagesTransfer PricingNaveed Mughal AcmaNo ratings yet

- Indian Economy Previous Question Paper ?Document9 pagesIndian Economy Previous Question Paper ?Atharva SherkarNo ratings yet

- Tender 26012023Document1 pageTender 26012023hasan jamiNo ratings yet

- Changing Structure of Rural Economy of IndiaDocument16 pagesChanging Structure of Rural Economy of IndiaShruthi JNo ratings yet

- A1 Global Marketing Scanning (Booc, M)Document8 pagesA1 Global Marketing Scanning (Booc, M)Aubrey Jenne DiazNo ratings yet

- 16 - Guinea Iron OreDocument25 pages16 - Guinea Iron OreBisto MasiloNo ratings yet

- EU Economy - Autumn Forecast 2013Document177 pagesEU Economy - Autumn Forecast 2013Yannis KoutsomitisNo ratings yet

- Practice Analytical Questions-Econ 471: Answers Are Found Under The "Answers" Title BelowDocument64 pagesPractice Analytical Questions-Econ 471: Answers Are Found Under The "Answers" Title BelowRawnit GhoshNo ratings yet

- About SIDCODocument3 pagesAbout SIDCOVeena S.SNo ratings yet

- Import Payment Covering Letter and A1 FormatDocument4 pagesImport Payment Covering Letter and A1 Formatgan_muruNo ratings yet

- Chapter 2Document10 pagesChapter 2JedidahCuevasNo ratings yet

- PIS and COFINS ContributionsDocument2 pagesPIS and COFINS ContributionsRod Don PerinaNo ratings yet

- Ageing PopulationDocument3 pagesAgeing PopulationBoglar BernadettNo ratings yet

- Muzaffar Alam: RK Nagar, Fci Road, Phulwari Sharif. PATNA, BIHAR - 801505. Mob:-+91 9631998317, +91 6205981017Document3 pagesMuzaffar Alam: RK Nagar, Fci Road, Phulwari Sharif. PATNA, BIHAR - 801505. Mob:-+91 9631998317, +91 6205981017ZAFAR ALAMNo ratings yet

- "Behavioral Biases On Investment Decision": Dr. Janki MistryDocument117 pages"Behavioral Biases On Investment Decision": Dr. Janki MistrySHUKLA YOGESHNo ratings yet

- Knowledge Management in HealthcareDocument2 pagesKnowledge Management in HealthcareAnonymous erh5kBqJLNo ratings yet

- Financial Model All BEk MiningDocument87 pagesFinancial Model All BEk MiningWien Daniel SilaenNo ratings yet

- SWOT Analysis - Docx544Document3 pagesSWOT Analysis - Docx544LA LA LA 02No ratings yet

- FR FEMA Group 1 (W)Document83 pagesFR FEMA Group 1 (W)rohanNo ratings yet

- Property Tax - Rent Rebate in PennsylvaniaDocument2 pagesProperty Tax - Rent Rebate in PennsylvaniaJesse WhiteNo ratings yet

- Yamaha - Musicial Instrument Plan 2013Document42 pagesYamaha - Musicial Instrument Plan 2013jazbo8No ratings yet