Professional Documents

Culture Documents

SEPWA09 - Rittig Shaed

SEPWA09 - Rittig Shaed

Uploaded by

Kutluay KabadayıOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEPWA09 - Rittig Shaed

SEPWA09 - Rittig Shaed

Uploaded by

Kutluay KabadayıCopyright:

Available Formats

Surfactant blends for emulsifying

and cleaning

F. Rittig*, R. Baur, C. Esper, U. Steinbrenner, J. Tropsch, S. Zimdahl

BASF SE, 67056 Ludwigshafen, E-EMV/GS-J550

Motivation

motivation

search for emulsifiers able to form stable emulsions

solution

surfactant combination with excellent emulsification results

(Steinbrenner et al. SEPWA Proceedings 2006, 373)

16.05.2008, F. Rittig SEPWA Nordic 2009 2

Evaluation of emulsifiers by the marker

method1

The product (oil) to be Determination of

emulsified is marked with droplets of mixed

2 different oil-soluble dyes color

e

blue dy

+

Homogenization

Oil to a fine emulsion

Raw emulsion A Gentle

Emulsifier

mixing

Water

+y

ello Mixture 1:1

wd Microscopic

ye

picture

Raw emulsion B 1 Thomas Danner, Thesis: „Tropfenkoaleszenz in Emulsionen“,

Univ. Karlsruhe, published by GCA, Herdecke 2001

16.05.2008, F. Rittig SEPWA Nordic 2009 3

Emulsion stabilities with blends based on

C10 Guerbet alcohol (> 60%)

30% sunflower oil, 1% emulsifier, 69% water, storage at 23°C

10% of the droplets blend of (C10-G + long

coalesced after chain alcohol) ethoxilates

month blends of C10

Guerbet with long

weeks chain alcohols work

well, much better

than C10 Guerbet

days

alone.

hours C16C18 blend of (C10-G + C12C15

C12C15 alcohol) ethoxilates

minutes C10-G ethox

6 8 10 12 14 16

HLB

16.05.2008, F. Rittig SEPWA Nordic 2009 4

The "Surfactant Team"

Coethoxilates of C10 Guerbet + long chain

alcohol

Examples: C10 Guerbet + 6 EO Coethethoxilate Long chain alc. + 9 EO

HLB ca. 12.5 HLB ca. 12.5 HLB ca. 12.5

1) wetting

(EN 1772, 23°C)

0.5 g/l ca. 60 s ca. 60 s > 300 s

1.0 g/l ca. 10 s ca. 10 s > 300 s

2.0 g/l ca. 5 s ca. 5 s > 300 s

2) gel phases in water solid gel at no solid gel solid from 0% to

(23°C) 40 w% water (<25 Pa*s) ca. 90% water

3) foam test

(EN 12728, 2 g/l, 40°C) ca. 250 ml ca. 280 ml ca. 160 ml

4) emulsion stability

paraffin oil, 23°C S = -0.2 S = 0.7 S = 0.9

sunflower oil, 23°C S = -1.0 S = 1.1 S = 0.8

16.05.2008, F. Rittig SEPWA Nordic 2009 5

Can synergistic properties of ethoxilates

of C10 Guerbet alcohol blends be utilized for

laundry detergents ?

Agenda

Laundry performance of surfactant blends

Liquid detergents

z high active contents

z low active contents

z fragrance solubilization

Eco-tox

Summary

16.05.2008, F. Rittig SEPWA Nordic 2009 6

Can synergistic properties of ethoxilates

of C10 Guerbet alcohol blends be utilized for

laundry detergents ?

Agenda

Laundry performance of surfactant blends

Liquid detergents

z high active contents

z low active contents

z fragrance solubilization

Eco-tox

Summary

16.05.2008, F. Rittig SEPWA Nordic 2009 7

Screening of synergistic surfactant blends

Test conditions

In combination with 5% AEO and 15% Na-LAS in a zeolite based powder

formulation

launder-o-meter tests

water hardness 2.5 mmol/l (4 parts Ca2+, 1 part Mg2+,

8 parts HCO3-)

z wash time 30 min

z wash temperature 30°C and 60°C

z liquor ratio 1 : 12.5

test swatches for screening

z wfk10D (pigment/sebum on cotton)

z wfk10PF (vegetable oil on cotton)

z wfk20D (pigment/sebum on PES/cotton blend)

16.05.2008, F. Rittig SEPWA Nordic 2009 8

Screening of synergistic surfactant blends

Wash tests at 30 °C

5

Blends of ethoxilates of C10-

Guerbet alcohol and long chain

0

alcohols are better than single

ΔΔ R vs. C13C15 x 7 EO

-5 components

-10

At certain ratios performance is

equal than system with standard

-15 wfk10D surfactants

wfk10PF

-20 wfk20D

-25

0 25 50 75 100

weight-% C10 alcohol ethoxilate

16.05.2008, F. Rittig SEPWA Nordic 2009 9

Screening of synergistic surfactant blends

Wash tests at 60 °C

5

Blends of ethoxilates of C10-

Guerbet alcohol and long chain

0

alcohols are better than single

ΔΔ R vs. C13C15 x 7 EO

-5 components

-10

At certain ratios performance is in

the range of the system with

-15 wfk10D standard surfactants

wfk10PF

-20 wfk20D

-25

0 25 50 75 100 Î More detailed studies are required

weight-% C10 alcohol ethoxilate

16.05.2008, F. Rittig SEPWA Nordic 2009 10

Special coethoxilates

Product and performance data

fixed alcohol composition (types and ratio)

ethoxilation according to cloud point of benchmark

full scale tests (washing machine) in powder and liquid detergents

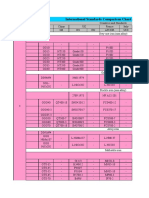

Physical data M5 ST5 M7 ST7

Alcohol G-C10+ C13/15 G-C10+ C13/15

Hydrophilic part 5 EO 7 EO

Cloud points (EN 1890, Method E,

59-63 °C 60-64 °C 73-76 °C 75 °C

BDG)

Foaming 2g/l EN 12728 110 ml 110 ml 300 ml 280 ml

Wetting @ 23°C (1g/l EN1772) 20 s 100 s 20 s 30 s

Wetting @ 70°C (1g/l EN1772) 35 s 160 s 30 s 30 s

M = Coethoxilates, ST = benchmark (e.g. Lutensol AO)

16.05.2008, F. Rittig SEPWA Nordic 2009 11

Can synergistic properties of ethoxilates

of C10 Guerbet alcohol blends be utilized for

laundry detergents?

Agenda

Laundry performance test of surfactant blends

Liquid detergents

z high active contents

z low active contents

z fragrance solubilization

Eco-tox

Summary

16.05.2008, F. Rittig SEPWA Nordic 2009 12

Formulations with high contents of WAS

Laundry wash test 40°C

30

formulation

FAS 10 ST 7

nonionic surfactant 15

25

M7

soap 10 20

MPG 6

Δ remission

citric acid 3 15

B(OH)3 1.5

Ethanol 2 10

percarbonate 15

Savinase Ultra 16 L 2 5

neutralized with ethanol amine

0

water balance bleachable enzymatic

general soil (w fk 20D, bleachable soil (EMPA enzymatical stain (EMPA

general

EMPA 101; 141/2; PCS 114; BC-1; BC-2; PCS 3) 112; 116; CS 1; CS-10;

stain 4) stain Stain

CS-8; AS-10; PC-5; CS-

28)

16.05.2008, F. Rittig SEPWA Nordic 2009 13

Different viscosity profile of coethoxilates

in dilution with water

1000000 Lower viscosities observed when

coethoxilated samples are diluted

100000 with water

10000 Advantages

visc /m Pas

1000 z Faster dilution in water

z In liquid dosing systems,

100

e.g. in I&I laundry

(all concentrations possible)

10

M7 ST 7 z During manufacturing

1 processes

0 20 40 60 80 100

conc. surfactant (%)

Special liquid detergent types

need more detailed investigations

16.05.2008, F. Rittig SEPWA Nordic 2009 14

“super concentrates” with high contents of

washing active substances (WAS)

C C D D

WAS (LAS + soap + AEO) 41 41 51.5 51.5

LAS (Lutensit A-LBS) 7.9 7.9 7.4 7.4

soap (Edenor K12-18) 11 11 14.6 14.6

ST 7 22 26.6

M7 22 26.6

1,2-propylene glycol 8.8 6 9 6 ST 7 M7

ethanol 2 2 2 2

pH 8.7 8.7 8.7 8.7

viscosity (Sp 2, 60 phase Formulation D

200 160 140

rpm)/mPas separated

Concentrations in active matter

16.05.2008, F. Rittig SEPWA Nordic 2009 15

“highly viscous super concentrates” with high

contents of washing active substances (WAS)

Formulation Formulation Formulation

D E F

WAS (LAS + soap + AEO) 51.5 51.5 51.5

LAS (Lutensit A-LBS) 7.4 7.4 7.4

soap (Edenor K12-18) 14.6 14.6 14.6

M7 26.6 26.6 26.6

1,2-propylene glycol 6 6 6

ethanol 2 2 2

Sokalan AT120 0.9 1.5

pH 8.7 8.7 8.7

viscosity (Sp 2, 60

140 500 1100

rpm)/mPas

Concentrations in active matter

16.05.2008, F. Rittig SEPWA Nordic 2009 16

Decrease of viscosity in regular formulas

with low WAS

200

Washing active substance

14.25% 19% 23.75%

180 (Nonionic+LAS+soap)

LAS (Lutensit ALBS)* 7.5% 10% 12.5%

160

ST 7 Soap (Edenor K12-18)* 1.5% 2% 2.5%

140 pH

AEO 5.25% 7% 8.75%

120 8.2

EtOH 2.82% 3.76% 4.7%

visc./mPas

8.6 NaCitrate 0.75% 1% 1.25%

100

9.0 water to 100 to 100 to 100

80

60

40

M7

20 Æ different viscosity profile

*viscosities measured with Sp 62, 60 rpm

0

0% 10% 20% 30%

WAS

16.05.2008, F. Rittig SEPWA Nordic 2009 17

Options to readjust viscosity

in regular liquid detergents

I. Reduce solvents

II. Check if thickeners are an option

16.05.2008, F. Rittig SEPWA Nordic 2009 18

Option I

Adjusting viscosity by solvent reduction

ST 7 M7

H 2O 43.9 43.9

Na2SO4 1.9 1.9

NaCl 0.1 0.1

HP56 0.2 0.2

Glycerin 1.2 1.2

EtOH 1.7 1.7

MPG 7.2 7.2

Triethylenglycolmonobutylether 1.5 1.5

AEO 16.4 16.4

Soap 6.1 6.1

SAS 11.6 11.6

pH 8 8

Viscosity (mPas) 112 65

Appearance opaque opaque

Cold cloud point <0 <0

Concentrations in active matter

16.05.2008, F. Rittig SEPWA Nordic 2009 19

Option I

Adjusting viscosity by solvent reduction

ST 7 M7 M7

H 2O 43.9 43.9 53.5

Na2SO4 1.9 1.9 1.9

NaCl 0.1 0.1 0.1

HP56 0.2 0.2 0.2

Glycerin 1.2 1.2 0

EtOH 1.7 1.7 0

MPG 7.2 7.2 2

Triethylenglycolmonobutylether 1.5 1.5 0

AEO 16.4 16.4 16.4

Soap 6.1 6.1 6.1

SAS 11.6 11.6 11,6

pH 8 8 8

Viscosity (mPas) 112 65 126

Appearance opaque opaque opaque

Cold cloud point <0 <0 <0

Concentrations in active matter

16.05.2008, F. Rittig SEPWA Nordic 2009 20

Option II

Adjusting viscosity by thickener

e.g. II/A II/B

LAS Lutensit A-LBS 10 10

Soap Edenor K12-18 2 2

KOH pH = 8.6

M7 0 7

ST 7 7 0

EtOH 2 2

MPG 1.2 1.2

NaCitrate 1 1

KOH pH = 8.6

NaCl

Viscosity/mPas 177 70

Concentrations in active matter

16.05.2008, F. Rittig SEPWA Nordic 2009 21

Option II

Adjusting viscosity by thickener

e.g. II/A II/B III/C III/D

LAS Lutensit A-LBS 10 10 10 10

Soap Edenor K12-18 2 2 2 2

KOH pH = 8.6

M7 0 7 7 7

ST 7 7 0 0 0

EtOH 2 2 2 2.5

MPG 1.2 1.2 1.2 1.2

NaCitrate 1 1 1 1

NaCl

Sokalan AT120 0.26 0.58

Viscosity/mPas 177 70 160 355

Concentrations in active matter

16.05.2008, F. Rittig SEPWA Nordic 2009 22

Make use of superior emulsification properties

Method

1 g Surfactant

0.1 to 0.5 g Perfume (orange

terpene)

Mix it 1 g ST

0.5 g orange terpene

1gMX

0.1 g orange terpene

1gMX

0.2 g orange terpene

1gMX

0.4 g orange terpene

1gMX

0.5 g orange terpene

Balance with water (100 g)

Stir for 5 min at given speed

cloudy Slightly cloudy clear Phase

Check samples after 24 h separated

16.05.2008, F. Rittig SEPWA Nordic 2009 23

Make use of superior emulsification properties

Method

Orange terpene

0.1 g 0.2 g 0.3 g 0.4 g 0.5 g 1 g ST

0.5 g orange terpene

1gMX

0.1 g orange terpene

1gMX

0.2 g orange terpene

1gMX

0.4 g orange terpene

1gMX

0.5 g orange terpene

ST 7

MX

Cloudy clear

2 phase slightly cloudy

Lillial C11 aldehyde

0.1 g 0.2 g 0.3 g 0.4 g 0.5 g 0.1 g 0.2 g 0.3 g 0.4 g 0.5 g

ST 7 ST 7

MX M7

Isoamylsalicylate Globalide

ST 7 ST 7

MX M7

16.05.2008, F. Rittig SEPWA Nordic 2009 24

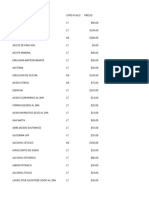

Eco-tox properties & labeling

M7 ST 7

Aquatic invertebrates: 1-10 mg/l 0.1-1 mg/l

Daphnia

magna/EC50(48h)

Aquatic plants: 1- 10 mg/l 0.1-1 mg/l

Scenedesmus

subspictus/EC50 (72h)

Labeling Xn, R22, R41 Xn, N, R22, R41, R50

Transport No hazardous material Class 9

16.05.2008, F. Rittig SEPWA Nordic 2009 25

Summary

Surfactant blends and coethoxilates with C10-Guerbet alcohols show

month

weeks

Synergistic effects in 30

days

hours C16C18

C12C15

z emulsification (triglycerides)

25

minutes C10-G ethox

20 6 8 10 12 14 16

HLB

Δ remission

z laundry detergents 15

10

200

180

160

140

5

120 8.2

visc./mPas

8.6

0 100

EMPA 101 WFK 10D WFK 20D Triolein Olive oil average

9.0

80

Different viscosity profiles vs. standards 60

40

20

0

0% 10% 20% 30%

Improved solubilization of fragrances

WAS/%

Sustainable eco-tox profile

16.05.2008, F. Rittig SEPWA Nordic 2009 26

Performance profile

labeling

Emulsification

Laundry

laundry (triglycerides)

emulsification (triglycer

performance

dynamics Emulsification(p

emulsification

(paraffin)

w etting cmc

low foam

Lutensol M

C12C15 ethoxylates

Thank you!

16.05.2008, F. Rittig SEPWA Nordic 2009 27

You might also like

- Lutensol A 1Document10 pagesLutensol A 1Vilas DhakappaNo ratings yet

- Hand Sanitizer Version 1 - 01.04.2020Document19 pagesHand Sanitizer Version 1 - 01.04.2020Heidy Roxana Lopez VelizNo ratings yet

- Welding Metallurgy of Non-Ferrous Cast IronDocument80 pagesWelding Metallurgy of Non-Ferrous Cast IronSantiago Cordova AlvaNo ratings yet

- Glucopon 650 EC: Technical InformationDocument4 pagesGlucopon 650 EC: Technical InformationJulián Herrera RestrepoNo ratings yet

- 192 12 56 14 TegosoftGCDocument9 pages192 12 56 14 TegosoftGCAhmed elsayehNo ratings yet

- Agnique PG 8105-G: Technical InformationDocument4 pagesAgnique PG 8105-G: Technical InformationADITYA MAHANo ratings yet

- Glucopon 225 DK: Technical InformationDocument4 pagesGlucopon 225 DK: Technical InformationrotulcmNo ratings yet

- Attn: Mr. Theodore Kolozian, CEO: Letter of Intent (Loi) (Purchase of Ago)Document4 pagesAttn: Mr. Theodore Kolozian, CEO: Letter of Intent (Loi) (Purchase of Ago)Даниил ЛебенNo ratings yet

- Lutensol atDocument10 pagesLutensol atVilas DhakappaNo ratings yet

- Olin - Low Viscosity Epoxy For Ultra High Solids Maintenance Protective CoatingsDocument31 pagesOlin - Low Viscosity Epoxy For Ultra High Solids Maintenance Protective CoatingsJOSEPH ABRAHAM CARDOSO ANGARITANo ratings yet

- Genapol X 080 20150608Document1 pageGenapol X 080 20150608Mostafa FawzyNo ratings yet

- Glucopon 425 NHH TI enDocument4 pagesGlucopon 425 NHH TI enledude21No ratings yet

- Resins For Water Based Liquid Inks - LawterDocument3 pagesResins For Water Based Liquid Inks - LawterSudhir KediaNo ratings yet

- Characteristic, Analytic and Sampling of WastewaterDocument20 pagesCharacteristic, Analytic and Sampling of WastewaterJack nguyenNo ratings yet

- Lutensol M Types: Technical InformationDocument6 pagesLutensol M Types: Technical InformationMehul KhimaniNo ratings yet

- Cognis EP Surfactants 2011junDocument80 pagesCognis EP Surfactants 2011junVilas DhakappaNo ratings yet

- Dow PDFDocument8 pagesDow PDFVeliYunusKavalciNo ratings yet

- Supporting Information For:: I. Hita, S. Ghoreishi, J.I. Santos, T. Barth, H.J. HeeresDocument10 pagesSupporting Information For:: I. Hita, S. Ghoreishi, J.I. Santos, T. Barth, H.J. HeeresinnshiNo ratings yet

- Eng Reaknitt ECPDocument4 pagesEng Reaknitt ECPrajasajjadNo ratings yet

- Dehydol LT 6 TI ENDocument6 pagesDehydol LT 6 TI ENErhan KüçükNo ratings yet

- 6 Sepawa-Nordic 1516 May EOC Surfactants FVDocument27 pages6 Sepawa-Nordic 1516 May EOC Surfactants FVmagdyNo ratings yet

- LutensolxpDocument11 pagesLutensolxppkh29No ratings yet

- Glucopon 215 UP TI enDocument4 pagesGlucopon 215 UP TI enKuan Yau HoongNo ratings yet

- Cromollient SCE DC108Document4 pagesCromollient SCE DC108alexanderNo ratings yet

- Dog Shampoo PDFDocument2 pagesDog Shampoo PDFTrần Văn Lộc75% (4)

- Lutensol OnDocument12 pagesLutensol OnHuy PhamNo ratings yet

- Gas SolubilityDocument59 pagesGas Solubilitysomsubhra100% (1)

- Disponil APG 215: Technical InformationDocument4 pagesDisponil APG 215: Technical InformationMartha Valentina Aguilar GonzalezNo ratings yet

- Tego SMS 60 - DS - H0109Document4 pagesTego SMS 60 - DS - H0109kodiNo ratings yet

- Role of Clay Tower in Jet Fuel Processing - No PicturesDocument68 pagesRole of Clay Tower in Jet Fuel Processing - No PicturesglovesjesusNo ratings yet

- Bentonite Wastewater Treatment PDFDocument12 pagesBentonite Wastewater Treatment PDFBiljana TausanovicNo ratings yet

- Table 1 HydrothermalDocument3 pagesTable 1 HydrothermalirhasNo ratings yet

- Distillery Industry 7Document15 pagesDistillery Industry 7gundreddy greeshmaNo ratings yet

- Tds Hordaphos 145Document7 pagesTds Hordaphos 145manitha.kovNo ratings yet

- Fiche Formulation Corneosticker 150915 PDFDocument12 pagesFiche Formulation Corneosticker 150915 PDFJovan708No ratings yet

- Data Sheet HFE-7100Document4 pagesData Sheet HFE-7100sshaffer_9No ratings yet

- EL10Document1 pageEL10emekaNo ratings yet

- Clear Shaveng Gel VsDocument1 pageClear Shaveng Gel Vsahmed lasdNo ratings yet

- Ecrylic KDA 790 - Die Ecronova Polymer GMBHDocument8 pagesEcrylic KDA 790 - Die Ecronova Polymer GMBHLong An ĐỗNo ratings yet

- BASF Industrial FormulatorsDocument22 pagesBASF Industrial FormulatorsSebastian Rodriguez PatinoNo ratings yet

- Maincote PR 71Document11 pagesMaincote PR 71Patricio ContrerasNo ratings yet

- CELULOSA MICROCRISTALINA PH 101Document1 pageCELULOSA MICROCRISTALINA PH 101Leandro SegoviaNo ratings yet

- Emanon Ev-EDocument3 pagesEmanon Ev-EJuan Carlos Constanzo PincheiraNo ratings yet

- Lutensol XP & XL - BasfDocument26 pagesLutensol XP & XL - BasfZoltan Kiraly100% (2)

- Relevant Details of AminesDocument2 pagesRelevant Details of AminesdbothejuNo ratings yet

- Brochure Transcutol P For Efficient Skin PenetrationDocument24 pagesBrochure Transcutol P For Efficient Skin PenetrationJoaozinhoMéndez100% (1)

- Corazol Golden Yellow RFTDocument3 pagesCorazol Golden Yellow RFTDHRUVNo ratings yet

- ET10 (Rigid Tags)Document1 pageET10 (Rigid Tags)emekaNo ratings yet

- Cop OilDocument2 pagesCop OilLuis Eduardo Corzo Enriquez100% (1)

- ES5V (UV Laminate + PVC Film)Document1 pageES5V (UV Laminate + PVC Film)emekaNo ratings yet

- 66 2010 Kovacs Et Al. - Catalytic-Hydrotreating-Of-Triglycerides-For-The-Production-Of-Bioparaffin-Mixture - 2010 - Chemical-Engineering-TransactionsDocument6 pages66 2010 Kovacs Et Al. - Catalytic-Hydrotreating-Of-Triglycerides-For-The-Production-Of-Bioparaffin-Mixture - 2010 - Chemical-Engineering-TransactionsArturo JuarezNo ratings yet

- Deep Desulfurization of Diesel Fuels: Kinetic Modeling of Model Compounds in Trickle-BedDocument8 pagesDeep Desulfurization of Diesel Fuels: Kinetic Modeling of Model Compounds in Trickle-Bedgarciajulio657No ratings yet

- Gama de Solventes Alifaticos en ChileDocument9 pagesGama de Solventes Alifaticos en ChileFelipe OtarolaNo ratings yet

- Corafix Rubine GDBDocument3 pagesCorafix Rubine GDBDHRUVNo ratings yet

- Sorbitol 70% Non Crystallizing Liquid RM COADocument2 pagesSorbitol 70% Non Crystallizing Liquid RM COAASHOK KUMAR LENKANo ratings yet

- Magnasoft FluidDocument7 pagesMagnasoft FluidbobbymayaaNo ratings yet

- H-DC-0016 Ultra Mild Hand DW LiquidDocument1 pageH-DC-0016 Ultra Mild Hand DW Liquidladyjane99100% (1)

- Dehydol LS 6 TI en 2013Document4 pagesDehydol LS 6 TI en 2013Erhan KüçükNo ratings yet

- Aceite de Ricino USP42 - Lote-SC1235815-Silverline ChemicalsDocument2 pagesAceite de Ricino USP42 - Lote-SC1235815-Silverline ChemicalsBienestar Natural100% (1)

- Handbook of Enology, Volume 2: The Chemistry of Wine - Stabilization and TreatmentsFrom EverandHandbook of Enology, Volume 2: The Chemistry of Wine - Stabilization and TreatmentsPascal Ribéreau-GayonNo ratings yet

- Pure Substances, Mixtures and SolutionsDocument19 pagesPure Substances, Mixtures and SolutionsJohn RodgersNo ratings yet

- Summative Test in Science: I. Direction: Read The Questions Carefully. Choose The Letter of The Correct AnswerDocument3 pagesSummative Test in Science: I. Direction: Read The Questions Carefully. Choose The Letter of The Correct Answergener r. rodelasNo ratings yet

- Aço China - Cross Reference SteelDocument12 pagesAço China - Cross Reference SteelPaulo BaltorNo ratings yet

- Alloy Reference LibraryDocument1 pageAlloy Reference LibraryDeepakNo ratings yet

- The History of Oil and Gas in Malaysia Starts From The Beginning of 20th CenturyDocument2 pagesThe History of Oil and Gas in Malaysia Starts From The Beginning of 20th CenturyAnonymous fMCxYHuPK2No ratings yet

- Fipronil 96 ECDocument2 pagesFipronil 96 ECElisabeth YunitaNo ratings yet

- 1st Monthly ExamDocument8 pages1st Monthly ExamRaven AvoNo ratings yet

- Worksheet No. 14 - HLB Value-1Document3 pagesWorksheet No. 14 - HLB Value-1CRISANTO JR. MABANTANo ratings yet

- M2 Science7aDocument2 pagesM2 Science7aSeb GanaraNo ratings yet

- Etchant Selection GuideDocument6 pagesEtchant Selection GuideSantosh KumarNo ratings yet

- Iron International StandardsDocument2 pagesIron International StandardsAmir MusaibNo ratings yet

- Unit 1 Physical Pharmaceutics 4th Sem MCQDocument37 pagesUnit 1 Physical Pharmaceutics 4th Sem MCQPankaj Chaurasiya50% (2)

- Worksheet in DOC-20210922-WA0010 (Compatibility Mode)Document29 pagesWorksheet in DOC-20210922-WA0010 (Compatibility Mode)eng20072007No ratings yet

- First Summative Test in Science ViDocument2 pagesFirst Summative Test in Science ViAlbert BautistaNo ratings yet

- M924 Application Guide - Speed & Feed (Inch) : Common Machining FormulasDocument1 pageM924 Application Guide - Speed & Feed (Inch) : Common Machining FormulasRobotNo ratings yet

- Materias PrimasDocument3 pagesMaterias PrimasRocitafresitaNo ratings yet

- Summ. Test GR, 6 2020Document8 pagesSumm. Test GR, 6 2020jenilynNo ratings yet

- EG - 2021may13 Fuel Marking Progress Slides DOFDocument4 pagesEG - 2021may13 Fuel Marking Progress Slides DOFmitch galaxNo ratings yet

- Refinery Master Apr20A - FinalDocument54 pagesRefinery Master Apr20A - Finaljack fernNo ratings yet

- 3865-Article Text-7837-1-10-20220918Document7 pages3865-Article Text-7837-1-10-20220918kuliahrissaNo ratings yet

- 6061 Aluminum Sheet SuppliersDocument8 pages6061 Aluminum Sheet Supplierssanghvi overseas incNo ratings yet

- Science 7 Module4Document24 pagesScience 7 Module4Hector PantiNo ratings yet

- DLP - Science Sses 6 - Q1 - W1 - D2Document2 pagesDLP - Science Sses 6 - Q1 - W1 - D2RAYMOND MINGUITONo ratings yet

- Concesssion MapDocument1 pageConcesssion MapAustinNo ratings yet

- Material EquivalentDocument3 pagesMaterial EquivalentSudhanshu670% (1)

- Siaran Khas 1 (SM) November 2017Document45 pagesSiaran Khas 1 (SM) November 2017Jusri Mustafa100% (4)

- 005-Sample Method Statement CivilDocument2 pages005-Sample Method Statement CivilS.C.Satish Chander100% (1)

- Kenna MetalDocument2 pagesKenna MetalArshadAliNo ratings yet

- PT Science Q1Document7 pagesPT Science Q1Ronalyn Tulabot - PasamaneroNo ratings yet