Professional Documents

Culture Documents

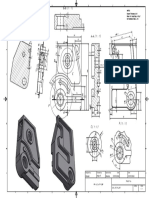

Piston Rod

Piston Rod

Uploaded by

jefedivisionadec24Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piston Rod

Piston Rod

Uploaded by

jefedivisionadec24Copyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12

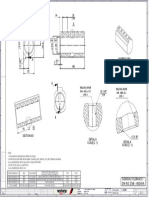

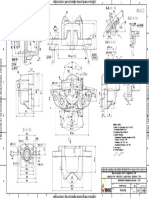

A-A (1:5)

1 1810 ±0,5

3,2

A A

55

View B 9 x 45° A ⌖ 1 ⌀ 37 3 x 45° View C

1 ⌰ 0.03 A ⌰ 0.03 A 1

B B

4 R

2, 2,

4

R

Deburr carefully

�

1 ⌀ 590 g6�-0,066�

1 ⌀ 600 g6�-0,066�

+0,36

+0,057

+0,057

-0,022

-0,022

Ebavurer soigneusement

1 ⌀ 369 H11�-0

1 ⌀ 320 H7�-0

1 ⌀ 320 H7�-0

3 x 45°

18

⌀ 300

C C

3 x 45°

R 18

R3

3

R3

1,6 3 1,6

B R

9x ⌀ 85

9x ⌀ 85

9x ⌀ 86

30°

30°

9x M 80 x 6H

D D

20 0,8 30 3,2

9x M 80 x 6H

5,7

°

1 175 ±0,2 20 100

⌾ 0.02 A 1

1 ⌖ ⌀0.5 A B (1:1) 1 275 ±0,2

1

R

View B View C ⌖ ⌀0.5 A 1

3,2

12,5

3,2

10° 10° 10° 3,2

E E

9x 9x R1

1 7,5 ±0,2

°

40 40 40 Material certificate including chemical analysis, tensile

° 9x °

+0,1

1 4,4 0 and yield strength test according to:

EN 10204-3.1

Certificat matière composé de l'analyse chimique,

caractéristiques mécaniques (Rm, Rp0.2, A%) selon:

1,6

100% UT of raw bar according to: EN 10228-3, Cl.4

100% UT de la barre brute selon: Testing type 1a

EN 10228-1, Cl.4

F 100% MT of machined surfaces accessible to: F

No linear indication

A A 100% MT des surfaces usinées accessibles selon:

Aucune indication linéaire

⌀ 470 ⌀ 470

The quality documentation must be produced according

to: P HS EX35 03/1e

to others without express authorization is prohibited. Offenders will be held liable for the payment of damages.

La documentation qualité doit-être produite selon:

The reproduction, distribution and utilization of this document as well as the communication of its contents

SQC114 | QA-DOCUMENTATION HS | 13.07.2022

CARUACHI CORPOELEC

34CrNiMo6+QT

Propriétés mécaniques (20°C): Project Description Customer Customer Doc. N°

G Mechanical Properties (20°C): G

Master

902265154 209954184 34CrNiMo6+QT EN10083-3 2825

All rights reserved in the event of the grant of a patent, utility model or design.

R e min : 450 N/mm²

R m min : 700 N/mm² TC MAT ID ASAP MAT ID Basic Material Name Basic Material Standard Mass (kg)

A min : 15 % 01.03.2024 05.03.2024 05.03.2024

Revision

Z min : 55 % vvyluc03 vvyseb01 vvyseb01

KV min : 20 J @ 0°C

Modification Created Checked Checked Approved

QUALITY CLASSIFICATION AND GEOMETRICAL 01.03.2024 05.03.2024 05.03.2024

TOLERANCES OF THERMAL CUT

ISO 9013-332 PISTON ROD vvyluc03 vvyseb01 vvyseb01

EDGES -0,2 GPS - DIMENSIONAL TOLERANCING refer to protection notice ISO 16016

CHAMFERED -0,4

ISO 13715 ISO 14405 Ⓔ

GENERAL TOLERANCES FOR METRIC SCREW

1 (1,2,3,.) NUMBERED DIMENSIONS HAVE TO BE INDICATED ON A SEPARATE DIMENSIONAL RECORD SHEET

THREADS / ALL THREADS CHAMFERED VÁSTAGO DEL PISTÓN TUR-15 | 15-200

H GENERAL TOLERANCES FOR LENGTH AND ANGLE MEASUREMENTS ISO 2768-1 - m ISO 965-1 H

FROM 0.5

1)

3 6 30 120 400 1000 2000 4000 8000 12000 16000 GENERAL

1)

TOLERANCES FOR Project Definition TC DOC ID Revision Sheet

FORM AND POSITION

902268157

"Copyright reserved"

1) 1) 1)

TO 3 6 30 120 400 1000 2000 4000 8000 12000 16000 20000 ISO 2768-2 - K C-70-852423 1

TOLERANCE 0.1 0.1 0.2 0.3 0.5 0.8 1.2 2 3 4 5 6 SURFACE

ISO 1302

Ra ISO 128 Code ASAP DOC ID

704052578 - of

1) FOR NOMINAL DIMENSIONS < 0.5 AND > 4000, THE LIMIT SIZES ARE NOT SPECIFIED IN ISO 2768-1. Ra in µm

EUROPE CARUA-23A-TU 1

1 2 3 4 5 6 7 8 9 10 11 A2

You might also like

- BlackBook English PDFDocument2 pagesBlackBook English PDFeinsten77714% (7)

- WaveSurfer 454 SchematicsDocument43 pagesWaveSurfer 454 SchematicsTom MillerNo ratings yet

- Our Price ListDocument110 pagesOur Price Listgman444No ratings yet

- Pdf24 MergedDocument32 pagesPdf24 MergedMechwell DesignNo ratings yet

- ABB Transformers: Afcuartasc A.Garzon - 0.7 N/A N/A Anchor - Bolt - M20 - Assy EN 1 2.6 KGDocument1 pageABB Transformers: Afcuartasc A.Garzon - 0.7 N/A N/A Anchor - Bolt - M20 - Assy EN 1 2.6 KGOscar BuitragoNo ratings yet

- BL90-30 - 951784Document1 pageBL90-30 - 951784Bps PSNo ratings yet

- Designed Sgd. PS Drawing Verified Aproved Sgd. PS: 1st Angle Projection Dimensions in Mm. 6/24/2019 11/19/2018Document1 pageDesigned Sgd. PS Drawing Verified Aproved Sgd. PS: 1st Angle Projection Dimensions in Mm. 6/24/2019 11/19/2018Birlan AdrianNo ratings yet

- Clel083e138 MVSWG Exe SCD 201.as BuiltDocument9 pagesClel083e138 MVSWG Exe SCD 201.as BuiltjosepablohgNo ratings yet

- Model Stand NorbarDocument3 pagesModel Stand NorbarDexter PoliNo ratings yet

- 7.1 L NG Qu T - Rovb2033 - dwg1-E-Vb2033 - PRTDocument1 page7.1 L NG Qu T - Rovb2033 - dwg1-E-Vb2033 - PRTToàn NguyễnNo ratings yet

- Cylinder Full ViewlargeDocument1 pageCylinder Full ViewlargeavinashNo ratings yet

- 2 Ton Hurricane Hook MountDocument1 page2 Ton Hurricane Hook MountVitor OlivettiNo ratings yet

- Forbes & Company LimitedDocument1 pageForbes & Company LimitedChandru ChristurajNo ratings yet

- EDC17C44-1.1 SchaltbildDocument9 pagesEDC17C44-1.1 SchaltbildT HNo ratings yet

- Unistar 15 A2Document1 pageUnistar 15 A2ikapi60No ratings yet

- Arquitectura DistribucionDocument1 pageArquitectura DistribucionJUAN FERNANDO ARESTEGUI HUILLCANo ratings yet

- Quy Trinh Cong Nghe Full Engsub Layout1Document1 pageQuy Trinh Cong Nghe Full Engsub Layout1HOÀNG LÊ PHẠMNo ratings yet

- Ascar Estructuras-01 Layout1Document1 pageAscar Estructuras-01 Layout1MARCO ANTONIO VALLADOLID JIMENEZNo ratings yet

- 640 0003 0011b05ed00Document1 page640 0003 0011b05ed00IlyasaNo ratings yet

- 1 Ton Hurricane IGRDocument1 page1 Ton Hurricane IGRVitor OlivettiNo ratings yet

- (Ajusted at Shop) : 45° Side SupportDocument1 page(Ajusted at Shop) : 45° Side SupportHiệp Phạm VănNo ratings yet

- Roof Plan: Two-Storey Residential House Oliver B. Patupat Oliver B. PatupatDocument1 pageRoof Plan: Two-Storey Residential House Oliver B. Patupat Oliver B. Patupatbenj panganibanNo ratings yet

- STR 0281y03b88 01 Edc17c46-2.1 HW11Document9 pagesSTR 0281y03b88 01 Edc17c46-2.1 HW11Omar Enrique ContrerasNo ratings yet

- Isometric View: Boonyanupa Pongkun C. - 21 MAR 2023 IssuedDocument1 pageIsometric View: Boonyanupa Pongkun C. - 21 MAR 2023 IssuedDETALHAMENTO ARQUIVOSNo ratings yet

- sk8072 RevaDocument1 pagesk8072 RevautkuNo ratings yet

- A-19 A-20 - (Arquitectura Nivel 700) - A-20Document1 pageA-19 A-20 - (Arquitectura Nivel 700) - A-20ianNo ratings yet

- Clamp Foot PinDocument1 pageClamp Foot PinCốGắngNàoNo ratings yet

- Wio Terminal SchematicsDocument1 pageWio Terminal SchematicsJ. MaruggNo ratings yet

- Induction MotorsDocument1 pageInduction MotorsElectrifying GuyNo ratings yet

- 7seg Auto Voltmeter REV1Document1 page7seg Auto Voltmeter REV1Daniel G Zeballos AsconaNo ratings yet

- Hanger System - Heating Surfaces 1.48760/00 213-0009: Zugehörige Zeichnungen / Relevant DrawingsDocument1 pageHanger System - Heating Surfaces 1.48760/00 213-0009: Zugehörige Zeichnungen / Relevant DrawingsDenkaNo ratings yet

- KC Me Eer 031 Rev. 1Document9 pagesKC Me Eer 031 Rev. 1danielNo ratings yet

- 07 - Plan Etaj 6Document1 page07 - Plan Etaj 6Ileana Daniela AnghelNo ratings yet

- Isometric View C-C (1: 5) D-D (1: 5) N 10Document1 pageIsometric View C-C (1: 5) D-D (1: 5) N 10rajitkumar.3005No ratings yet

- Pasillo Pasillo: Camara de FrioDocument1 pagePasillo Pasillo: Camara de FrioRuben Guevara FernandezNo ratings yet

- Soal Pra Lks Fix1Document1 pageSoal Pra Lks Fix1Timothy AlfaNo ratings yet

- Label Identification:: Existing Public Road & Public Parking AreaDocument1 pageLabel Identification:: Existing Public Road & Public Parking AreaPhilbert RamirezNo ratings yet

- Corte E-E: Matricula InmobiliariaDocument1 pageCorte E-E: Matricula InmobiliariaSANTIAGO ANDRES LEMUS RODRIGUEZNo ratings yet

- 2-ModelDocument1 page2-Modeljoselito navarroNo ratings yet

- Ylitg Atex 250Document1 pageYlitg Atex 250Vitor OlivettiNo ratings yet

- Ground Floor Plan: Scale 1:100Document2 pagesGround Floor Plan: Scale 1:100CSEC Uganda Ltd.No ratings yet

- Elevation of Tower - 1 (Facing West) Part 2 of 3: LegendsDocument1 pageElevation of Tower - 1 (Facing West) Part 2 of 3: LegendsHozien OnofreNo ratings yet

- Manifold CasingDocument1 pageManifold Casingamitava11duttaNo ratings yet

- Part Drawing Sheet1Document1 pagePart Drawing Sheet1Shrikrushna MaliNo ratings yet

- PH-1518-C960 - Transformer Station Foundation Detail - C2Document1 pagePH-1518-C960 - Transformer Station Foundation Detail - C2Alden BrionesNo ratings yet

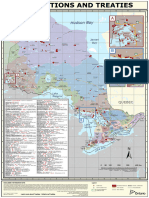

- Treaties MapDocument1 pageTreaties MapGateway Education TeamNo ratings yet

- Data Extraction and Multileaders Sample-Layout2Document1 pageData Extraction and Multileaders Sample-Layout2Sunem Rios YañacNo ratings yet

- Nivel 2Document1 pageNivel 2Mishell Tanner DiazNo ratings yet

- AP2 Arm - 1035386A1Document1 pageAP2 Arm - 1035386A1byjurpNo ratings yet

- SGH-E900 SchematicsDocument7 pagesSGH-E900 SchematicsrobertdenchNo ratings yet

- Amb-Agcc02-Tun Ce 1002 - P0Document1 pageAmb-Agcc02-Tun Ce 1002 - P0Sugam JainNo ratings yet

- A Plan ParterDocument1 pageA Plan ParterDani SerbanNo ratings yet

- DRONE d2 Drawing v1Document1 pageDRONE d2 Drawing v1Hllmy fajarusidiqNo ratings yet

- SchemtsDocument9 pagesSchemtsThiện KhiêmNo ratings yet

- 6 Drawing 3D 2Document1 page6 Drawing 3D 2wassimwalha2016No ratings yet

- Gambar Kerja Asc Vietnam 2014Document1 pageGambar Kerja Asc Vietnam 2014Rinaldi PraharsaNo ratings yet

- AREA APRX. 3000 M : SITE LAYOUT PLAN (Not To Scale)Document1 pageAREA APRX. 3000 M : SITE LAYOUT PLAN (Not To Scale)Manish MishraNo ratings yet

- Audio 600Document3 pagesAudio 600rea sonerNo ratings yet

- Si Me Dejas No Vale - Alto Sax 1Document2 pagesSi Me Dejas No Vale - Alto Sax 1Jorge Luis Guevara MoraNo ratings yet

- ESAIKAII 00.00.03 v100z2 (Upconvertor Cover Top)Document1 pageESAIKAII 00.00.03 v100z2 (Upconvertor Cover Top)grandeurvoxNo ratings yet

- Kerb KonusDocument34 pagesKerb KonusDHEERAJ413No ratings yet

- 12 06 PM P185 XP185 WirDocument203 pages12 06 PM P185 XP185 WirJoel100% (1)

- Linde H80D-1100 H2X396Z00362 2009 Parts Catalog AutoBukva For ATLET - 2Document235 pagesLinde H80D-1100 H2X396Z00362 2009 Parts Catalog AutoBukva For ATLET - 2kirill100% (2)

- Lead Screw Nut Mounting Details 1Document1 pageLead Screw Nut Mounting Details 1shubham tadeNo ratings yet

- NH 143186 307997 1486172Document5 pagesNH 143186 307997 1486172Saul ChampacNo ratings yet

- Ohe Material Assesment in Railway ElectrificationDocument84 pagesOhe Material Assesment in Railway Electrificationganesh92.gugulothuNo ratings yet

- Precision Coil BookletDocument8 pagesPrecision Coil Bookletricko2503No ratings yet

- Flipkart Labels 30 Jan 2024-11-26Document5 pagesFlipkart Labels 30 Jan 2024-11-26ajay shahNo ratings yet

- DIY PVC Crossbow: Technology Workshop Craft Home Food Play Outside CostumesDocument14 pagesDIY PVC Crossbow: Technology Workshop Craft Home Food Play Outside CostumesToe100% (2)

- Galvanizing ProcedureDocument4 pagesGalvanizing Procedurecerverus13No ratings yet

- Assembly and Detail Drawing Pressure ClampDocument2 pagesAssembly and Detail Drawing Pressure ClampShandy Dwi PrayogaNo ratings yet

- Stanley 86 106 CatalogDocument24 pagesStanley 86 106 CatalograghuramNo ratings yet

- XO22LR PartlistDocument1 pageXO22LR PartlistTonio JimenezNo ratings yet

- (DONE) OPIM - Practice Questions Week 4Document8 pages(DONE) OPIM - Practice Questions Week 4Dexter KhooNo ratings yet

- 580M 2043M 143812 Eco13141 Eixo TrazDocument10 pages580M 2043M 143812 Eco13141 Eixo Trazavant comercialNo ratings yet

- Steelmasters Torque TableDocument6 pagesSteelmasters Torque TableIbrahim SaidNo ratings yet

- GE Renewal Parts: Contactor Model 17Cm53E10ADocument3 pagesGE Renewal Parts: Contactor Model 17Cm53E10ARafael Dutil LucianaNo ratings yet

- Shuqaiq 3 Independent Water Project: Ro Building T7 GDF03-001Document1 pageShuqaiq 3 Independent Water Project: Ro Building T7 GDF03-001ABAID ULLAHNo ratings yet

- 12 Point Flange Bolt Dimensions & SpecsDocument1 page12 Point Flange Bolt Dimensions & SpecskannivelNo ratings yet

- JICS TemplateDocument2 pagesJICS TemplateMohd Effiezool YaserNo ratings yet

- Fleet MasterDocument13 pagesFleet MasterJesus Manuel Nanguse MurilloNo ratings yet

- Detailed Design and Report For Knuckle Joint - 19ME8170Document7 pagesDetailed Design and Report For Knuckle Joint - 19ME8170ShanmukhNo ratings yet

- Ai01798 AlDocument11 pagesAi01798 Alrajit kumarNo ratings yet

- Is 554 1999Document13 pagesIs 554 1999Mohsin AkhterNo ratings yet

- BN - 56 - 1 - Bossard - 1 - DIN 933 - 8.8 GradeDocument6 pagesBN - 56 - 1 - Bossard - 1 - DIN 933 - 8.8 GradeJaganNo ratings yet

- How To Read A Screw Thread CalloutDocument6 pagesHow To Read A Screw Thread Calloutbraddy02No ratings yet

- Asme b16.36 Orifice FlangesDocument5 pagesAsme b16.36 Orifice FlangesPippozzo Pipini100% (1)

- Din en Iso 4014Document16 pagesDin en Iso 4014hasan_676489616100% (7)